Bubble fluidised bed combustion device and method for burning-used biologic mass fuel

A technology of bubbling fluidized bed and biomass fuel, which is applied in the direction of fluidized bed combustion equipment, combustion method, fuel burned in molten state, etc., can solve the problem of material separation and poor material circulation, low energy density of biomass fuel, The temperature in the upper part of the furnace is difficult to control and other problems, so as to improve the reliability of redundancy, reduce the cost of pretreatment, and simplify the fuel preparation and feeding system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

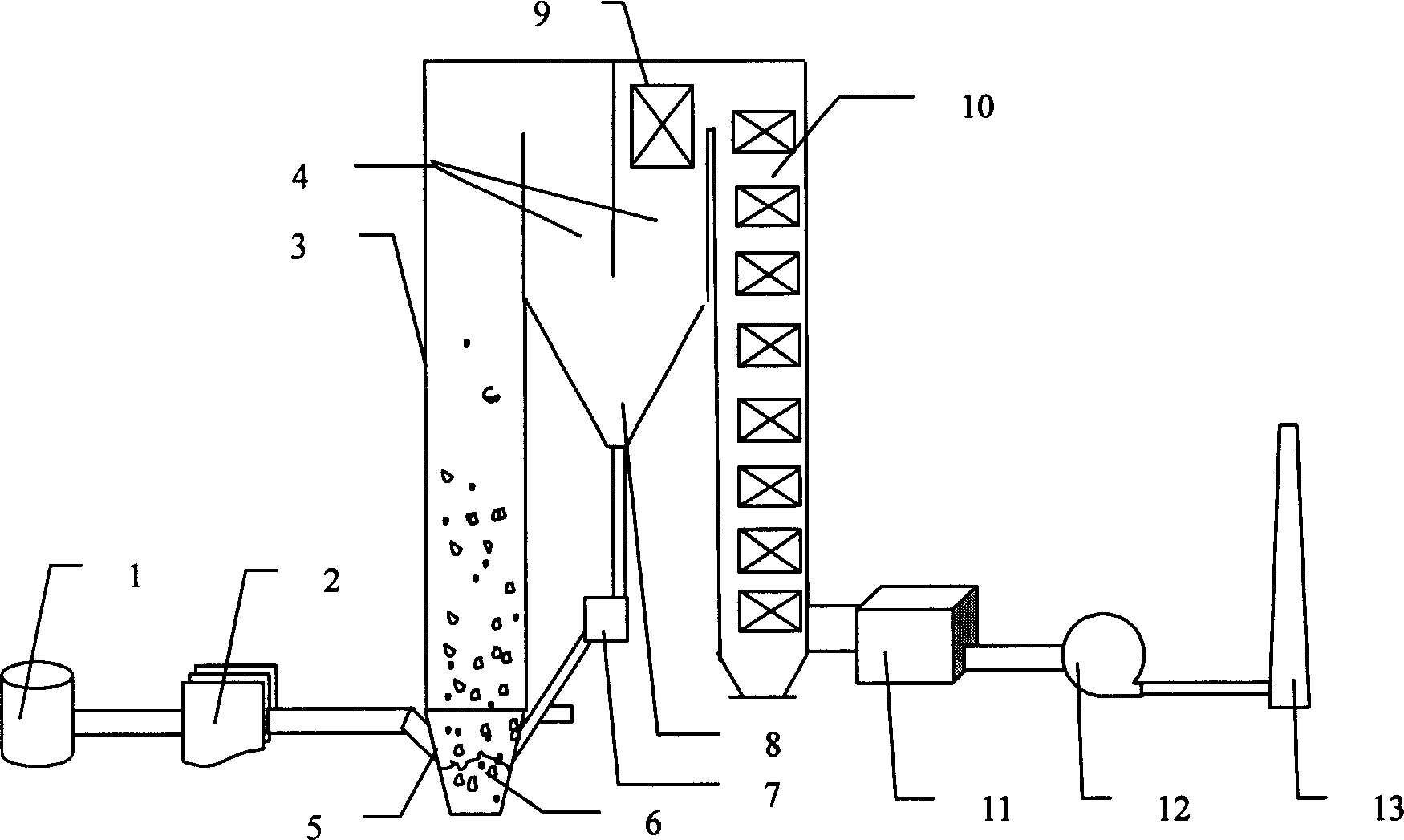

[0020] As shown in the drawings, the bubbling fluidized bed combustion device for burning biomass fuel includes a furnace 3, the upper part of the furnace is connected with a secondary flue 4, a convective heating surface 9 arranged in the secondary flue, and the tail is connected subsequently Flue 10, dust collector 11, induced draft fan 12 and chimney 13, and the lower part of the secondary flue 4 is arranged with a settling ash hopper 8, where the settled fly ash is sent back to the variable cross-section furnace dense phase zone 6 through the fly ash return device 7 , The biomass raw material storage bin 1 is connected to the fuel inlet 5 through the biomass crushing equipment 2 .

[0021] Before the operation of the bubbling fluidized bed combustion device for biomass fuel, the bed material is first screened for particle size, and the maximum particle size of the bed material is controlled below 2mm. After the average particle size is determined, it will be selected for n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com