Two-stage hydrocarbon hydrogenation method with serial high-pressure parts

A high-pressure part and part technology, which is applied in the field of producing diesel components by the two-stage method of hydrorefining first and then hydrocracking of anthracene oil, which can solve the problems of fast coking speed, large equipment and pipeline size, and reducing the total amount of circulating hydrogen, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

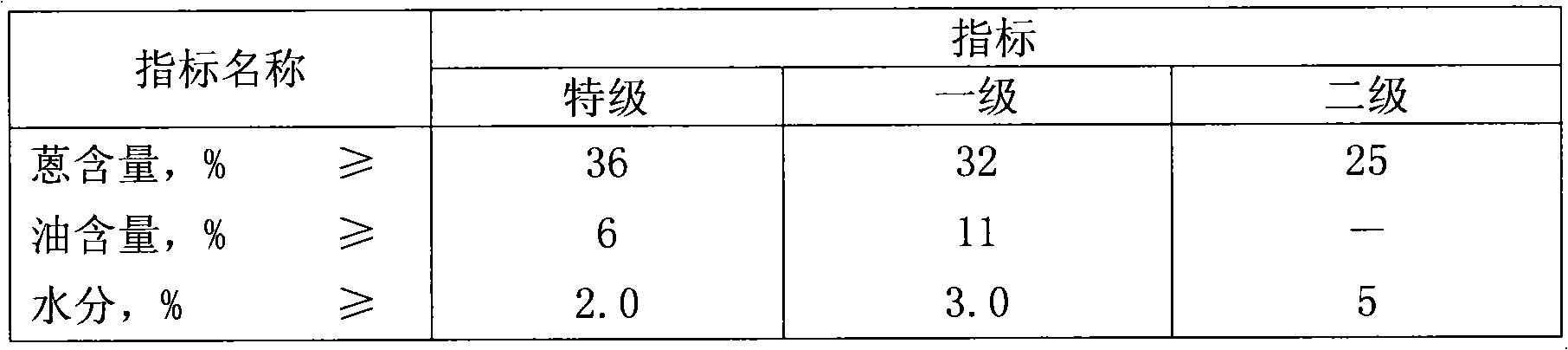

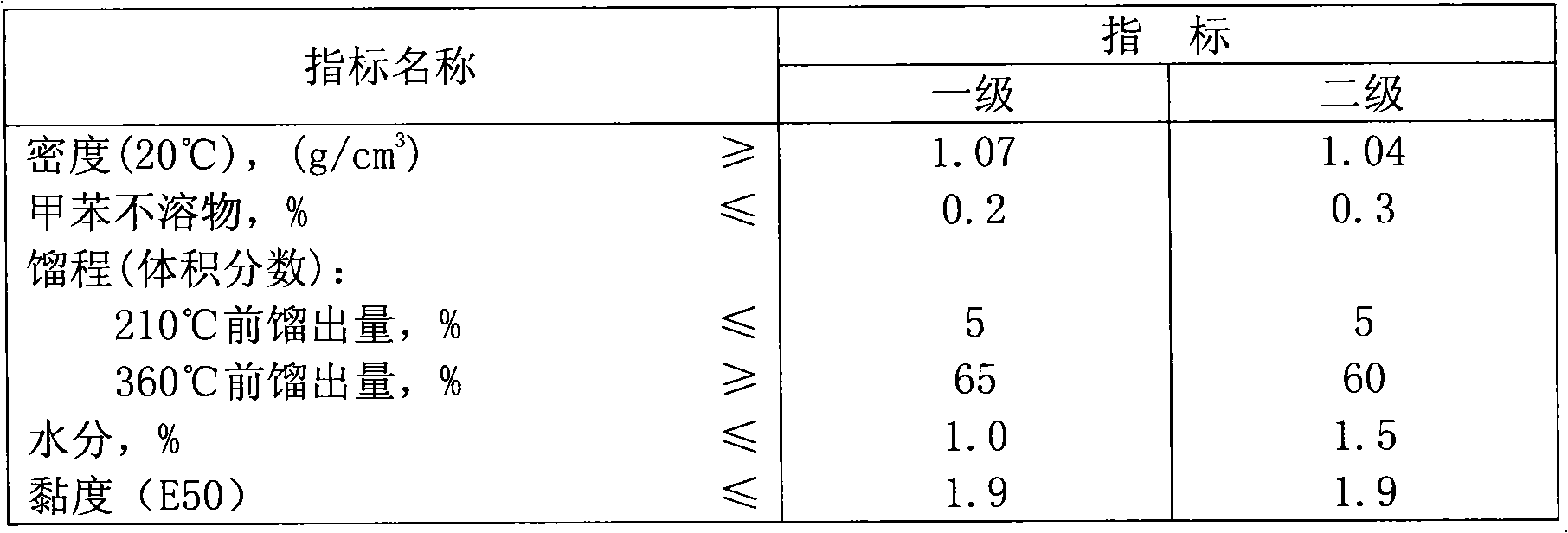

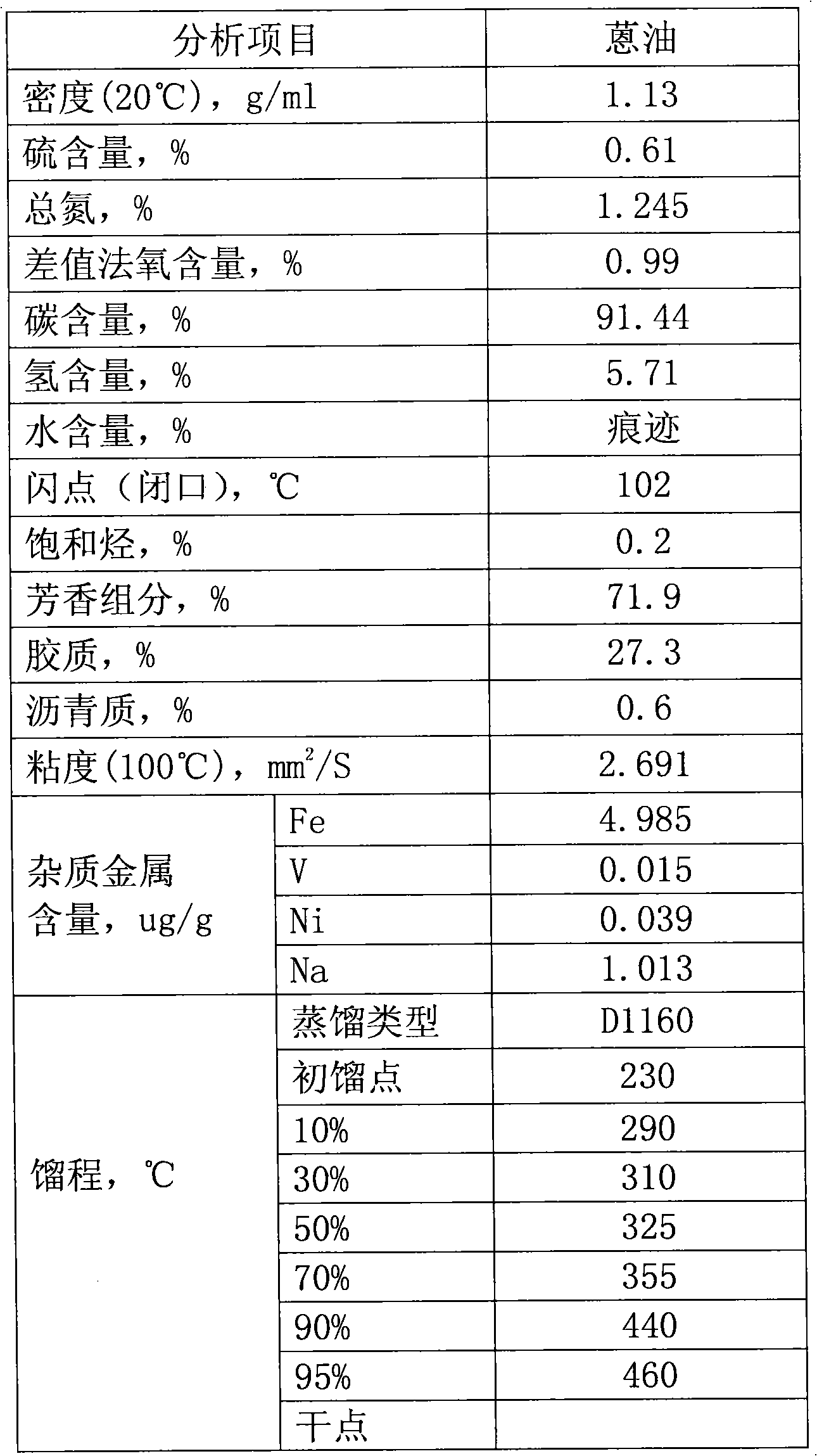

[0131] Properties such as the anthracene oil of Table 3 and Table 4, the processing capacity is 12500kg / h, using the flow process of the present invention, the operating conditions of the reaction part and the properties of the oil produced by hydrogenation are shown in Table 5, the conventional method of one section of hot high fraction oil and one section of cold high fraction oil The components with a boiling point higher than 130°C and the first-stage cold high fraction gas all enter the second-stage hydrogenation reaction part. The properties of the naphtha fraction of the oil produced by the second-stage hydrogenation are shown in Table 6, and the properties of the diesel fraction of the oil produced by the second-stage hydrogenation are shown in Table 7.

[0132] In this embodiment, the objectives of demetallization, deep desulfurization, deep denitrogenation, deep aromatic saturation and moderate hydrocracking are achieved. From the comparison of the properties of the ...

Embodiment 2

[0151] Compared with Example 1 of the present invention, increasing the operating temperature of the first-stage thermal high-pressure separation part to 330°C can achieve the following effects: ① Reduce the heat load of the first-stage reaction effluent cooling down and entering the thermal high-pressure separation part, and reduce the thermal high-pressure separation part of the first stage. The heating load of the oil temperature rising into the second-stage reaction part reduces the investment of related high-pressure heat exchangers; Small, the pressure drop in the gas phase heating process of the first-stage cold high-pressure gas entering the second-stage reaction part is very small, increasing the operating temperature of the first-stage hot high-pressure separation part, reducing the pressure drop of the first-stage reaction effluent cooling down into the first-stage hot high-pressure separation part, and reducing the pressure drop of the first stage The pressure drop ...

Embodiment 3

[0156] Compared with Example 1 of the present invention, reducing the operating temperature of the first-stage hot high-pressure separation part to 230°C can achieve the following effects: ① The amount of hot high-separation gas in the first-stage heat is reduced, and the amount of hot high-separation gas in the first-stage heat is reduced correspondingly. Air cooler or water cooling ②The total weight of the first-stage cold high-separation oil and the proportion of heavy components in it are reduced, and the first-stage cold high-separation oil can be directly introduced into the second-stage reaction part without dehydration and degassing to achieve the effect of simplifying the process, or The first-stage cold high-fraction oil or fractions thereof may be introduced into the second or subsequent catalyst bed of the second-stage reaction part.

[0157] Table 10 Summary of parameters affected by the operating temperature of the first-stage thermal high-pressure separation sect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com