Thermal fatigue tester

A testing machine and thermal fatigue technology, applied in thermal analysis of materials, measuring devices, instruments, etc., can solve problems such as the influence of test results, and achieve the effect of accurate and reliable positioning and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

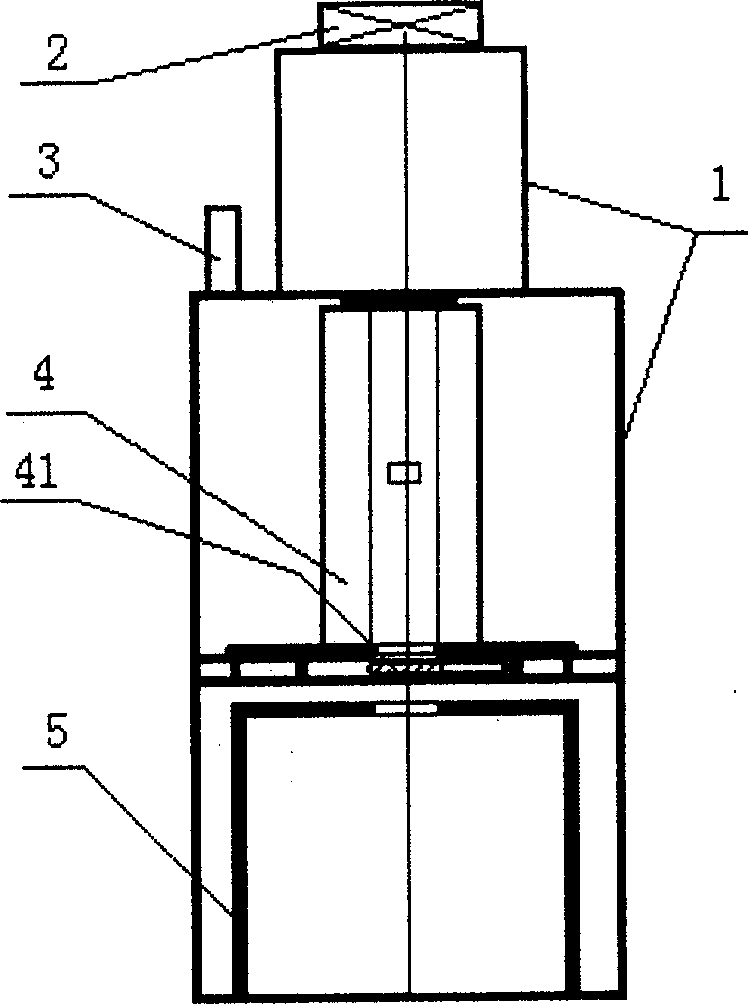

[0026] The structural diagram of the thermal fatigue testing machine is as follows figure 1 As shown, it is mainly composed of bracket (1), lifting system (2), control system (3), heating system (4) and cooling system (5), cooling system (5), heating system (4), control system ( 3) and the lifting system (2) are placed on the support (1) sequentially from bottom to top;

[0027] The bracket (1) is welded by angle iron,

[0028] The cooling system (5) consists of a water tank and a thermometer inserted into the water,

[0029] The heating system (4) consists of a resistance furnace, a sliding door (41) and a thermocouple inserted into the furnace,

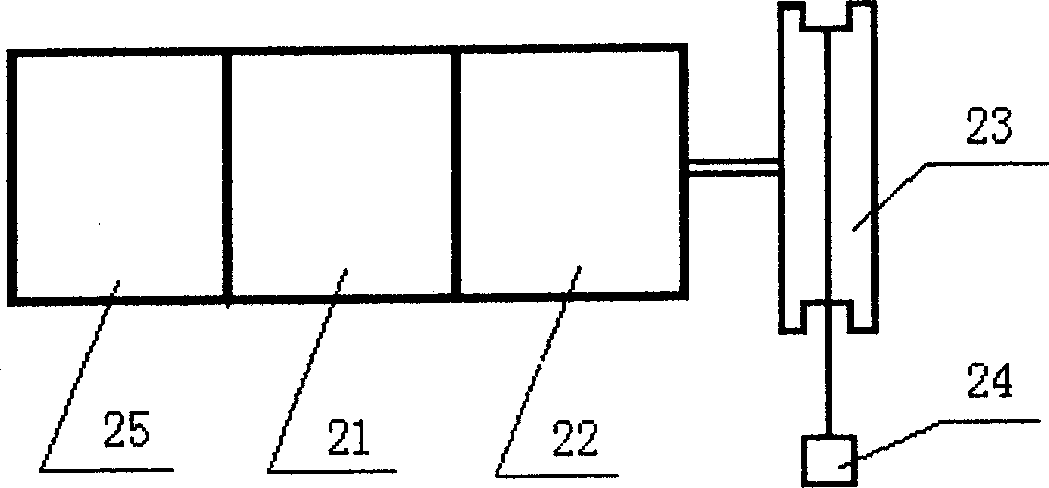

[0030] Lifting system (2) (see figure 2 ) Is composed of a motor (21) with a brake (25), a reduction box (22) and a wheel (23). The motor (21) realizes a transmission connection with the wheel (23) through the reduction box (22);

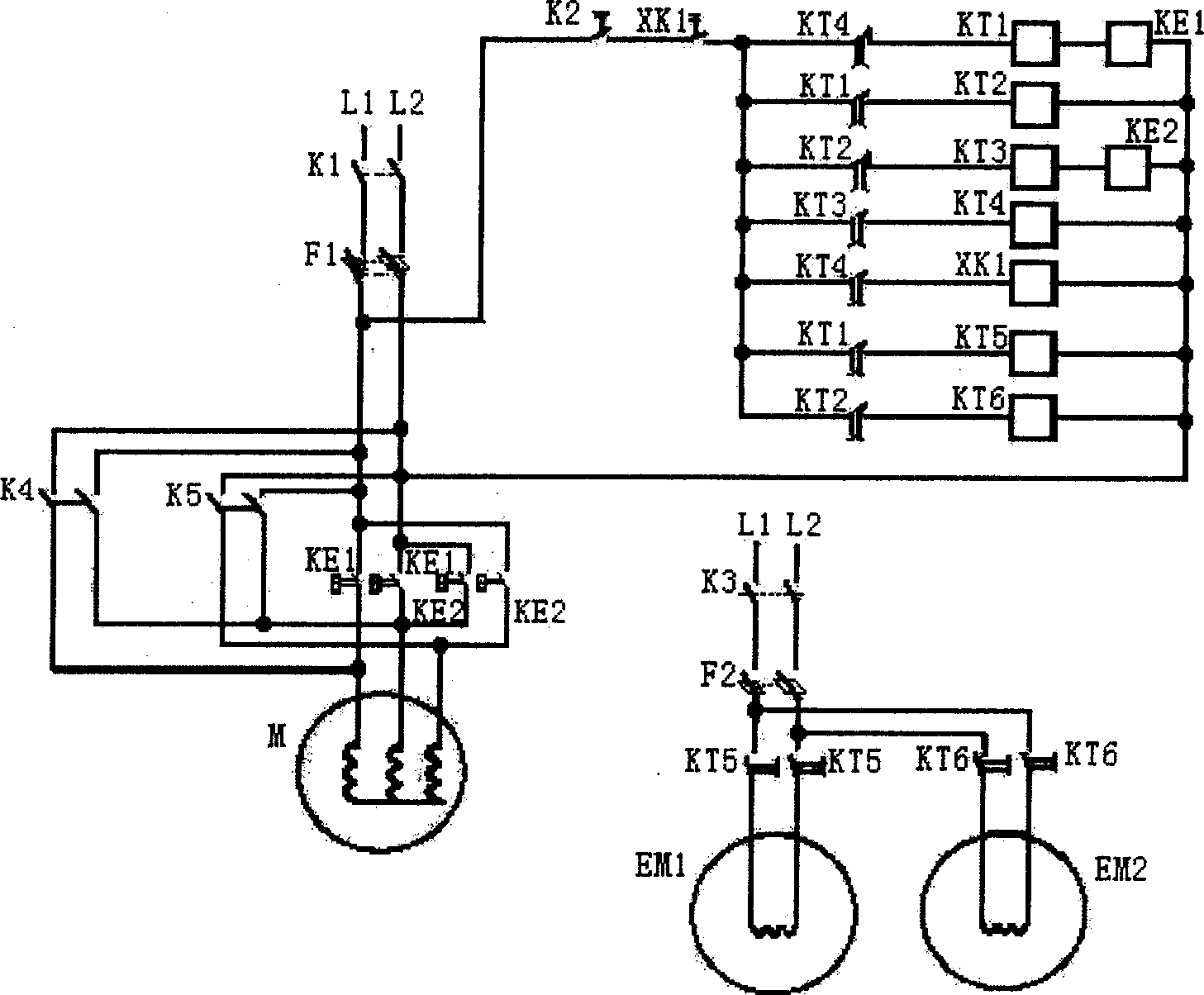

[0031] Control system (3) (see image 3 ) Mainly composed of motor (21) rise time control circuit, heat p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com