Megawatt-grade permanent magnet generator

A permanent magnet generator, megawatt-level technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of uneven cooling, local overheating, etc., and achieve the effects of uniform axial direction, quick installation and reasonable distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

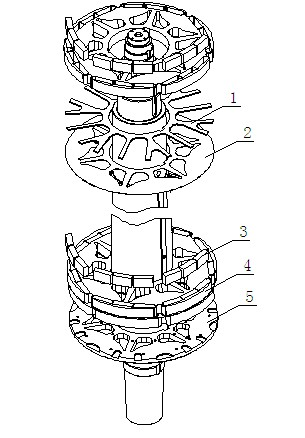

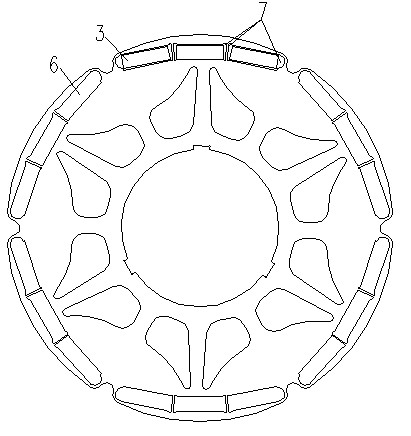

[0033] The invention discloses a megawatt-level permanent magnet generator, which includes a rotor magnetic steel fixing structure and a motor ventilation structure, etc., referring to Figure 1~2 . The fixed structure of the magnetic steel includes a rotor core disk 4, and a plurality of core disks 4 are fixed on the rotating shaft through a square key. The adjacent two core disks 4 are separated by stainless steel ventilation groove plates 1, and there are The stainless steel core pressing plate 5 is provided with a plurality of magnetic steel slots 6 on the iron core punching sheet close to the outer circle of the iron core plate 4. The shape of the magnetic steel slots 6 matches the shape of the magnetic steel 3 to be assembled, and the plurality of magnetic steel slots 6 evenly distributed around the circumference. The magnetic steel grooves 6 are in six groups, and each group includes three rectangular magnetic steel grooves 6 , and there is a gap 7 at the edge of the m...

Embodiment 2

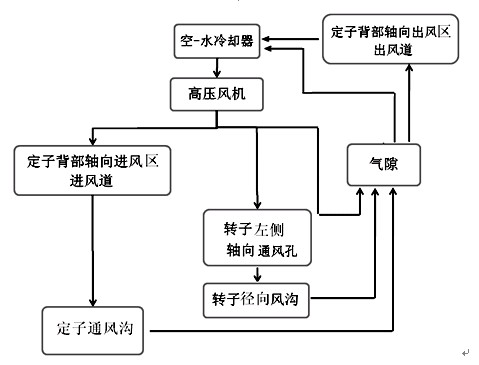

[0036] As a best embodiment of the present invention, refer to Figure 3~6, the motor ventilation structure includes a cooler set above the motor and a forced-air centrifugal fan 1 attached to the cooler, and a plurality of air inlet areas 2 and air outlet areas 3 are alternately arranged on the back 4 of the stator core of the motor. Area 2 and air outlet area 3 are evenly distributed along the radial circumference of the motor, wherein the air inlet area 2 is open at the air inlet end 6 of the centrifugal fan 1 and closed at the air outlet end 7 of the centrifugal fan 1; the air outlet area 3 Open at the air outlet end 7 of the centrifugal fan 1, and close at the air inlet end 6 of the centrifugal fan 1; inside the stator core 8, there are a plurality of stator ventilation grooves 10 distributed along the radial direction of the motor, and also inside the rotor core 9 There are a plurality of rotor ventilation grooves 11 distributed along the radial direction of the motor, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com