Underground coal mine drilling, heat injection and hole sealing integration method

A technology of sealing holes and injecting heat, which is applied in mining fluids, mining equipment, earthwork drilling, etc. It can solve the problems of low concentration of drilling gas drainage, failure to realize recycling, and hidden dangers of coal seam safety, so as to reduce heat loss, Wide applicability and effect of reducing heat injection cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

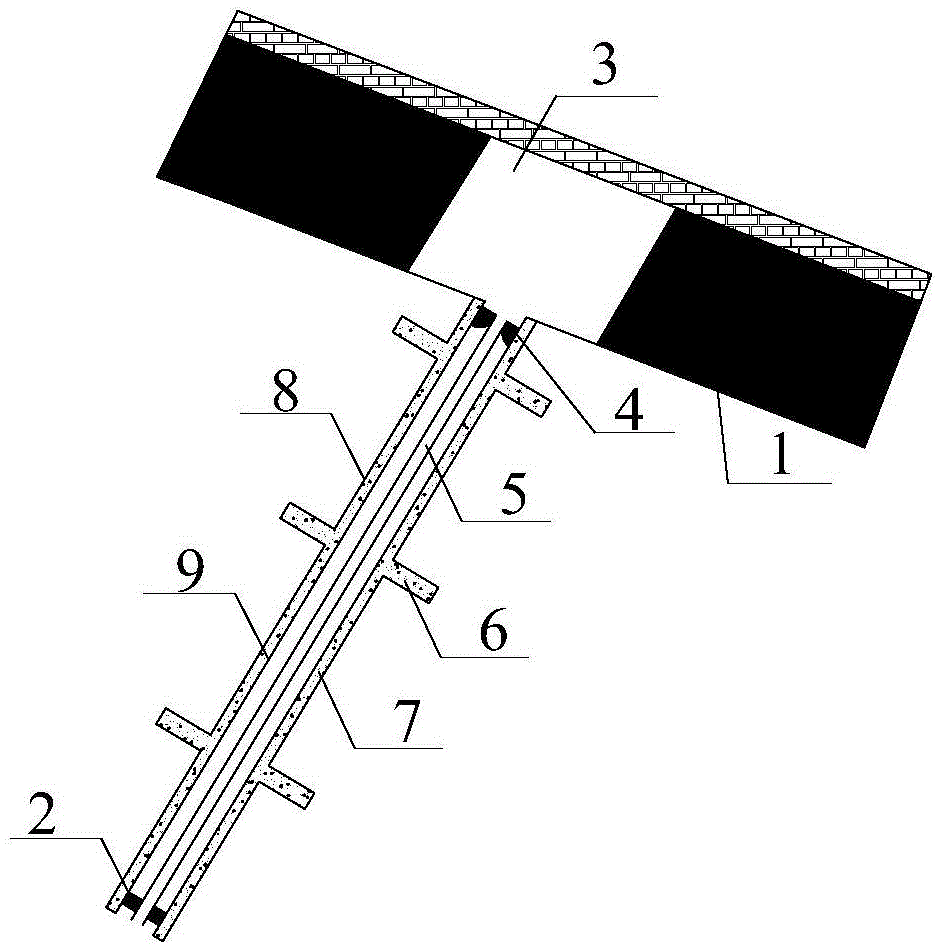

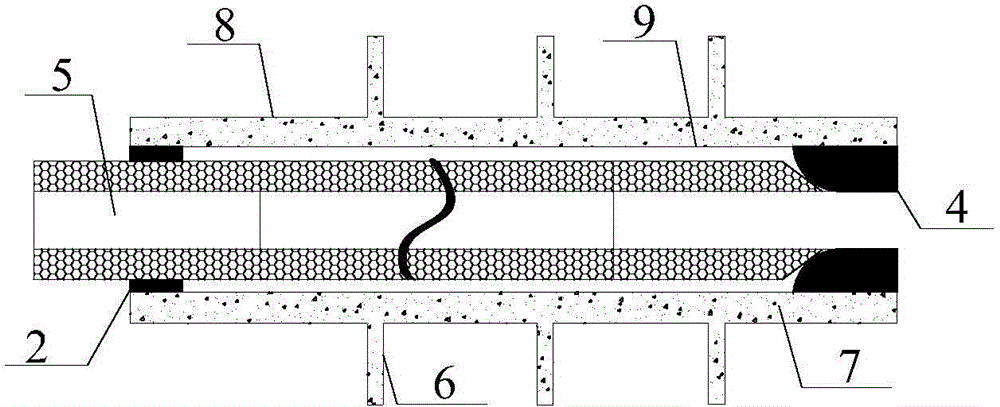

[0020] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0021] The integrated method of heat injection and hole sealing for coal mine underground drilling of the present invention has the following steps:

[0022] a. Construct a disc-shaped slot 6 at intervals of 5-10m in the rock formation section in the borehole 8 by using a high-pressure jet;

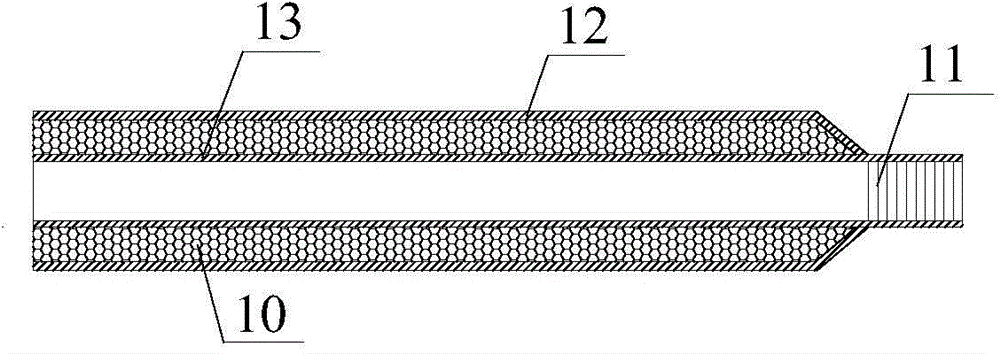

[0023] b. Connect the 1m-long plastic casing 9 through the screw connection between the ends, and send it to the coal-seeing point of the drill hole 8;

[0024] c. Grouting between the outer wall of the plastic sleeve 9 and the wall of the borehole 8 to fix the plastic sleeve 9;

[0025] d. After the grouting slurry 7 is condensed, send it into the heat injection pipe 5 in the plastic sleeve 9, inject superheated steam into the coal seam 1 through the heat injection pipe 5, and withdraw the heat injection pipe 5 after injecting heat for 2 to 4 hours; The heat pipe 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com