Valvular electrically heated furnace and application in catalyst carrier decomposition thereof

A catalyst carrier and electric heating furnace technology, applied in the field of heating furnaces, can solve the problems of delayed production, waste of materials, long cycle, etc., and achieve the effect of reasonable temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following description only represents a specific embodiment of the present invention, and is only for further illustrating the present invention, but not limiting the present invention.

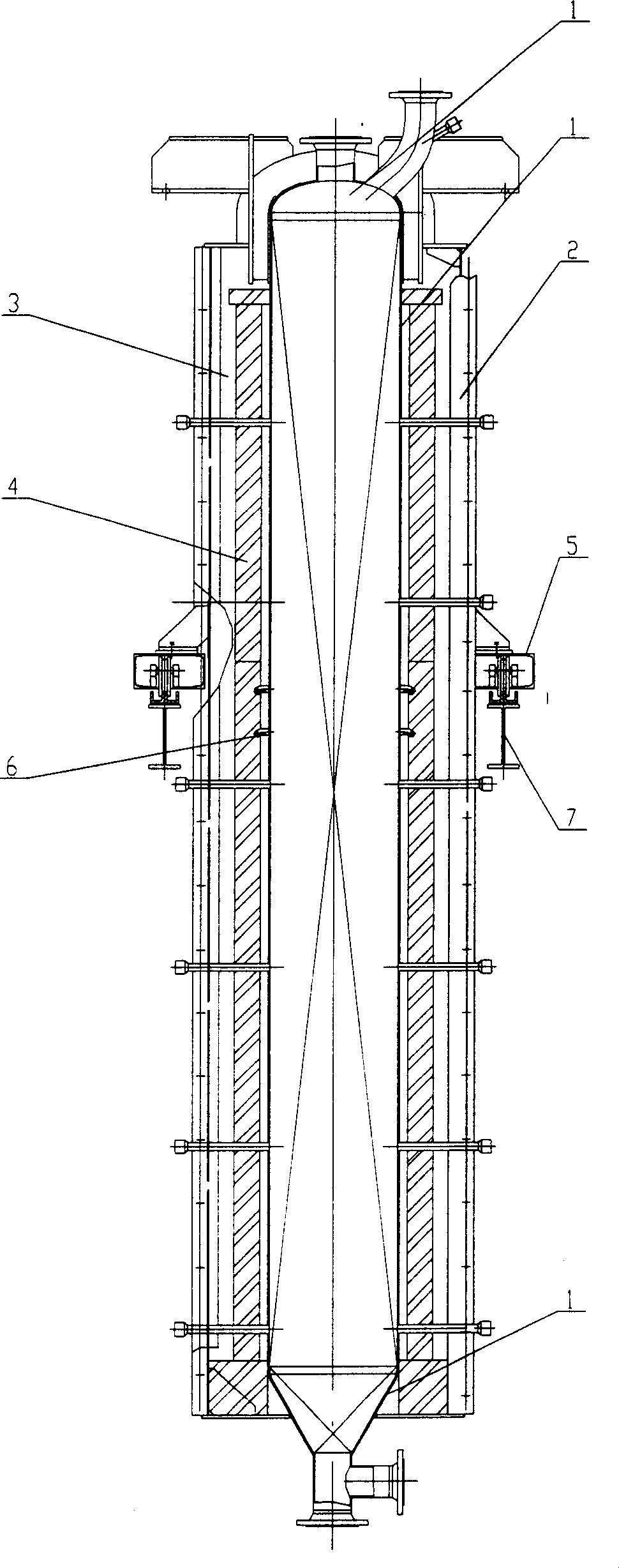

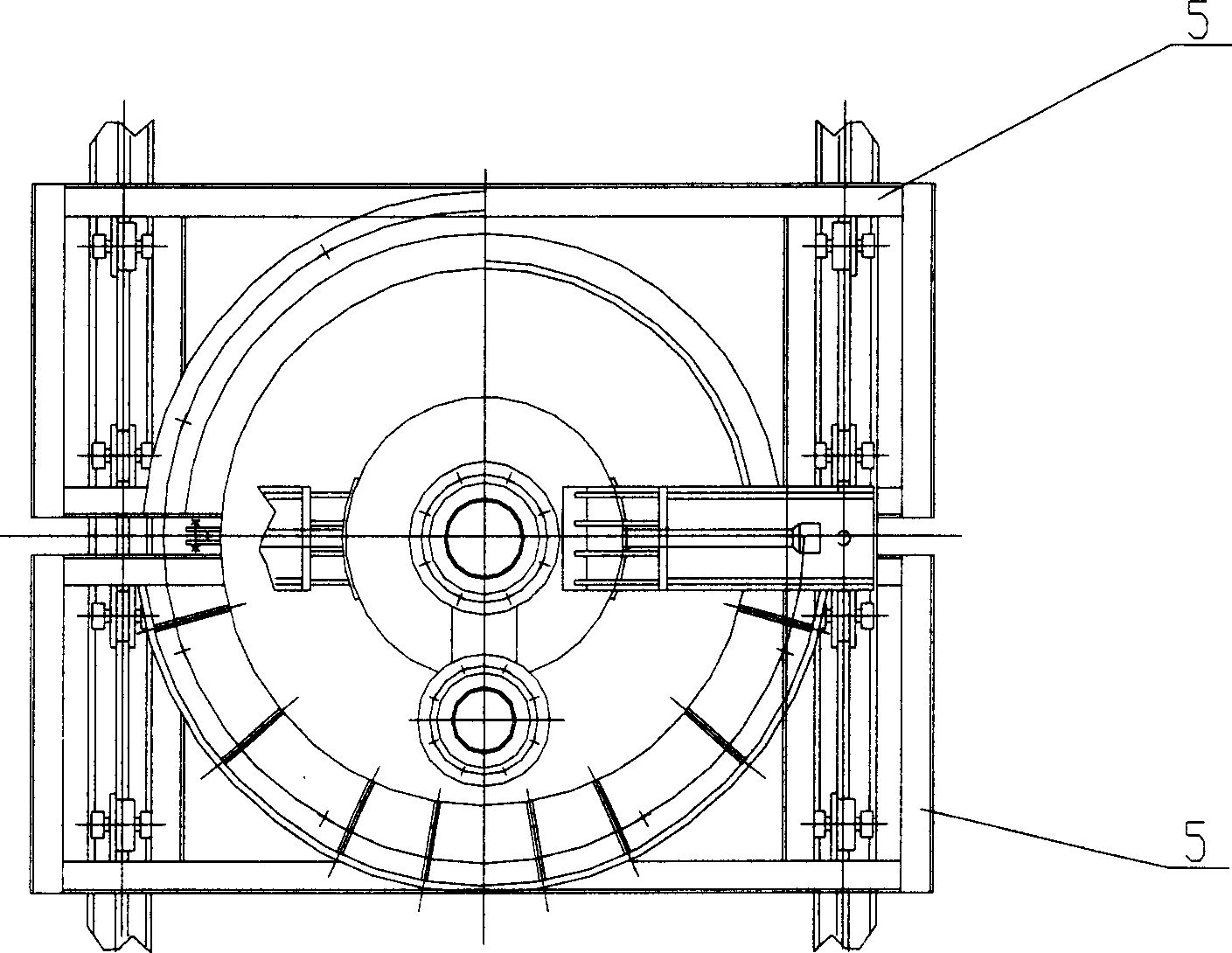

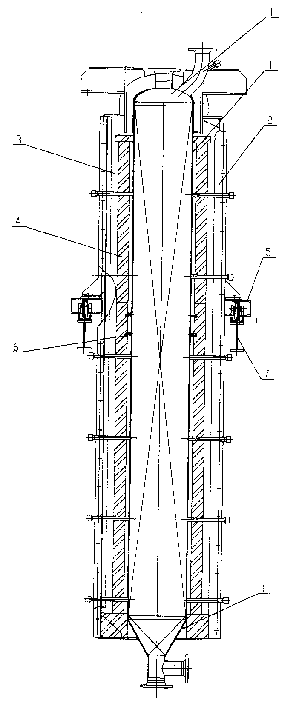

[0032] Complete a split-type electric heating furnace, including an upright circular stainless steel inner cylinder with a diameter of 0.5m and a furnace body height of 3m. The inner cylinder is covered with furnace tiles, and the distance between the furnace tiles and the outer wall of the inner cylinder is 35mm; the furnace tiles are divided into two parts in the circumferential direction. The furnace tile is an arc-shaped heat insulation board, which is made of polycrystalline mullite; a chromium-nickel resistance wire is installed inside each petal of the furnace tile, and there are several horizontal grooves on the inner side of the furnace tile, and the chromium-nickel resistance wire is wound into a spiral The shape is placed in the groove, and the two ends of the resistance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com