Cooling system for a metallurgical furnace

A cooling system, metallurgical furnace technology, applied in the direction of cooling devices, etc., can solve the problem of frequent discharge of emergency cooling system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

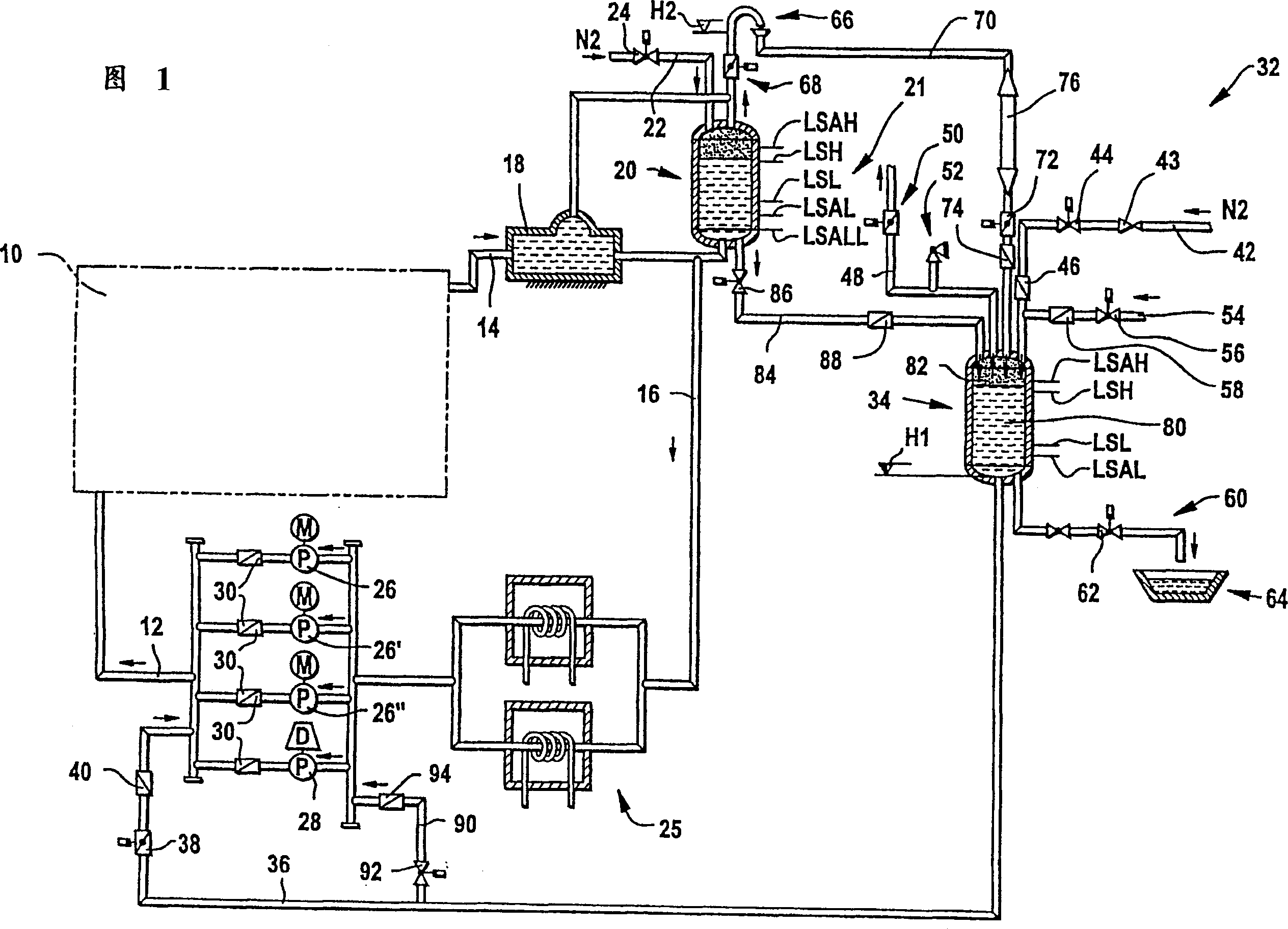

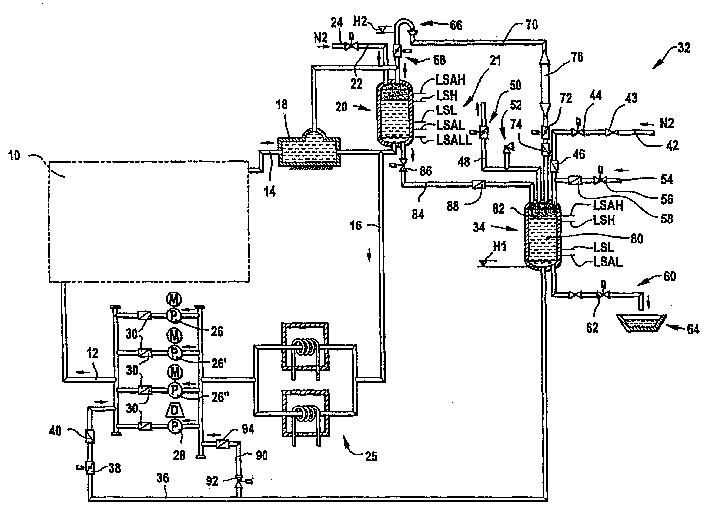

[0020] In FIG. 1 , reference numeral 10 refers to a blast furnace cooling circuit comprising a cooling water inlet 12 and an outlet 14 . This cooling circuit 10 is subdivided into the blast furnace components to be cooled, ie vertical cooling plates and cooling boxes of the furnace walls, tuyeres and hot blast equipment. A return line 16 connects the outlet 14 with the inlet 12, forming a closed cooling circuit. Near the outlet 14, at the top of the blast furnace, the return line 16 includes a degasser 18 in which the heated cooling water is substantially free of gas. At this highest point of the cooling water circuit 10 there is also a closed expansion vessel 20 through which pressurized gas (such as N 2 ) for pressurization. This gas helps to ensure that the pressure in the cooling circuit is sufficiently high that the cooling water in said cooling circuit 10 has no risk of evaporating. The expansion vessel is also provided with low and high water limit switches and an al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com