Method and apparatus for controlling microfluidic flow

a microfluidic and flow control technology, applied in the field of microfluidic flow control, can solve the problems of limited precision/range, high cost of miniature pressure sensors, and limited control of open loop, and achieve the effects of simple and cheaper, price, range and precision, and easy integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

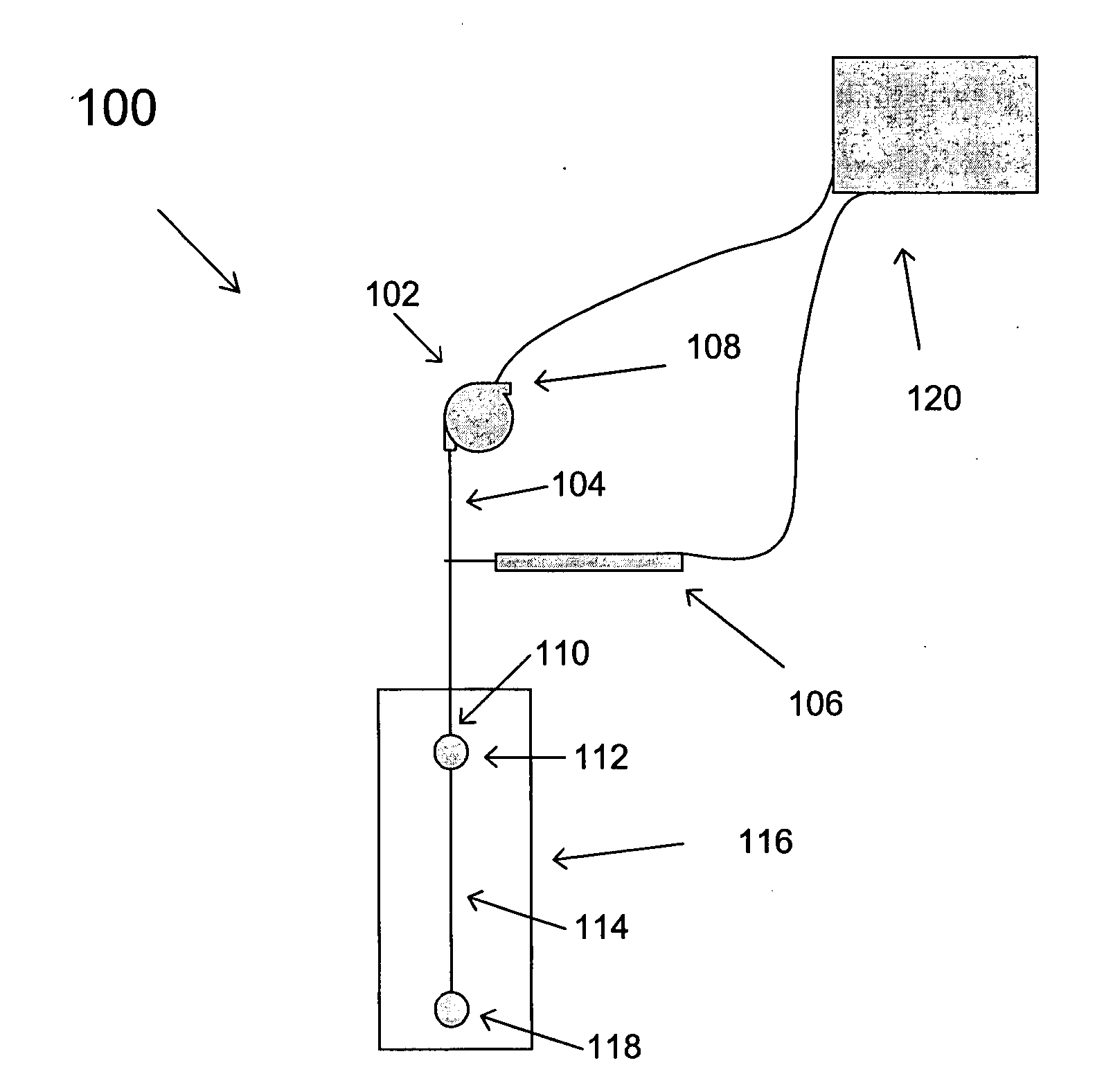

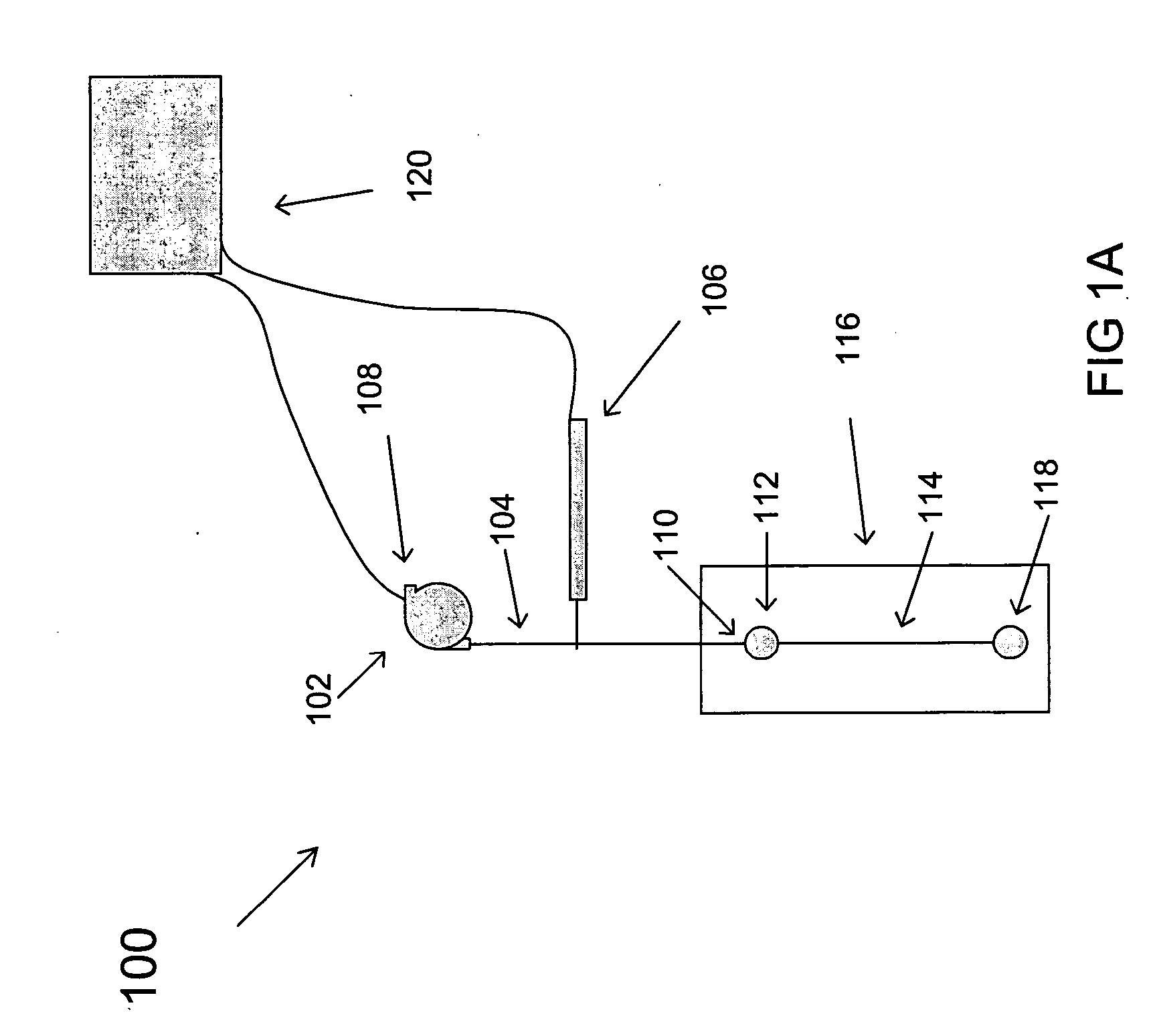

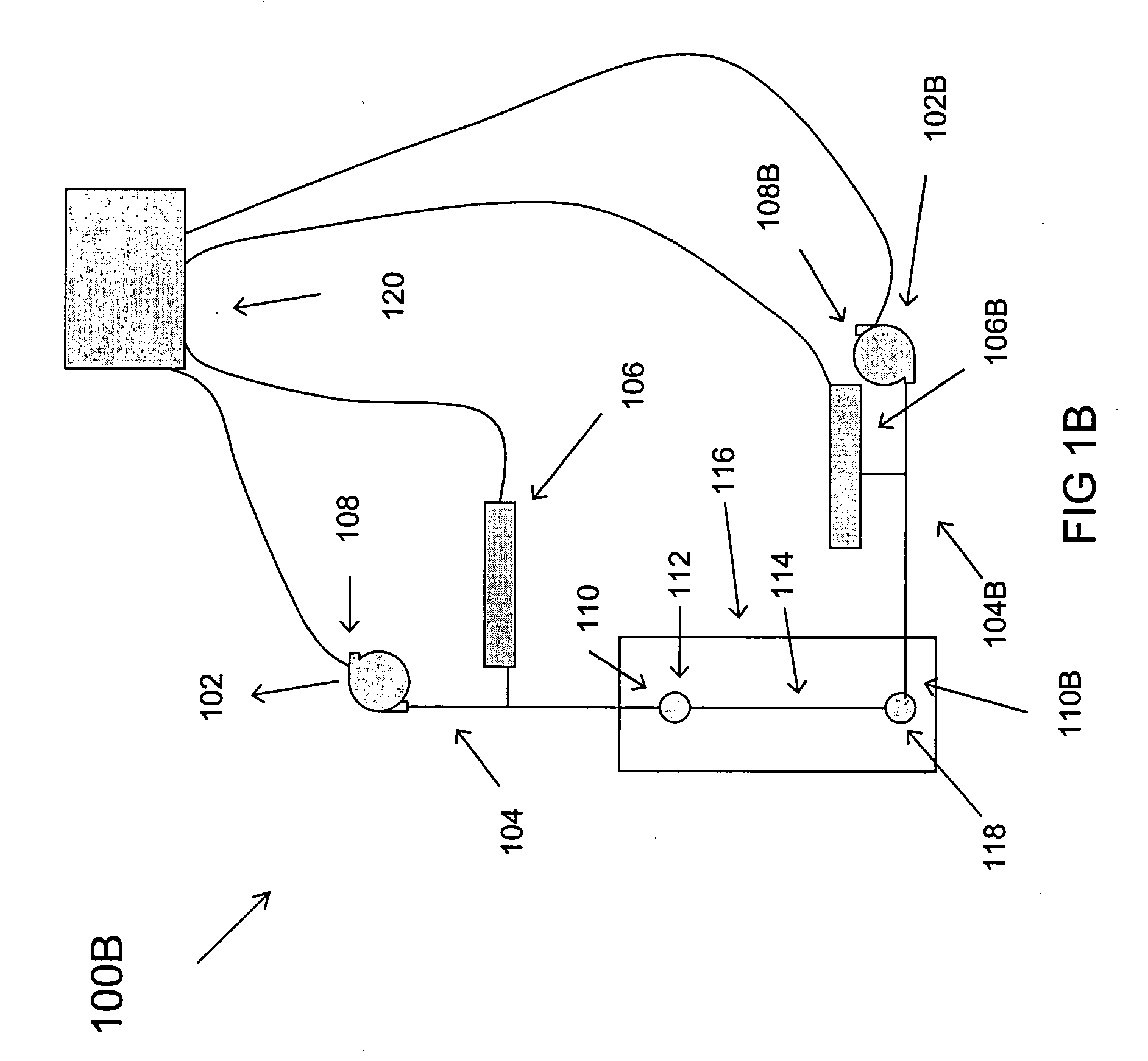

Image

Examples

example 1

[0051] A pressure controller was built according to the disclosed pressure controller. By appropriate selection of components, eight pressure channels were combined with a 15 PSI differential gas pressure sensor with an accuracy of + / −0.015 PSI. The accuracy and range can depend on the gas pressure sensor chosen, but in this example the pressure was found to be regulated to within better than 0.067% of the gas pressure sensor output. In this system, target pressures were reached well within one second.

[0052] A portion of the control electronics was dedicated to getting an accurate pressure measurement. A silicon piezo-resistive differential gas pressure sensor received constant current excitation and its output was calibrated for gain and zero offset. The output gain was set at 0.333 volts / pounds per square inch (V / PSI, e.g., 0.9 PSI air pressure corresponds to 0.3 V signal and −0.9 PSI air pressure corresponds to −0.3 V signal).

[0053]FIG. 6 is a graph of press...

example 2

Electrical Controller

[0063] Example 2 demonstrates one electrical channel of a prototype 8 electrical channel 0-5000 V controller that can support constant voltage or constant current modes to an accuracy of within 0.1 microamperes.

[0064] For each electrical channel, a commercially available programmable voltage supply was employed that was capable of 0-5000 V at 200 microamperes. The output of each supply enters the disclosed electrical control network which can calculate the output voltage and current and which can be connected via an output to an electrode contacting a conduit in a microfluidic chip.

[0065] In this example, two electrical channels were connected to each other through a 100 megaohm resistor, so that, for example, a 500 V difference between the electrical channels can result in one electrical channel sourcing 5 microamperes and the other electrical channel sinking 5 microamperes.

[0066] One electrical channel was held at 2000 V while the other electrical channel ...

example 3

Computer and Software Control

[0070] The pressure and electrical controllers can interact with the microfluidic chip through analog voltage signals, producing measurements and responding to input stimuli in terms of voltages. Thus, a desirable computer control system can work with analog voltages as well. An exemplary setup (employed in Examples 1 and 2) can be driven by a single desktop computer which can be equipped with appropriate analog inputs, outputs, and control software. Using commercially available components (e.g., a 32 channel 13 bit analog output card and two 16 channel 16 bit analog input cards, controlled by LabView software from National Instruments, Austin Tex.; In other embodiments, custom components can be employed, e.g., dedicated analog inputs and outputs, custom software programming), real-time graphical monitoring of all channels was achieved. Moreover, these values were recorded, and could be correlated with the output of other instruments or used to control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com