Method for pretreating cotton fabric at low temperature by using biological enzymes and hydrogen peroxide through one bath process

A cotton-type fabric and low-temperature technology, which is applied in the field of textile printing and dyeing pretreatment, can solve the problems of unsuitable joint use, poor water solubility, and limited application, and achieve the effects of reducing energy consumption, reducing sewage discharge, and reducing the time required for heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0026] Fabric: pure cotton plain weave gray cloth (122g / m 2 )

[0027] Prescription: 2g / L wetting agent (Sutafon D)

[0028] 0.53g / L chelating agent (Marquest PB)

[0029] 2.88g / L acid-base regulator (NaHCO 3 )

[0030] 0.32g / L desizing enzyme (Aquazym Prime12000L)

[0031] 2.86g / L H 2 o 2 (w / w35%)

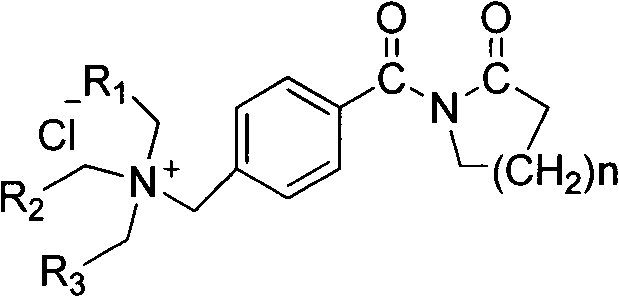

[0032] 8.3g / L N-[4-(trialkylammoniummethylene)benzoyl]lactam chloride

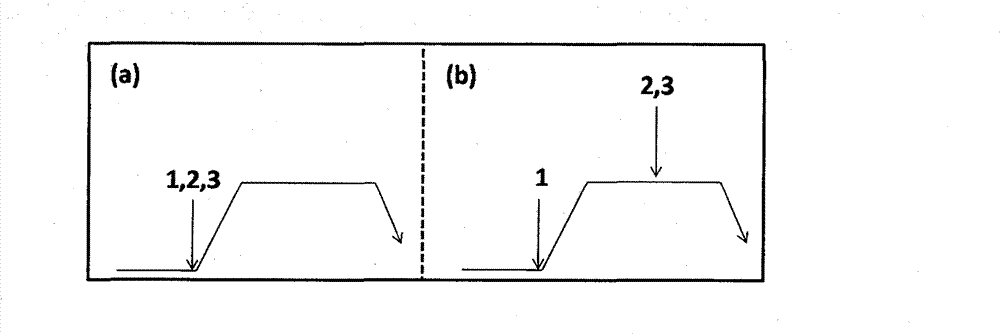

[0033] Method: one bath two steps (see figure 1 b)

[0034] Bath ratio: 15:1

[0035] Temperature: 50°C

[0036] Time: 30 minutes for the first step, 60 minutes for the second step

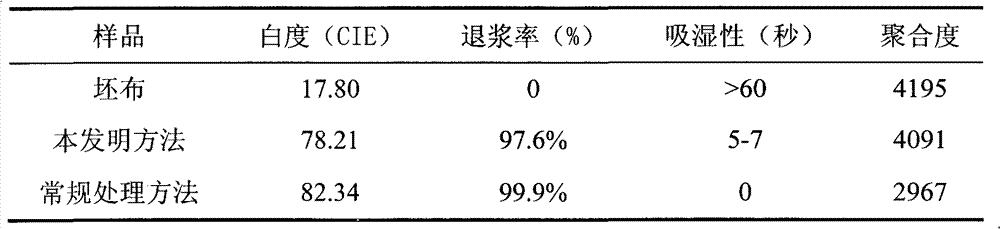

[0037] The inventive method compares with conventional processing method:

[0038]

example 2

[0040] Fabric: pure cotton knitted fabric (137g / m 2 )

[0041] Prescription: 1g / L wetting agent (Triton X-100)

[0042] 1g / L chelating agent (Prestogen N-D)

[0043] 3.1 Acid-base regulator (NaHCO 3 )

[0044] 2.0g / L pectinase

[0045] 3.44g / L H 2 o 2 (w / w35%)

[0046] 10g / L N-[4-(trialkylammoniummethylene)benzoyl]lactam chloride

[0047] Method: one bath, one step (see figure 1 a)

[0048] Bath ratio: 10:1

[0049] Temperature: 50°C

[0050] Time: 60 minutes

[0051] The inventive method compares with conventional processing method:

[0052]

example 3

[0054] Fabric: pure cotton plain weave gray cloth (122g / m 2 )

[0055] Prescription: 1g / L wetting agent (Triton X-100)

[0056] 1g / L chelating agent (Prestogen N-D)

[0057] 0.1M acid-base regulator (phosphate)

[0058] 3.23g / L desizing enzyme (Aquazym Prime12000L)

[0059] 3.0g / L pectinase

[0060] 2.81g / L H 2 o 2 (w / w35%)

[0061] 8.15g / L N-[4-(trialkylammoniummethylene)benzoyl]lactam chloride

[0062] Method: one step at a time

[0063] Bath ratio: 20:1

[0064] Temperature: 50°C

[0065] Time: 50 minutes

[0066] The inventive method compares with conventional processing method:

[0067]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com