Projecting simulator stand for coal and firedamp

A technology for simulating test benches and gas outbursts, applied in instruments, measuring devices, scientific instruments, etc., can solve problems affecting the time and intensity of coal and gas outburst, small model size, slow opening speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

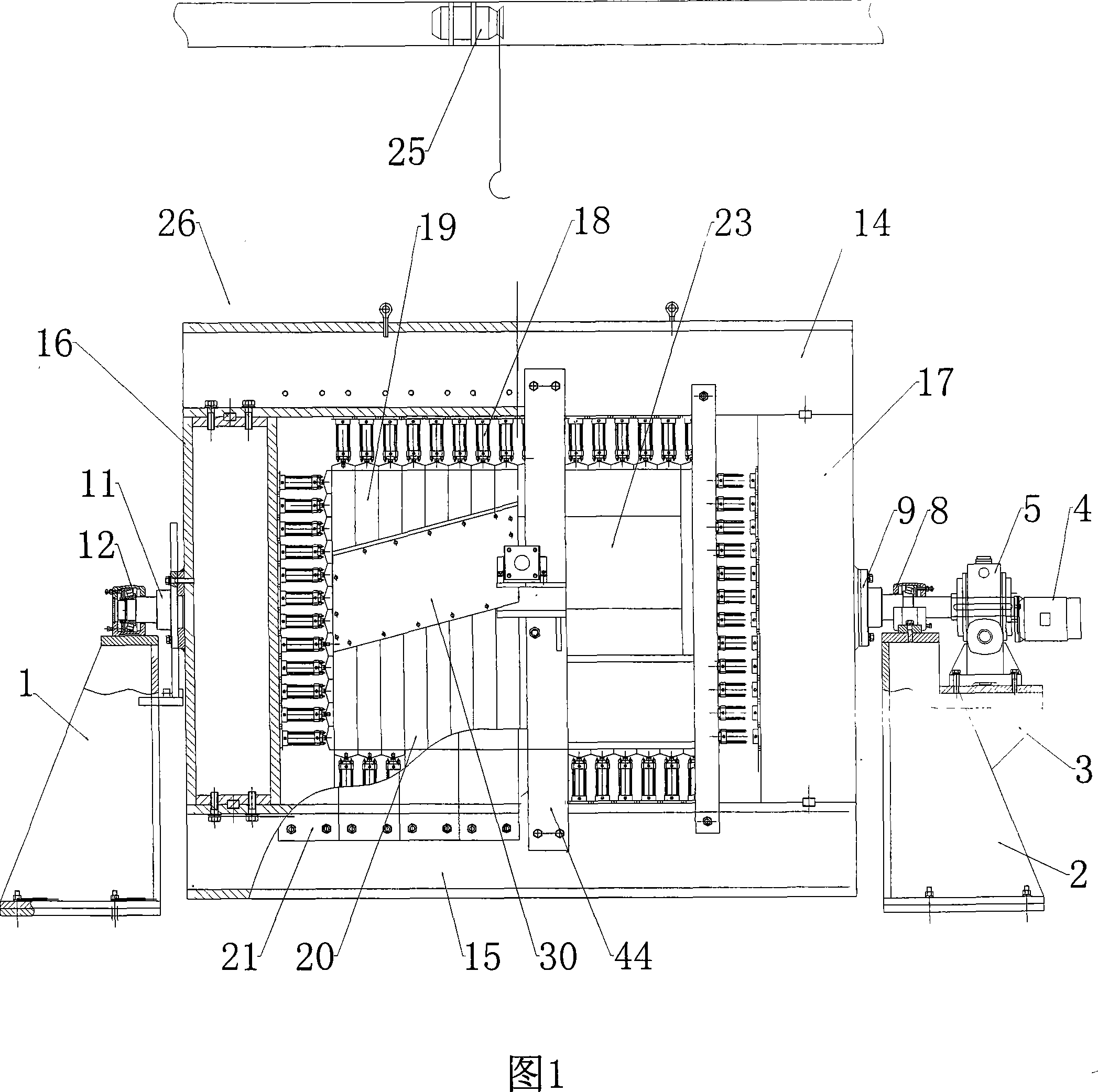

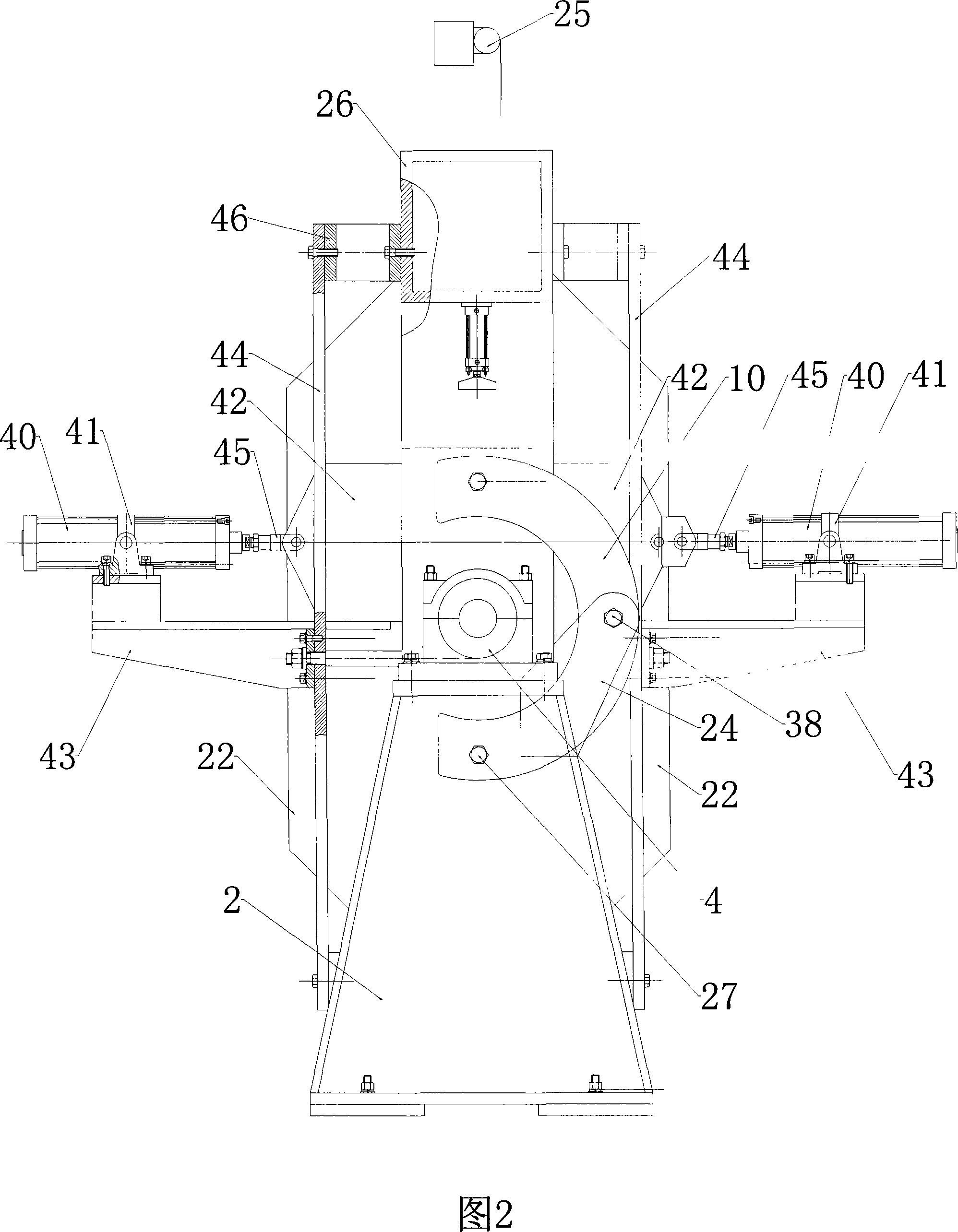

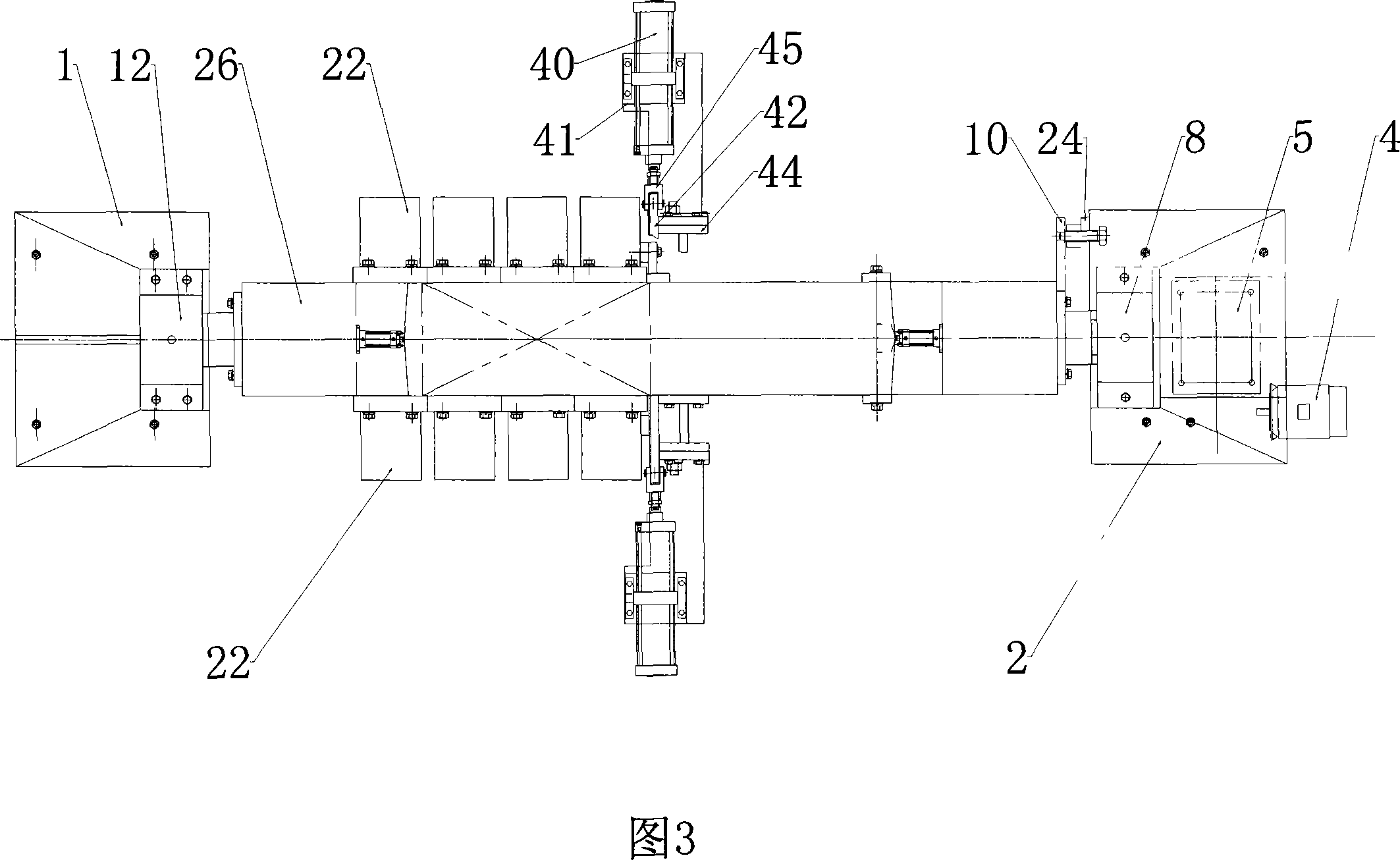

[0041] As shown in Fig. 1, Fig. 2 and Fig. 3, it is the coal and gas outburst simulation test bench of the present invention. The test bench is mainly composed of a reaction force frame 26, a pressure test box 30, a quick release mechanism and a jack 18.

[0042] Reaction force frame 26 is made up of left column 16, right column 17 and upper beam 14 and lower beam 15 that are installed on this left column 16, right column 17 upper and lower ends, and a row of jacks 18 is respectively installed around the inside of reaction force frame 26, Each jack 18 is all connected with an oil pump, so that the pressure of each jack 18 can be controlled by adjusting the oil pump, and a program can be set to control the pressure of each jack 18 by computer. Wherein, the ejector pin of upper row jack 18 faces downward, and the front end of each jack in the upper row jack 18 is respectively connected with an upper pressing block 19, and the ejector rod of lower row jack 18 faces upwards, and ea...

Embodiment 2

[0058] The structure of the test bench is the same as that of Embodiment 1, except that the pressure test box 30 is different. As shown in Figure 11, the angle between the axis line of the pressure test box 30 and the horizontal plane is 0°, and the upper pressure block 19 and the lower support are replaced accordingly. Block 20 can simulate the coal and gas outburst process under the horizontal dip coal seam.

Embodiment 3

[0060] The structure of the test bench is the same as in Embodiment 1, except that the pressure test box 30 is different. As shown in Figure 12, the angle between the axis line of the pressure test box 30 and the horizontal plane is 30°, and the upper pressure block 19 and the lower support are replaced accordingly. Block 20 can simulate the coal and gas outburst process under the 30° inclination coal seam.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com