Road retained method for extrusion molding of waste rock

A technology of extrusion molding and empty roadway retention, which is used in filling materials, safety devices, ground mining, etc., can solve the problems of expensive filling equipment, high filling material cost, poor roadway maintenance effect, etc. Improve work efficiency and safety, safe and reliable effect of lane retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

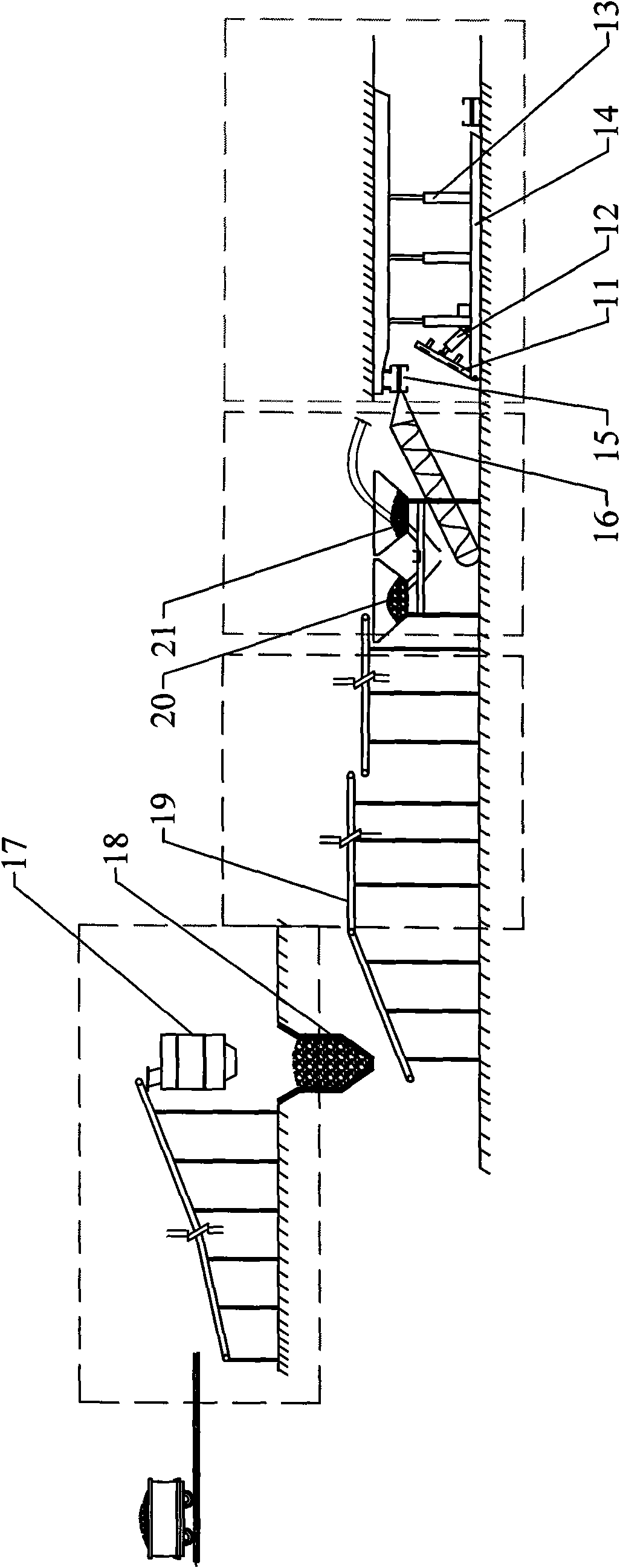

[0022] The gangue extrusion molding gob-side entry method includes the following steps:

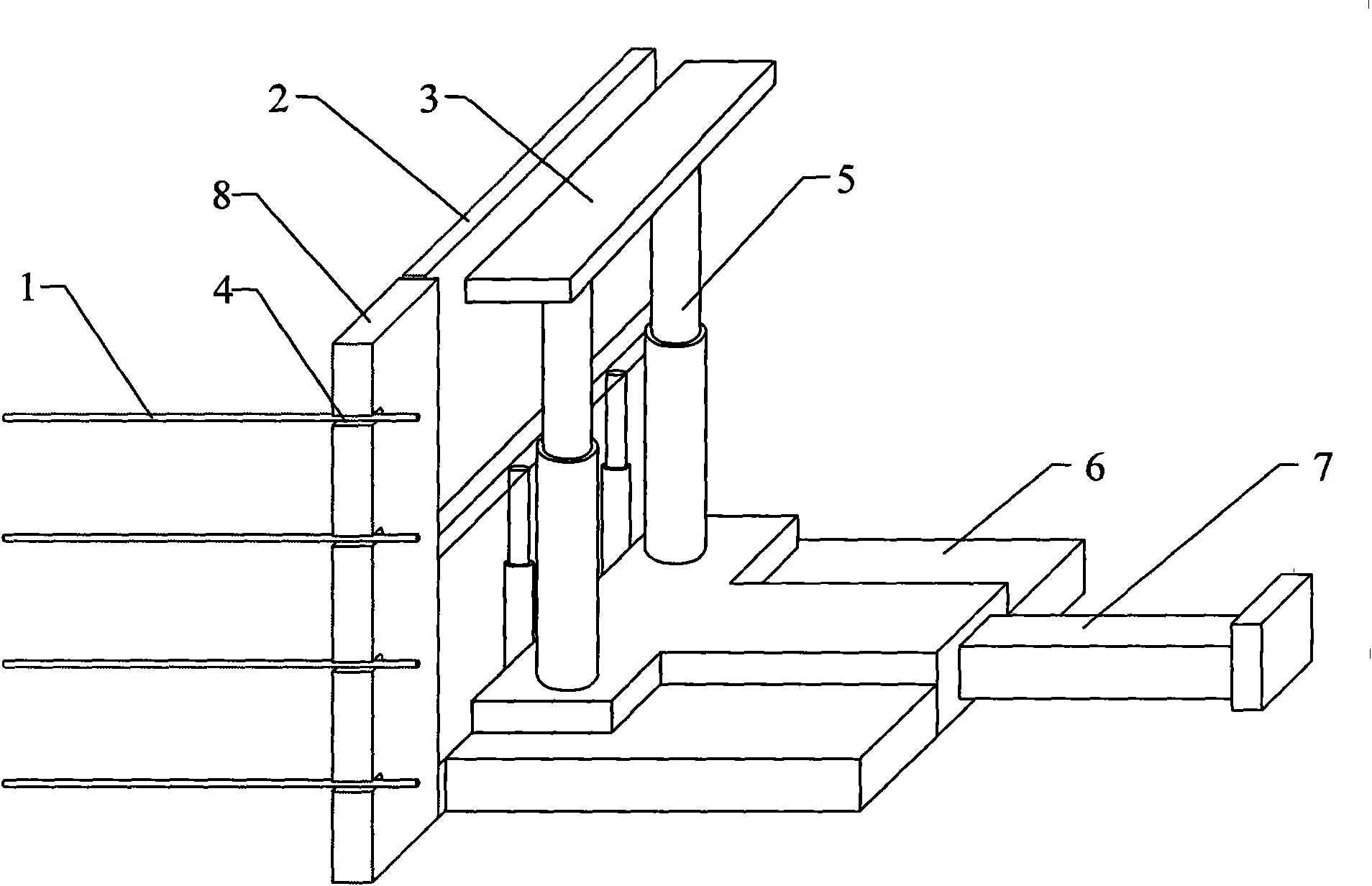

[0023] 1) Erection formwork and compaction device

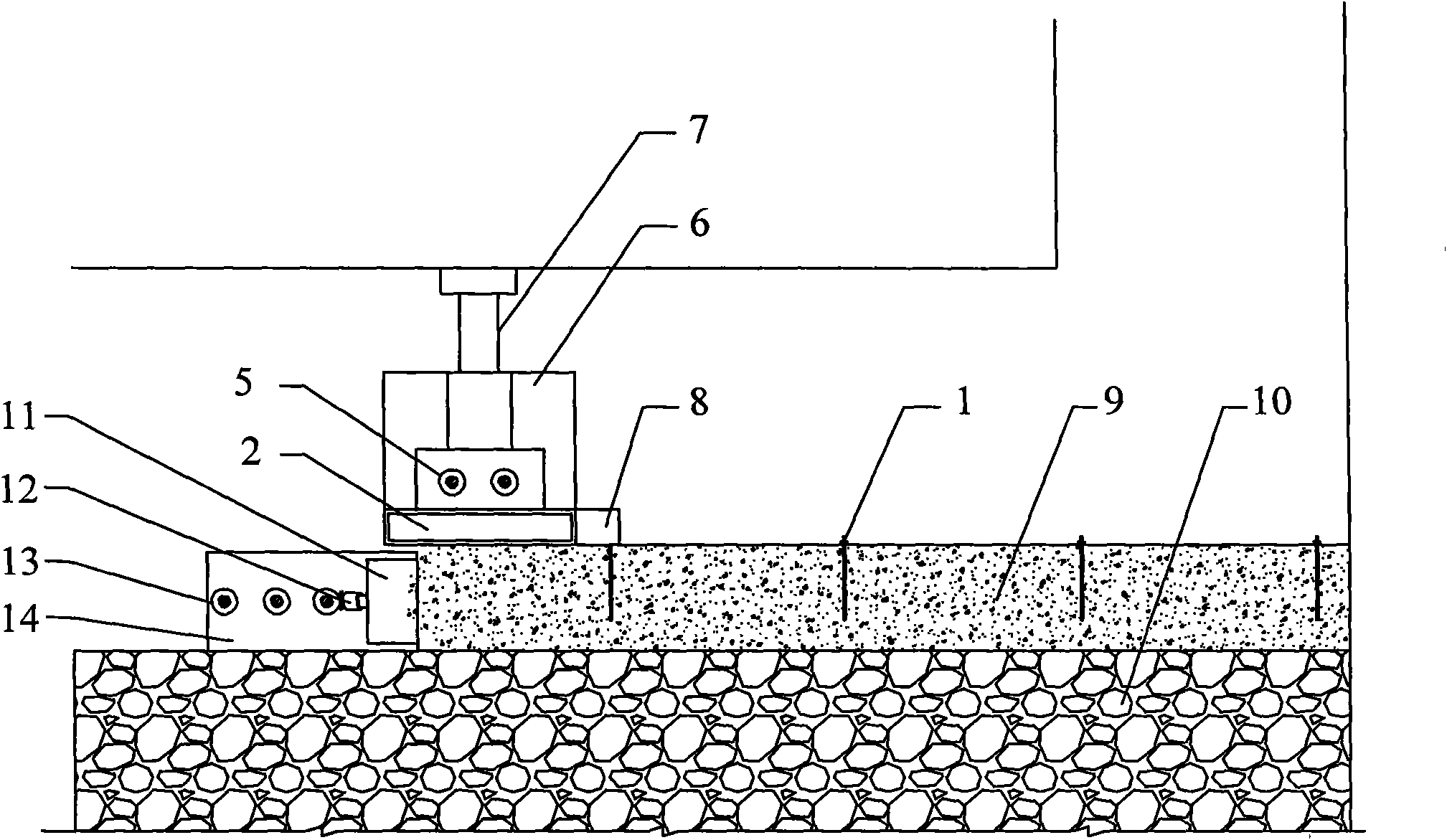

[0024] Such as figure 1 and figure 2 As shown, the template is spliced by two parts, the longitudinal expansion plate 2 and the anchor rod fixing plate 8, and the two are detachably connected. When filling for the first time, vertically place the longitudinal expansion board 2 facing the goaf 10 and make it parallel to the direction of the roadway. A certain distance is kept between the longitudinal expansion board 2 and the waste rocks falling from the goaf 10, and the space between the longitudinal expansion board 2 and the waste rocks to be filled is Area; a base 6 is installed under the back of the longitudinal expansion plate 2, a hydraulic column 5 is installed on the base 6, and a steel beam 3 is fixed on the top of the hydraulic column 5. Extend the longitudinal telescopic plate 2 so that its height is equivalent to the hei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com