Method for preparing unsaturated acid from unsaturated aldehyde

A technology of unsaturated and acrolein, applied in the field of unsaturated aldehydes to prepare unsaturated acids, can solve the problems of difficult and accurate control, and achieve the effects of difficult phase transition, high product selectivity and yield, and reasonable temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Preparation of catalyst (I)

[0035] Under stirring conditions, take 180.1 grams of ammonium molybdate and 19.9 grams of ammonium metavanadate and dissolve them in 1000 ml of pure water (water temperature above 65°C) to obtain slurry (1), then take 98.9 grams of copper nitrate, 26.7 grams of strontium nitrate, 2.5 Dissolve one gram of zinc nitrate in 1000ml of purified water (water temperature above 65°C), stir well and mix evenly to obtain slurry (2). Then, the slurry (1) was mixed with the slurry (2) to obtain the slurry (3), and then 1.4 g of titanium dioxide and 64.4 g of antimony trioxide were added to obtain the active component slurry (a). Add 4.6 grams of silicon dioxide and 3.1 grams of graphite to the active component slurry (a), stir vigorously at 80°C for co-precipitation reaction, heat and dry, heat-treat at 160°C for 3 hours in nitrogen, and then extrude through an extruder It is a hollow columnar particle of φ4.5×5mm, which is dried at 110°C and then ...

Embodiment 2

[0043] Preparation of Catalyst 2

[0044] The preparation steps and main raw materials are the same as those of catalyst 1 in Example 1, and the catalyst (I) is obtained by calcining at 480° C. for 4 hours. Catalyst (I) is mainly composed of: Mo 12 V 6 Cu 0.6 Sb 0.5 Sr 1.9 Si 2.3 La 3 Zr 0.3 Ti 0.2 o x ,

[0045] Take 97 parts of catalyst (I), 3 parts of magnesium-based lanthanum hexaaluminate, add deionized water and knead in a kneader, extrude into hollow columnar particles of φ4.5×5mm, dry at 120°C, and dry at 500°C Calcined for 3.5 hours to obtain catalyst 2.

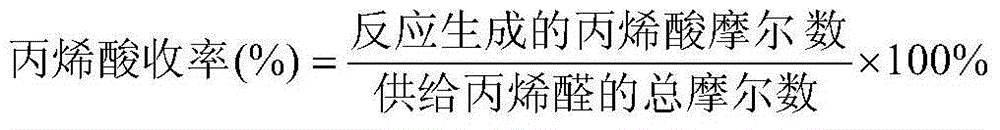

[0046] The inner diameter of the fixed-bed single-tube reactor is 25mm, and a thermocouple is installed inside. 45ml of the above-mentioned catalyst is loaded into the reactor bed along the feeding direction, and heated in a salt bath with a salt bath temperature of 255°C. From the entrance of the above reaction tube at a space velocity of 1700h -1 A mixed gas of 9 vol % of acrolein, 13 vol % of oxygen,...

Embodiment 3

[0048] The preparation steps and main raw materials are the same as those of catalyst 1 in Example 1, and the catalyst (I) is obtained by calcining at 500°C for 4 hours. Catalyst (I) is mainly composed of: Mo 12 V 4 Cu 3.5 Sb 3.5 Sr 0.1 Si 1.1 La 1.0 Zr 0.2 o x , take 94 parts of catalyst (Ⅰ), 6 parts of magnesium-based lanthanum hexaaluminate, add deionized water and knead in a kneader, extrude into hollow columnar particles of φ4.5×5mm, dry at 120°C, 500°C The catalyst 3 was obtained by lower calcining for 4 hours.

[0049] The internal diameter of the fixed-bed single-tube reactor is 25 mm, and a thermocouple is installed inside. The reactor bed layer is filled with 50 ml of the above-mentioned catalyst along the feeding direction, and heated in a salt bath with a temperature of 257 °C. From the entrance of the above reaction tube at a space velocity of 2000h -1 A mixed gas of 10% by volume of acrolein, 14% by volume of oxygen, 15% by volume of water vapor, and 61...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com