Tunnel type magnesian refractory brick salt immersing heat treatment kiln and technology

A heat treatment kiln and refractory brick technology, which is applied in waste heat treatment, lighting and heating equipment, furnace types, etc., can solve the problems affecting product quality, heat treatment kiln temperature and pressure, etc., and achieve the effect of reasonable temperature distribution and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

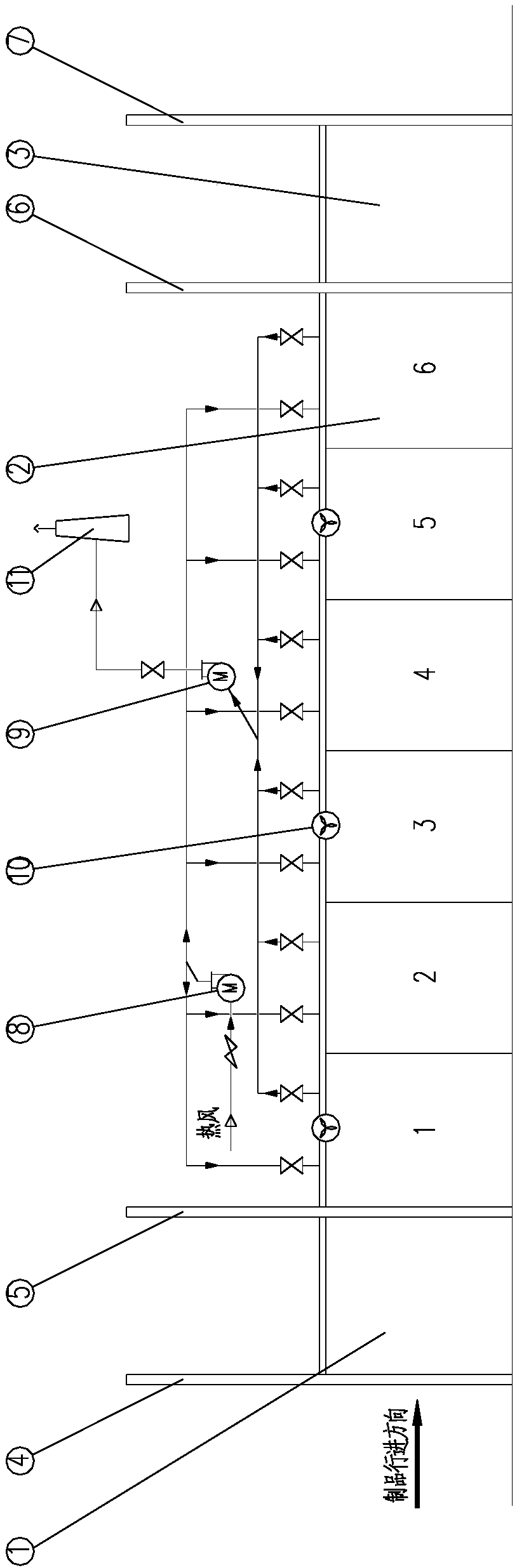

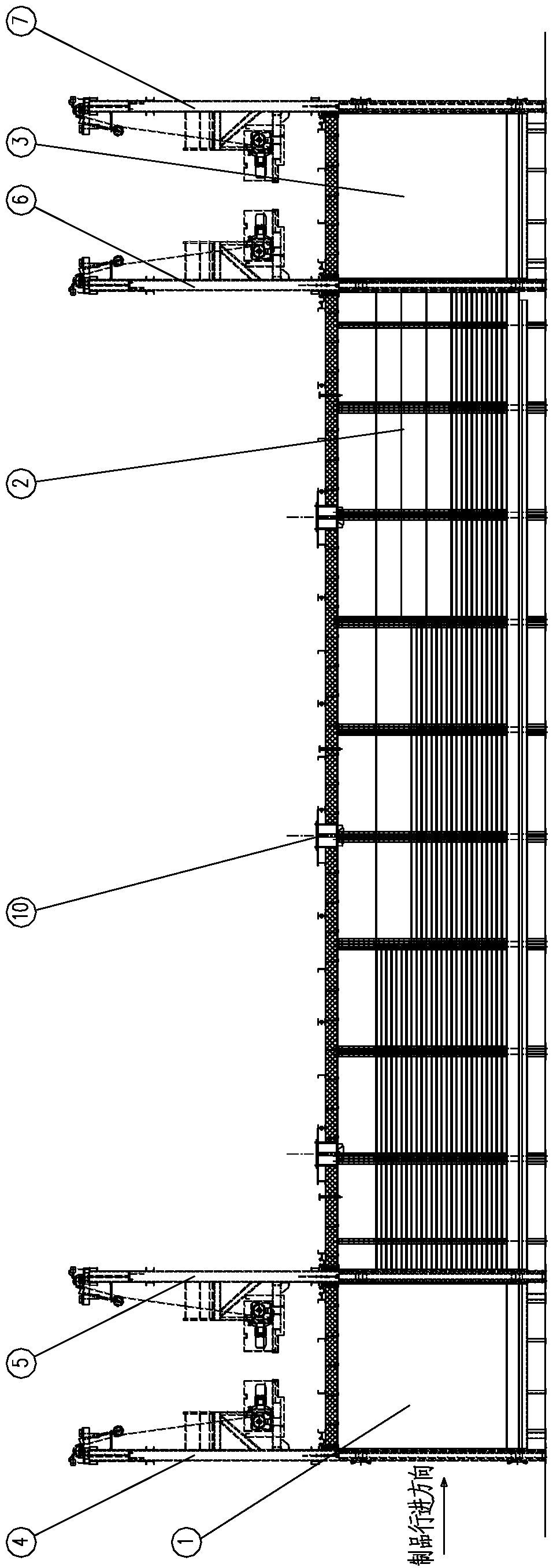

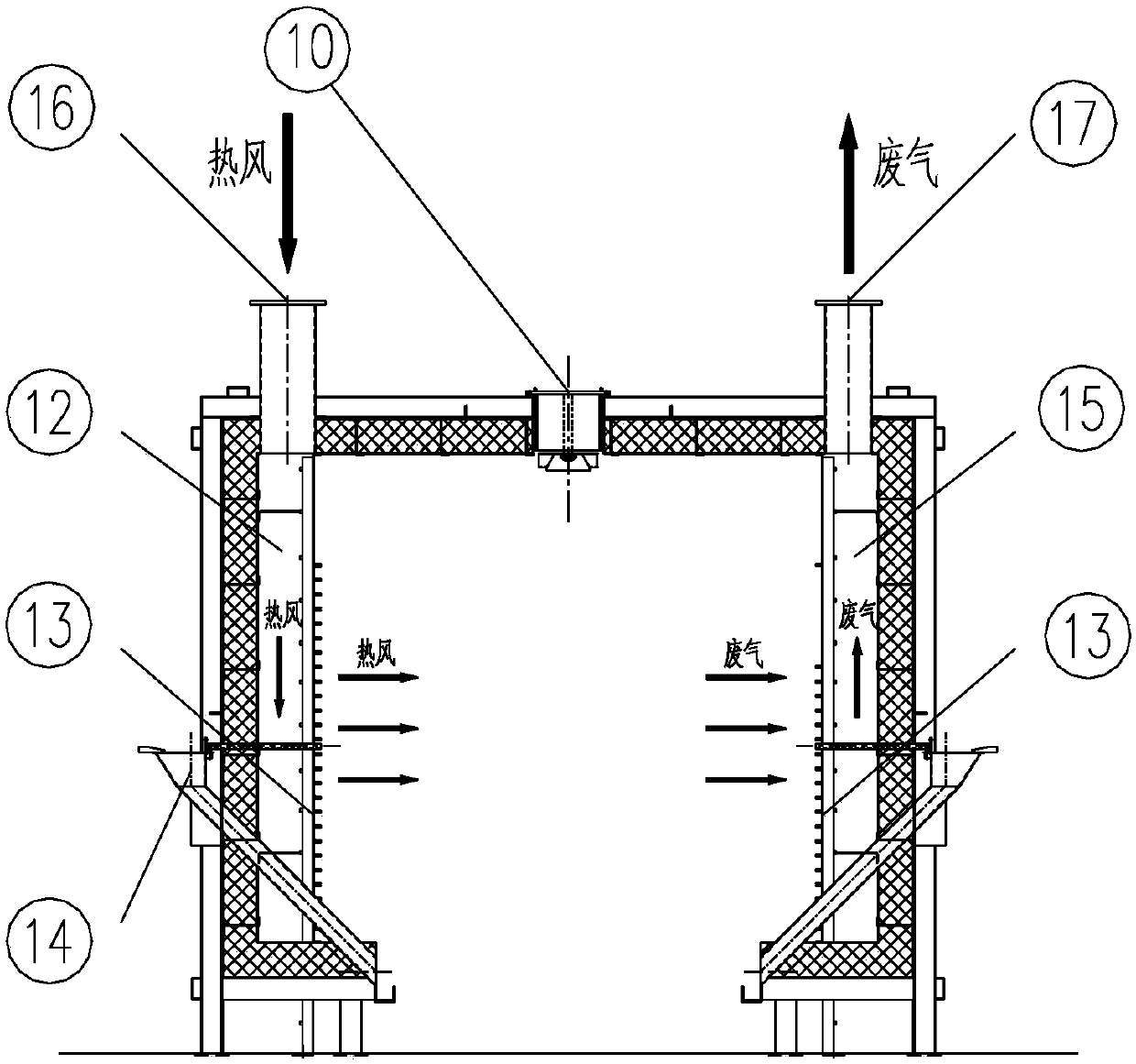

[0042] Heat treatment kiln body 2 from left to right ( figure 1 , figure 2The orientation shown in ) has a total of 6 parking spaces, and every two parking spaces are an air supply and exhaust area. The two sides of the kiln body are the interlayer on the hot air inlet side (hot air supply area 12) and the interlayer on the exhaust gas outlet side (exhaust area 15), a hot air inlet 16 and an exhaust air outlet 17 are arranged above each parking space of the kiln body, and partitions are arranged in the interlayers on both sides of the heat treatment kiln to ensure that the hot air volume of each area of the heat treatment kiln can be adjusted independently, will not interfere with each other. The hot air enters the hot air inlet 16 through the air blower 8, and is sent into the heat treatment kiln body 2 through the air regulating plate 13 on the side of the hot air inlet to provide heat for a certain area and heat treat the products in the kiln. Three circulating fans 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com