Tester for simulation and real-time test of gaseous corrosion failure of thermal barrier coating

A technology of thermal barrier coatings and testing devices, applied in measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problems of lack of real-time detection and evaluation of thermal barrier coating corrosion performance, etc., to achieve convenient pressure control, The effect of fast temperature rise and cool down rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention provides a test device for simulating and real-time testing of gas corrosion of thermal barrier coatings, and the present invention will be further described below through the description of drawings and specific implementation methods.

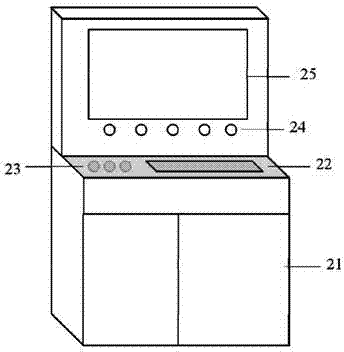

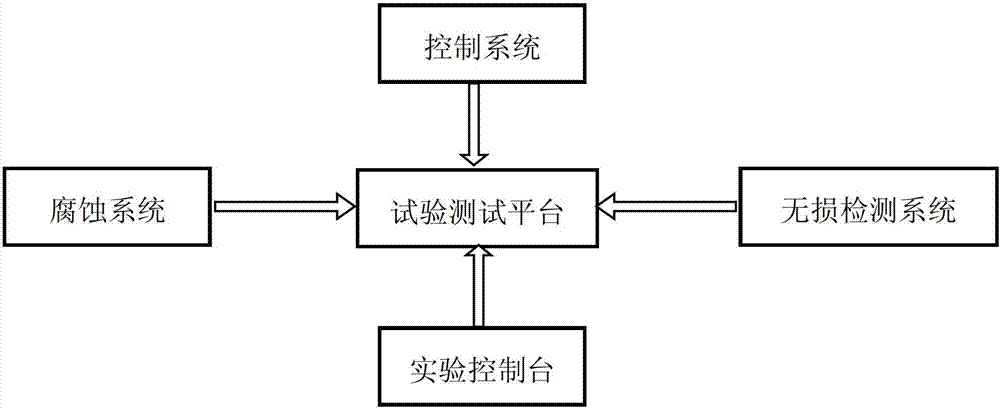

[0019] like figure 1 as shown, figure 1 It is a schematic diagram of the overall logical structure of the present invention. The structure of the test device includes: a test bench, a corrosion system, a control system, and a non-destructive testing system.

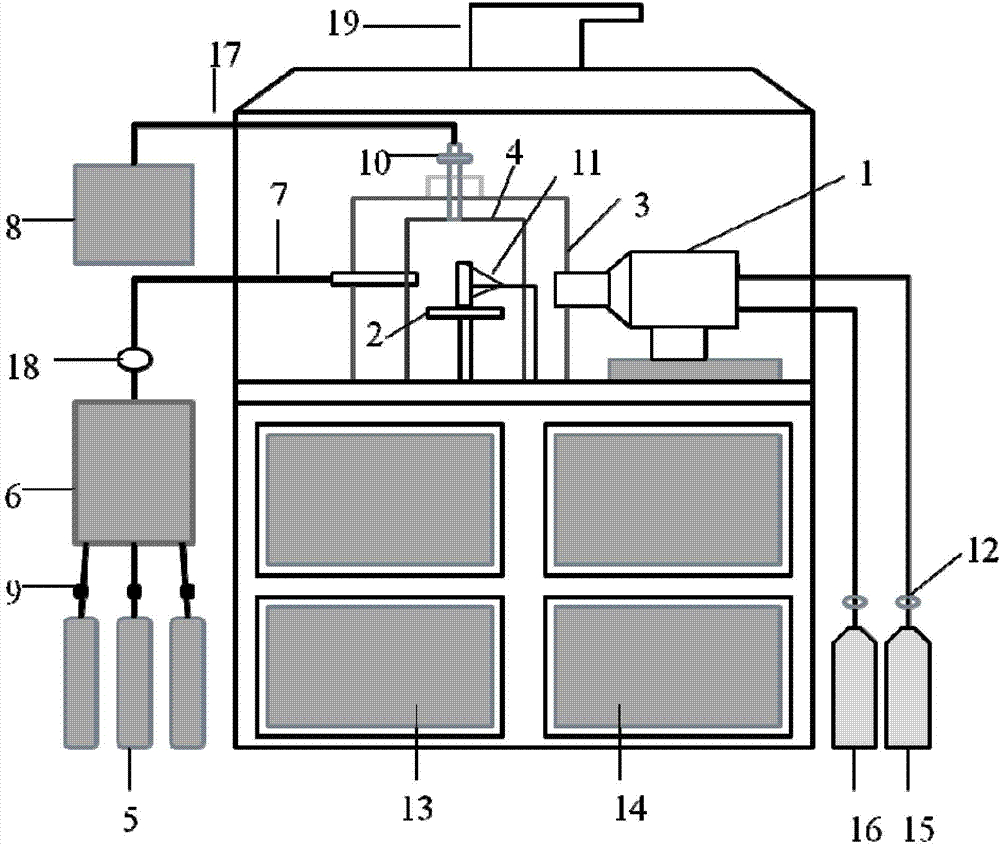

[0020] like figure 2 shown figure 2 It is the overall structure diagram. The overall structure of the device is: propane gas and oxygen used in the heating spray gun, and the gas pressure is controlled by the computer through the gas controller to adjust the flame temperature to heat the corrosion reaction chamber. There is an annular cooling channel in the spray gun, and the coolant can circulate between the cooling channel of the spray gun and the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com