Hot fatigue performance test and analysis method for steel

An analysis method and thermal fatigue technology, applied in the direction of analyzing materials, optical testing flaws/defects, measuring devices, etc., can solve the problems of slow heating and cooling, and achieve the effect of avoiding errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] A preferred embodiment of the present invention is described in the following:

[0030] In this example, two kinds of hot work die steels (SDH2 and ASSAB8407) with different components were used for the test. The smelting conditions of the two groups of samples were the same, and then both were quenched at 1020°C, and the hardness was adjusted by tempering. To 48 ~ 49HRC.

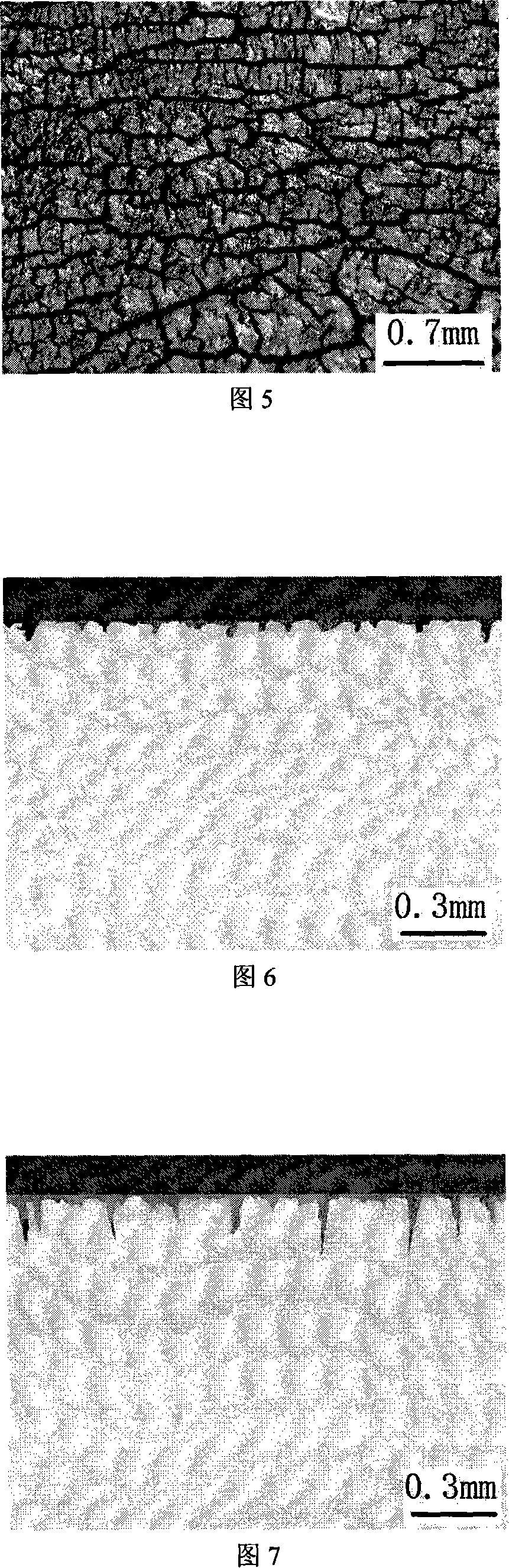

[0031] The steps of using the thermal fatigue performance testing and analysis system of the present embodiment are as follows:

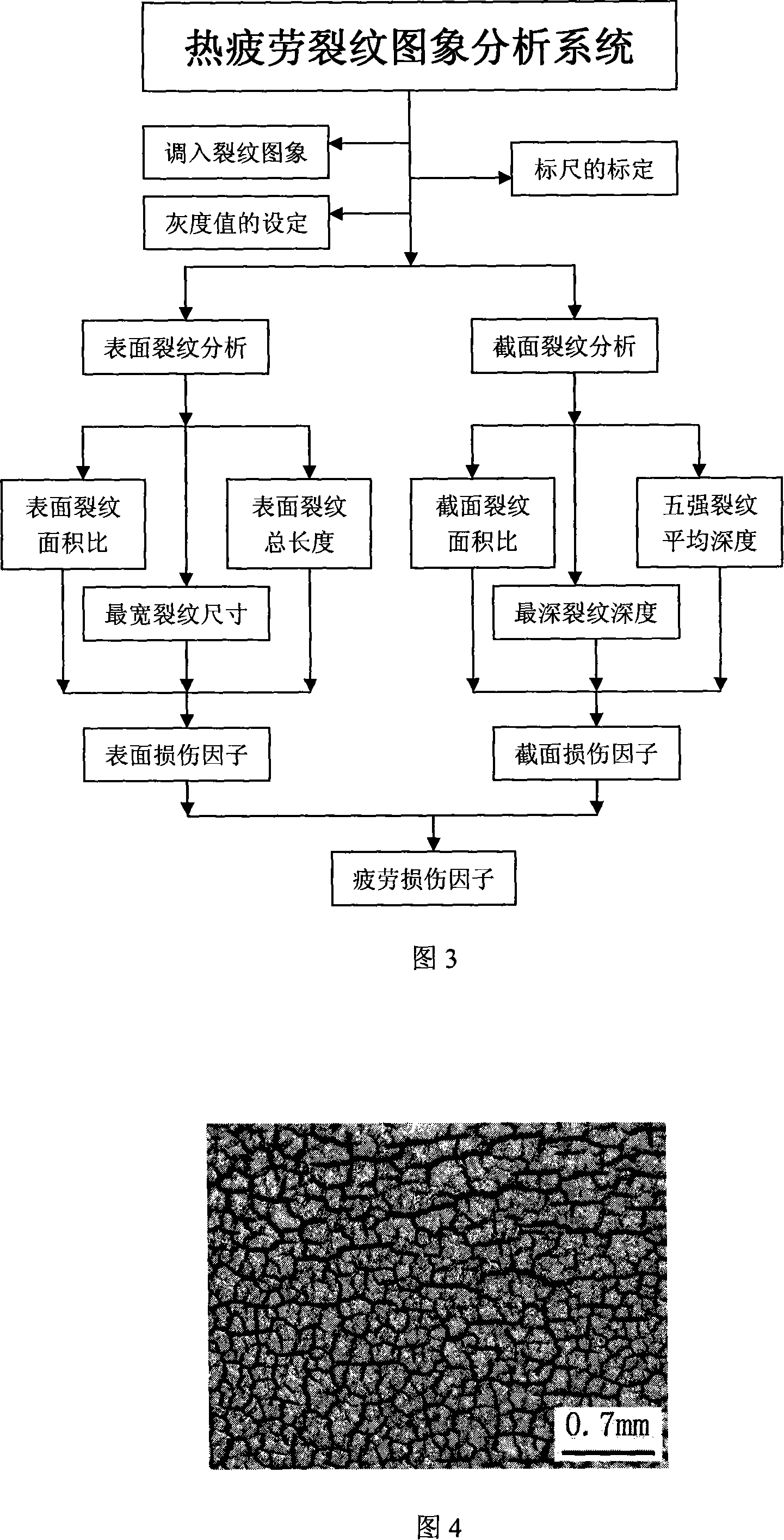

[0032] 1. First, before the thermal fatigue test, the sample is processed according to the requirements, and the surface is ground to a polished state (see Figure 2).

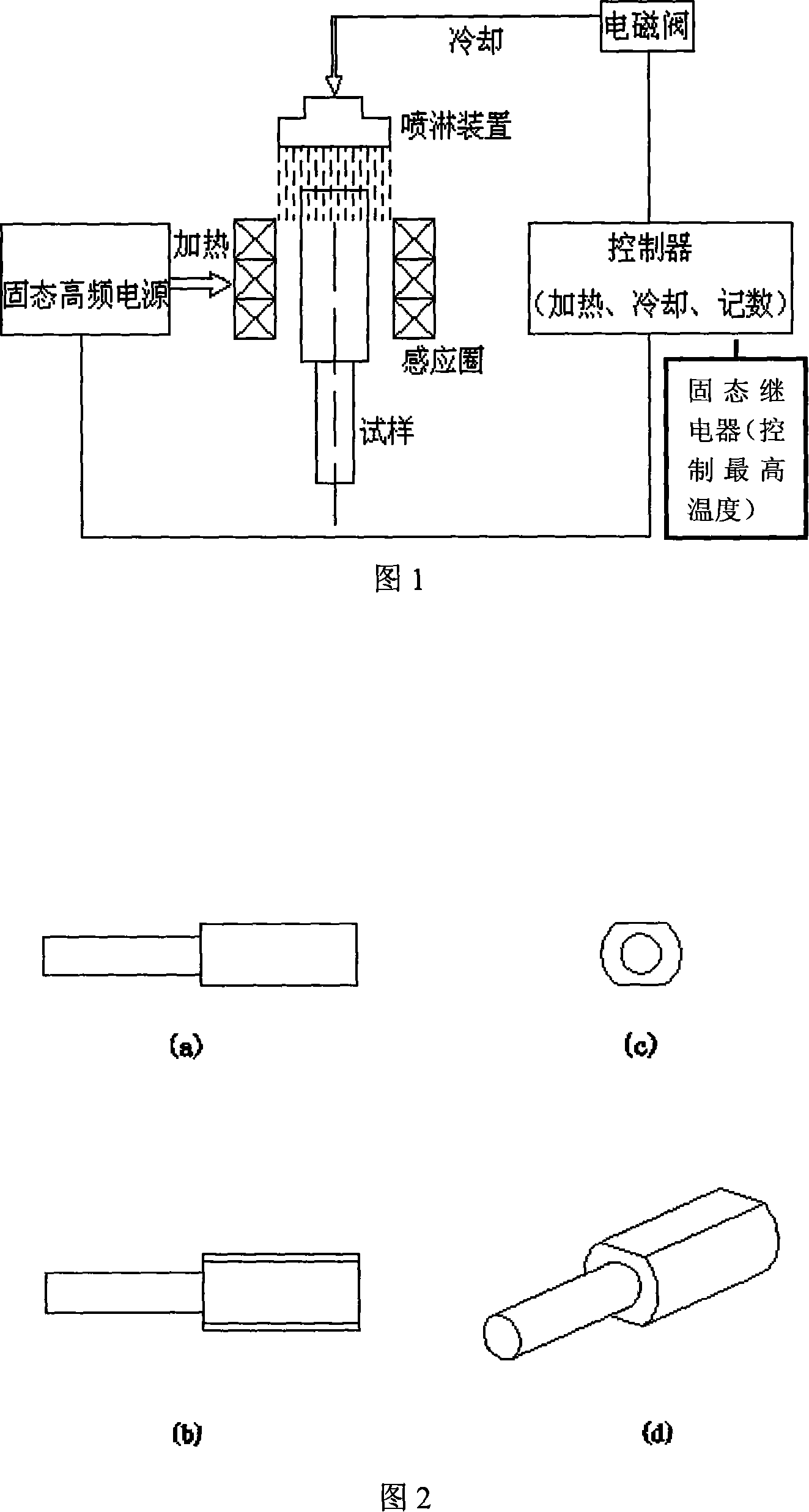

[0033] 2. Conduct a thermal fatigue test (see Figure 1). The solid state relay (XMT62X series intelligent self-tuning PID industrial regulator) is set to a maximum heating temperature of 700°C, and the heat treatment process controller is set to a cooling time of 7.5s. After 3000 cycles of alternating co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com