Production of propene and high-quality gasoline and diesel oil by two-stage catalyzed crack

A catalytic cracking, gasoline and diesel technology, applied in the field of diesel with a higher cetane number, can solve the problems of increased yield of dry gas and coke, deterioration of diesel quality, difficulty in propylene exceeding 15%, and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

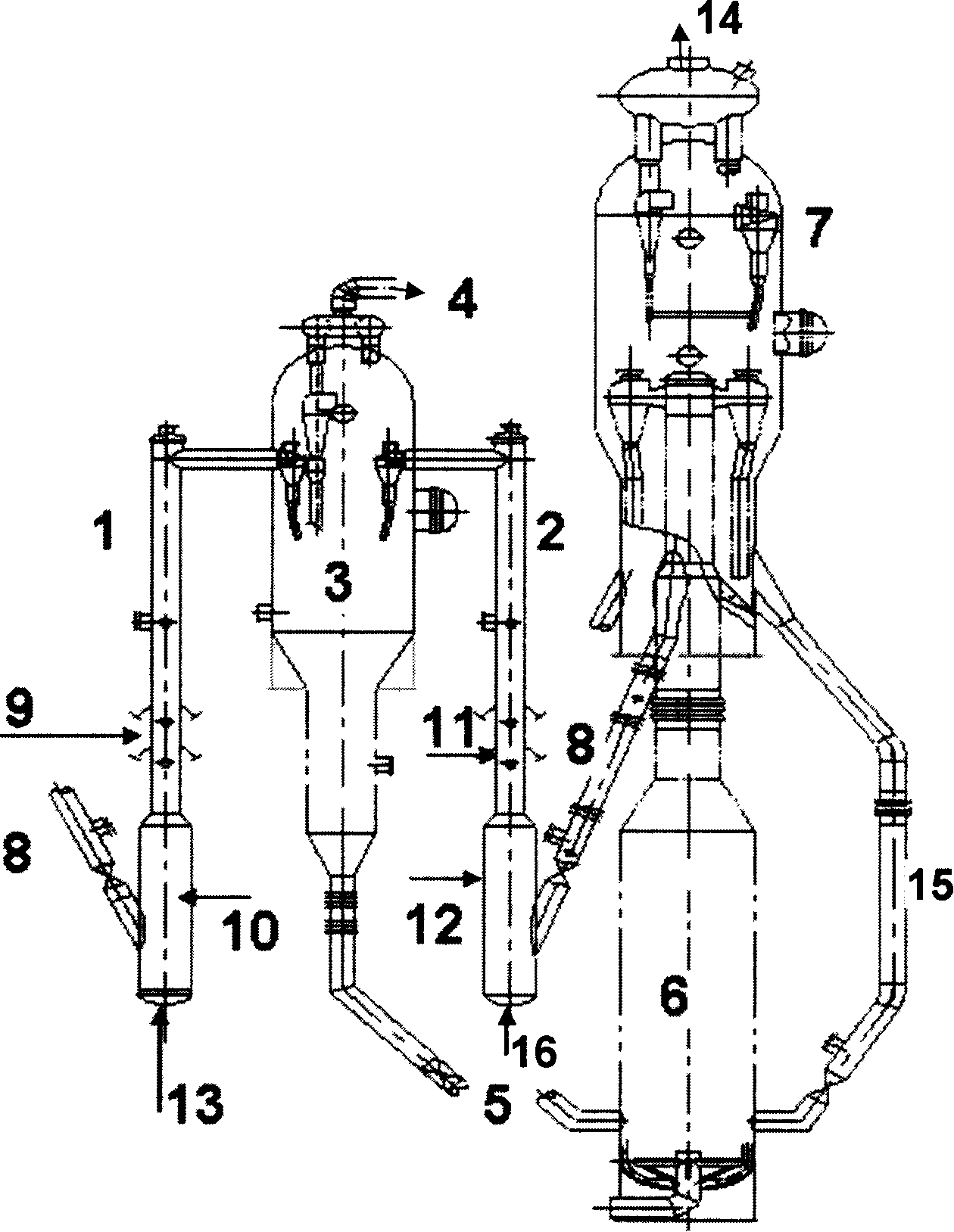

Method used

Image

Examples

Embodiment 1

[0025] Example 1 On the two-stage riser pilot plant in the laboratory, the atmospheric residue raw material (see Table 1 for properties) of Daqing crude oil taken from Fushun Petrochemical Company was used, and the LTB-2 catalyst with a ZSM-5 molecular sieve content of 30% was used (taken from Dongying Hanyi Chemical Co., Ltd.), the raw material of the first stage is atmospheric residual oil, and the raw material of the second stage is gasoline and cycle oil. Under the condition that the outlet temperature of the two-stage riser reactor is 520 ° C, the yield of propylene reaches 20.5%, butene yield was 18.6%, gasoline and diesel yields were 24.0% and 18.5%, and dry gas and coke yields were 7.0% and 5.5%, respectively. The gasoline produced by the reaction has a low olefin content (30%), a high aromatic content (35.8%), and a research octane number of 93; at the same time, the quality of diesel oil is also well protected, and its cetane number is 30.2.

[0026] If the obtained ...

Embodiment 2

[0028] Example 2 On the two-stage riser pilot plant in the laboratory, the heavy feed oil (see Table 2 for properties) from the 1.4 million tons / year catalytic cracking unit of Lanzhou Petrochemical Company was used, and the ZSM-5 molecular sieve content was 20%. LTB-1 catalyst (taken from Dongying Hanyi Chemical Co., Ltd.), the raw material of the first stage is heavy feedstock oil, the raw material of the second stage is gasoline and cycle oil, and the outlet temperatures of the two-stage riser reactors are 510 ° C and 525 ° C respectively Under the conditions, the yield of propylene is 15%, the yield of butene is 14.5%, the yields of gasoline and diesel oil are 25.0% and 22.6% respectively, and the yields of dry gas and coke are 4.5% and 9.5% respectively.

[0029] Original

material

sex

quality

Density (20℃), g / cm 3

0.9134

Carbon residue, m%

5.69

four components

m%

Saturation

52.71

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com