Dual-purpose copy arrangement for ultraviolet lighting micro-nano graph air pressure stamping and photolithography

A copying device and ultraviolet light technology, which are applied in microlithography exposure equipment, photolithographic process exposure devices, patterned surface photolithographic process, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

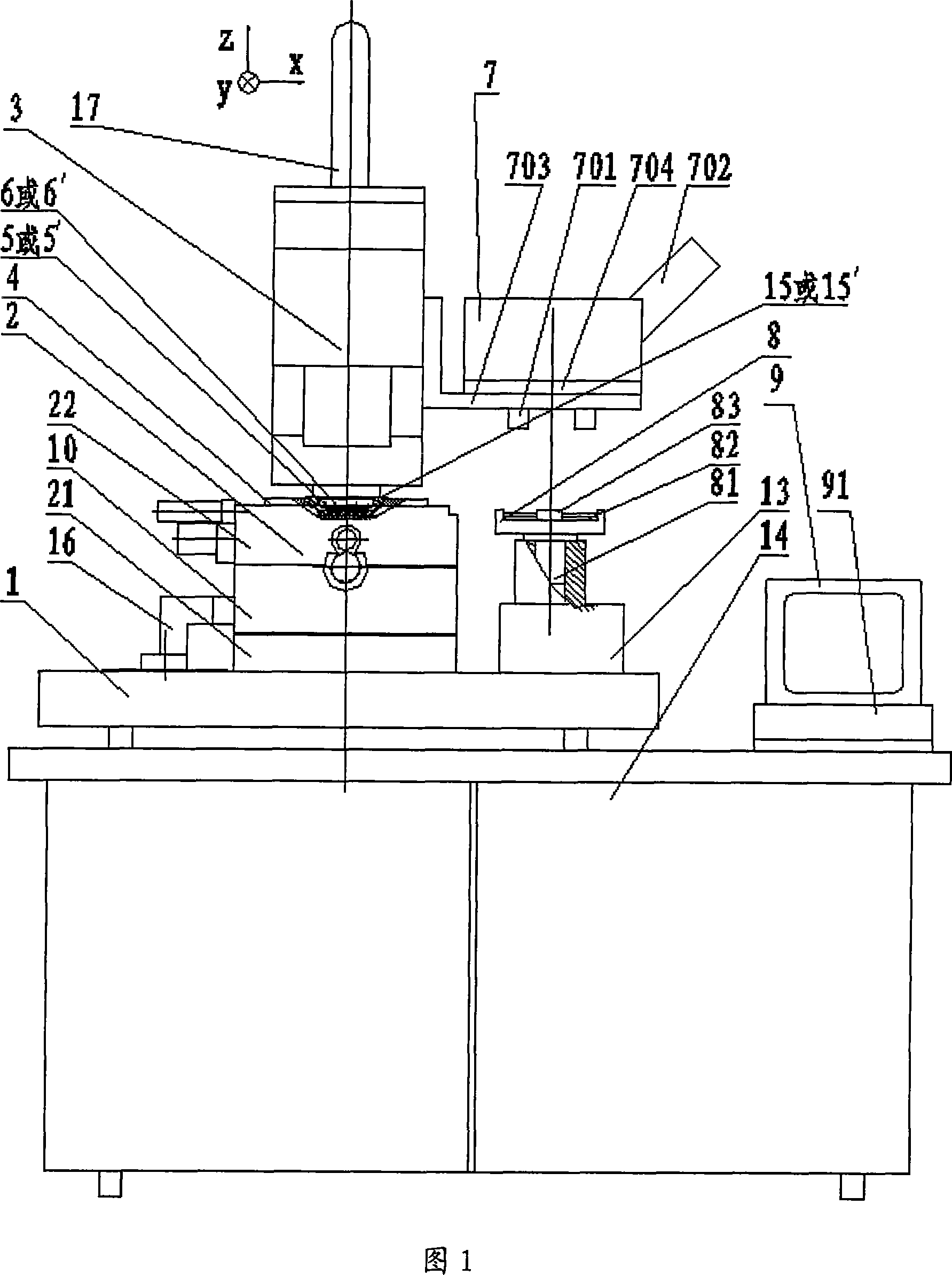

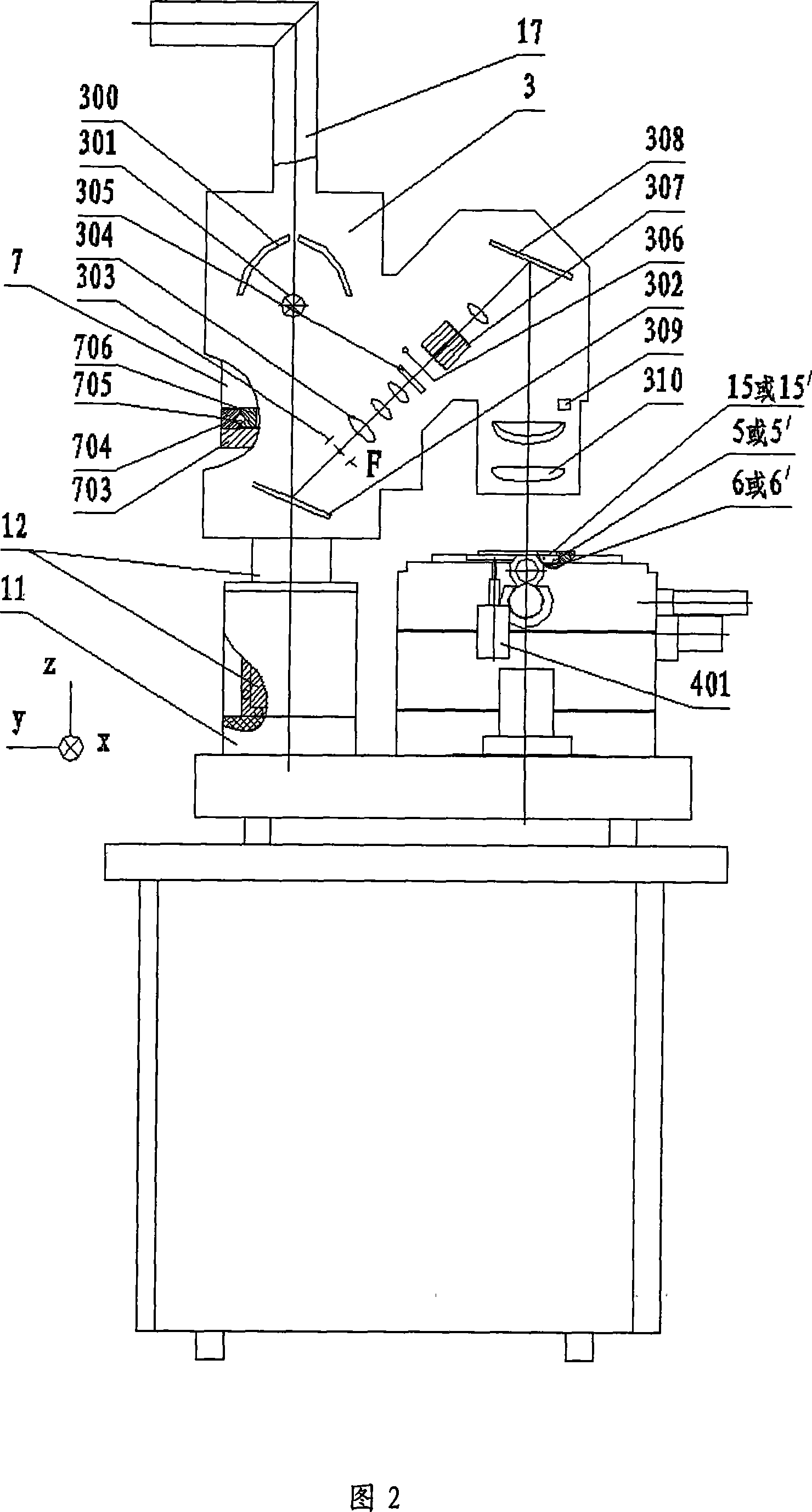

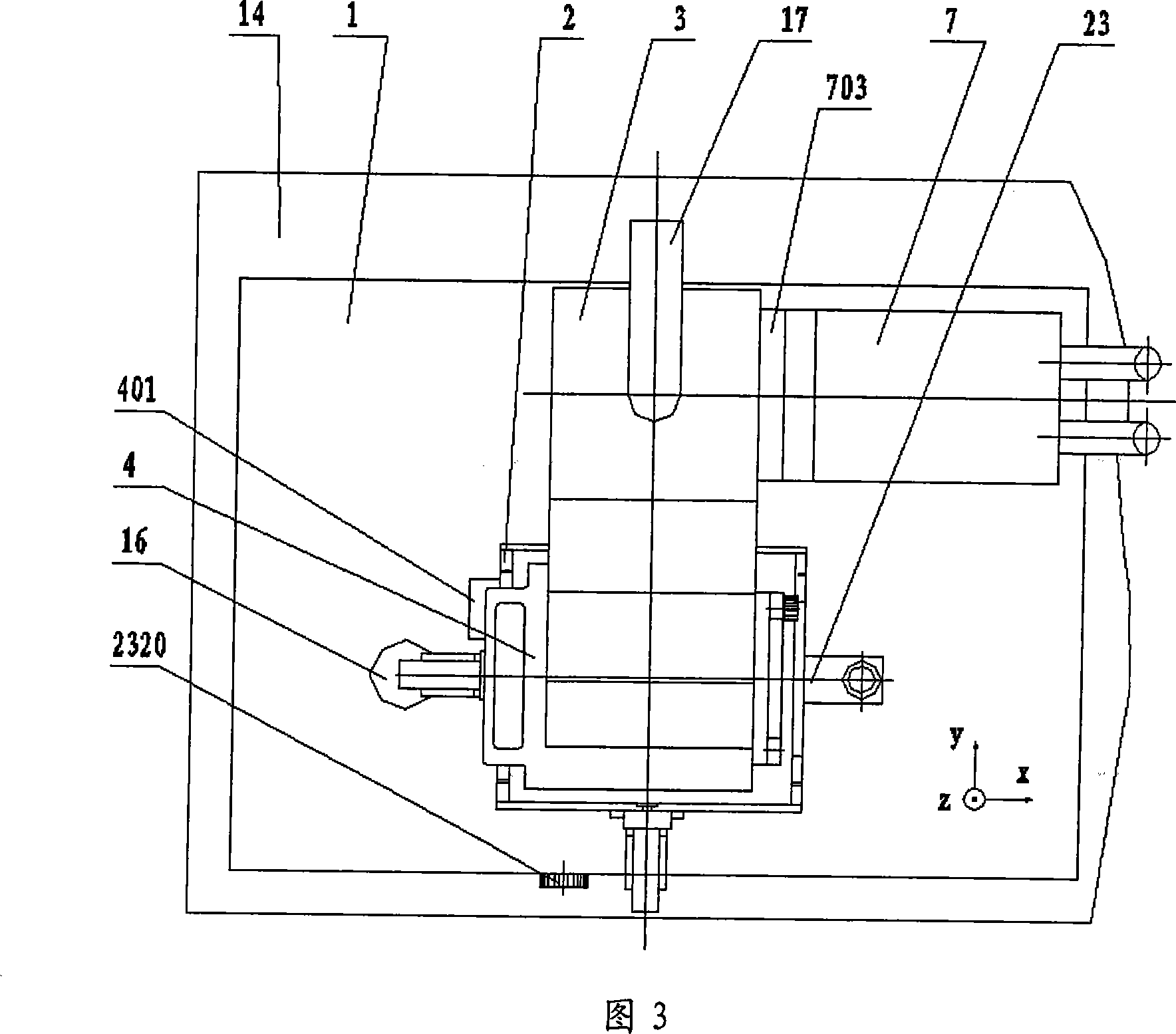

[0025] As shown in Figure 1, it is the front view of the structure of the dual-purpose replication device structure of ultraviolet light micro-nano pattern air pressure embossing and photolithography of the present invention, which includes a large substrate of the host machine 1, a stamper mobile station system 2, a uniform lighting system 3, and a stamper Frame 4, stamper 5 or mask 5', substrate 6 or silicon wafer 6', alignment system 7, illumination uniformity detection system 8 and control system 9, the host large substrate 1 is placed The vibration isolation table and the control cabinet 14 of the vibration isolation function make the host of the present invention not be affected by the vibration of the external environment when embossing or photolithography is carried out. On the large base plate 1 of the host computer, a stamper mobile system 2 and an illumination uniformity detection system 8 are respectively fixed, wherein the illumination uniformity detection system 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com