Heating method for preventing high carbon belt steel bloom decarburization

A heating method and billet technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve problems such as the reduction of steel yield and achieve the effects of improving recovery rate, reducing residence time, and reducing fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

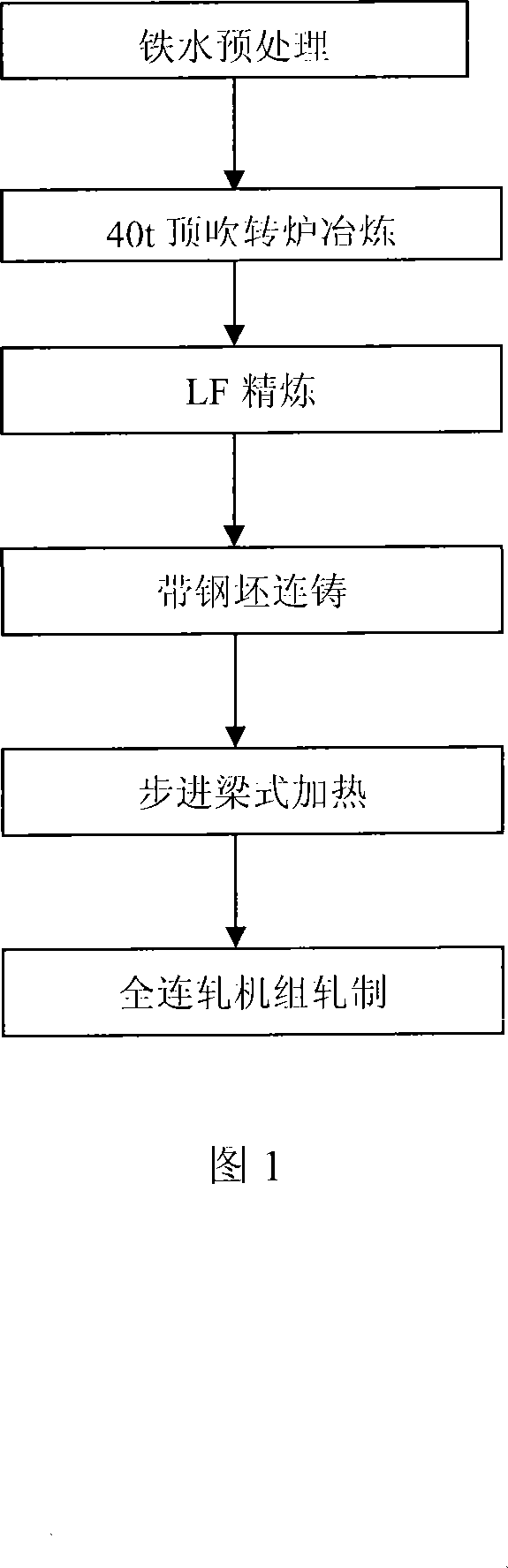

[0031] Adopt the technological process of accompanying drawing 1 when producing 65Mn (0.62~0.70% of carbon range) thickness to be 3.3mm * 325mm steel strip.

[0032] In the process step shown in Fig. 1, the walking beam type heating furnace heats a 120mm×360mm 65Mn high-quality carbon structural steel billet, and the method of the present invention is adopted. The billet is charged into the furnace by hot charging, and the temperature of the billet into the furnace is 500-550°C. In order to prevent severe decarburization on the surface of the 65Mn steel strip, the heating process parameters of the walking beam heating furnace are as follows:

[0033] heating furnace

[0034] During the heating process, a slight positive pressure (pressure of 10-40 Pa (gauge pressure)) and a weakly oxidizing atmosphere (mixed atmosphere of coke oven gas, blast furnace gas and air) are used, and the ratio of coke oven gas and blast furnace gas is 1:1. The excess air coefficient is 1.0...

Embodiment 2

[0036] Adopt the technological process of accompanying drawing 1 when producing 65Mn (0.62~0.70% of carbon range) thickness to be 3.3mm * 325mm steel strip.

[0037] In the process step shown in Fig. 1, the walking beam type heating furnace heats a 120mm×360mm 65Mn high-quality carbon structural steel billet, and the method of the present invention is adopted. The billet is charged into the furnace by cold charging, and the temperature of the billet into the furnace is 150-200°C. In order to prevent severe decarburization on the surface of the 65Mn steel strip, the heating process parameters of the walking beam heating furnace are as follows:

[0038] heating furnace

[0039] During the heating process, a slight positive pressure (pressure of 10-40 Pa (gauge pressure)) and a weakly oxidizing atmosphere (mixed atmosphere of coke oven gas, blast furnace gas and air) are used, and the ratio of coke oven gas and blast furnace gas is 1:1. The excess air coefficient is 1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com