High-temperature comprehensive property evaluation experimental device of sealing spacer

A comprehensive performance evaluation and sealing gasket technology, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, testing material ductility, and measuring fluid growth and deceleration rates, etc., can solve functional dispersion, backward testing methods, Low test accuracy and other problems, to achieve the effect of convenient processing, small footprint and convenient test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The technical problem to be solved by the present invention is to propose a new structure, use high-precision sensors, and design a set of high-temperature comprehensive performance evaluation tests for sealing gaskets in view of the shortcomings of existing gasket sealing test devices, such as scattered functions, low test accuracy, and backward testing methods device.

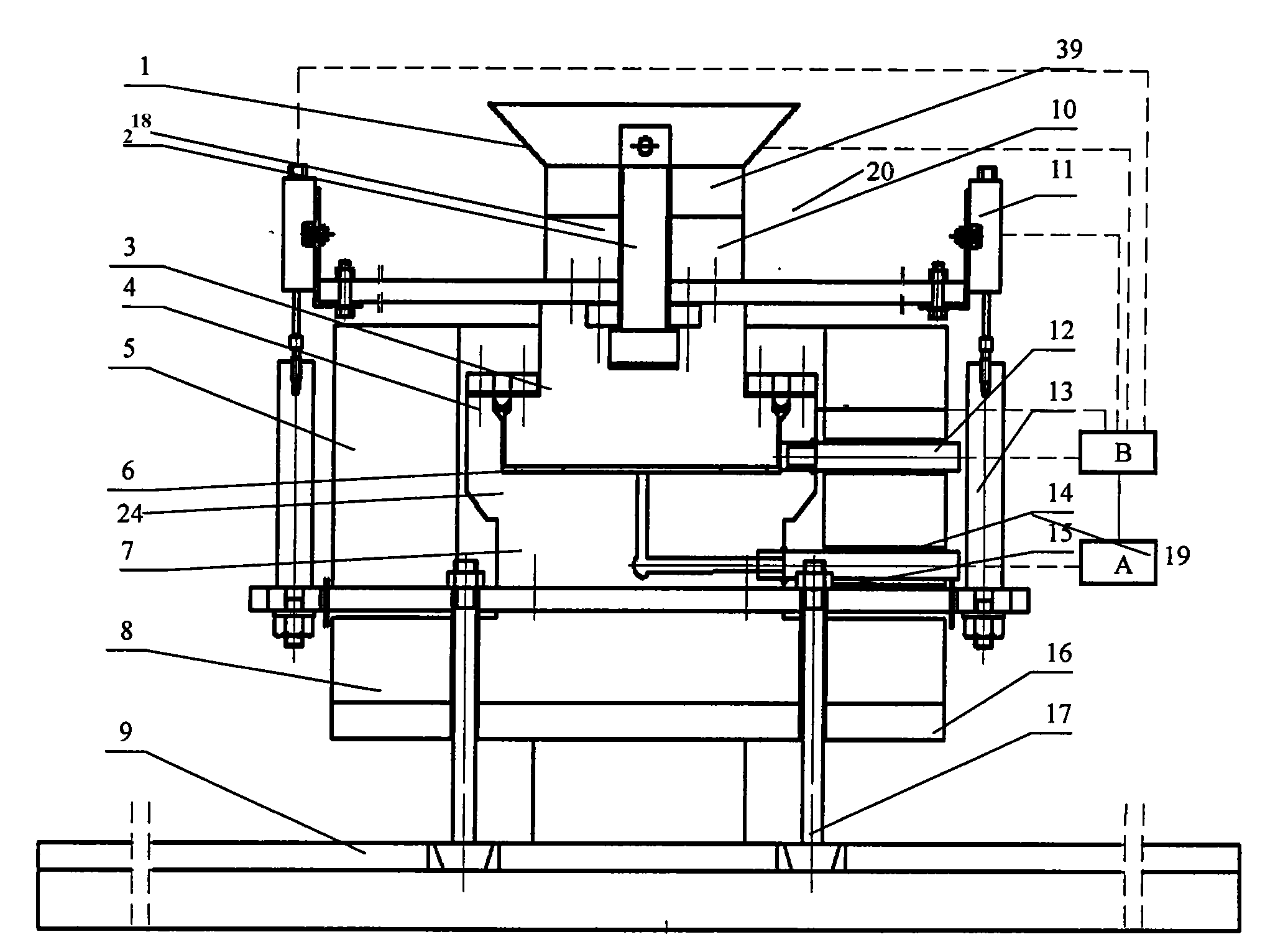

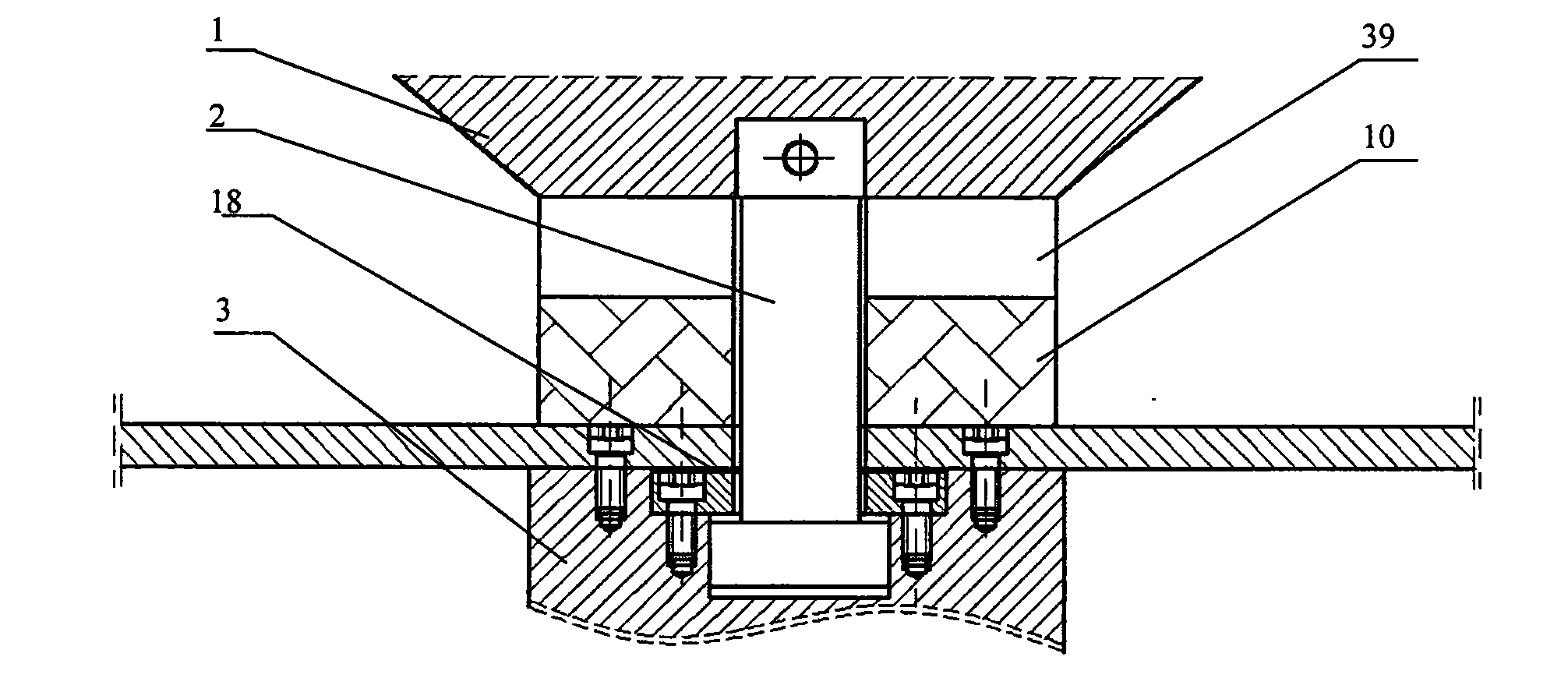

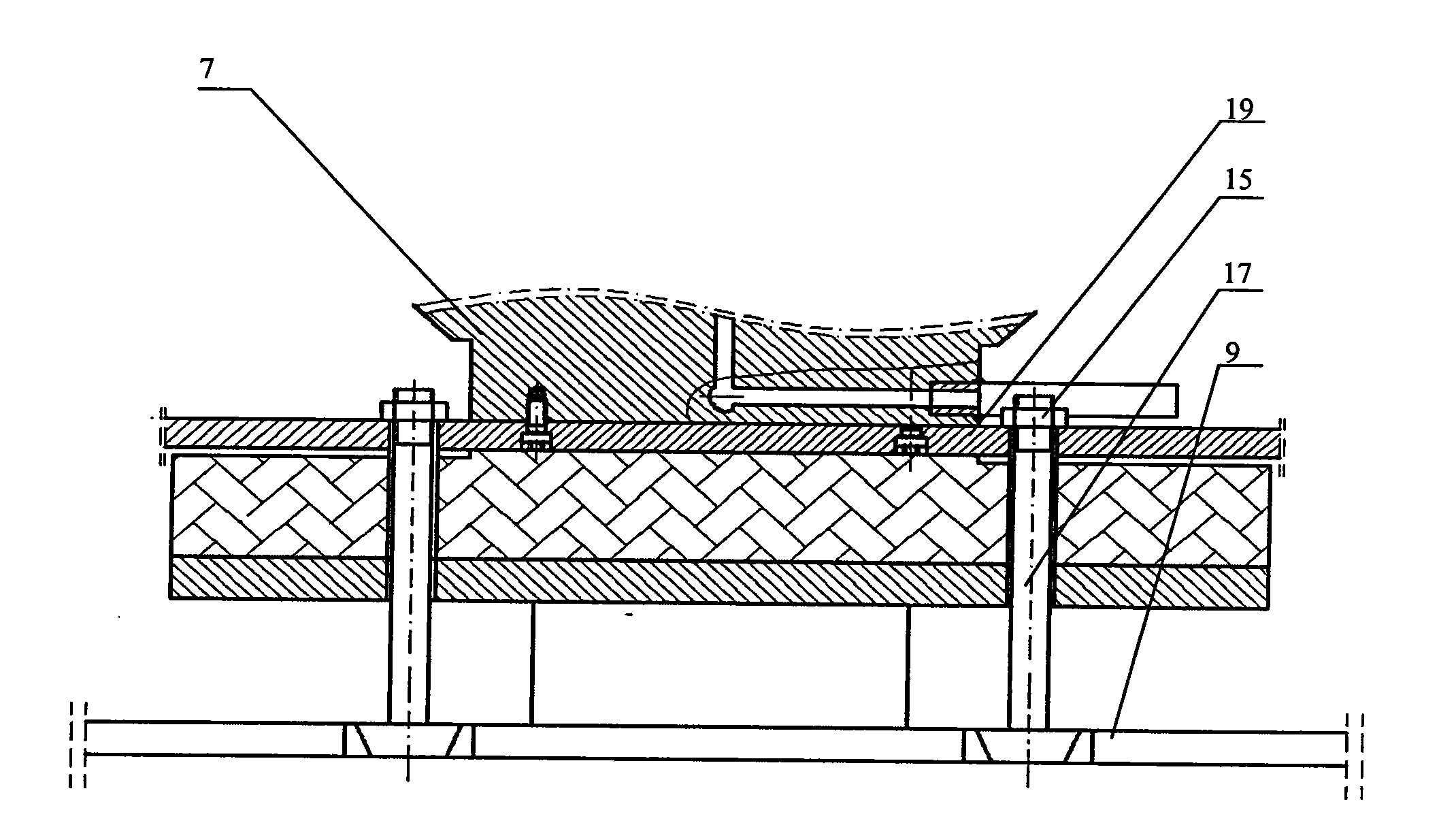

[0051] A high-temperature comprehensive performance evaluation test device for sealing gaskets, including an upper flange 3 and a lower flange 7, the convex upper flange 3 is placed in the concave platform of the concave lower flange 7, and the test gasket 6 Loaded between the upper flange 3 and the lower flange 7, the upper flange 3 and the lower flange 7 are arranged in the heating chamber 24 of the electric heating furnace 5, the heating chamber 24 is provided with a thermocouple 25, and the bottom of the lower flange 7 is provided with There is a displacement sensor lower pressure plate 19, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com