Method for simulating spray mixing in low-temperature propellant storage boxes

A low-temperature propellant and simulation method technology, applied in design optimization/simulation, special data processing applications, instruments, etc., can solve the problems of lack of storage tank pressure, air pillow temperature, fluid form and spray form simulation methods, etc., to achieve accurate Pressure change trend, good fit, and effect of improving calculation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

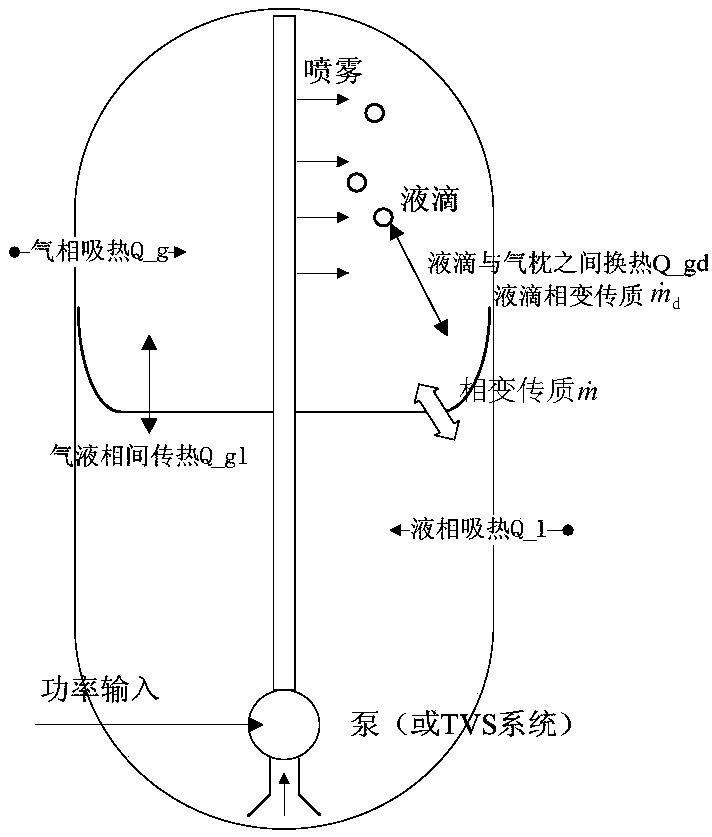

[0111] (1) Establish a grid for spray mixing in a large liquid hydrogen storage tank under microgravity;

[0112] (2) Program the evaporation / condensation model, the heat and mass transfer model between the droplet and the continuous phase, and the conversion model between the droplet and the continuous phase into the FLUENT software, define the physical properties of liquid hydrogen and oxygen, and open the energy and composition Divide the model, add the discrete phase, and set the physical property of the discrete phase to liquid hydrogen, open the VOF model, check the implicit body force, and complete the setting of the discrete phase and VOF method;

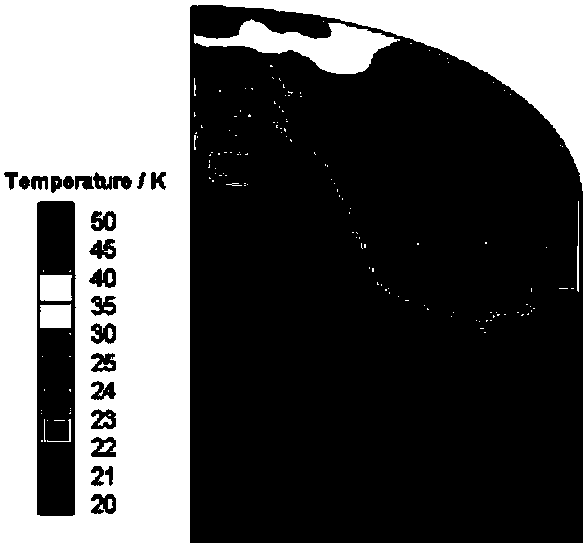

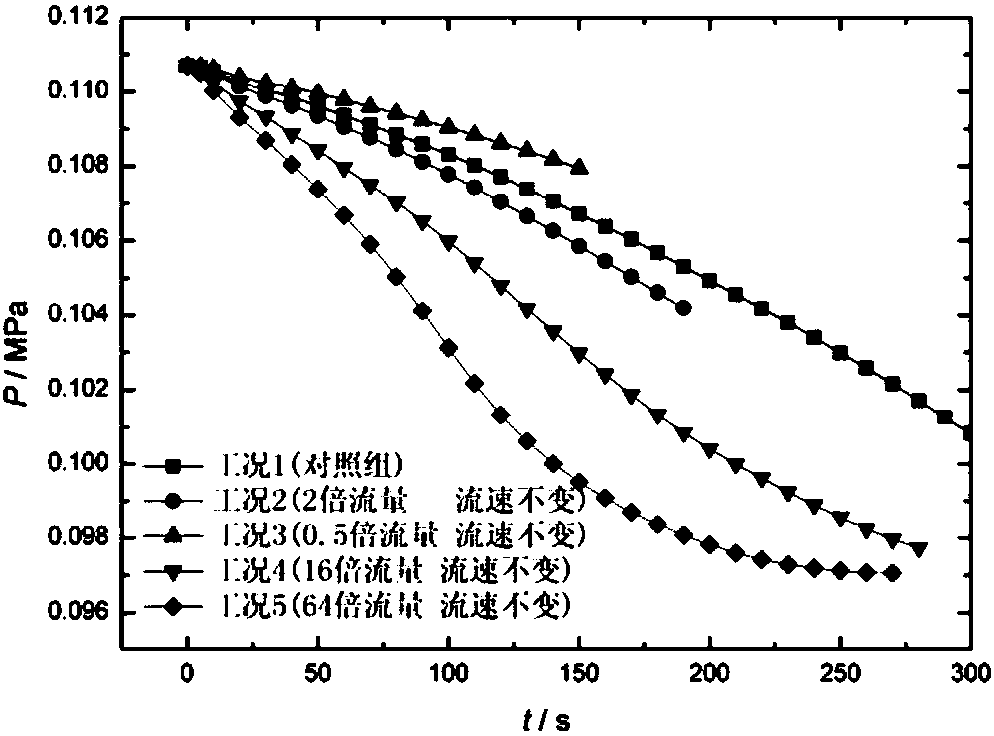

[0113] (3) Define the nozzle type, position, speed as 0.1m / s, injection temperature as 20K, flow rate as 3.9×10 -5 kg / s. Initialize the process, start the simulation calculation, and obtain the fluid behavior characteristics (including tank pressure, temperature distribution and other parameters) in the tank under this grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com