Device and method for testing fuel cell stack leakage rate

A technology of fuel cell stack and fuel cell stack, which is applied in the direction of measuring the increase and decrease rate of fluid, using liquid/vacuum degree to measure liquid tightness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

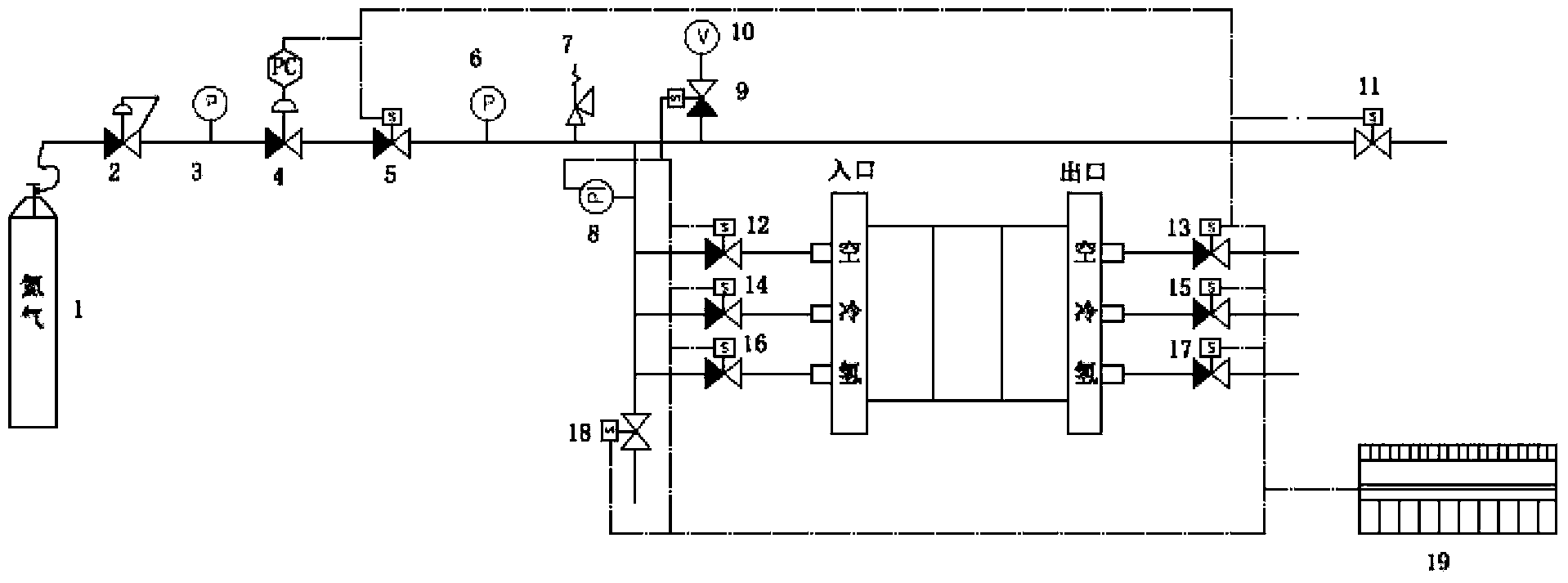

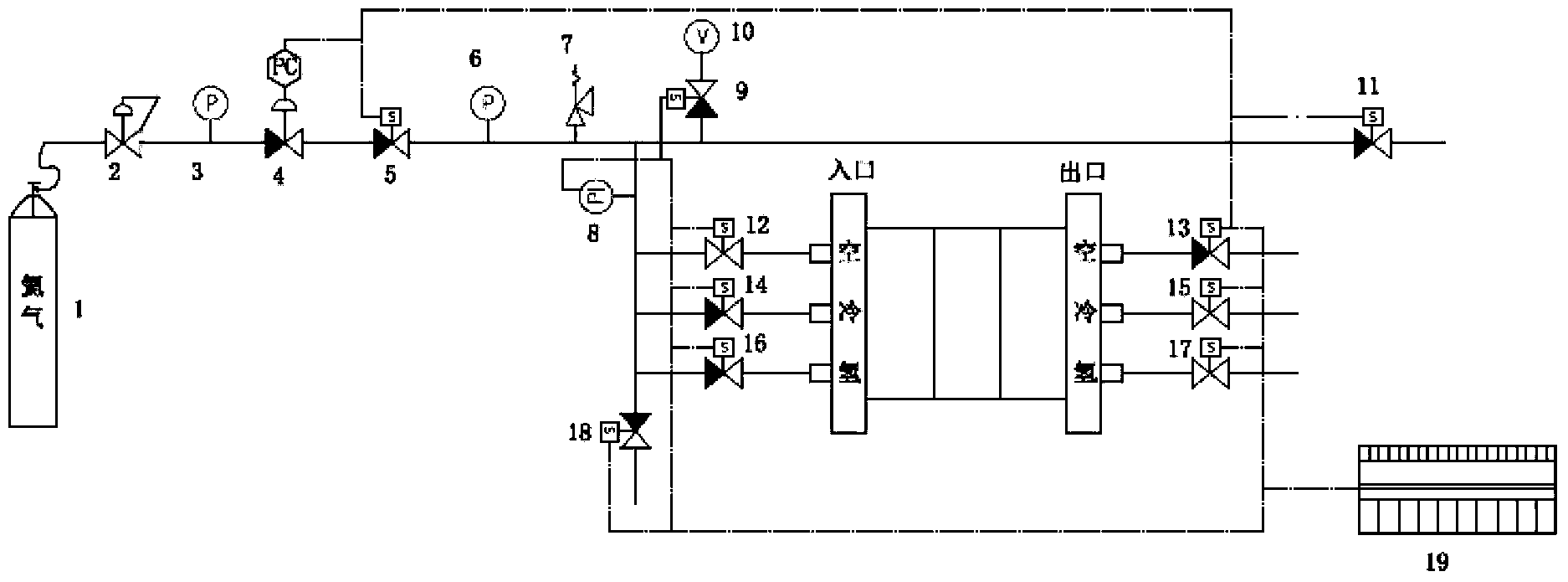

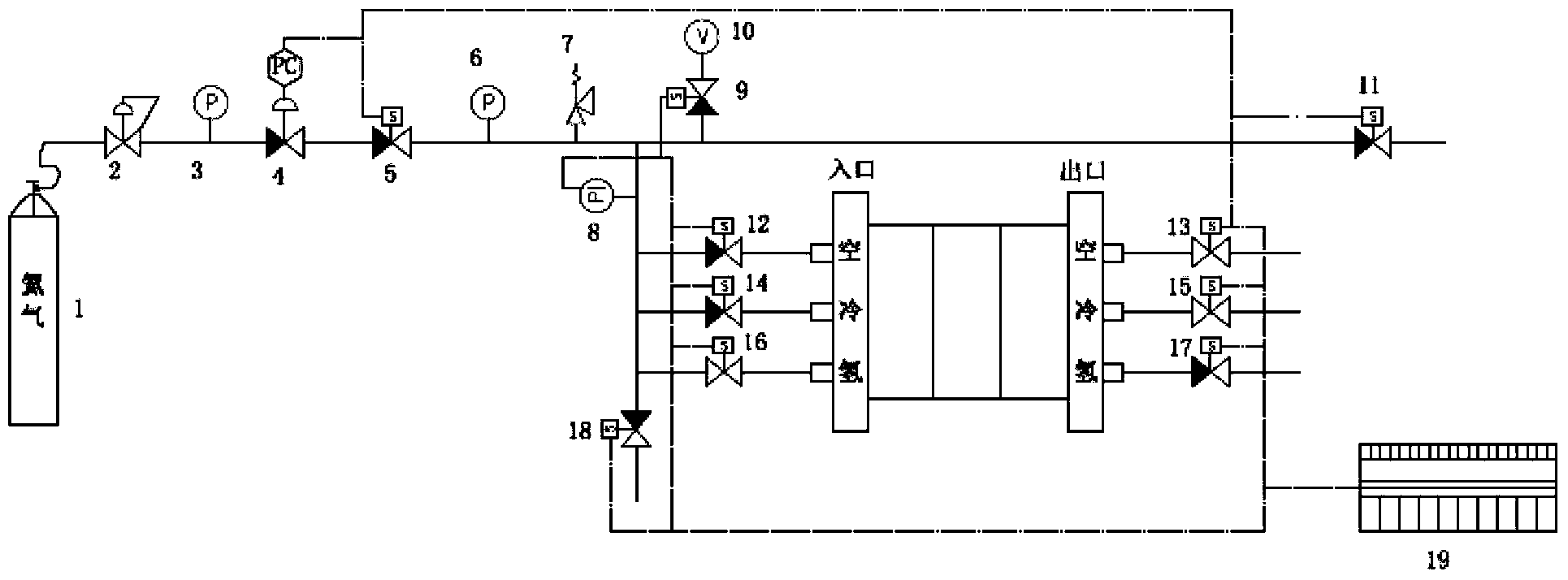

[0047] figure 1 It is a structural diagram of the leak rate testing device of the present invention. In order to automatically test the leakage rate caused by various internal and external leakages in the fuel cell stack, the device mainly includes 11 solenoid valves, 1 precision pressure sensor, 1 proportional pressure regulating valve, 1 safety valve, 1 constant container and corresponding pressure gauges, pipelines, etc.; the realization of all leak rate test functions is controlled by an industrial computer.

[0048] like figure 1 As shown, a fuel cell stack leakage rate test device is installed on the fuel cell stack. Air intake branch pipes, hydrogen gas intake branch pipes, and coolant inlet branch pipes are provided in front of the fuel cell stack. Air outlet pipes are provided behind the fuel cell stack. Branch pipe, hydrogen outlet branch pipe, coolant outlet branch pipe, characterized in that the device includes a helium cylinder 1 and an intake manifold, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com