Iron ore sintering device and method with coke replaced with biomass charcoal based on fuel layering and flue gas circulating

A technology of flue gas circulation and biochar, which is applied in the field of iron and steel industry, can solve the problems of reducing sintered minerals and quality, and achieve the effects of reasonable material layer temperature distribution, reduced consumption and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

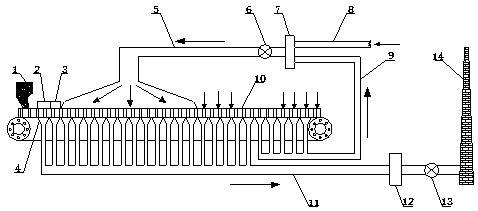

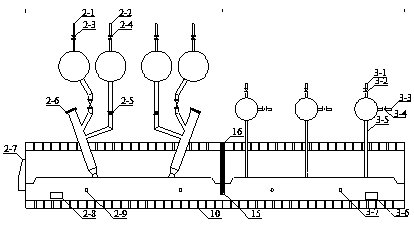

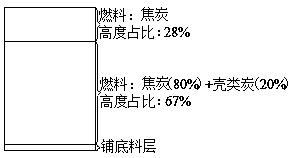

[0024] The iron ore sintering device based on fuel stratification and flue gas circulation, which replaces coke with biomass charcoal, includes a sintering machine body, a mixing tank 1, an ignition furnace 2, a holding furnace 3, an air box 4, a mixed flue gas circulation pipe 5, Mixed flue gas circulation fan 6, mixed flue gas dedusting device 7, sinter cooling exhaust gas pipeline 8, circulating flue gas pipeline 9, sintering trolley 10, large flue 11, large flue dust removal and desulfurization device 12, large flue fan 13 , chimney 14 and sintering furnace, the top of one end of the sintering machine body is connected to the outlet of the sintering material in the mixing tank 1 through a distributor, and the sintering machine body is located at the end of the mixing tank 1 and is sequentially provided with an ignition furnace 2, a holding furnace 3 and a sintering furnace. A sintering trolley 10 is arranged at the bottom of the fuselage, and the sintering machine fuselage ...

Embodiment 2

[0032] The iron ore sintering device based on fuel stratification and flue gas circulation, which replaces coke with biomass charcoal, includes a sintering machine body, a mixing tank 1, an ignition furnace 2, a holding furnace 3, an air box 4, a mixed flue gas circulation pipe 5, Mixed flue gas circulation fan 6, mixed flue gas dedusting device 7, sinter cooling exhaust gas pipeline 8, circulating flue gas pipeline 9, sintering trolley 10, large flue 11, large flue dust removal and desulfurization device 12, large flue fan 13 , chimney 14 and sintering furnace, the top of one end of the sintering machine body is connected to the outlet of the sintering material in the mixing tank 1 through a distributor, and the sintering machine body is located at the end of the mixing tank 1 and is sequentially provided with an ignition furnace 2, a holding furnace 3 and a sintering furnace. A sintering trolley 10 is arranged at the bottom of the fuselage, and the sintering machine fuselage ...

Embodiment 3

[0040] The iron ore sintering device based on fuel stratification and flue gas circulation, which replaces coke with biomass charcoal, includes a sintering machine body, a mixing tank 1, an ignition furnace 2, a holding furnace 3, an air box 4, a mixed flue gas circulation pipe 5, Mixed flue gas circulation fan 6, mixed flue gas dedusting device 7, sinter cooling exhaust gas pipeline 8, circulating flue gas pipeline 9, sintering trolley 10, large flue 11, large flue dust removal and desulfurization device 12, large flue fan 13 , chimney 14 and sintering furnace, the top of one end of the sintering machine body is connected to the outlet of the sintering material in the mixing tank 1 through a distributor, and the sintering machine body is located at the end of the mixing tank 1 and is sequentially provided with an ignition furnace 2, a holding furnace 3 and a sintering furnace. A sintering trolley 10 is arranged at the bottom of the fuselage, and the sintering machine fuselage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com