Process for preparing softening water by alkali wastewater

A technology for softening water and waste water, applied in water softening, descaling, water softening, water/sludge/sewage treatment, etc. It can solve problems such as strong continuity, impact, and complicated process, and achieve the effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

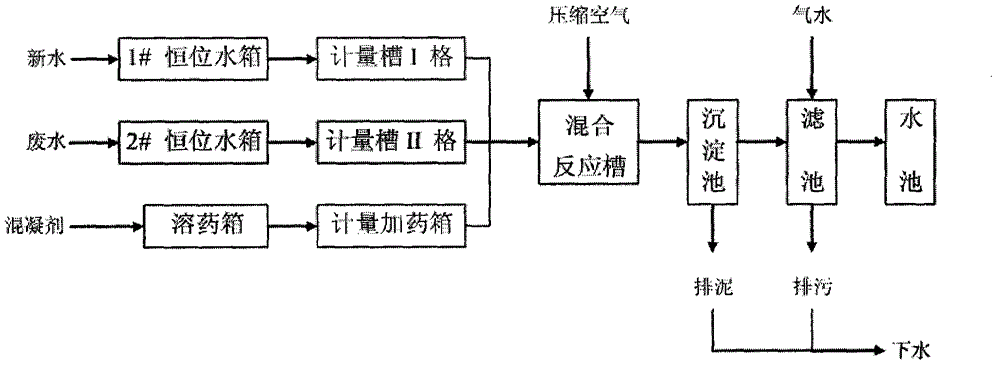

[0013] refer to figure 1 , the specific implementation method adopts the following technical scheme: the process of utilizing alkaline waste water to prepare demineralized water, its technological process is: based on the principle of equivalent reaction of waste water alkalinity and new water hardness, new water and waste water are respectively entered into 1# constant position The metering tank I of the water tank, the metering tank II of the 2# constant level water tank, and the coagulant is added to the metering dosing box of the dissolving tank, and the new water and waste water are mixed with new water and waste water in an approved ratio, and then enter The mixed reaction tank is stirred by compressed air, and the residence time is 4.8min. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com