Microwave heating device and method

A microwave heating device and microwave technology, applied in the microwave field, can solve the problems of fast peripheral heating, slow central heating, slow heat dissipation in the center of the workpiece, etc., and achieve the effects of shortening heating time, easy control, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

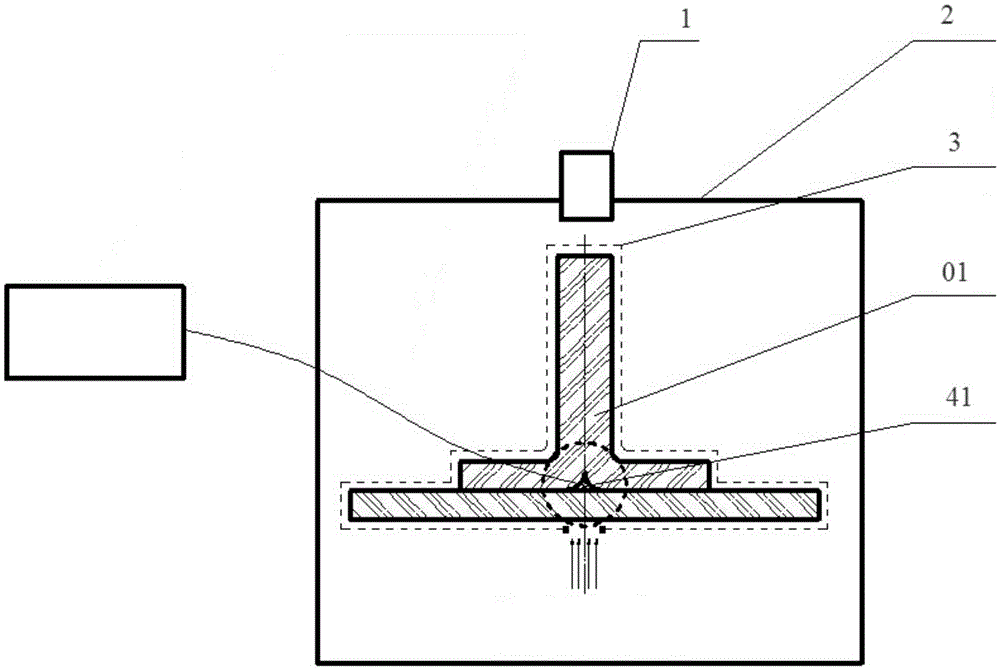

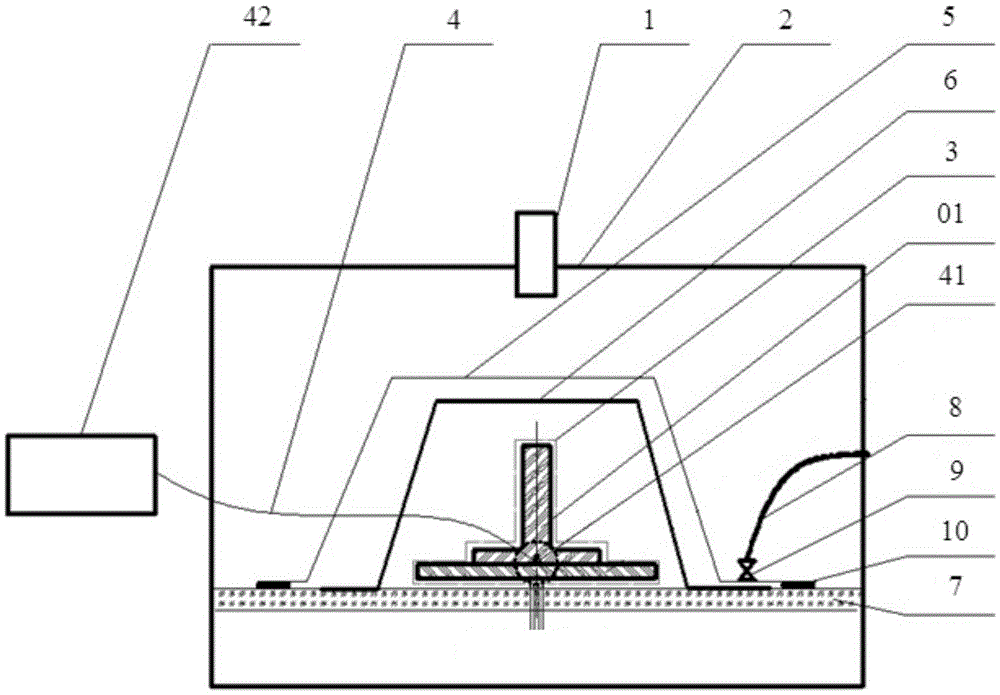

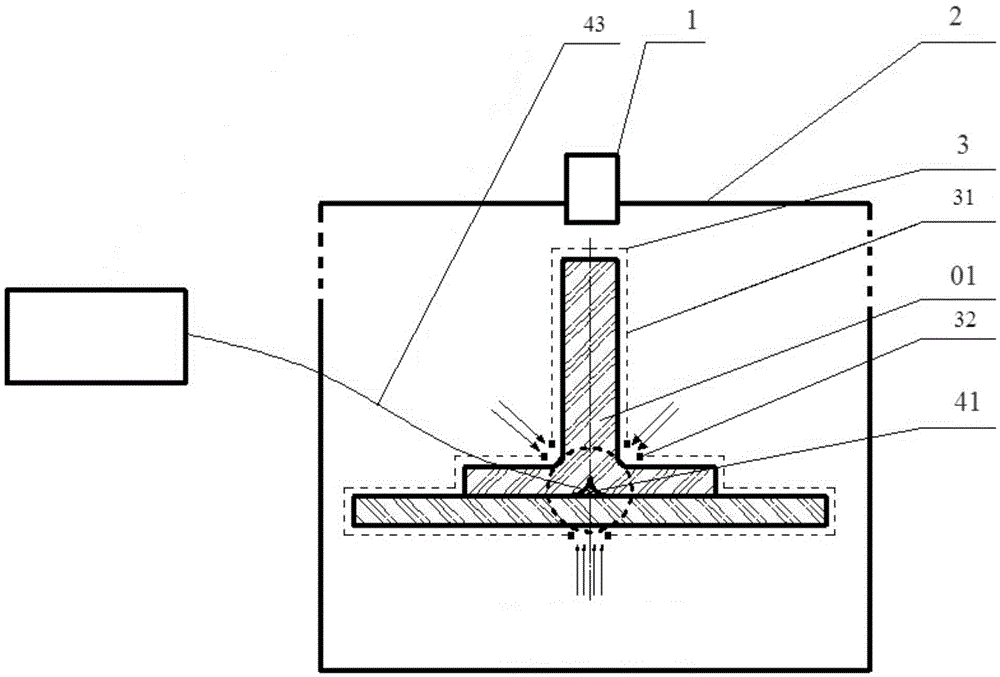

[0030] figure 1 A microwave heating device is provided, including a microwave generator 1, a microwave cavity 2, a microwave partial shield 3 and a temperature measuring device 4, the microwave generator sends microwaves into the microwave cavity, and the microwave cavity is used to place microwave-absorbing materials 01. The microwave partial shield is located in the microwave cavity and is used to cover the outer surface of the microwave-absorbing material. The microwave partial shield is composed of a microwave-shielding area and a microwave-transmitting area, and the microwave-transmitting area includes one or A plurality of slits make the microwave energy in the microwave cavity enter the absorbing material from the slits and be absorbed by it; the temperature measuring device includes a temperature measuring head 41 and a temperature measuring transmission line 43, and the temperature measuring head is arranged on the microwave partial shield In the microwave-absorbing m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com