Low-temperature charge and heating system and method for power battery for all-electric vehicles

A pure electric vehicle, power battery technology, applied in the direction of electric vehicle, secondary battery charging/discharging, secondary battery, etc., can solve the problems of low heating power, prolonged charging time, reduced system efficiency, etc. The effect of shortening heating time and improving system efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

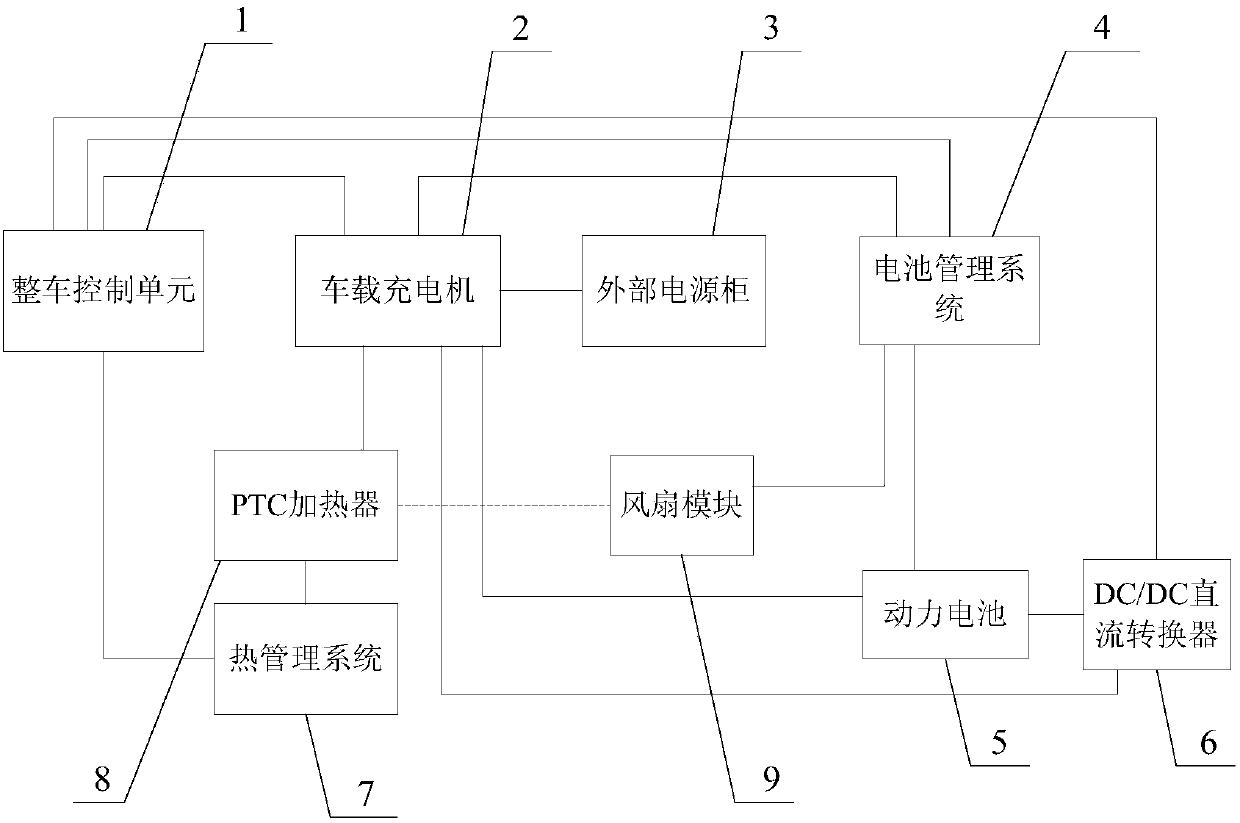

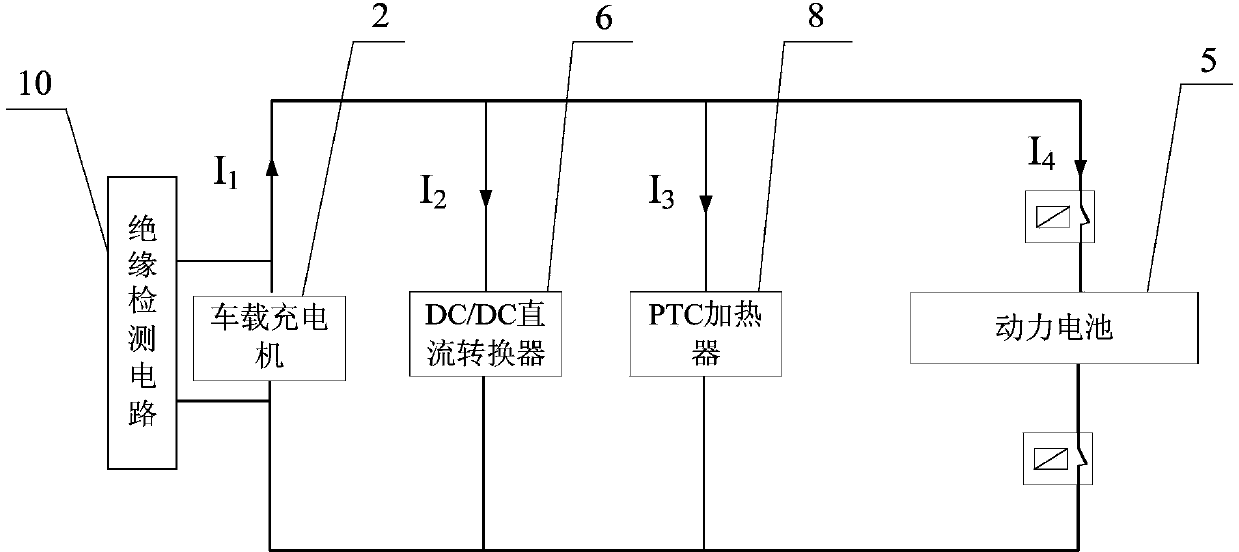

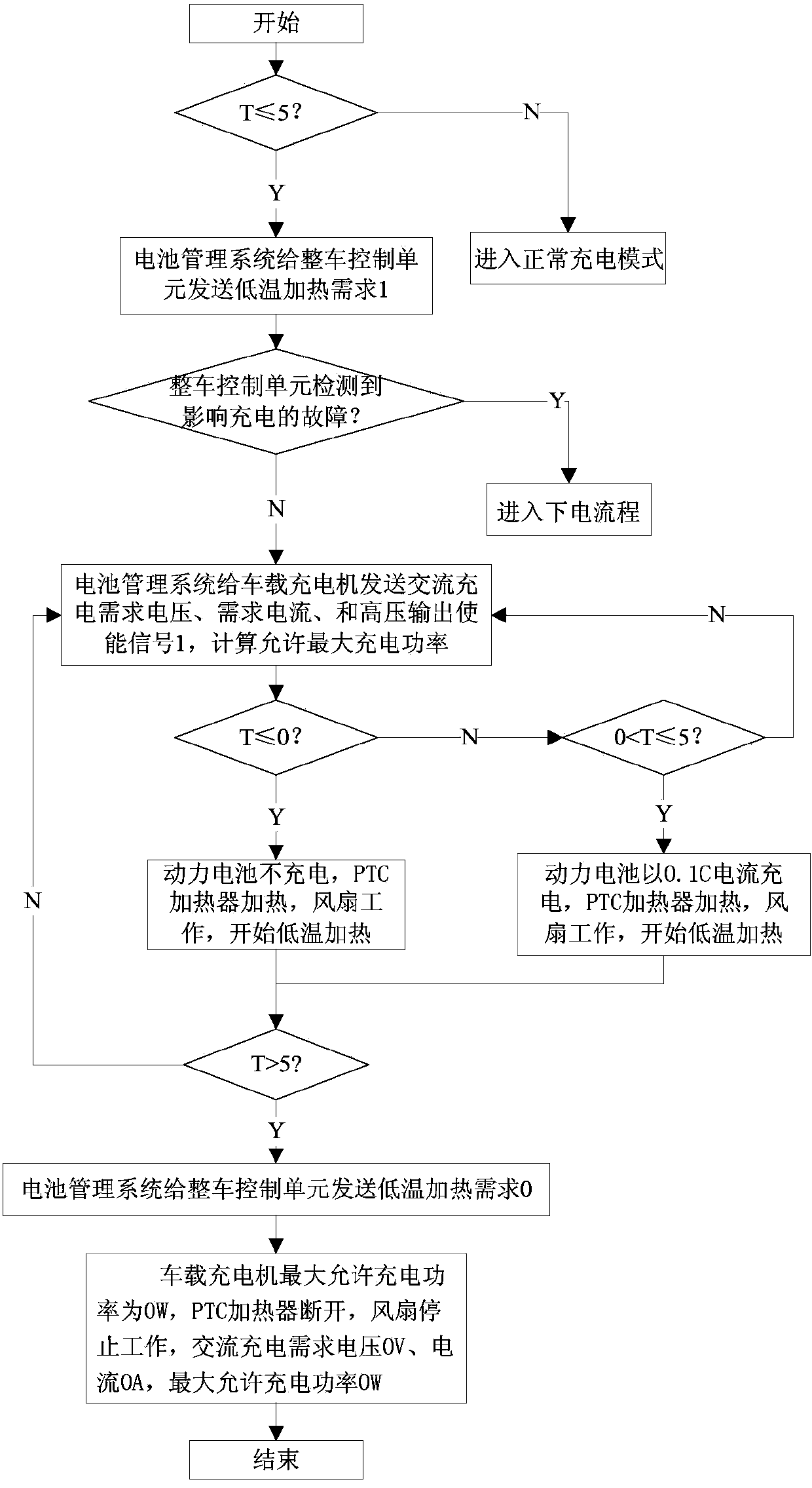

[0021] Such as figure 1 , figure 2 The low-temperature charging and heating system of the pure electric vehicle power battery shown includes the vehicle control unit 1, the on-board charger 2, the battery management system 4, the power battery 5, the DC / DC converter 6, the thermal management system 7, and the PTC heating system. 8 and a fan module 9, the on-board charger 2 is connected in parallel with an insulation detection circuit 10, and the fan module 9 is composed of a fan and a fan relay for controlling the fan to be powered on. The vehicle control unit 1 communicates with the on-board charger 2, battery management system 4, DC / DC converter 6, and thermal management system 7 to coordinate the on-board charger 2, battery management system 4, and DC / DC converter 6 , the work of the thermal management system 7; the on-board charger 2 is connected with the external po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com