System and process for cooling after H-shaped steel is hot-rolled

A cooling system, H-beam technology, applied in metal rolling, manufacturing tools, metal rolling, etc., can solve the problems of large investment and poor effect, and achieve the effect of improving yield strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

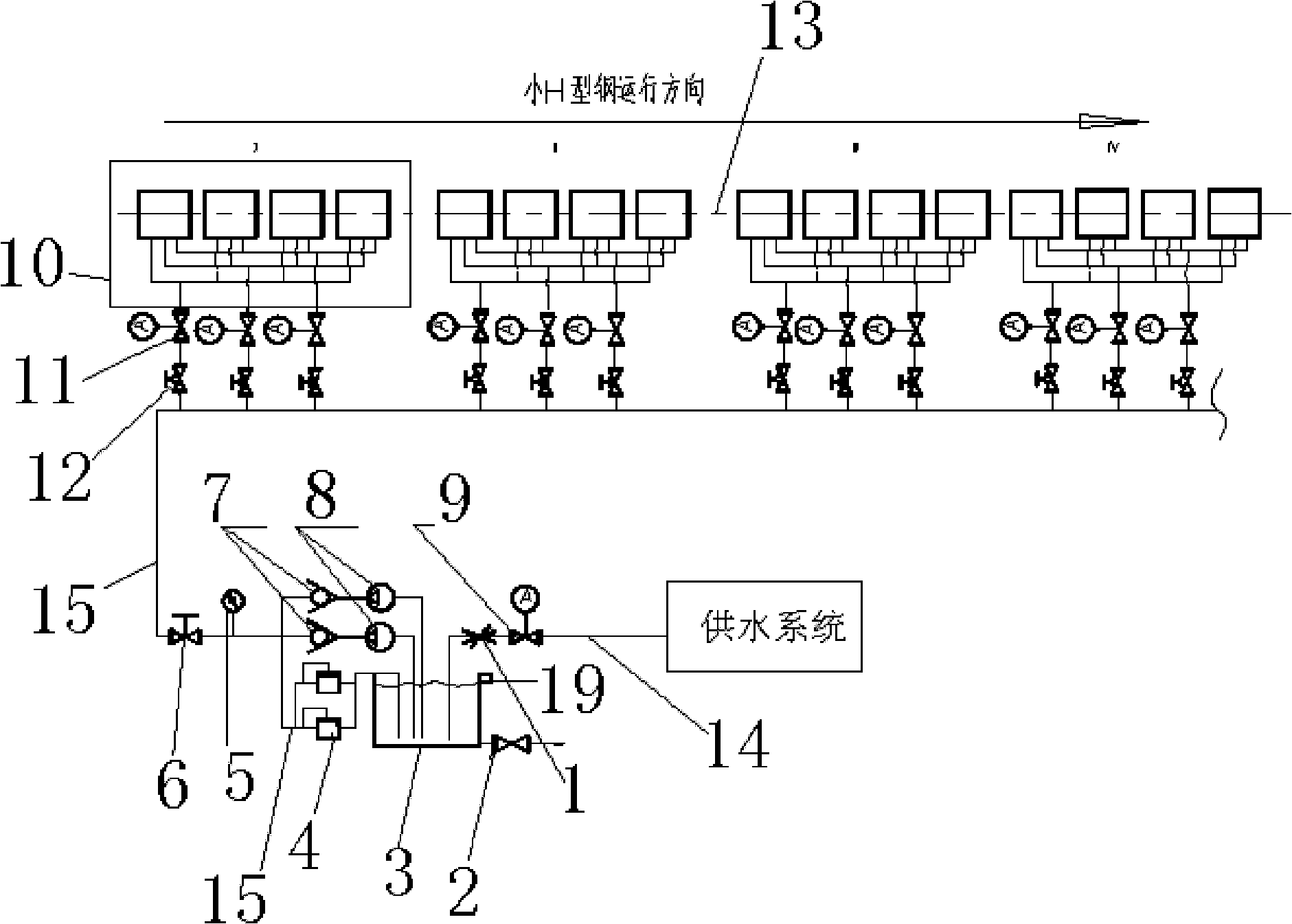

Method used

Image

Examples

Embodiment 1

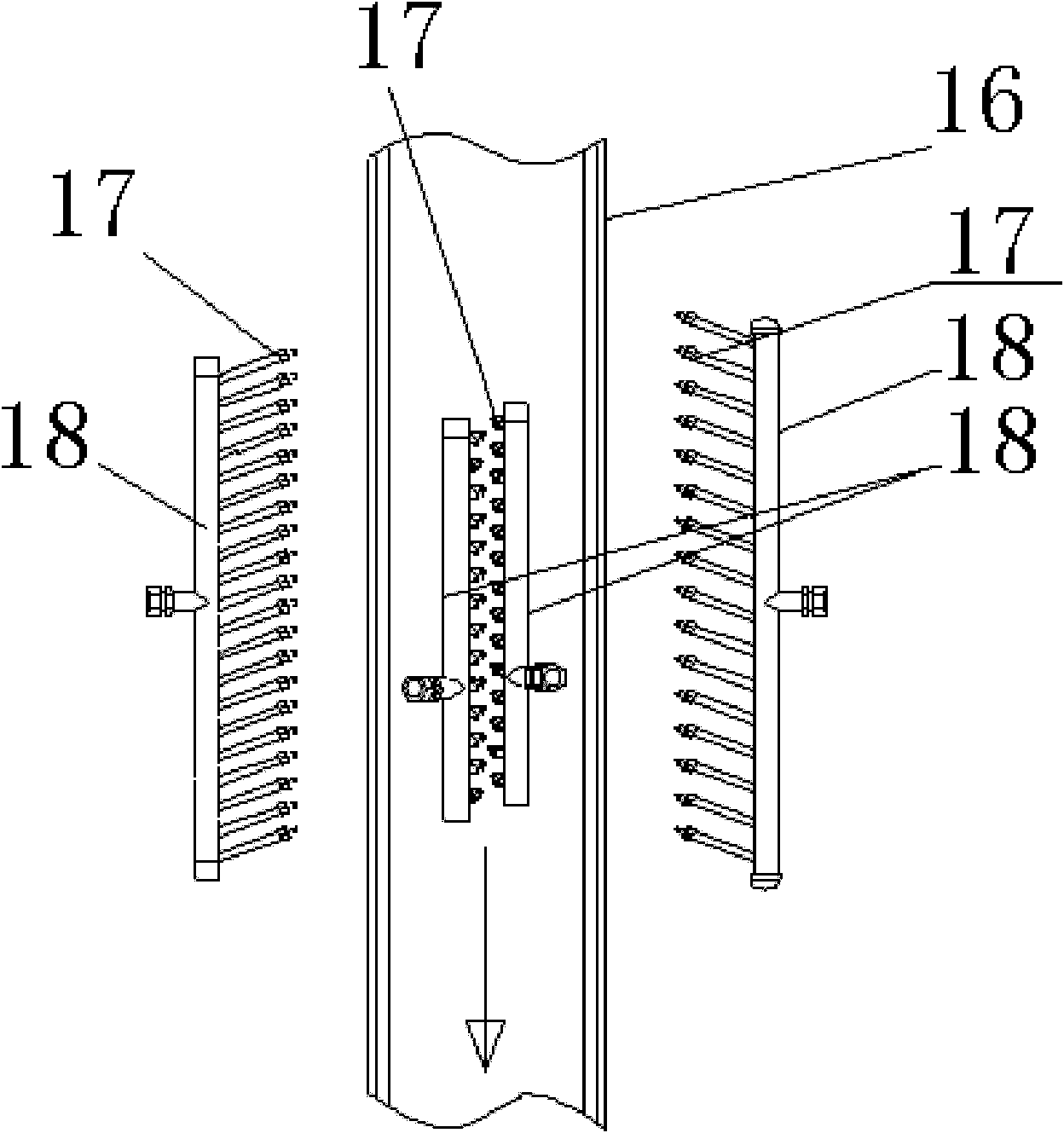

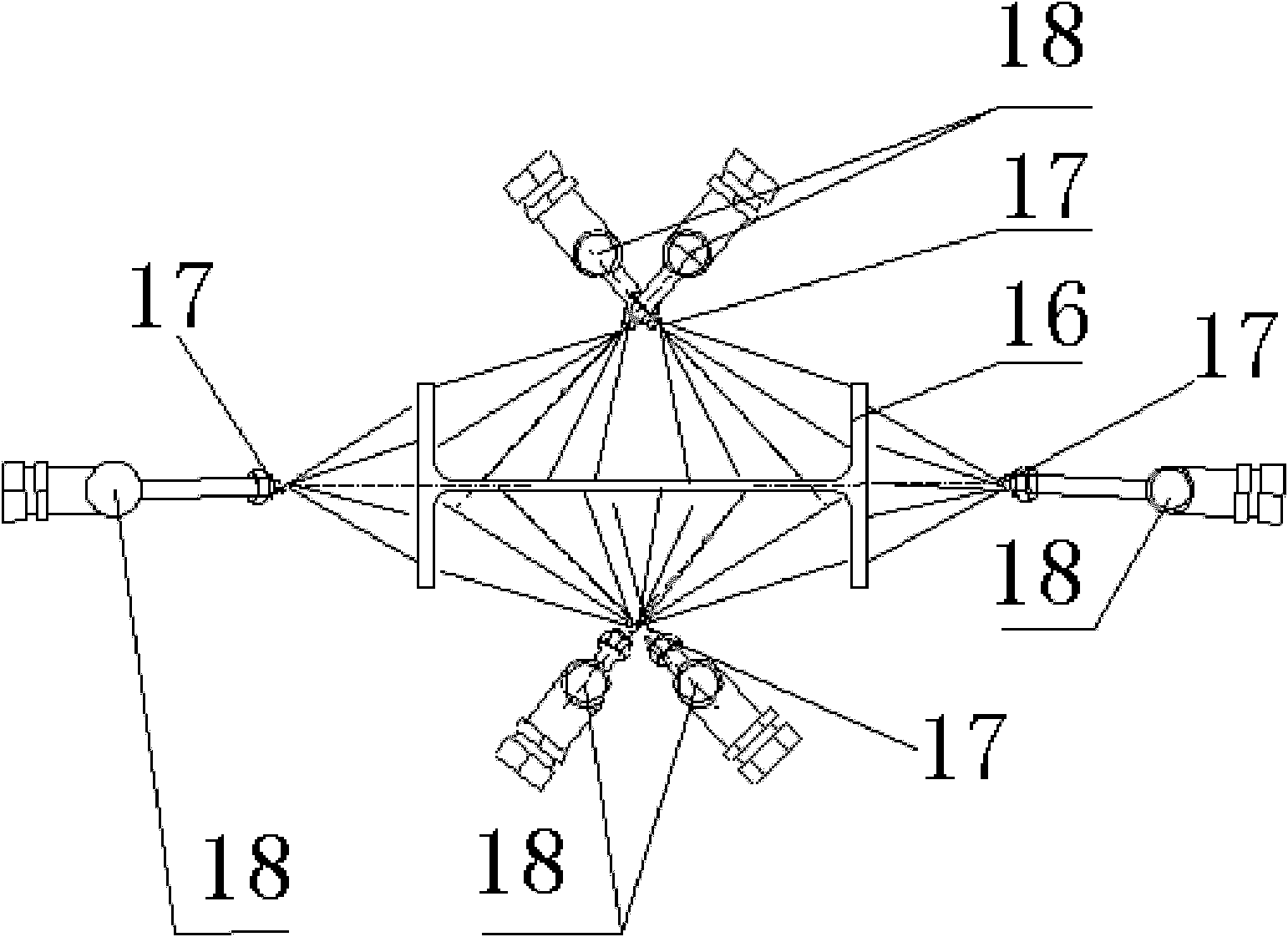

[0056] The hot-rolled H-shaped steel enters the post-rolling cooling system, the cooling nozzles on the cooling nozzles on the upper and lower sides are aligned with the upper and lower R parts of the hot-rolled H-shaped steel, and the cooling nozzles on the cooling nozzles on both horizontal sides are aligned with the hot-rolled H-shaped steel The center of the flange on both sides of the horizontal side is sprayed for cooling, and the cooling water pressure and cooling water flow are controlled through the control system, and the cooling water pressure is controlled at 8MPa; the cooling water flow rate is 600m 3 / hour; control the continuous cooling time of each section on the steel section to 10 seconds; control the cooling rate at 50°C / s.

Embodiment 2

[0058] The hot-rolled H-shaped steel enters the post-rolling cooling system, the cooling nozzles on the cooling nozzles on the upper and lower sides are aligned with the upper and lower R parts of the hot-rolled H-shaped steel, and the cooling nozzles on the cooling nozzles on both horizontal sides are aligned with the hot-rolled H-shaped steel The center of the flange on both sides of the horizontal is sprayed for cooling, and the cooling water pressure and cooling water flow are controlled through the control system, and the cooling water pressure is controlled at 10MPa; the cooling water flow rate is 400m 3 / hour; control the continuous cooling time of each section on the steel section to 10 seconds; control the cooling rate at 40°C / s.

Embodiment 3

[0060] The hot-rolled H-shaped steel enters the post-rolling cooling system, the cooling nozzles on the cooling nozzles on the upper and lower sides are aligned with the upper and lower R parts of the hot-rolled H-shaped steel, and the cooling nozzles on the cooling nozzles on both horizontal sides are aligned with the hot-rolled H-shaped steel The center of the flange on both sides of the horizontal side is sprayed for cooling, and the cooling water pressure and cooling water flow are controlled through the control system, and the cooling water pressure is controlled at 9MPa; the cooling water flow rate is 500m 3 / hour; control the continuous cooling time of each section on the steel section to 12 seconds; control the cooling rate at 30°C / s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com