Patents

Literature

43results about How to "Restraining the drop in productivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

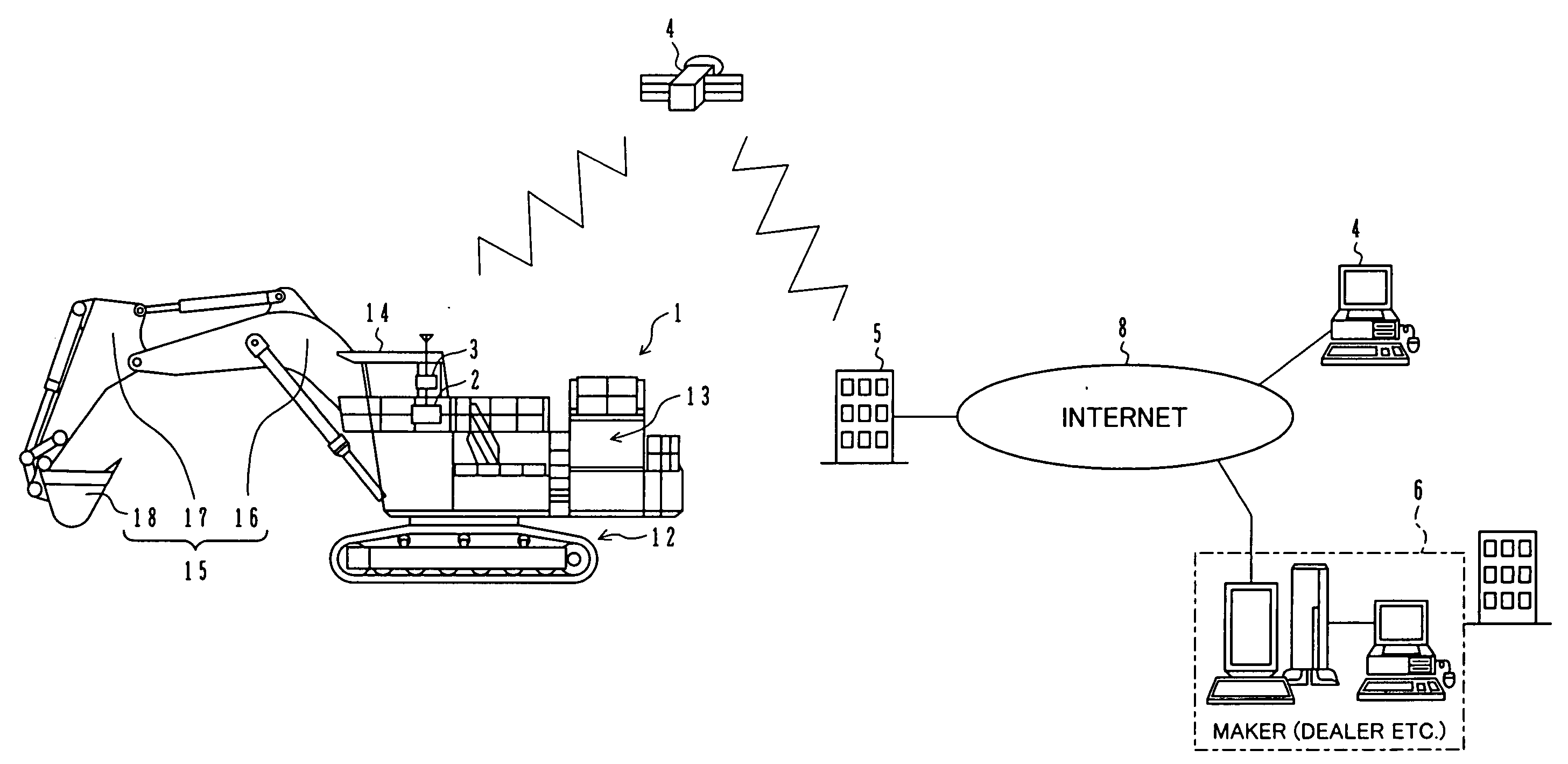

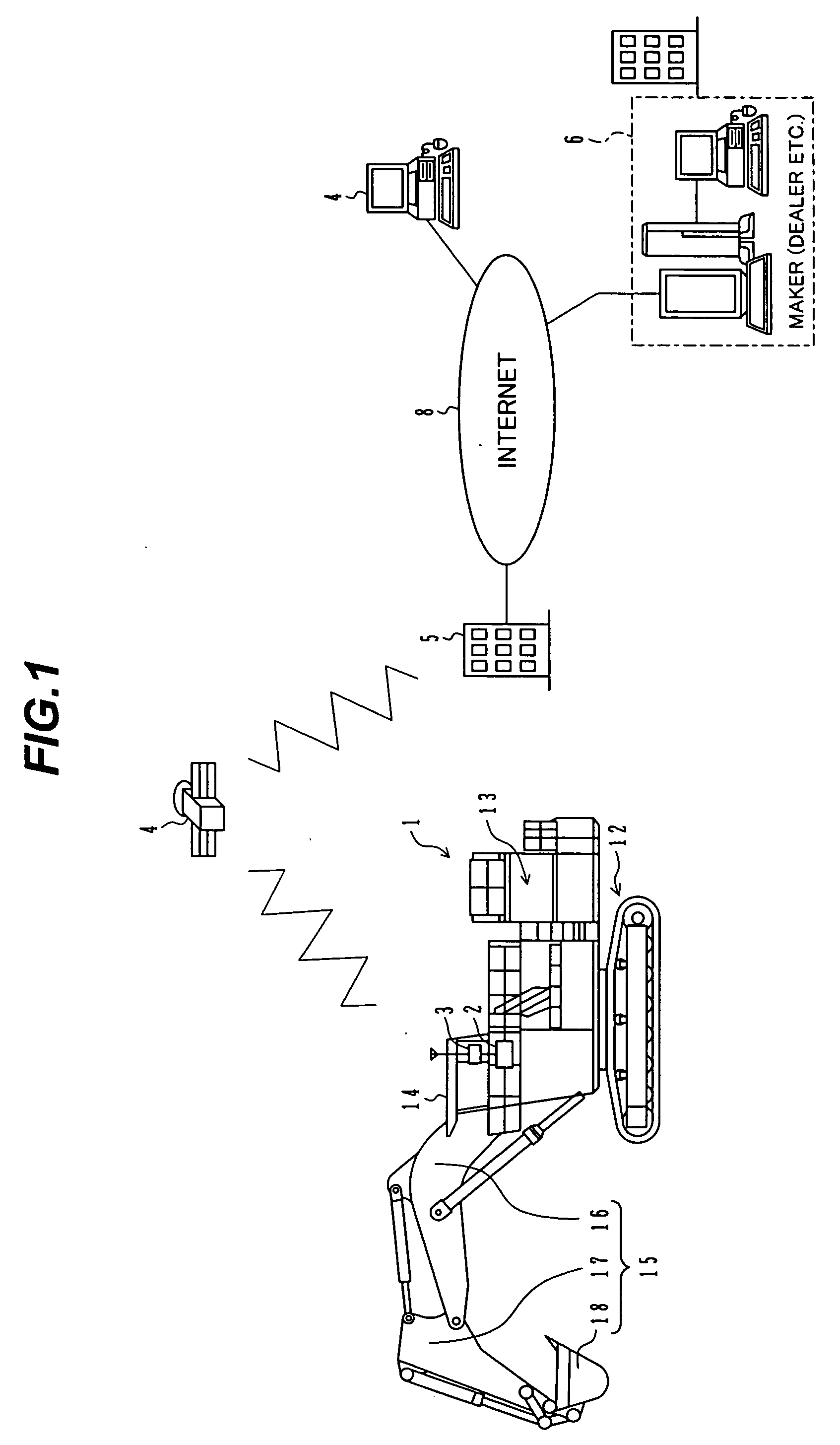

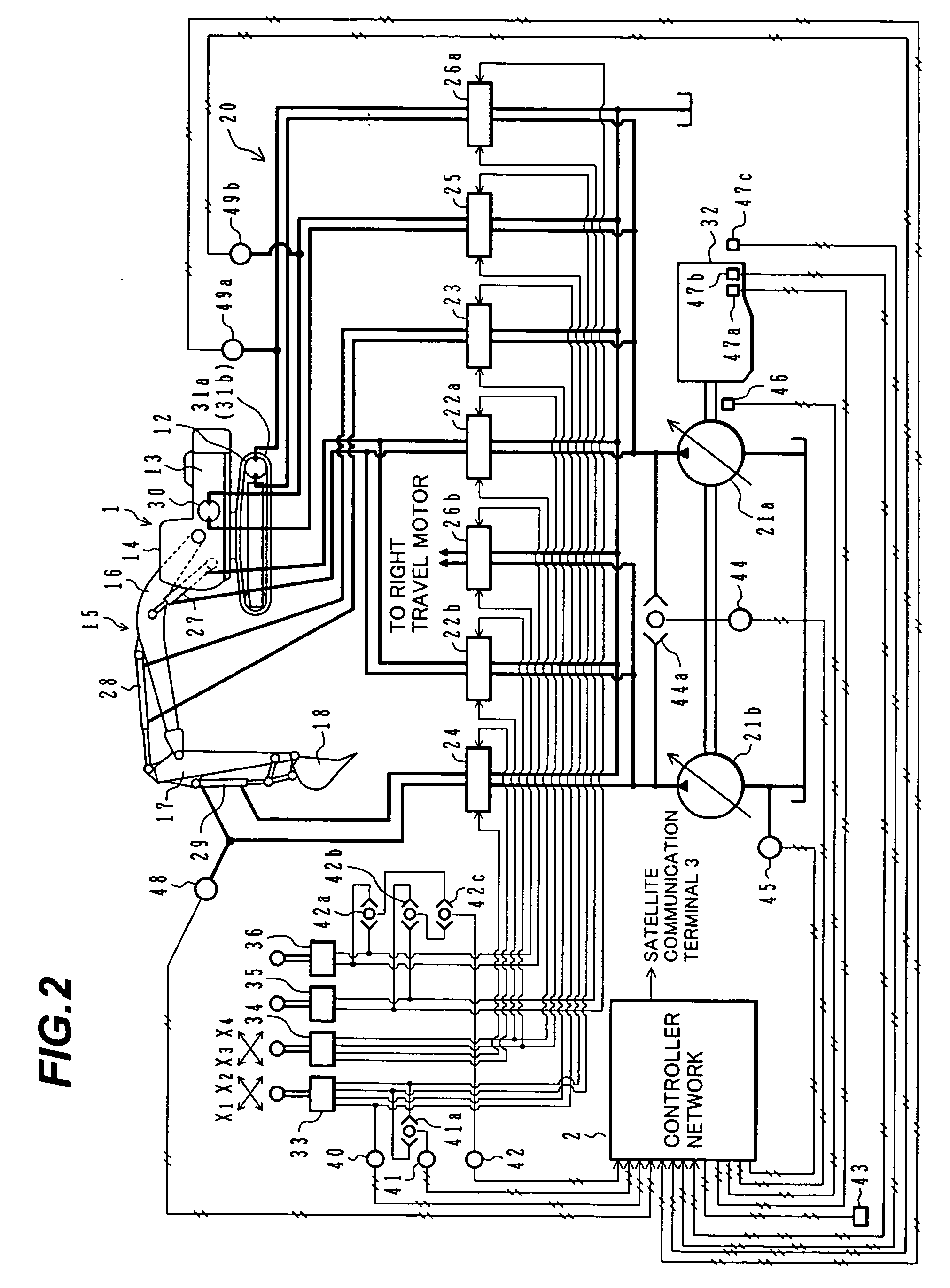

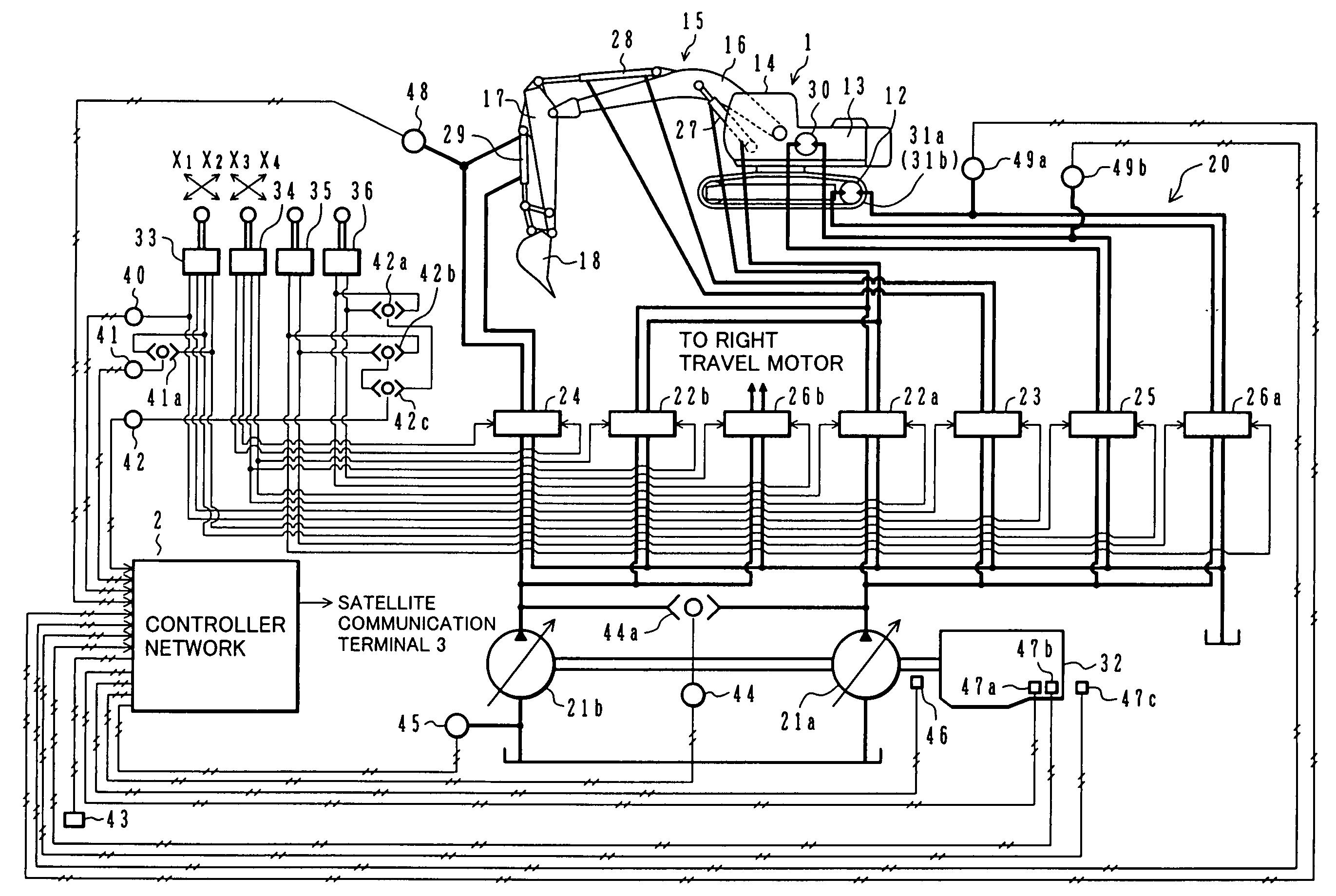

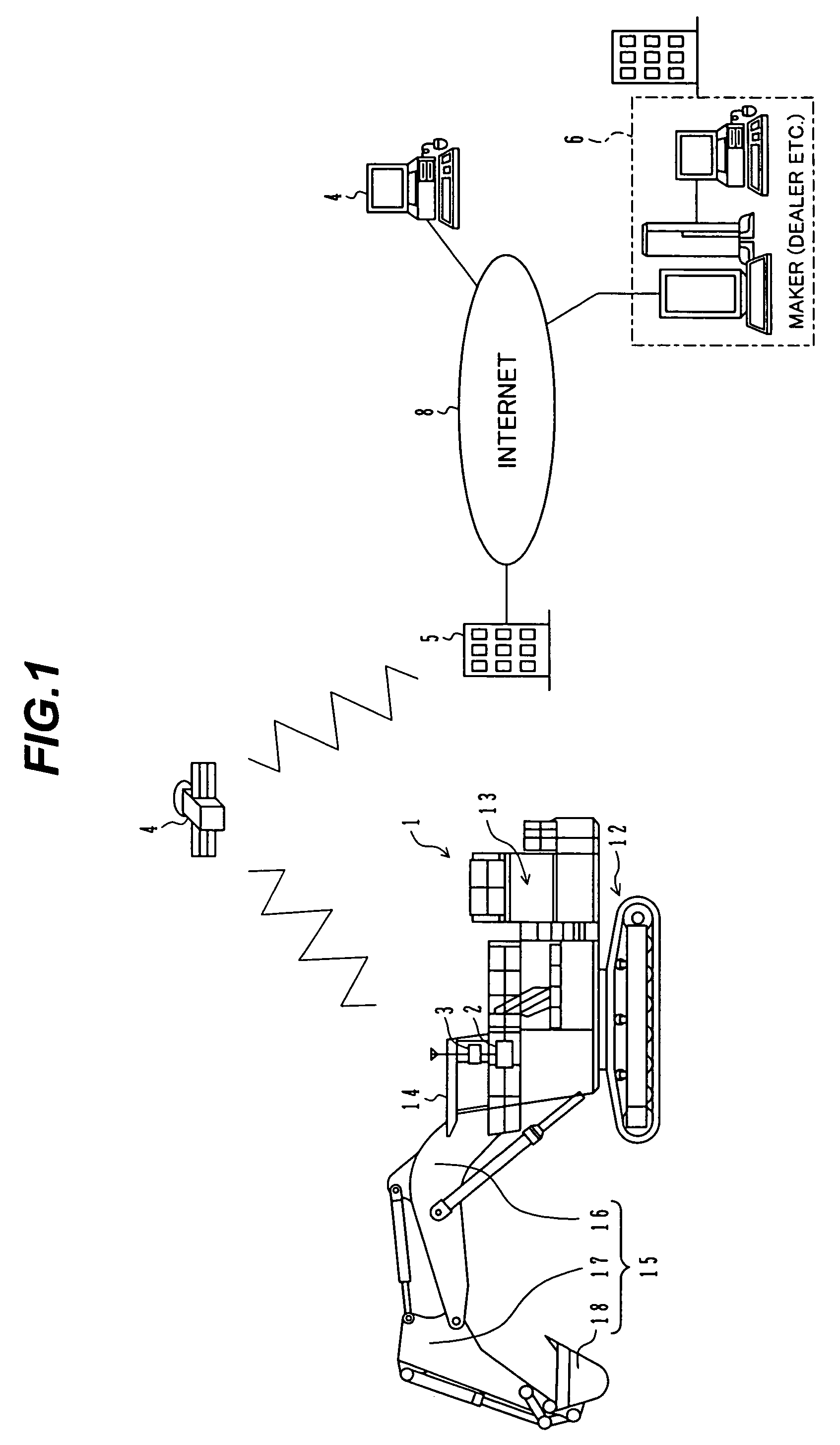

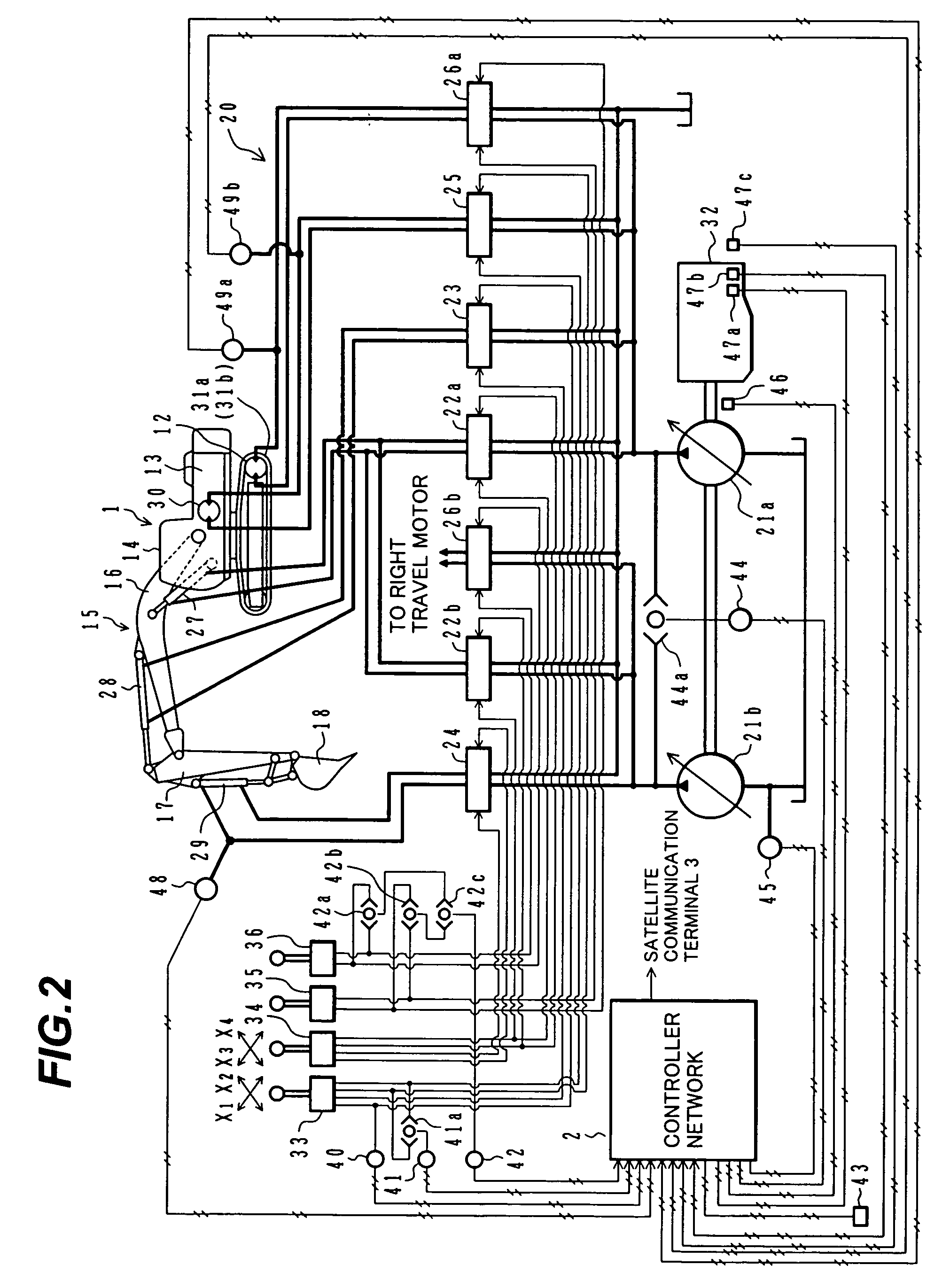

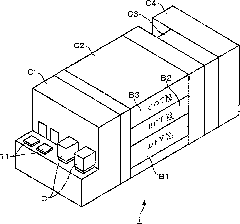

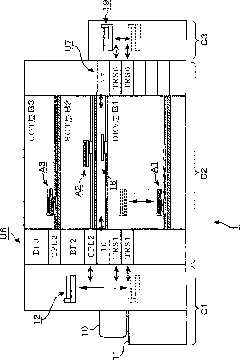

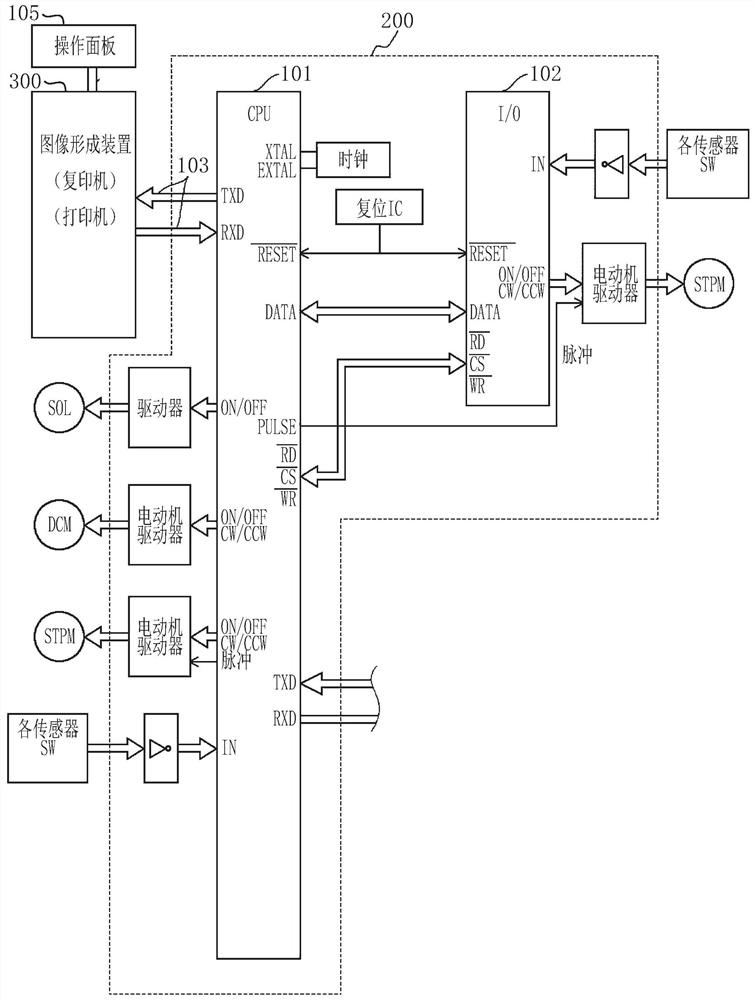

Operation information control device for construction machine and construction machine operation information control system provided with it

InactiveUS20060212203A1Drawback can be obviatedRestraining the drop in productivityVehicle testingData processing applicationsMachineOperational data store

A data recording unit 60 for managing operating situations of a hydraulic excavator 1 comprises a RAM 67 for taking in and storing plural kinds of operational information regarding the hydraulic excavator 1 as operational data, and a CPU 65 for extracting top priority operational data from among the plural kinds of operational data stored in the RAM 67, and transmitting the extracted data to the supervising side via satellite communication. Top priority data among the plural kinds of operational data of the hydraulic excavator, which may bring the hydraulic excavator into rest, can be presented to a supervisor of the hydraulic excavator, etc.

Owner:NIHON KENKI CO LTD

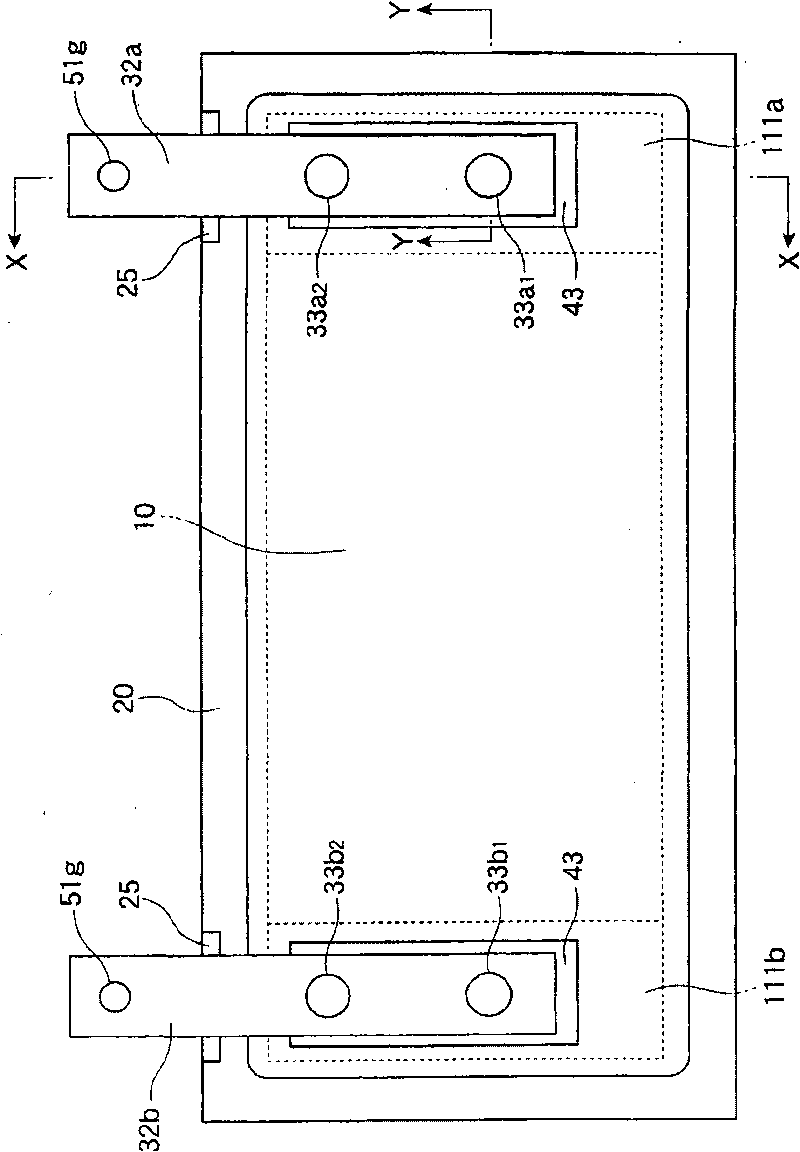

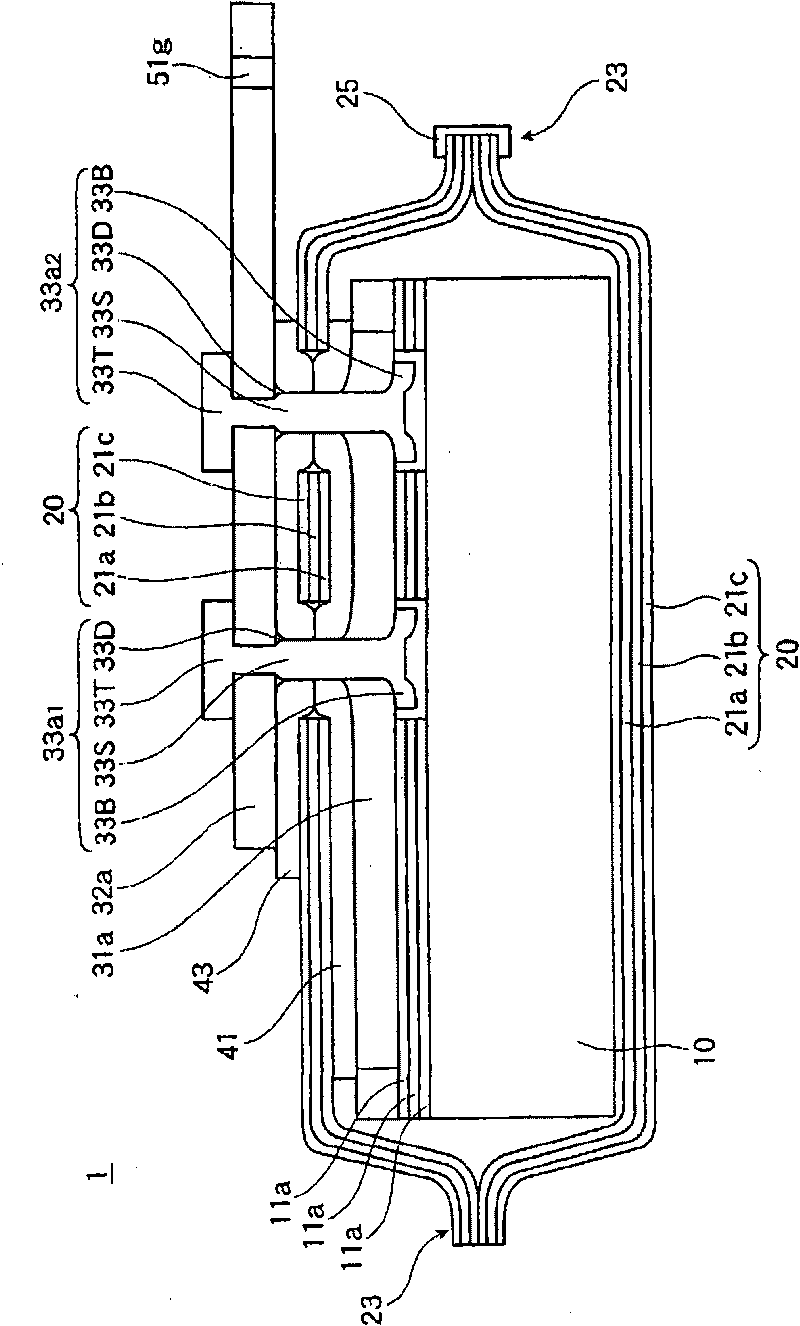

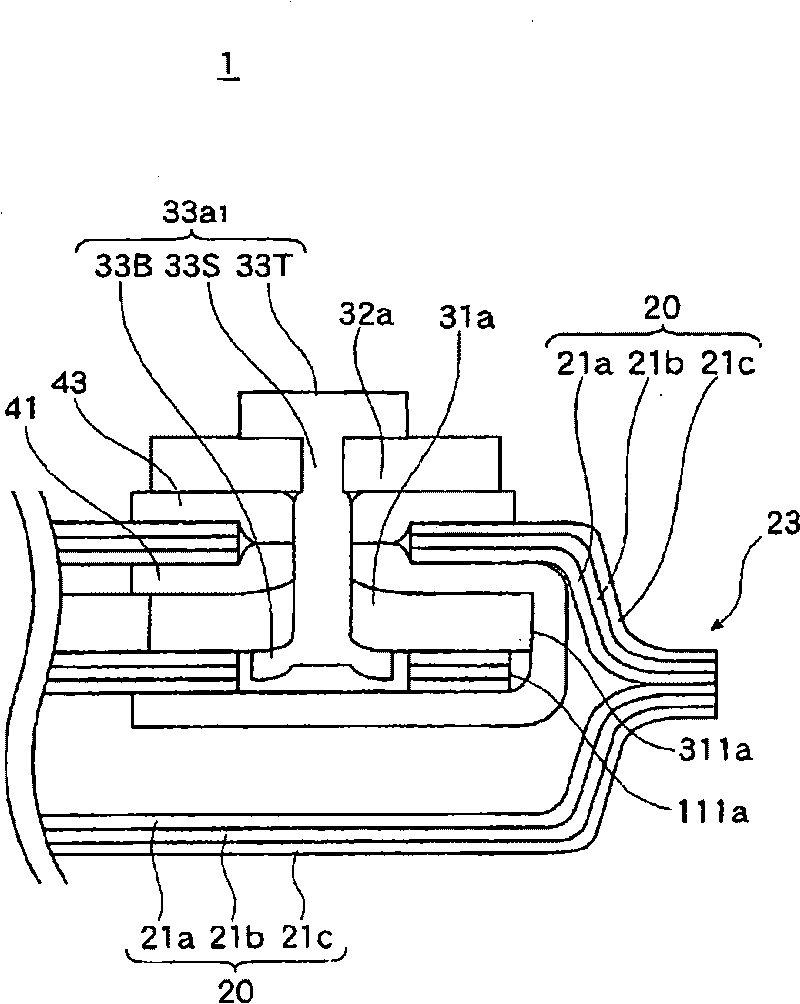

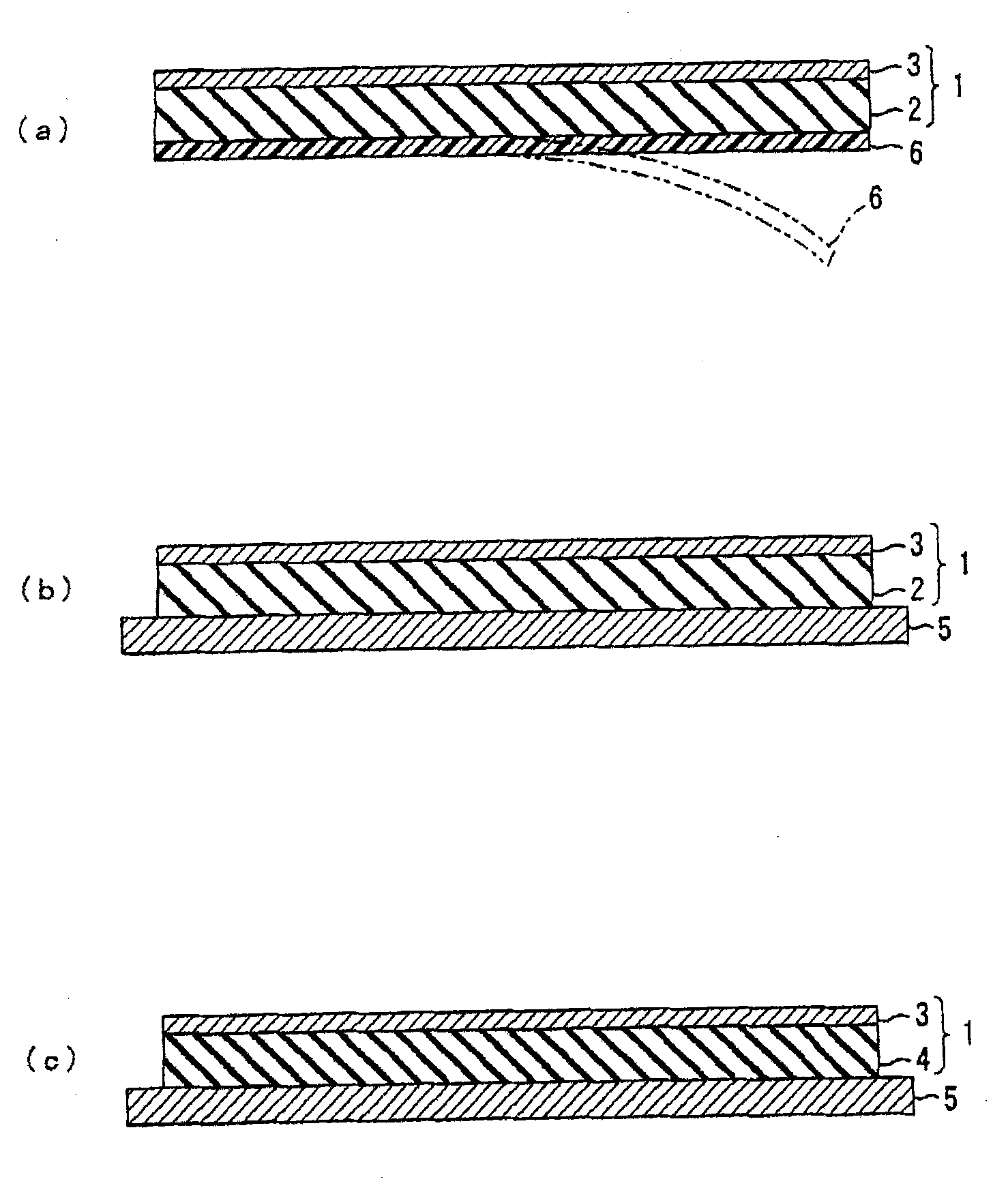

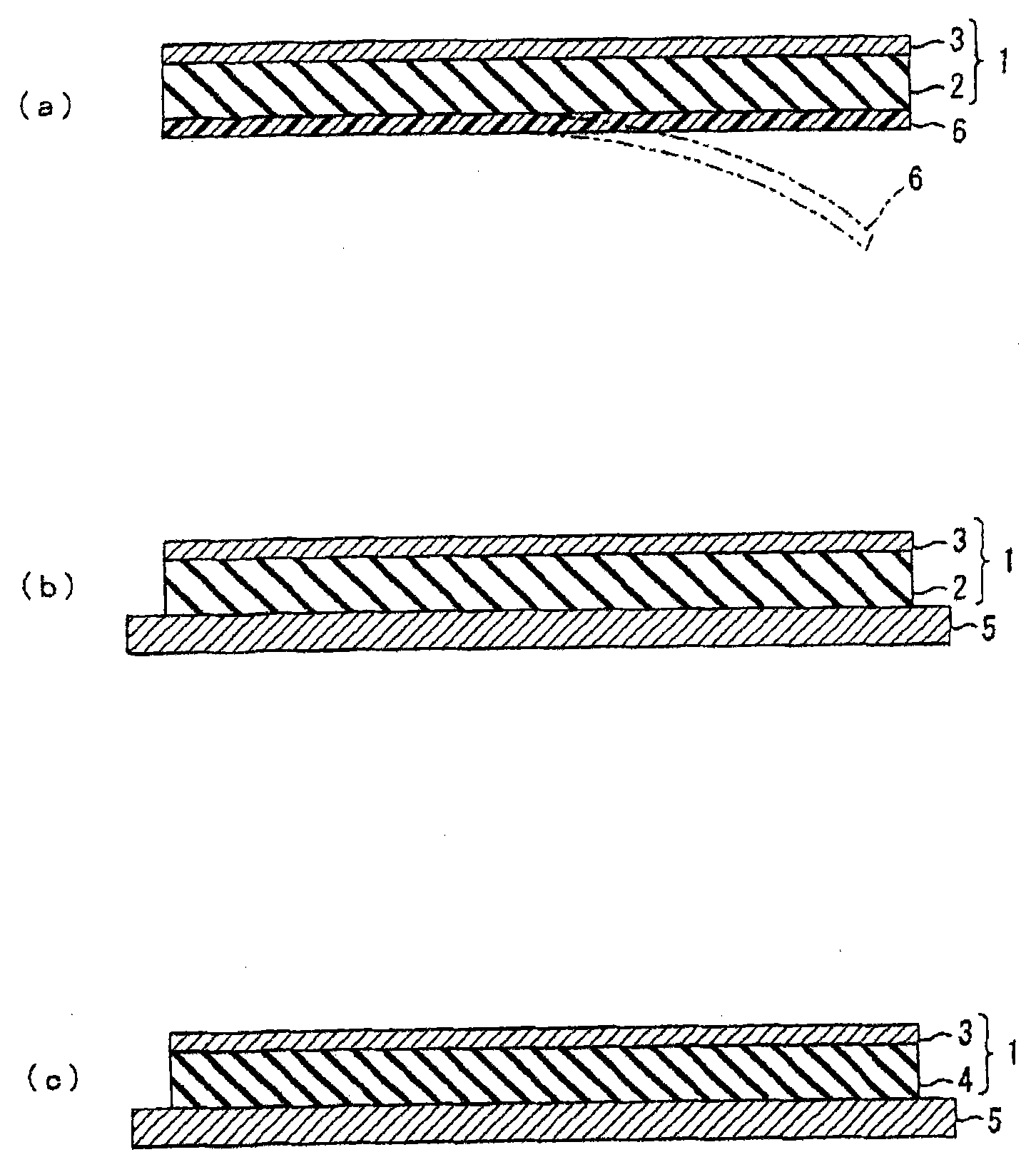

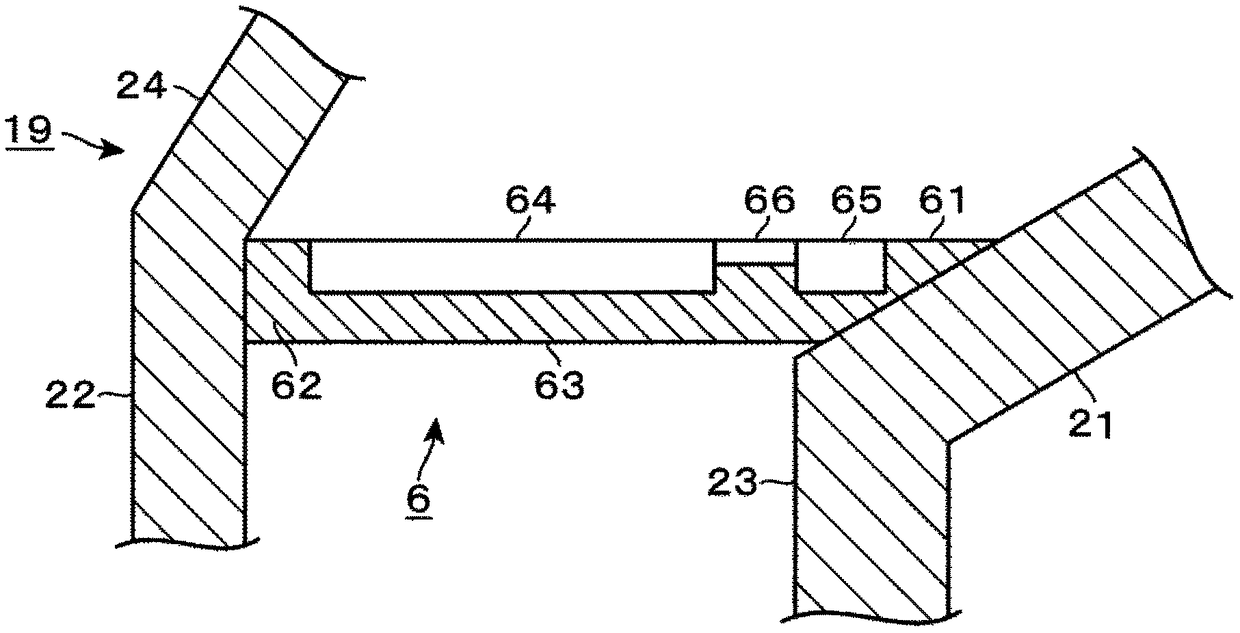

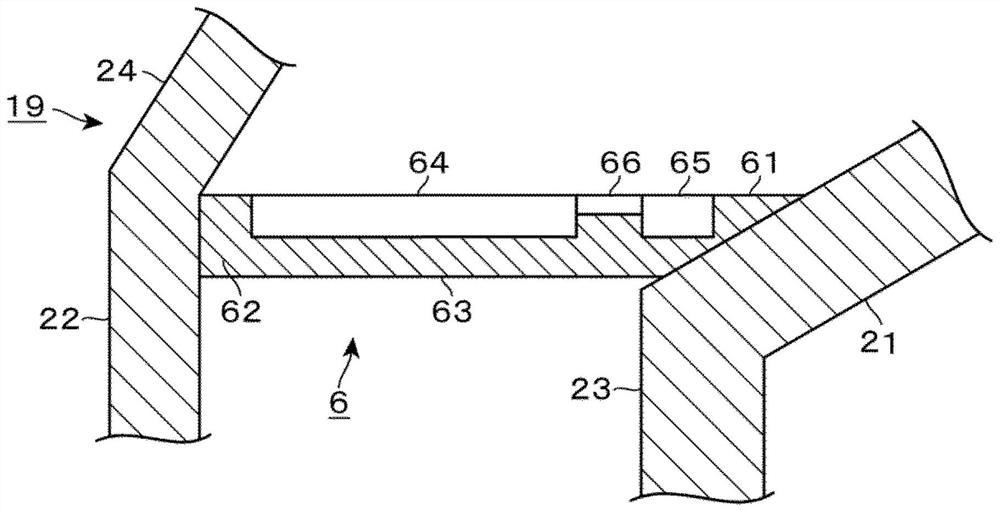

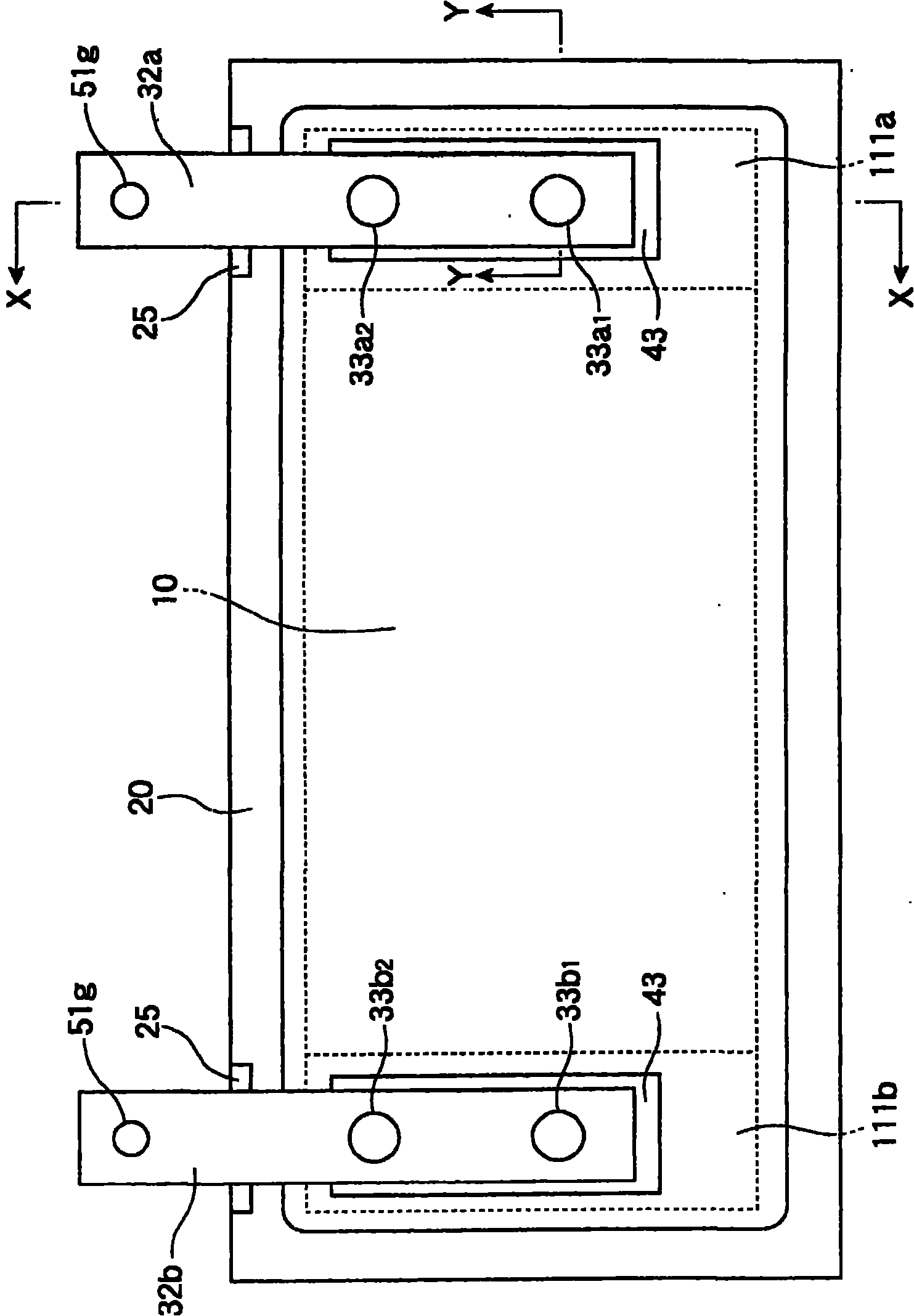

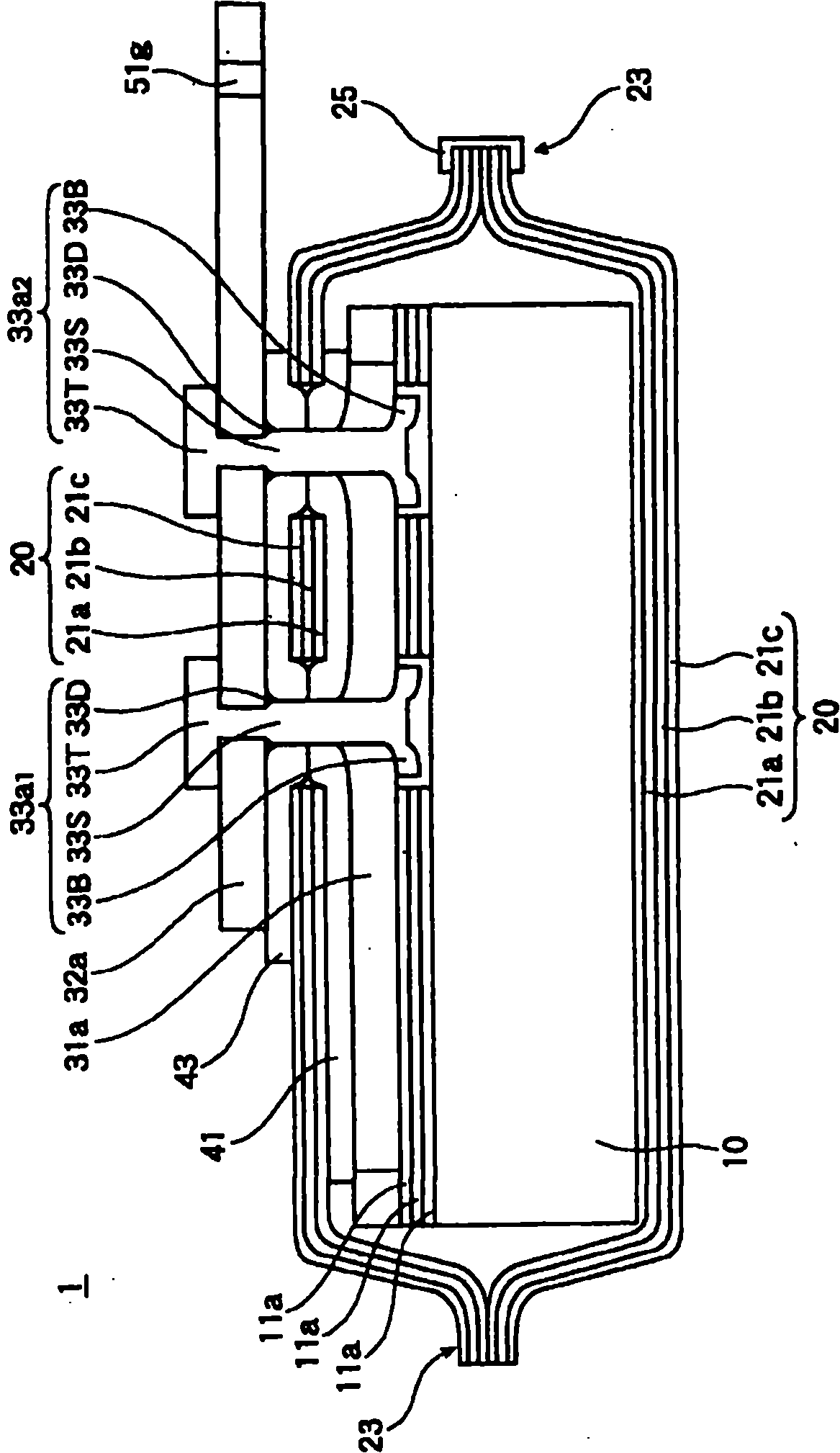

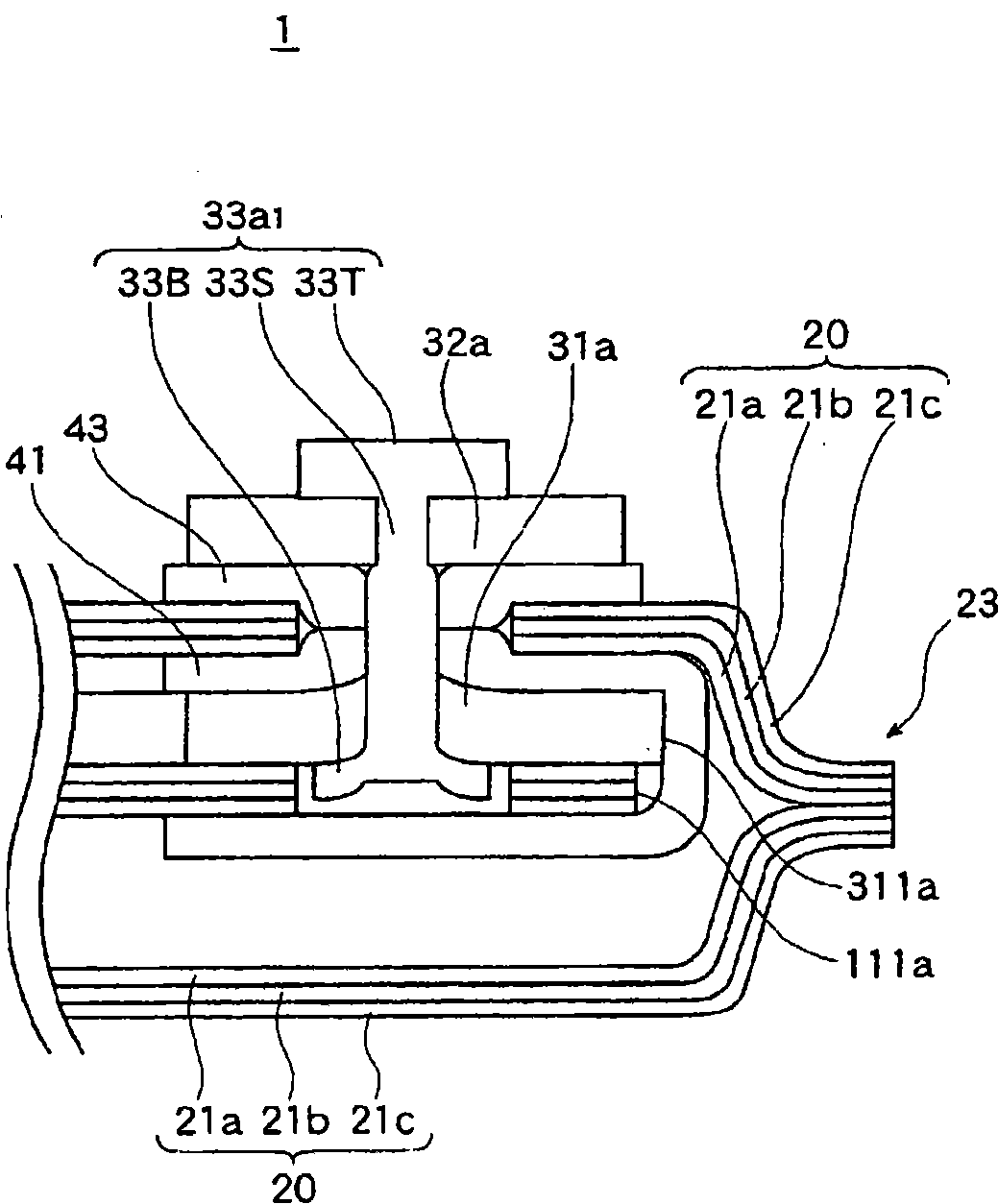

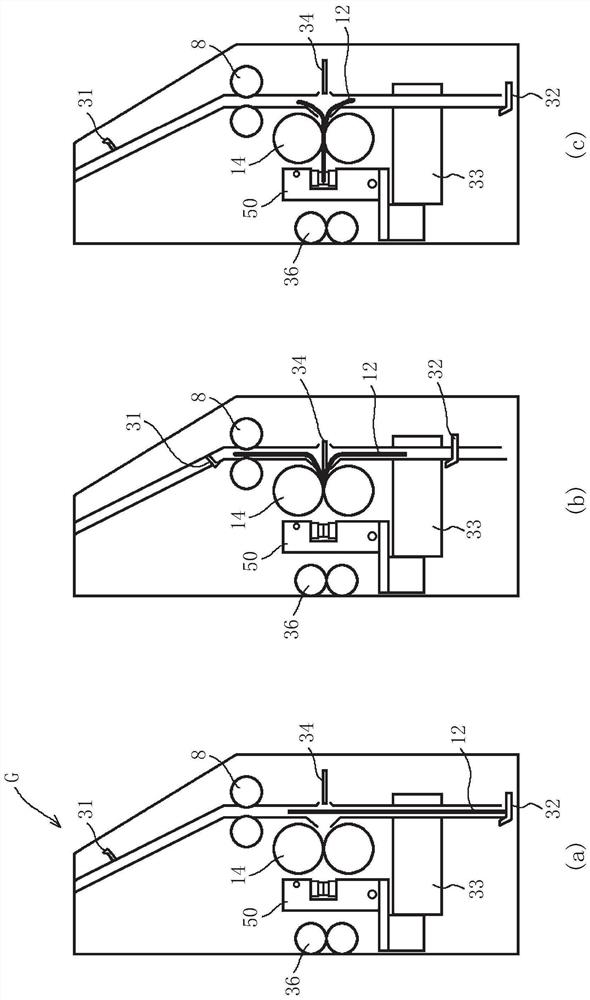

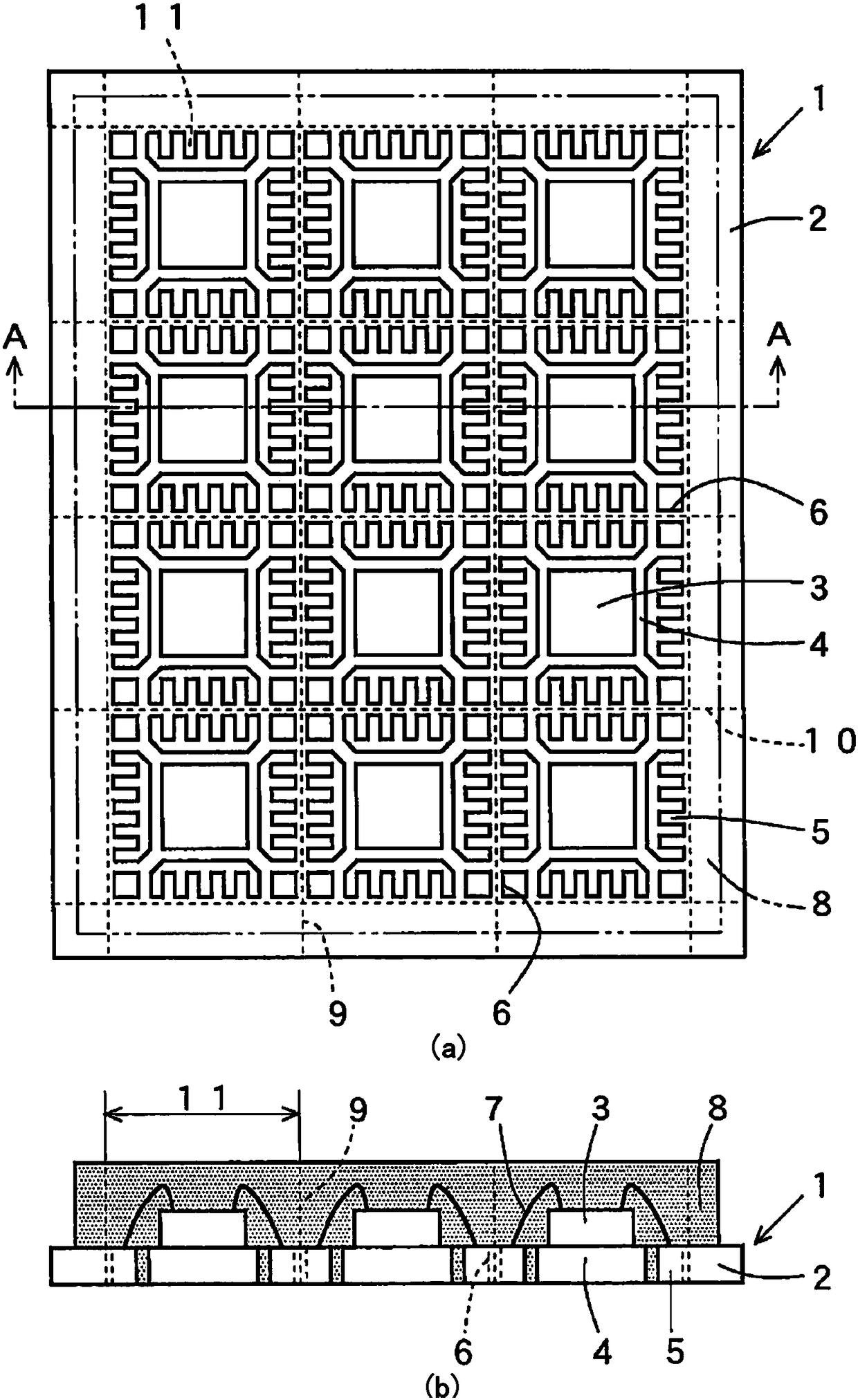

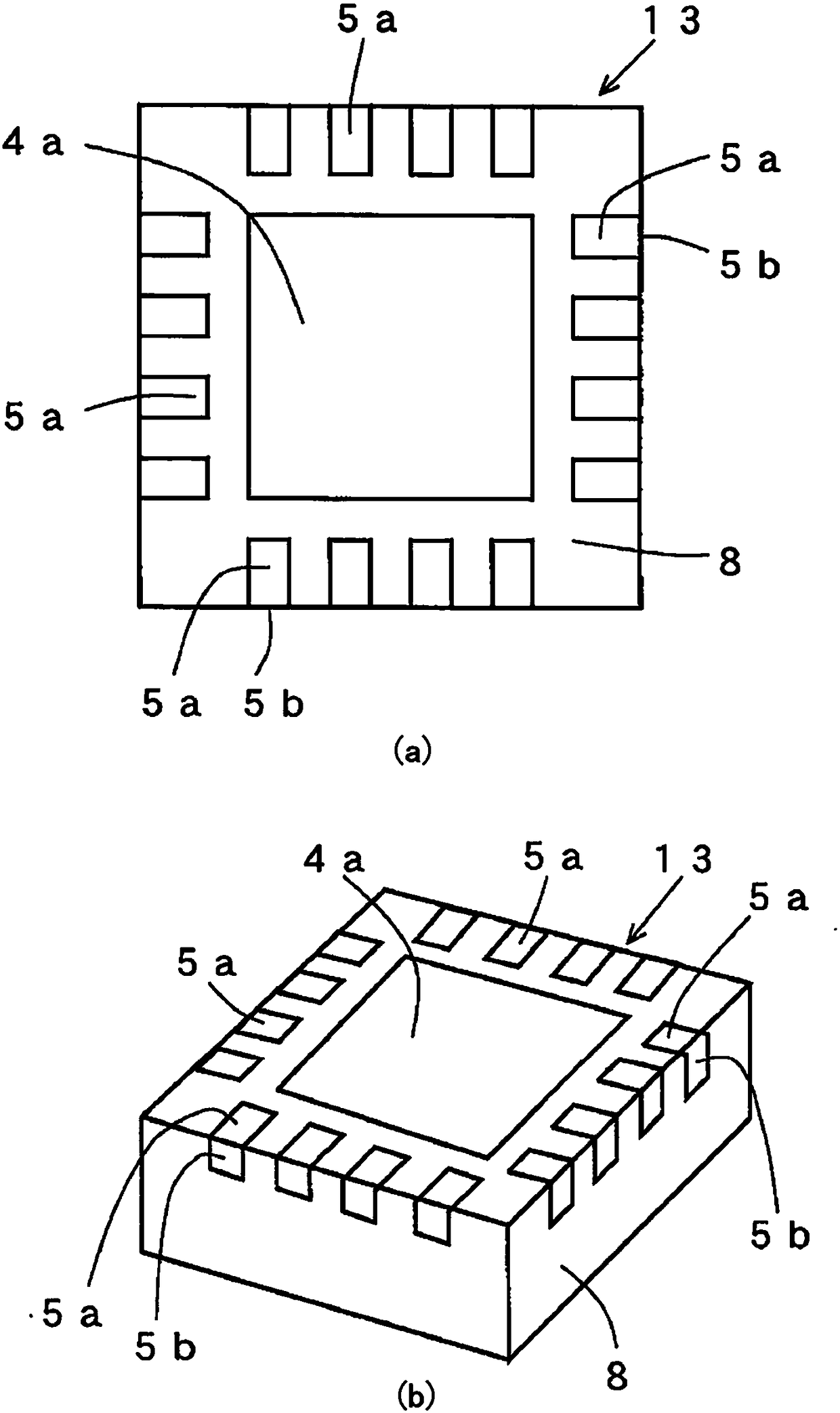

Electric energy storage device and its manufacturing method

InactiveCN101743654ASimple compositionImprove insulation reliabilityLarge-sized flat cells/batteriesFinal product manufactureMetalFlange

An electric energy storage device which has a connection structure having a high connection reliability and can avoid contact between an outer-packaging body and a connection terminal by a simple structure. The electric energy storage device comprises a battery element (10) stored in an outer-packaging body (20) including a metal layer (21b), a plate-like internal lead (31) connected to the battery element (10), a plate-like external lead (32), a connection terminal (33) for electrically connecting the internal lead (31) and the external lead (32), an inside insulation member (41), and an outside insulation member (43). The electric energy storage device is characterized in that flanges (33T, 33B) on both sides of the connection terminal (33) hold the outside insulation member (43), the outer-packaging body (20), and the inside insulation member (41) in between while pressing them via the plate-like external lead (32) and internal lead (31) and that the outside insulation member (43) and / or the inside insulation member (41) is press-fit between a through shaft (33S) of the connection terminal (33) and the metal layer (21b) of the outer-packaging body (20).

Owner:ENAX INC

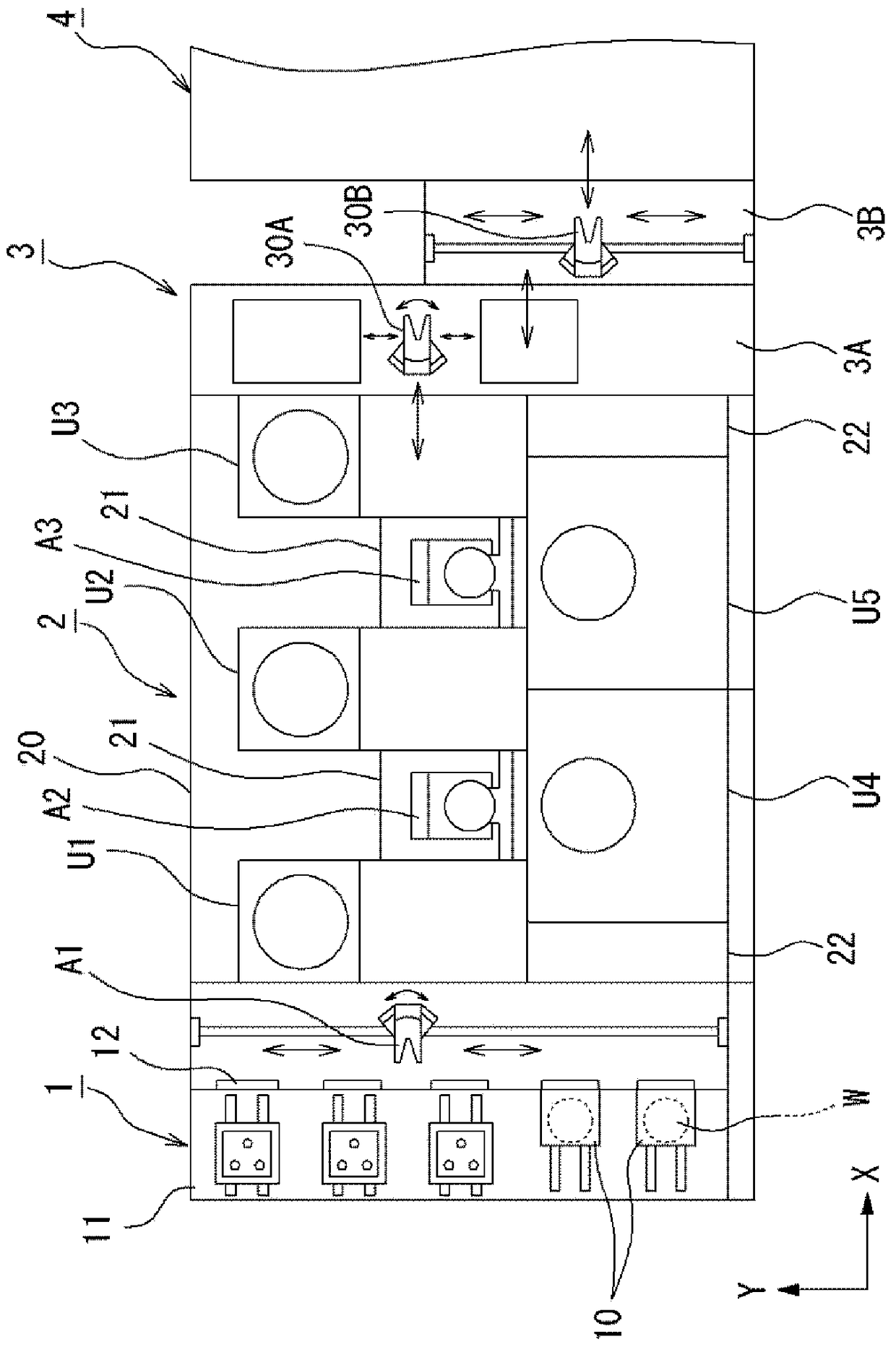

Operation information control device and system for a construction machine

InactiveUS7599775B2Drawback can be obviatedRestraining the drop in productivityVehicle testingData processing applicationsInformation controlData recording

A data recording unit 60 for managing operating situations of a hydraulic excavator 1 comprises a RAM 67 for taking in and storing plural kinds of operational information regarding the hydraulic excavator 1 as operational data, and a CPU 65 for extracting top priority operational data from among the plural kinds of operational data stored in the RAM 67, and transmitting the extracted data to the supervising side via satellite communication. Top priority data among the plural kinds of operational data of the hydraulic excavator, which may bring the hydraulic excavator into rest, can be presented to a supervisor of the hydraulic excavator, etc.

Owner:NIHON KENKI CO LTD

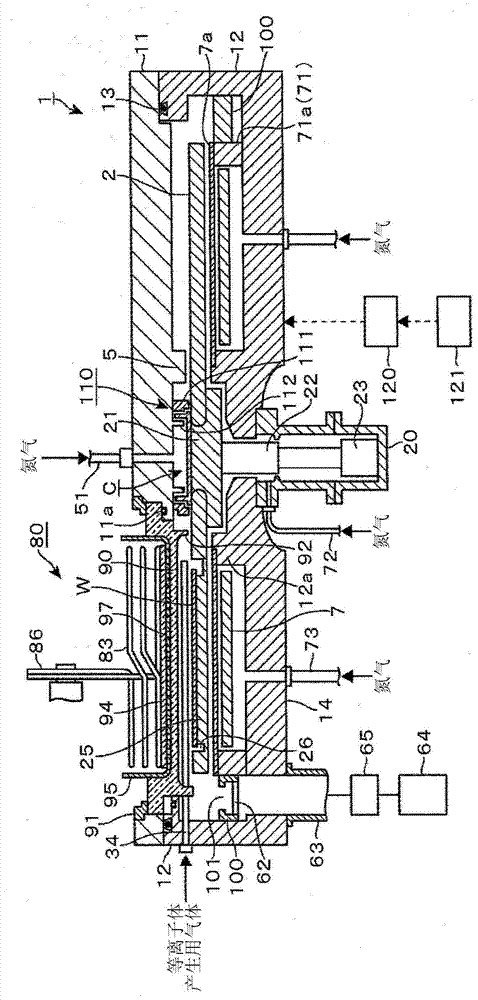

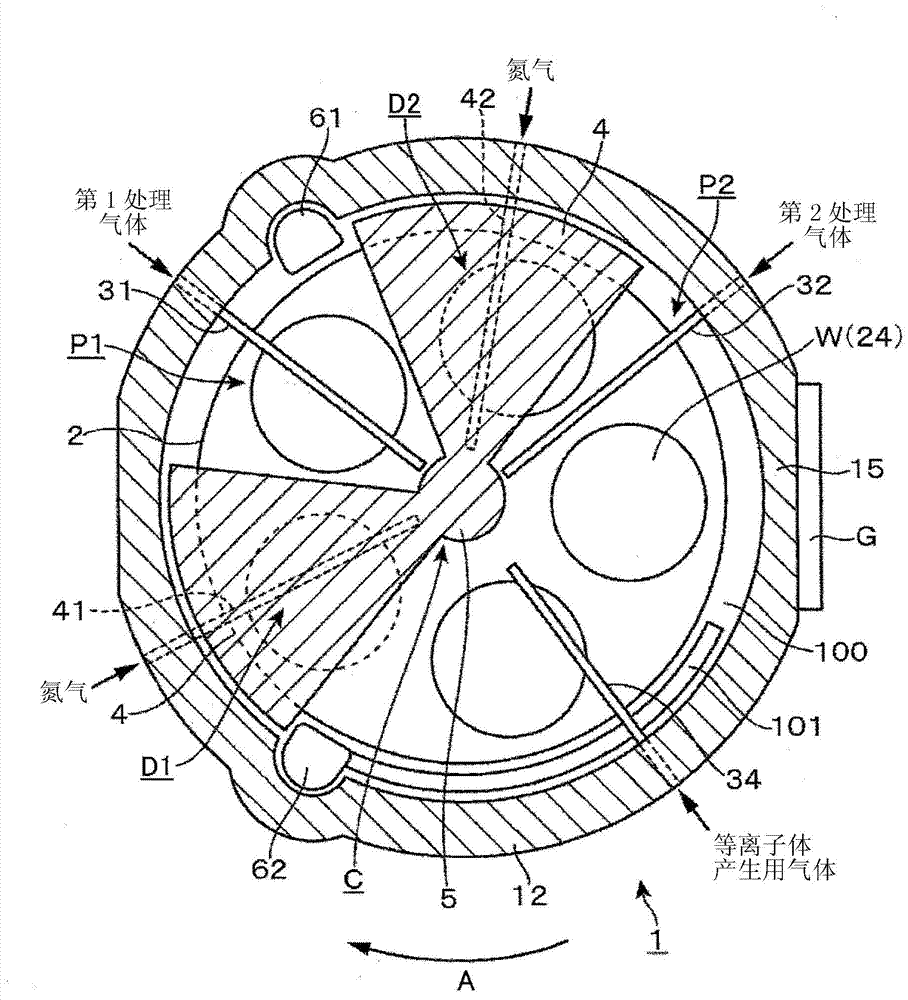

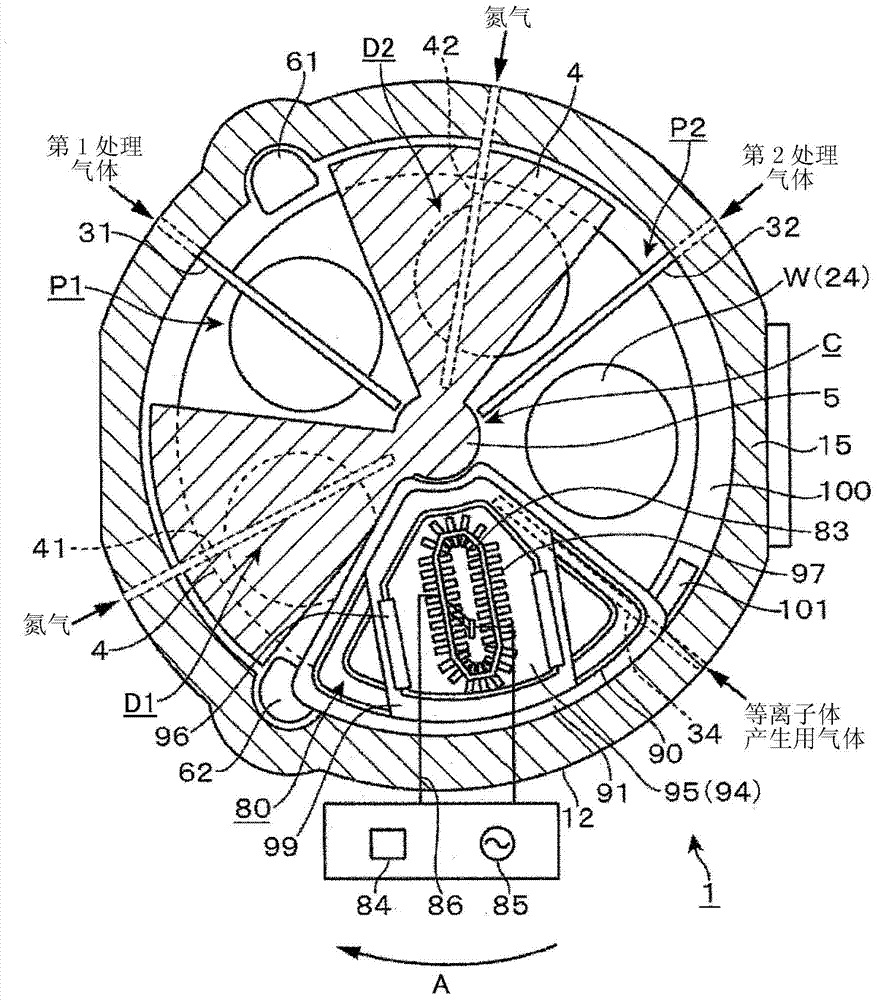

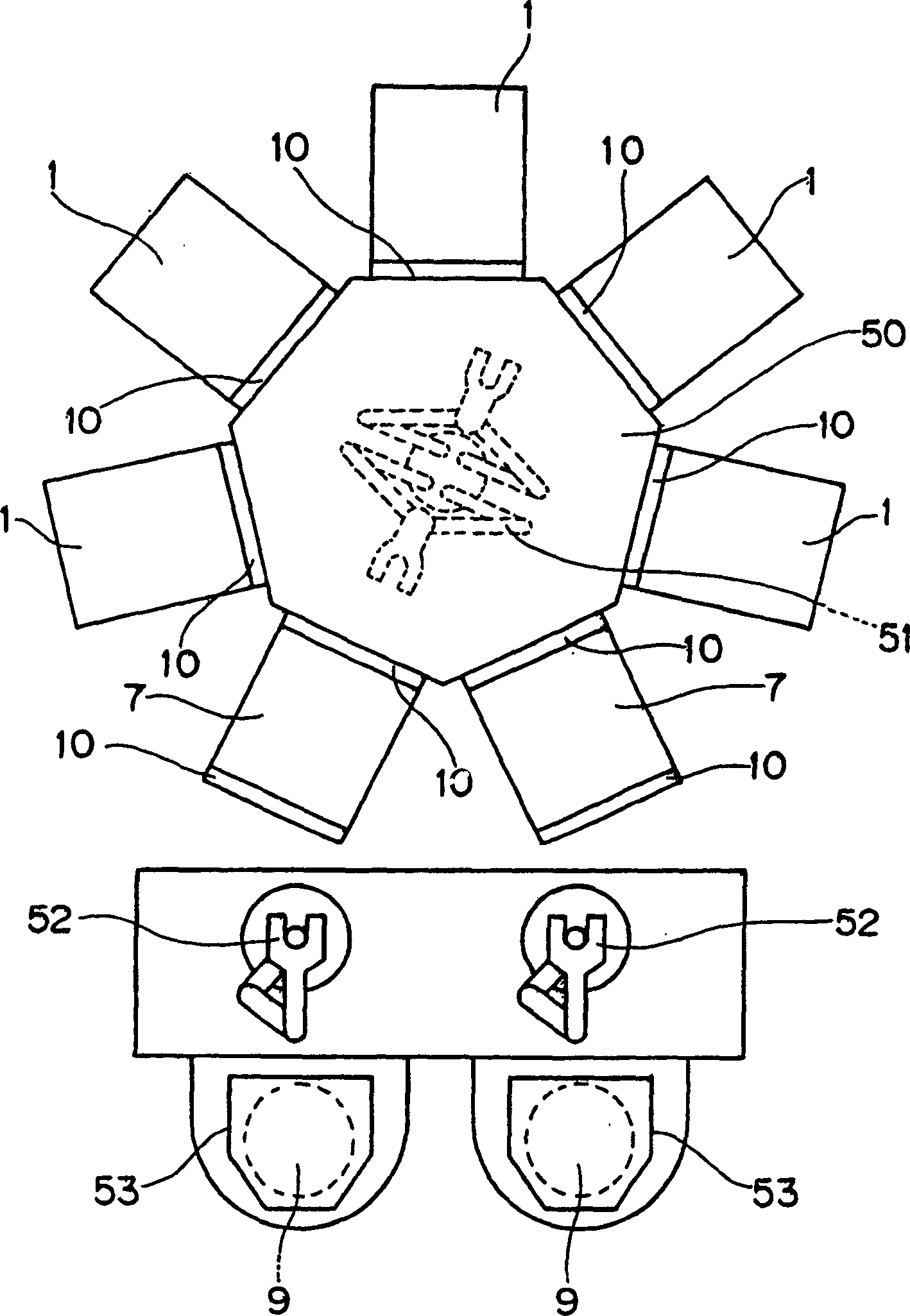

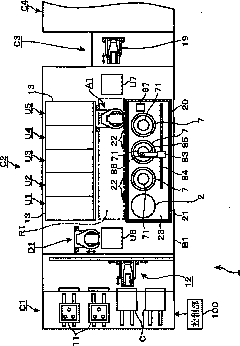

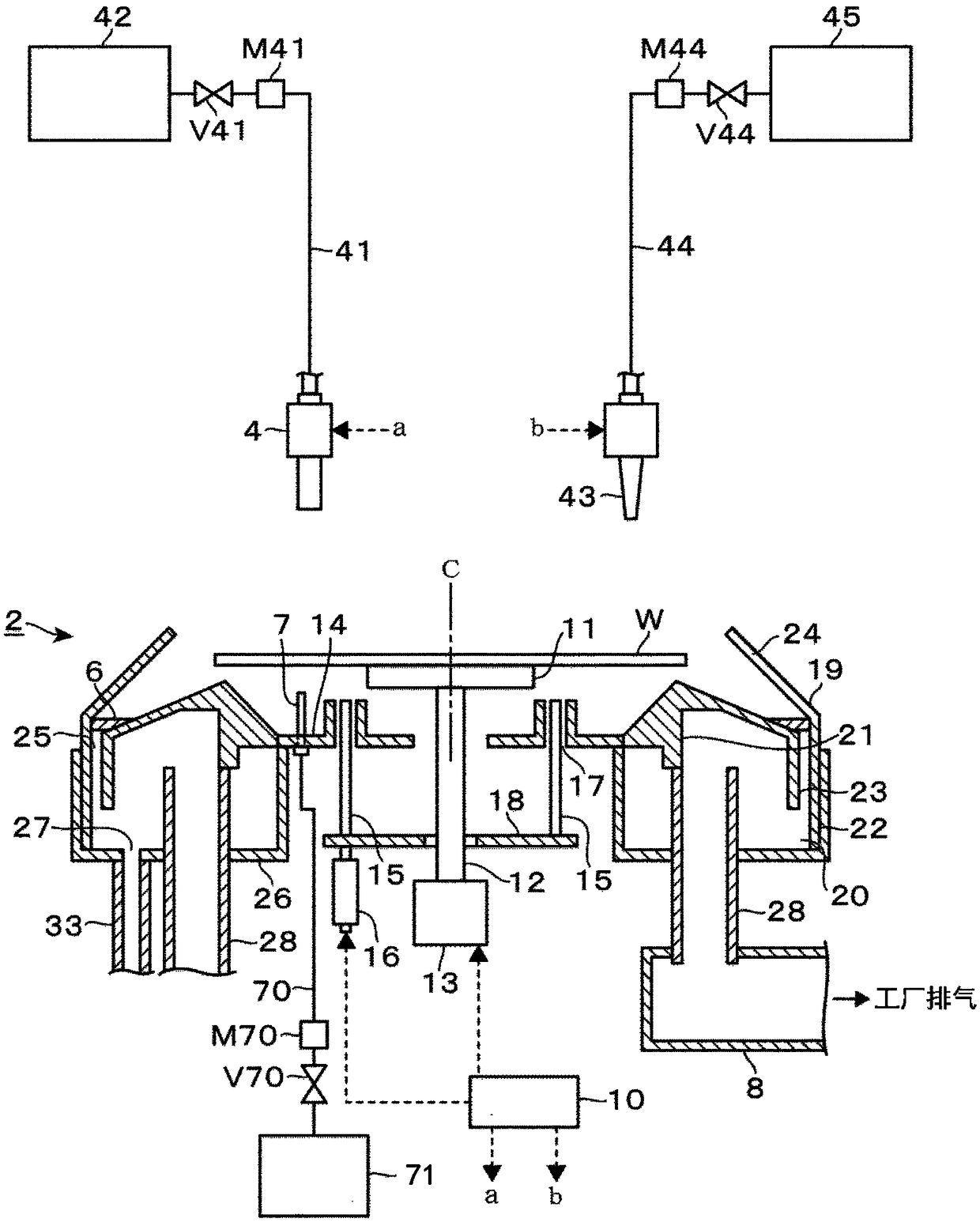

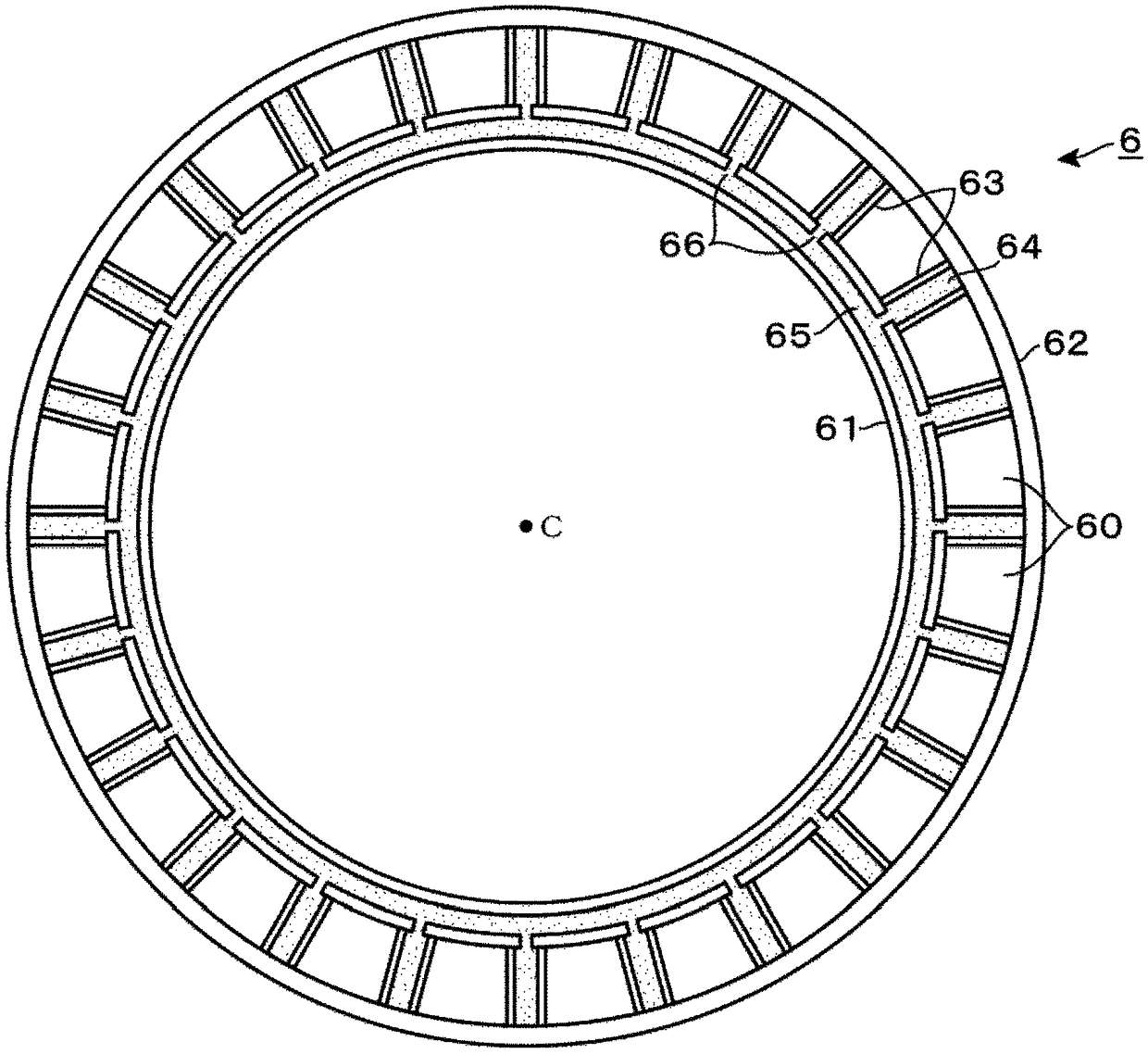

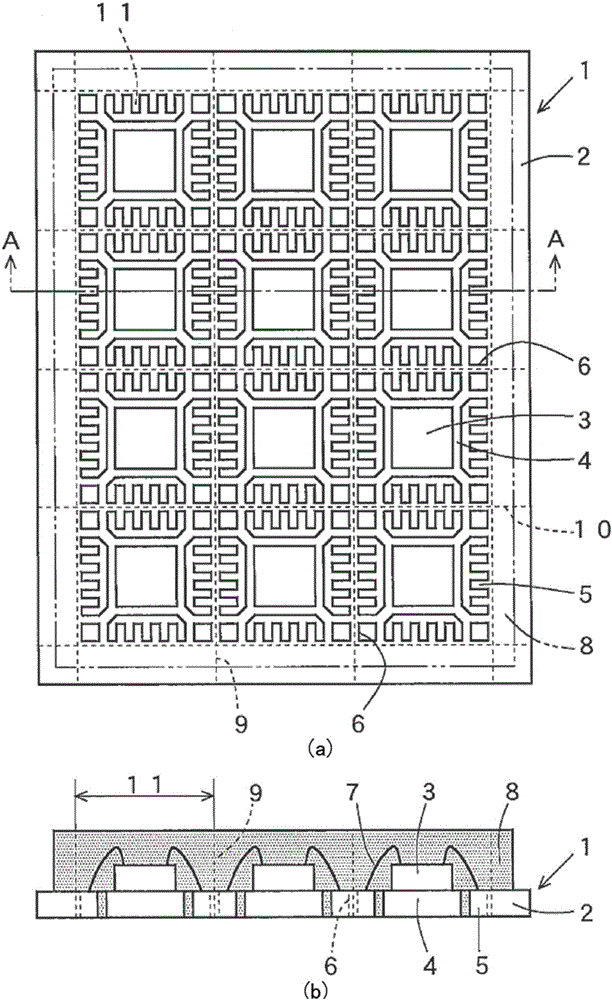

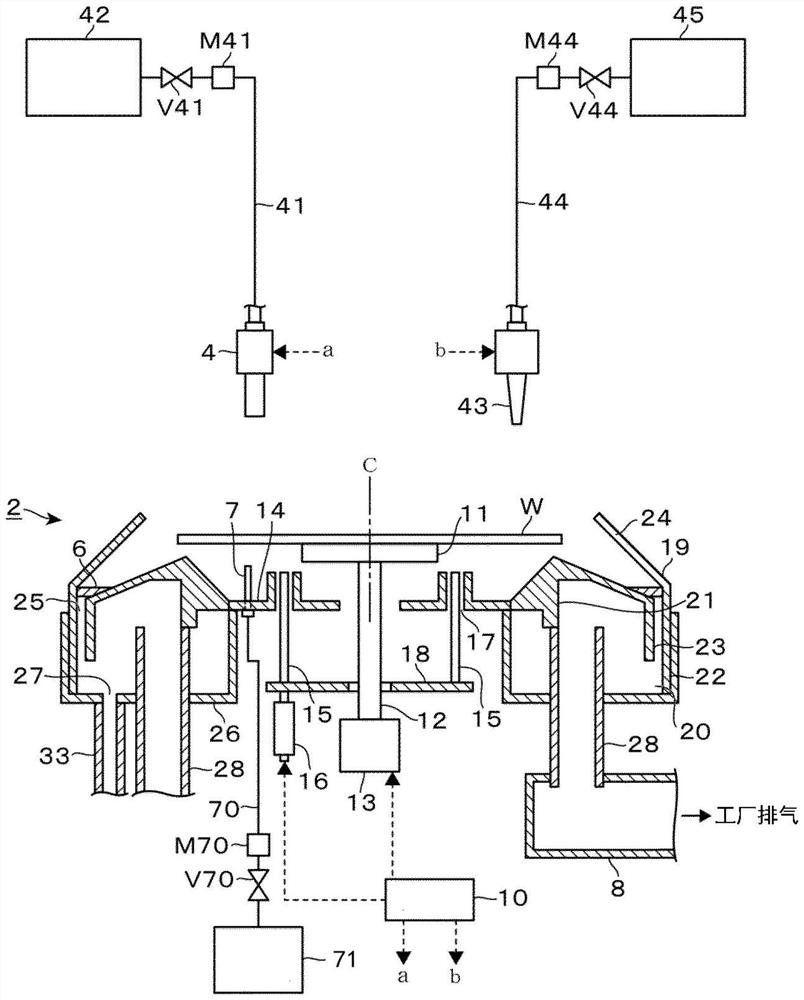

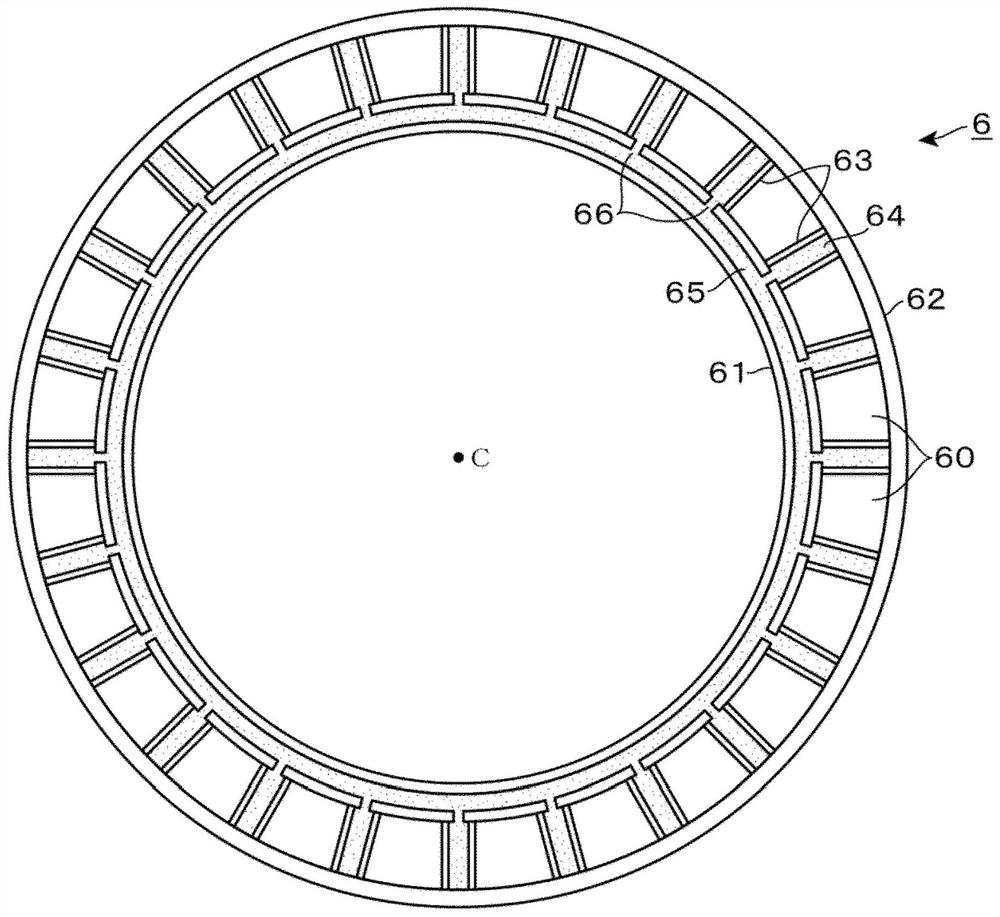

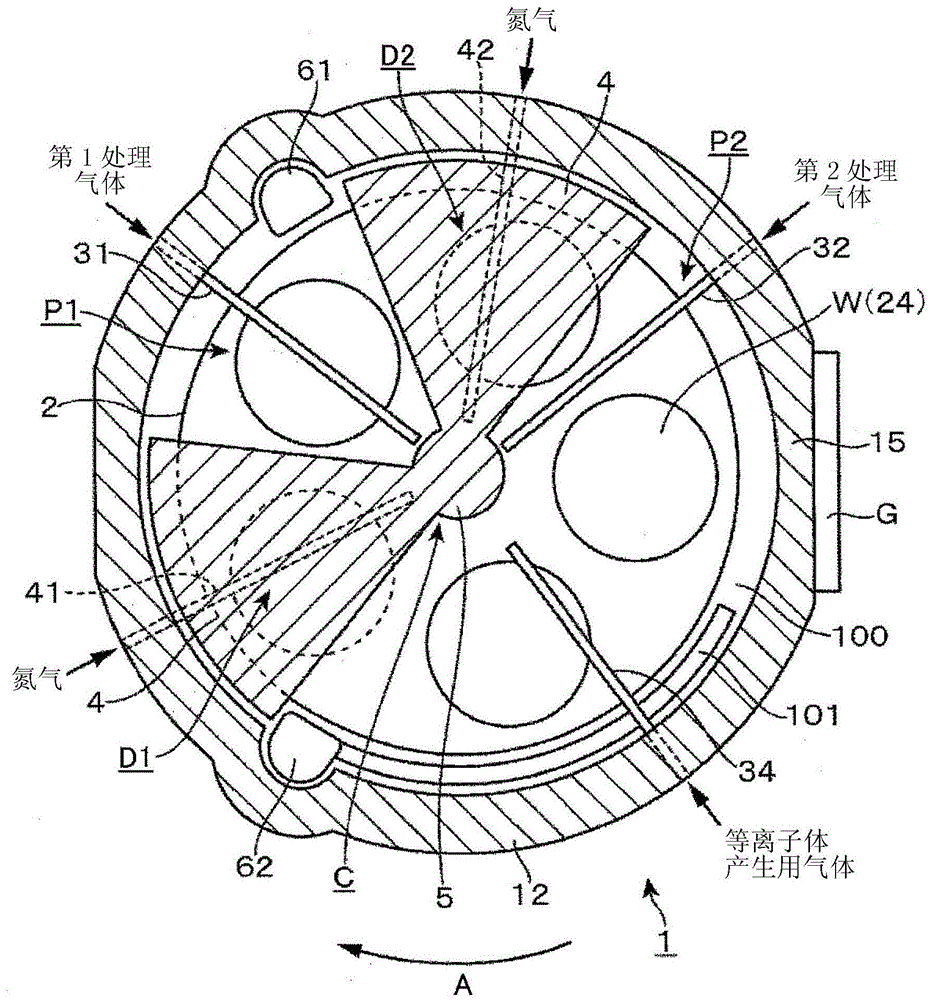

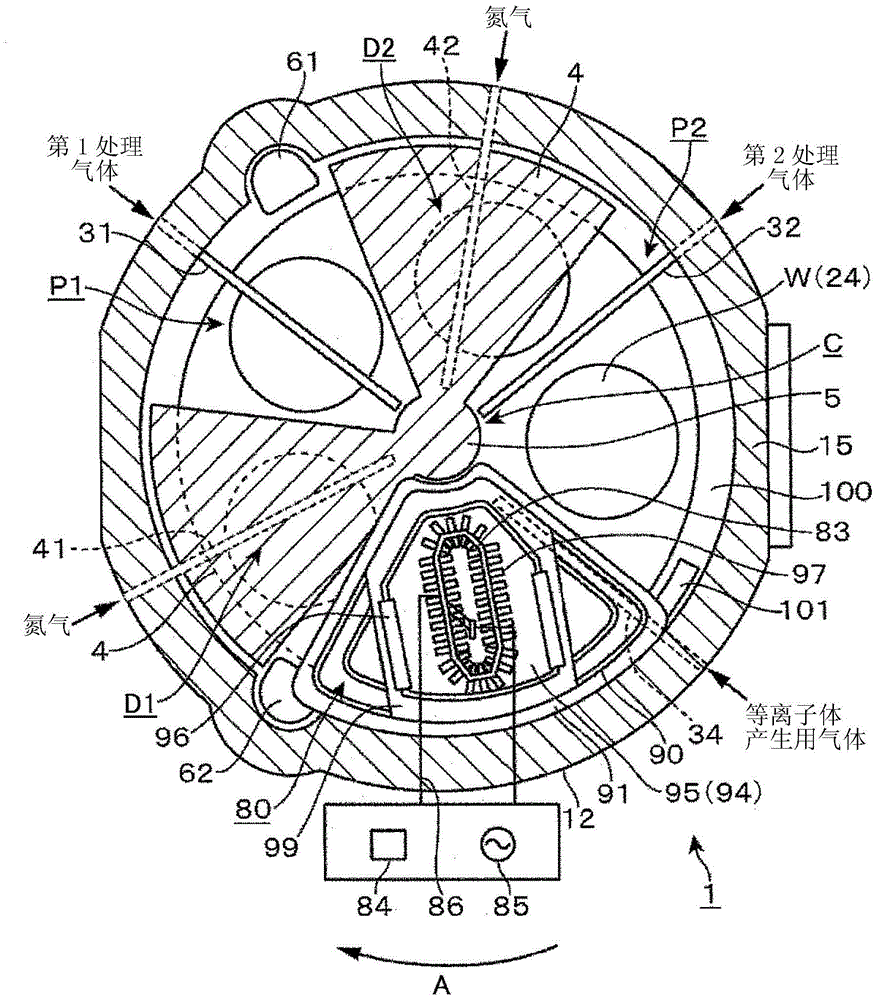

Substrate processing apparatus

ActiveCN103374713AGuaranteed uniformityWhen suppressing a large space that spreads so muchChemical vapor deposition coatingGas supplyVacuum chamber

A substrate processing apparatus includes a vacuum chamber; a turntable rotatably provided in the vacuum chamber, on which a circular substrate is to be mounted, and provided with a circular concave portion at a front surface having a larger diameter than that of the substrate, and a circular substrate mounting portion provided in the concave portion having a diameter smaller than that of the concave portion and the substrate at a position higher than a bottom portion of the concave portion, the center of the substrate mounting portion being off center with respect to the center of the concave portion toward an outer peripheral portion side of the turntable; a process gas supplying unit which supplies a process gas to the substrate; and a vacuum evacuation mechanism which evacuates the vacuum chamber.

Owner:TOKYO ELECTRON LTD

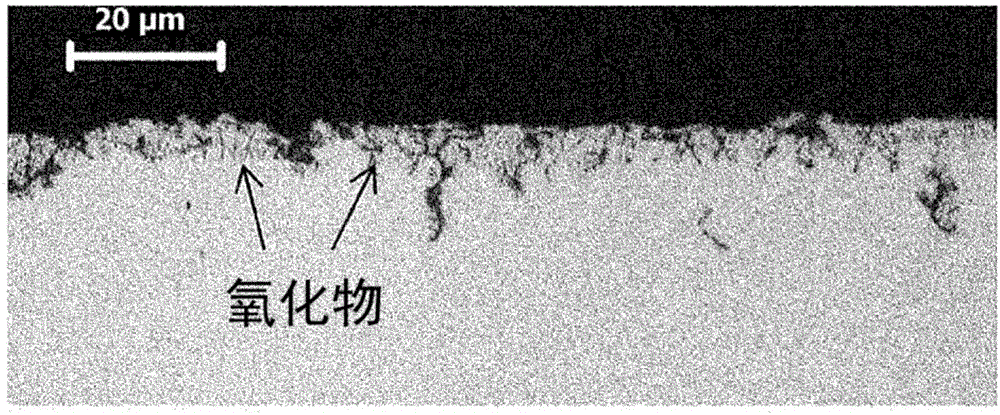

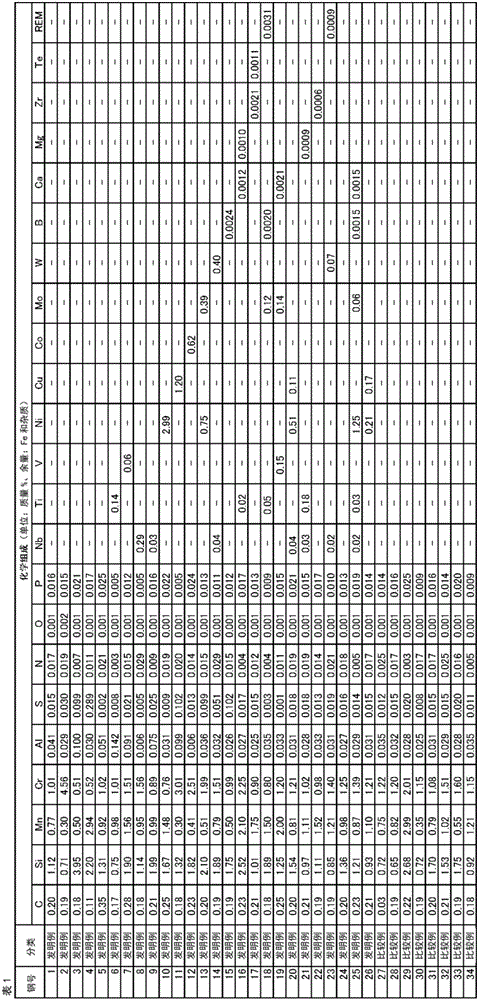

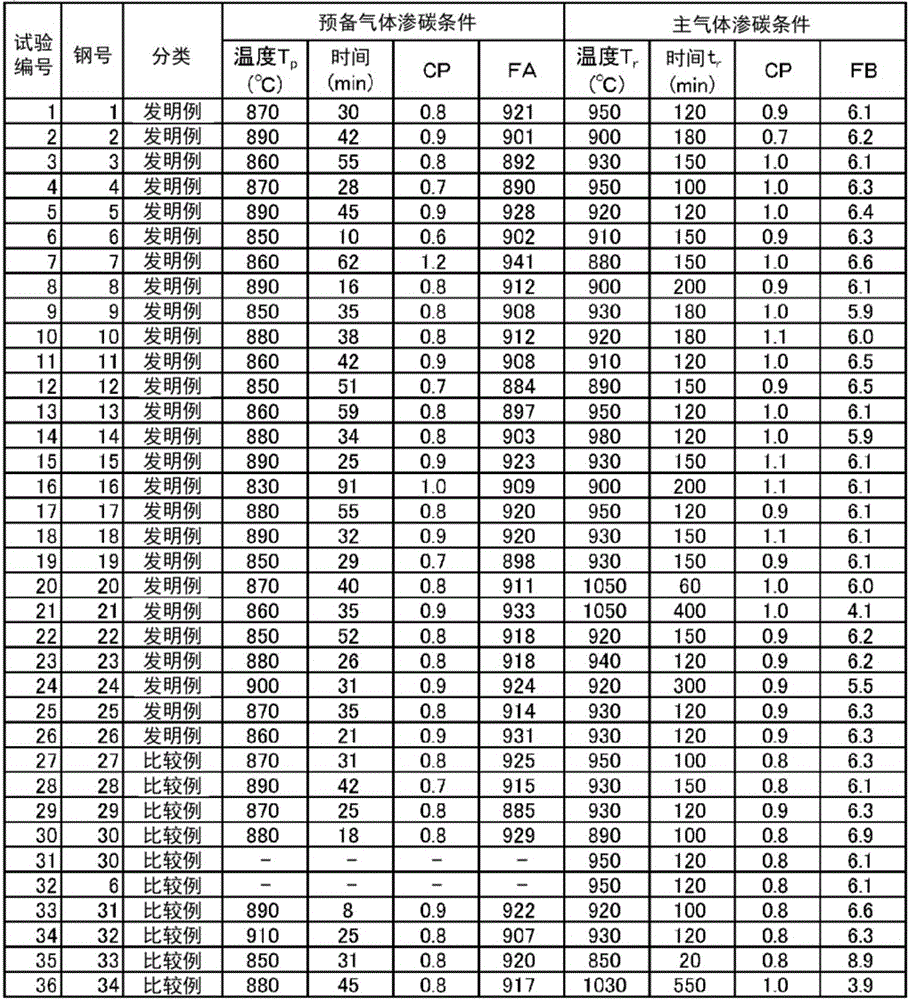

Carburized-steel-component production method, and carburized steel component

InactiveCN105899697AImprove gas carburizationRestraining the drop in productivitySolid state diffusion coatingFurnace typesProduction rateCarbon potential

Provided is a carburized-steel-component production method with which gas carburization properties of a steel component having a high Si content are improved, and with which a reduction in productivity can be inhibited. This production method is provided with a preliminary gas-carburization step, and a main gas-carburization step. In the preliminary gas-carburization step, a steel component having a chemical composition which includes, expressed in mass%, C, Si, Mn, and Cr, and which satisfies formula (1), namely (see description), is subjected to gas-carburization treatment for at least 10 minutes, but for less than 20 hours, at a carburization temperature (Tp) (in DEG C) satisfying formula (A), namely(see description), CP being substituted for the carbon potential during carburization in the preliminary gas-carburization step. In the main gas-carburization step, gas-carburization treatment is performed using a carburization time period (tr) (in minutes) and a carburization temperature (Tr) (in DEG C) which satisfy formula (B), namely (see description).

Owner:NIPPON STEEL CORP

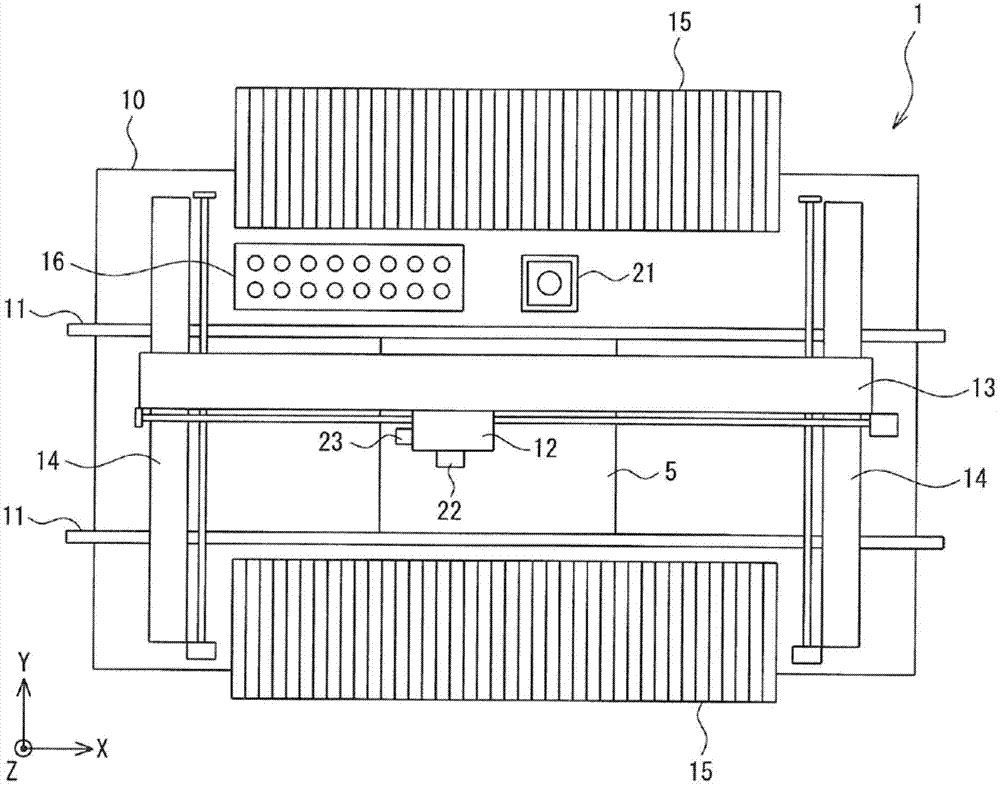

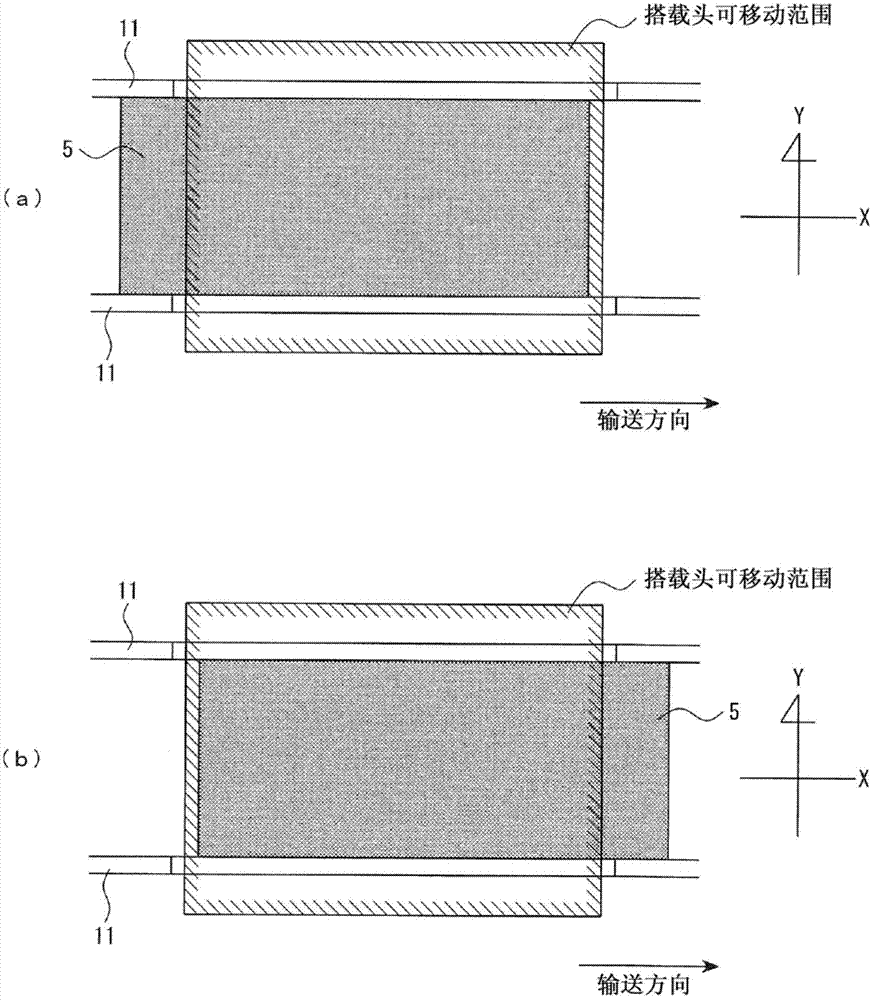

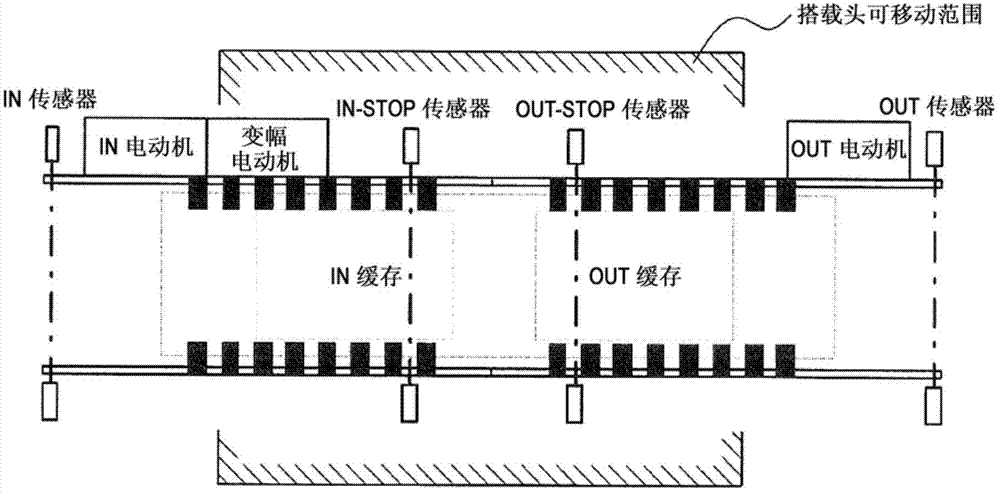

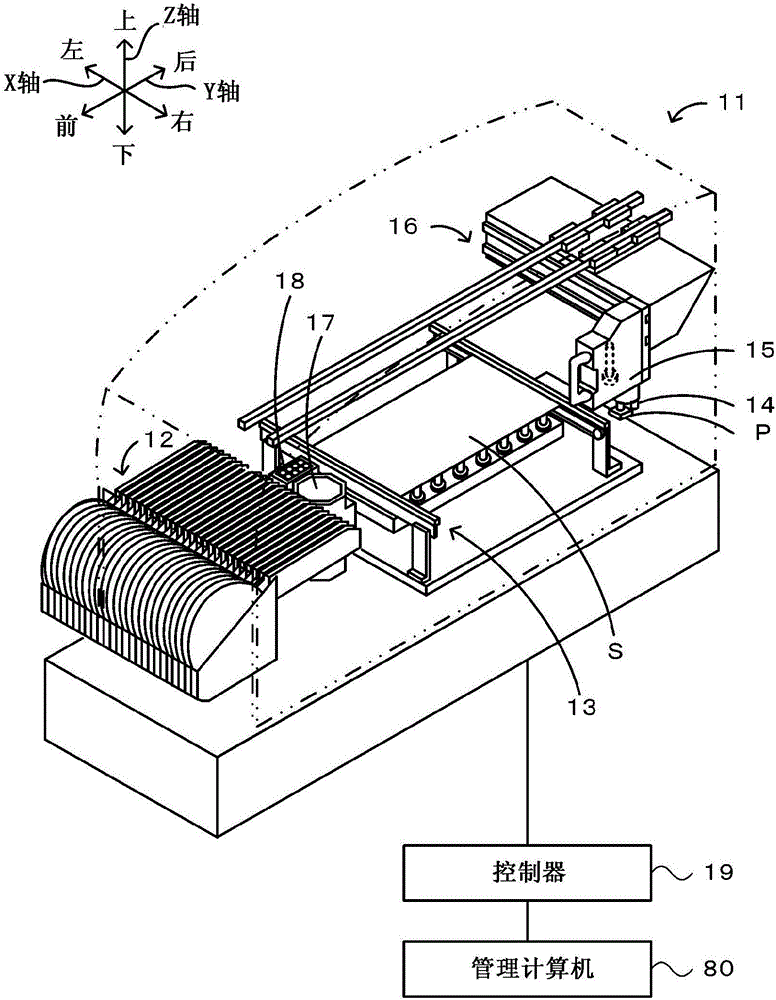

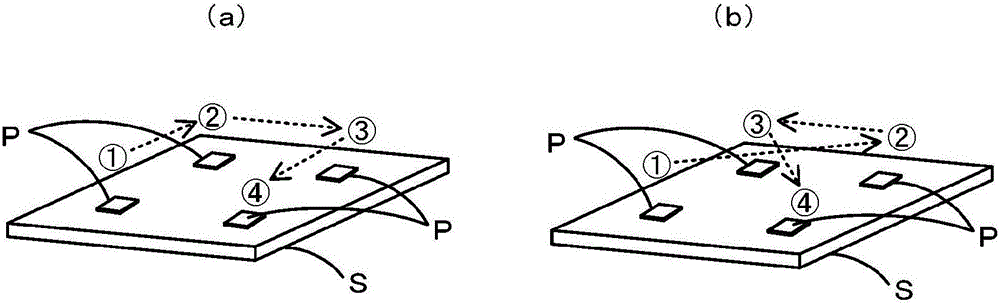

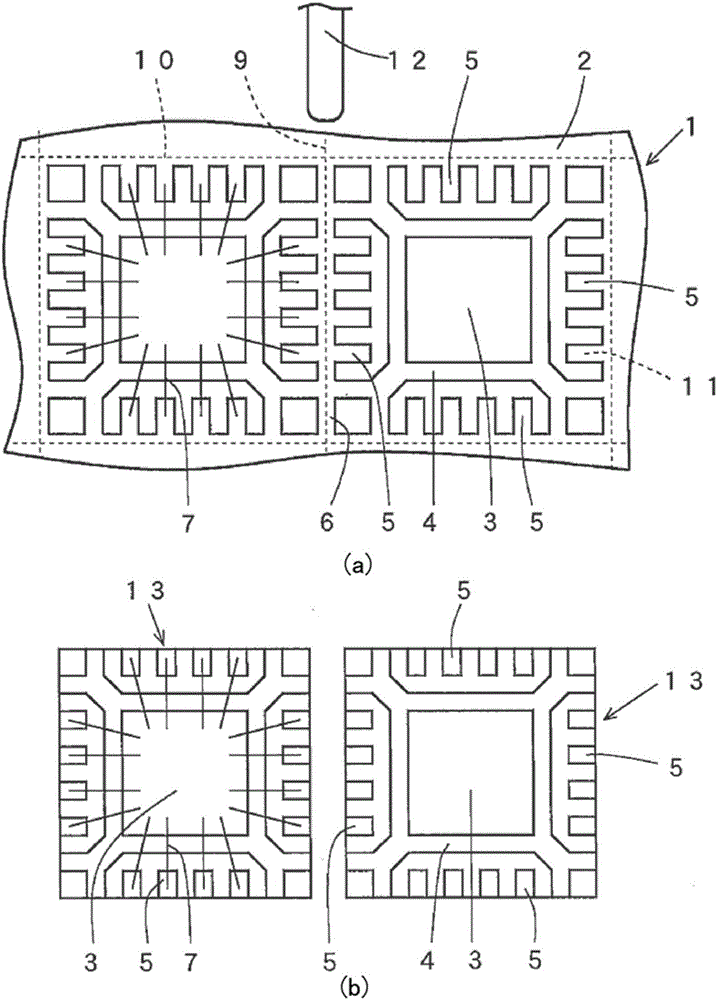

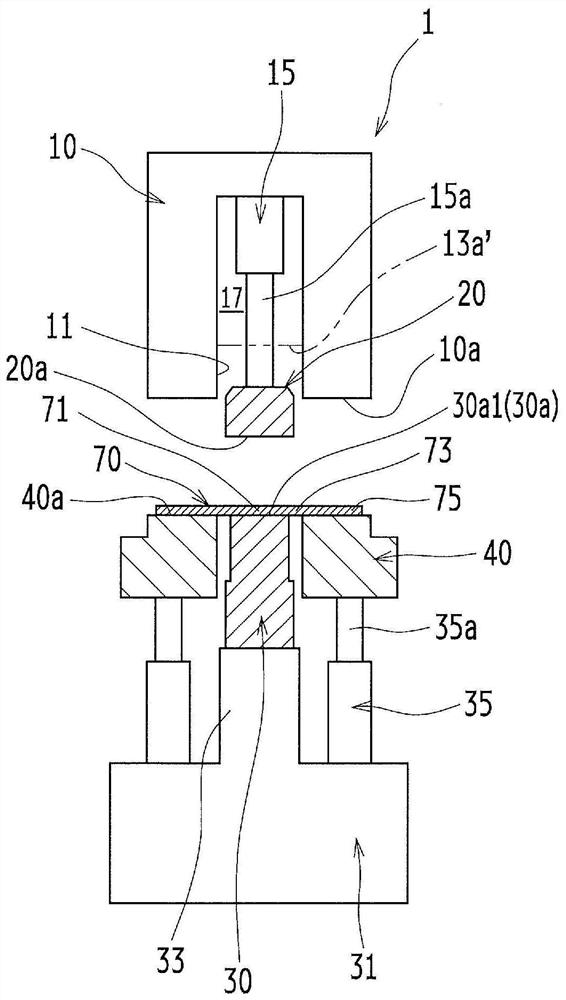

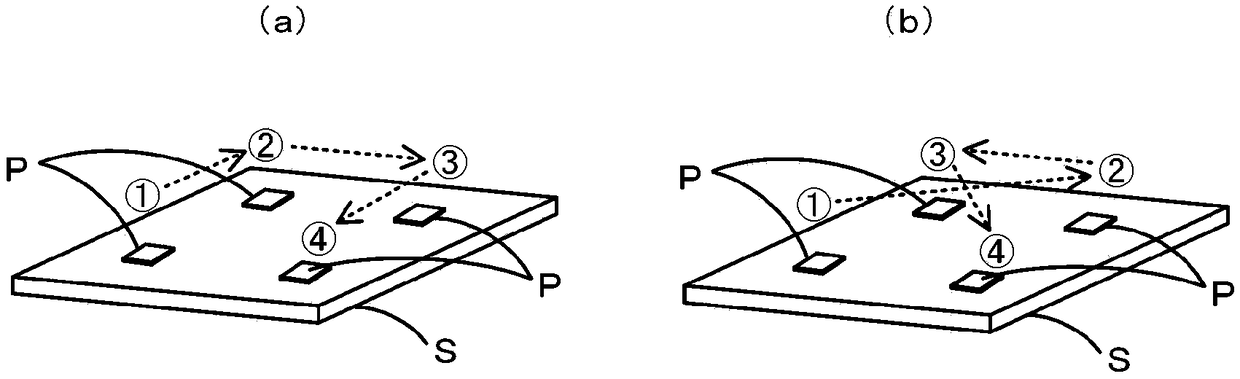

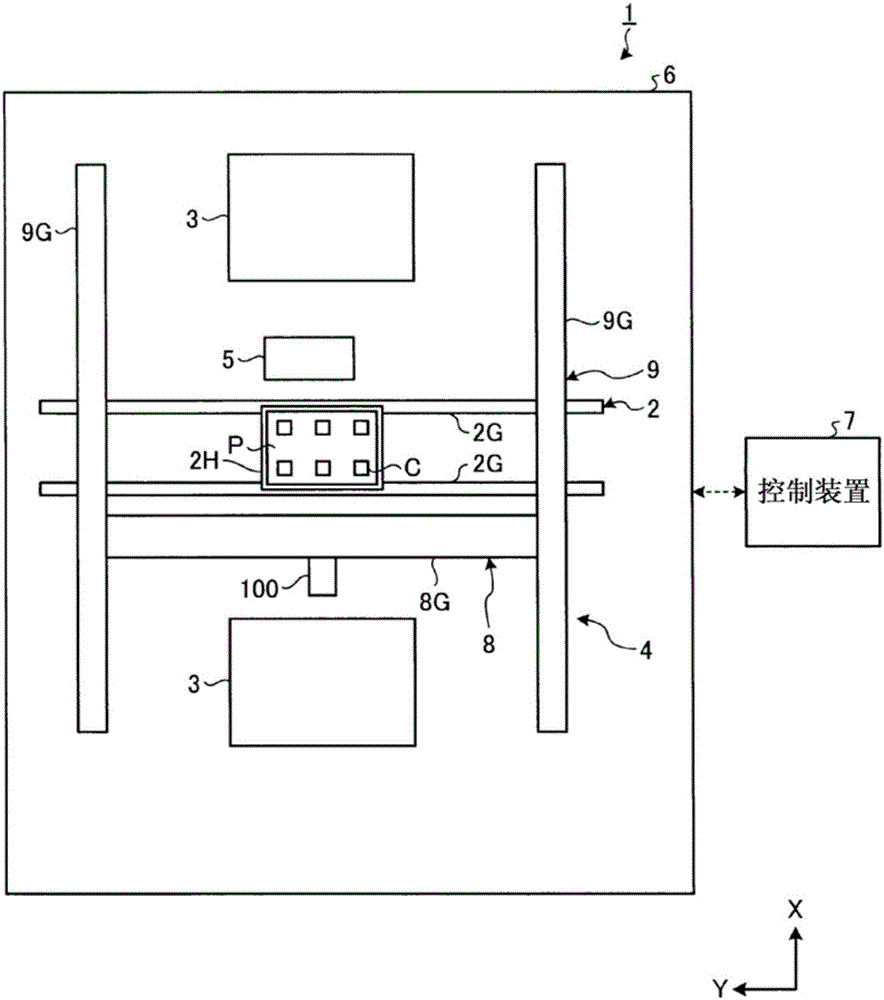

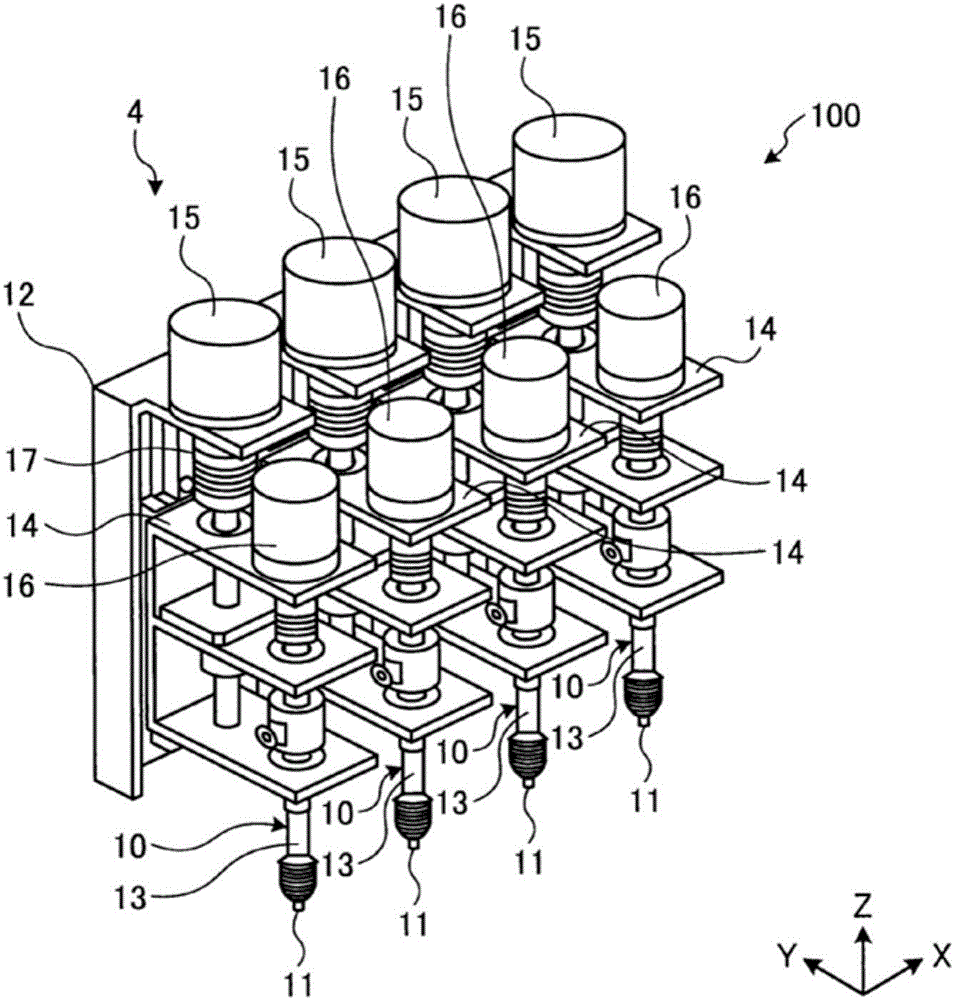

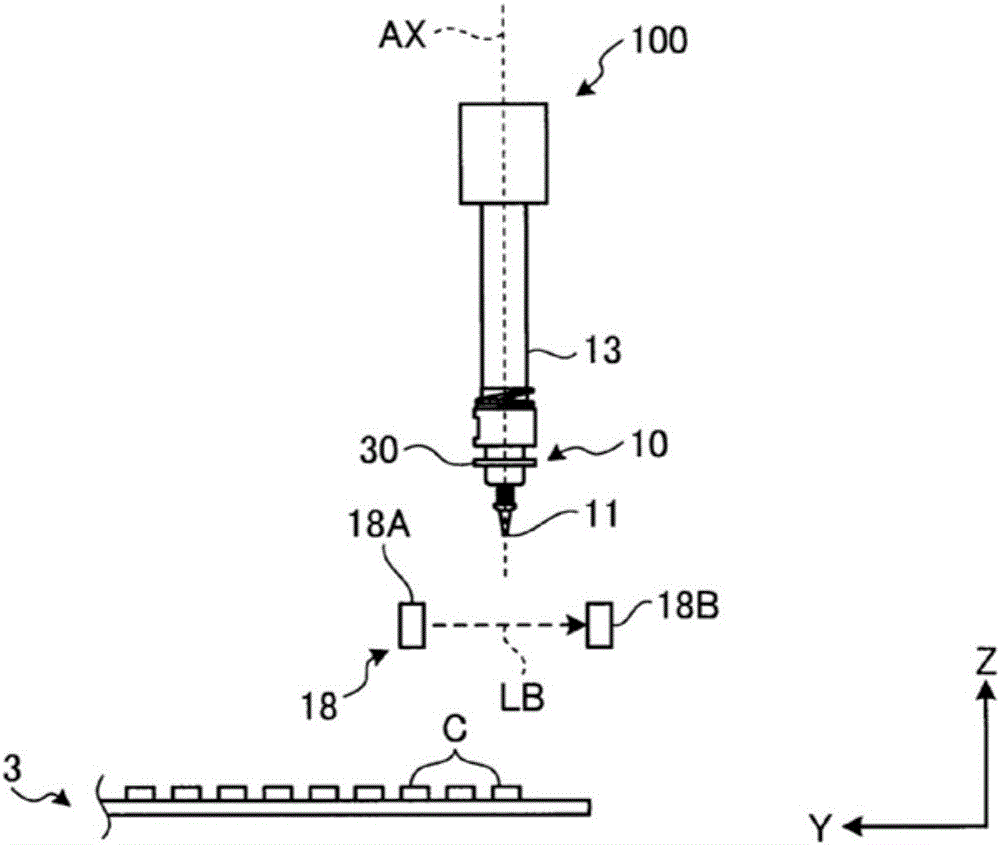

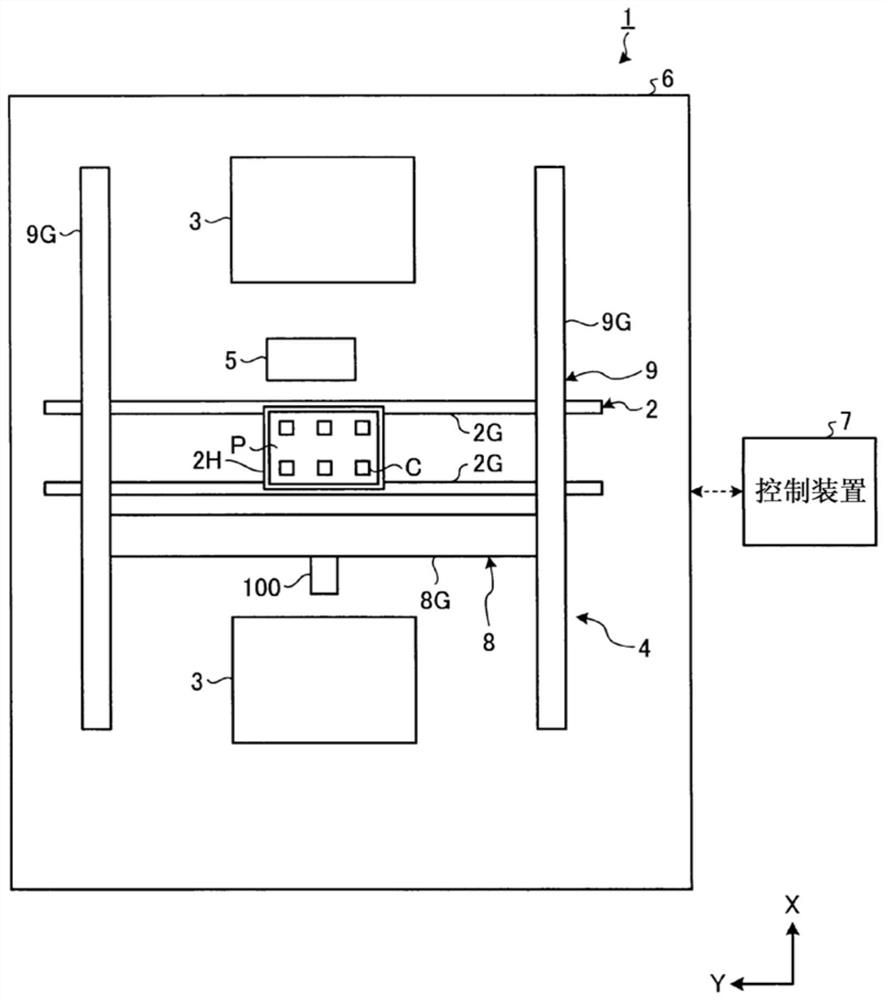

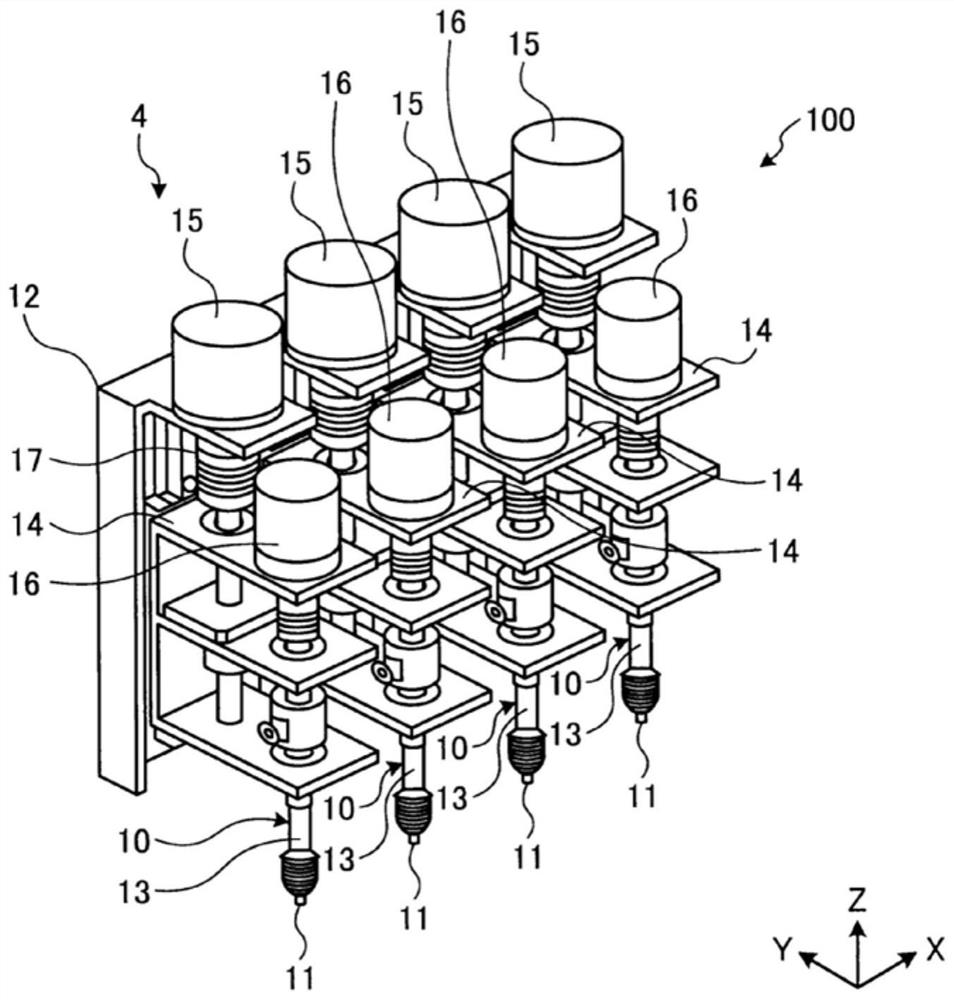

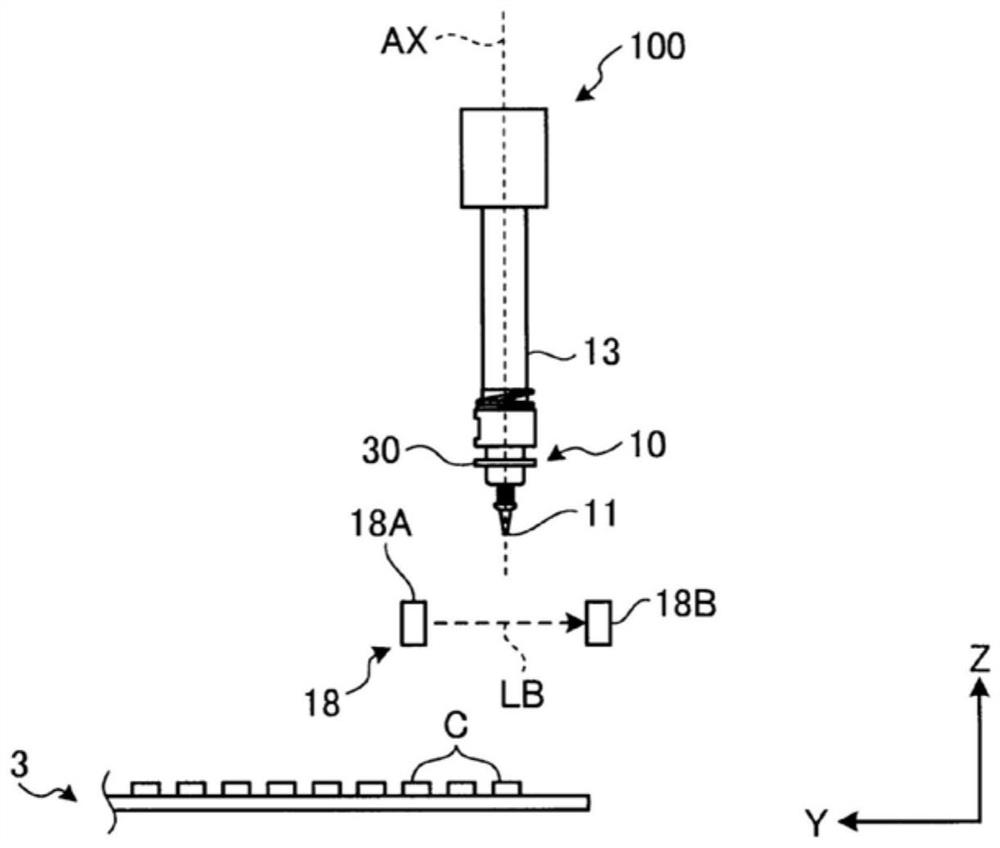

Element installation apparatus and method thereof

ActiveCN103327802ASuppression of productivity dropRemove restrictionsElectrical componentsBarcodeEngineering

The invention provides an element installation apparatus and a method thereof.A substrate barcode on a bar-shaped substrate is properly identified, The element installation apparatus (1) clamps a plurality of positions on a circuit substrate (5) along X direction, an electric element (20) is loaded at each stop position, before the element is loaded, the coordinate information of the substrate barcode (B) is obtained through a production programme, and the stop position of the substrate barcode (B) is identified employing a loading head camera (22). The circuit substrate (5) is clamped at the stop position, the substrate barcode is identified employing the loading head camera (22), and element loading action is performed at each stop position.

Owner:JUKI CORP

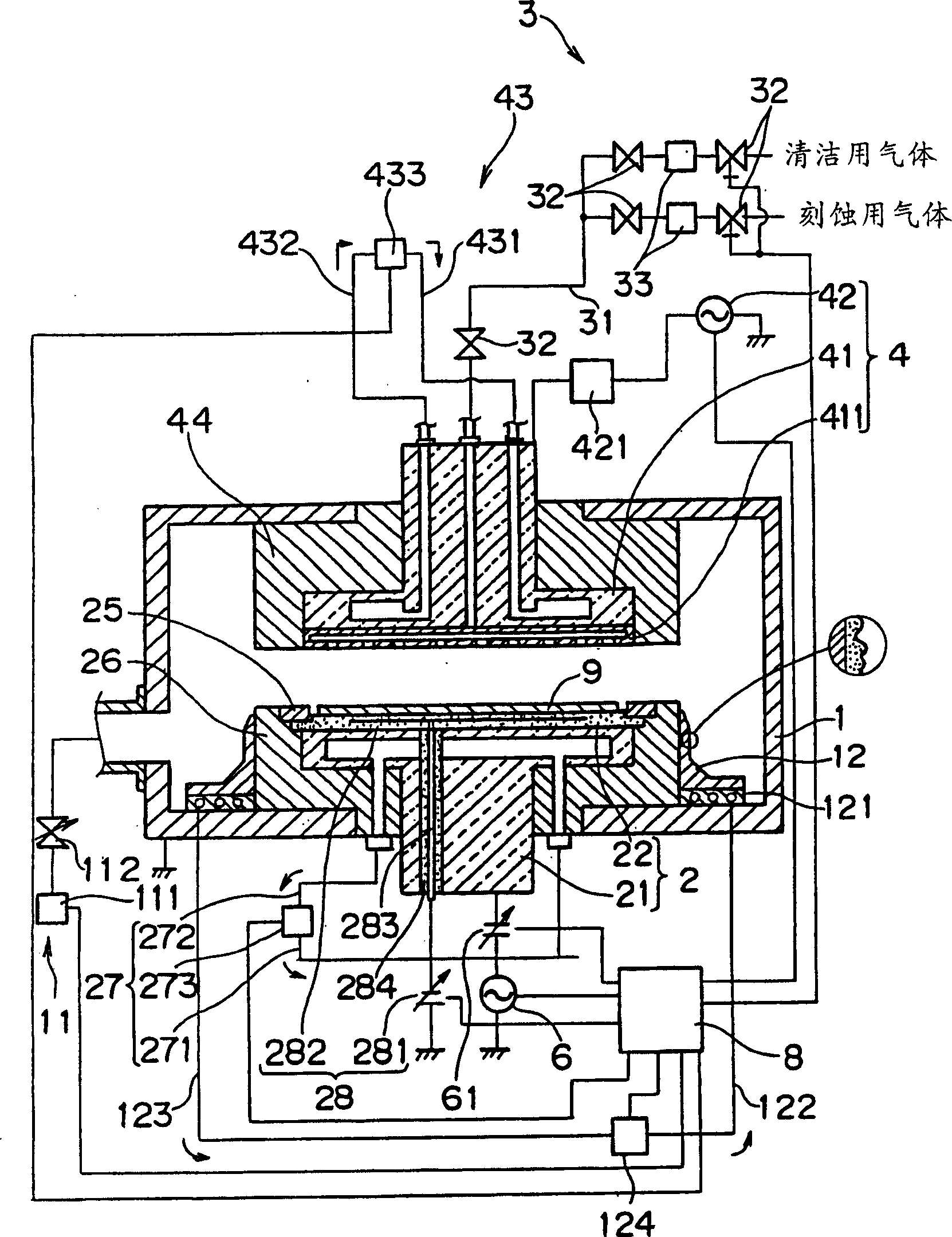

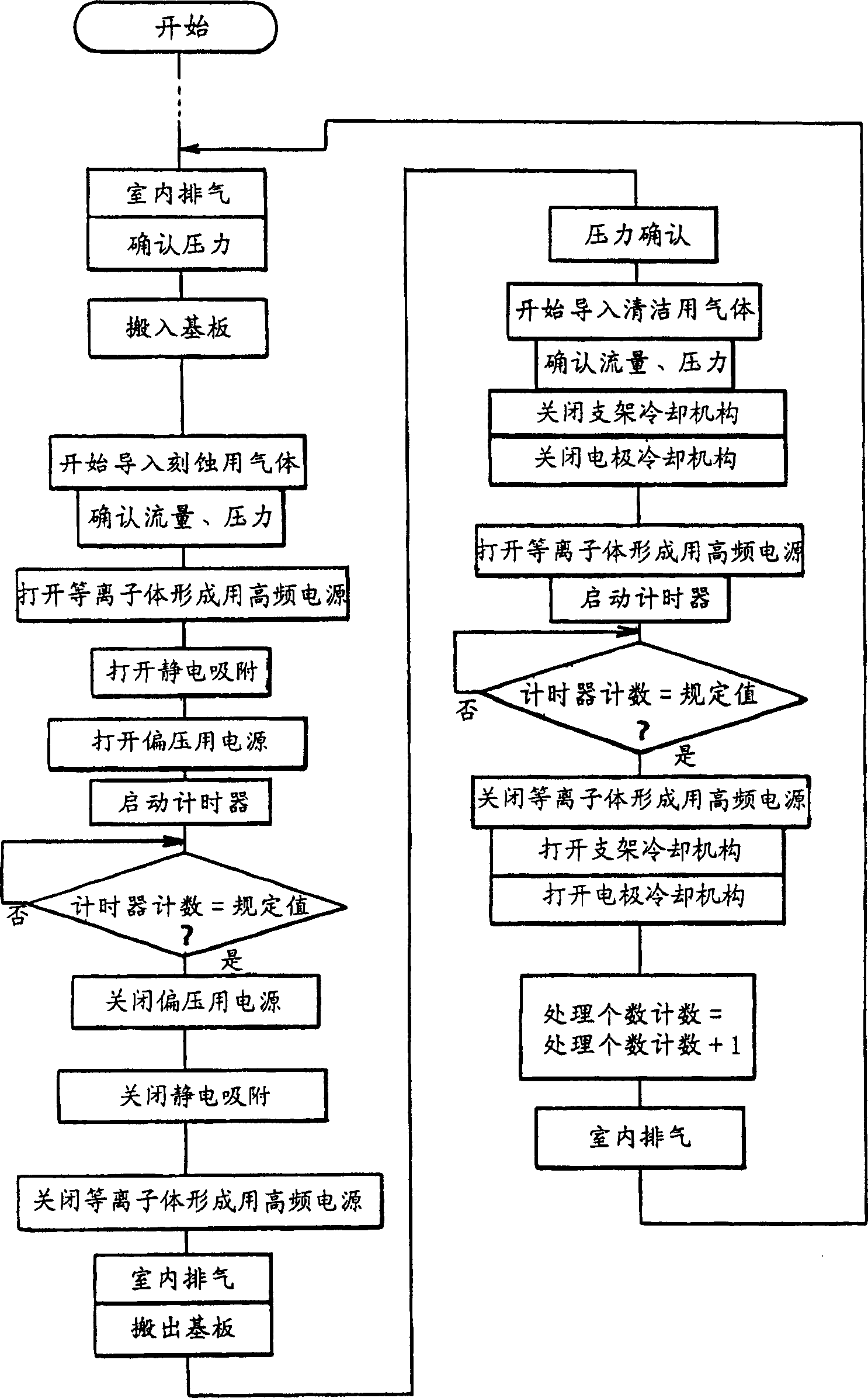

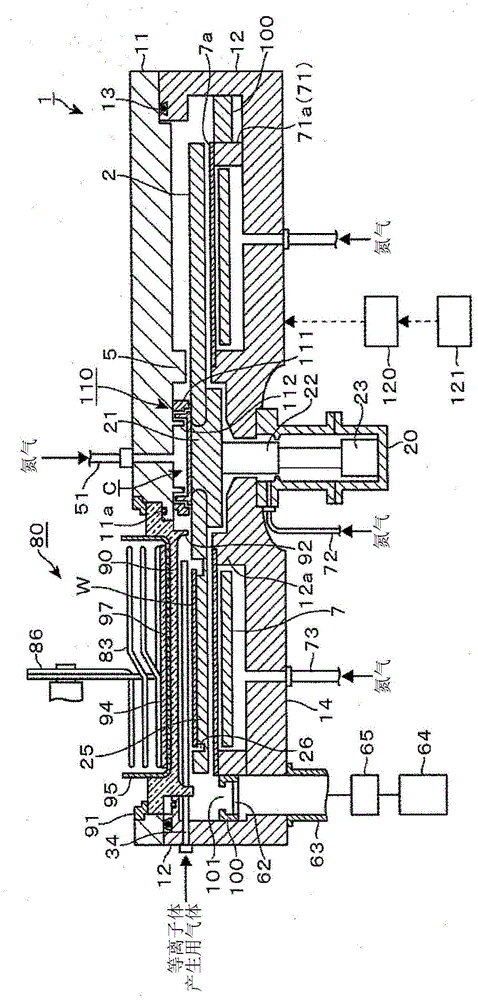

Insulative film etching device

InactiveCN1427457AReduce faults such as circuit abnormalitiesImprove pass rateSemiconductor/solid-state device manufacturingEtchingPhysics

This application discloses an insulation-film etching system that etches an insulator film on a substrate by a species produced in plasma. While the substrate (9) is held by a substrate holder (2) provided in a process chamber (1), an etching gas is introduced into the chamber (1) by a gas inlet system (3). An insulating film on the surface of the substrate (9) is etched by the action of an active species and ions contained in a plasma formed by a plasma forming means (4). After completion of the etching, a control section (8) takes out the substrate (9) from the process chamber (1) by a transport robot (51) and evacuates the chamber (1) by an exhaust system. Then the section (8) removes films deposited on exposed surfaces in the chamber (1) by the action of a plasma formed by the plasma forming means (4) by introducing a cleaning gas by the gas inlet system (3). A cooling trap (12) provided at a level lower than the substrate holding surface of the substrate holder (2) is forcibly cooled and causes many films to deposit by collecting gas molecules which tend to deposit. The trap (12) is replaceable and the surface of the trap (12) has irregularity sections to prevent the peeling of deposited films. The surfaces of the irregularity sections are composed of an oxide or insulator.

Owner:ANELVA CORP

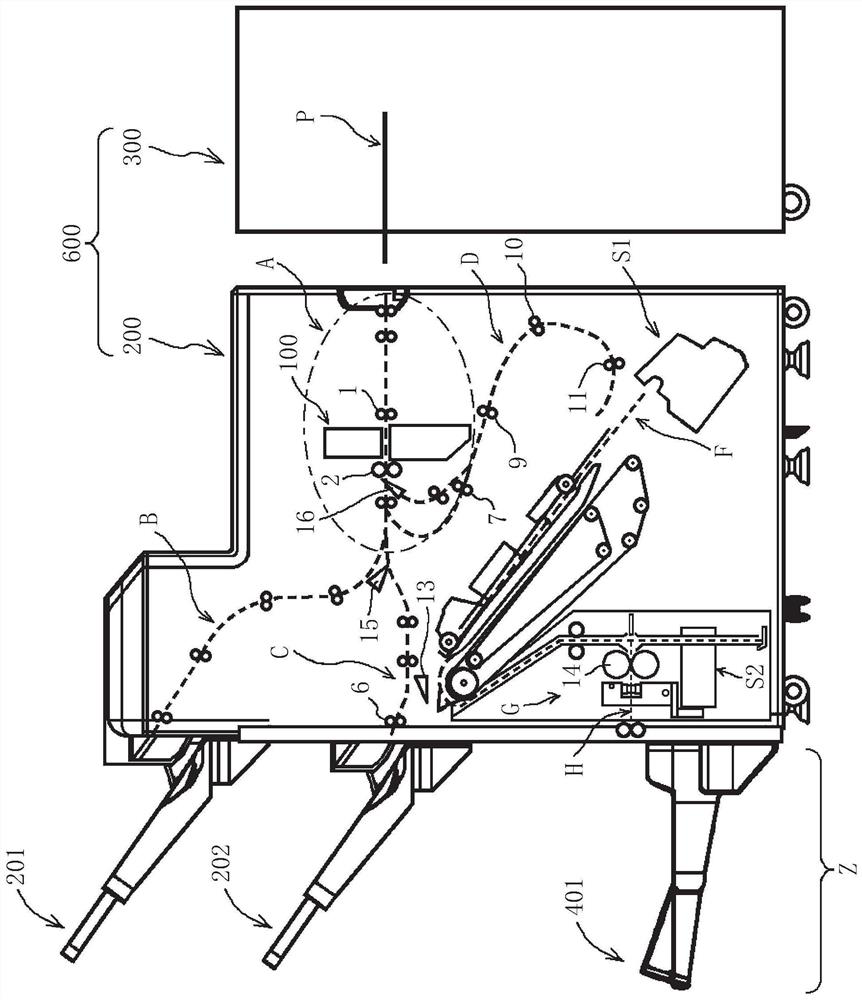

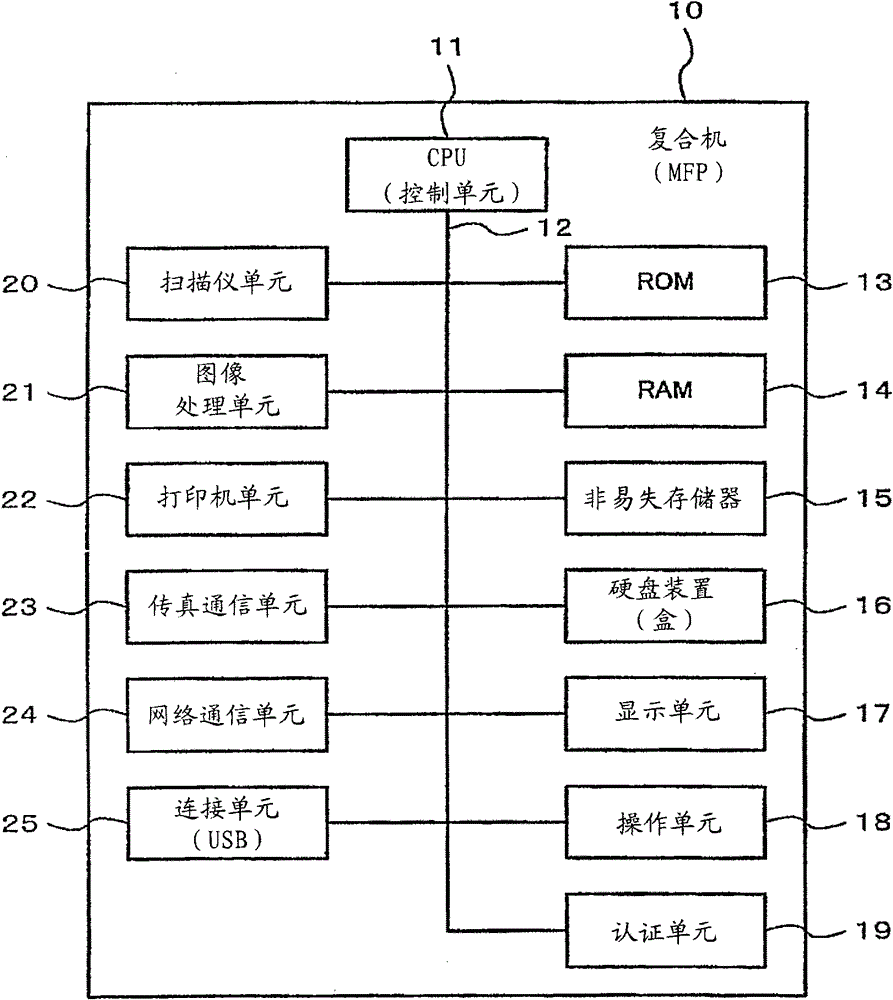

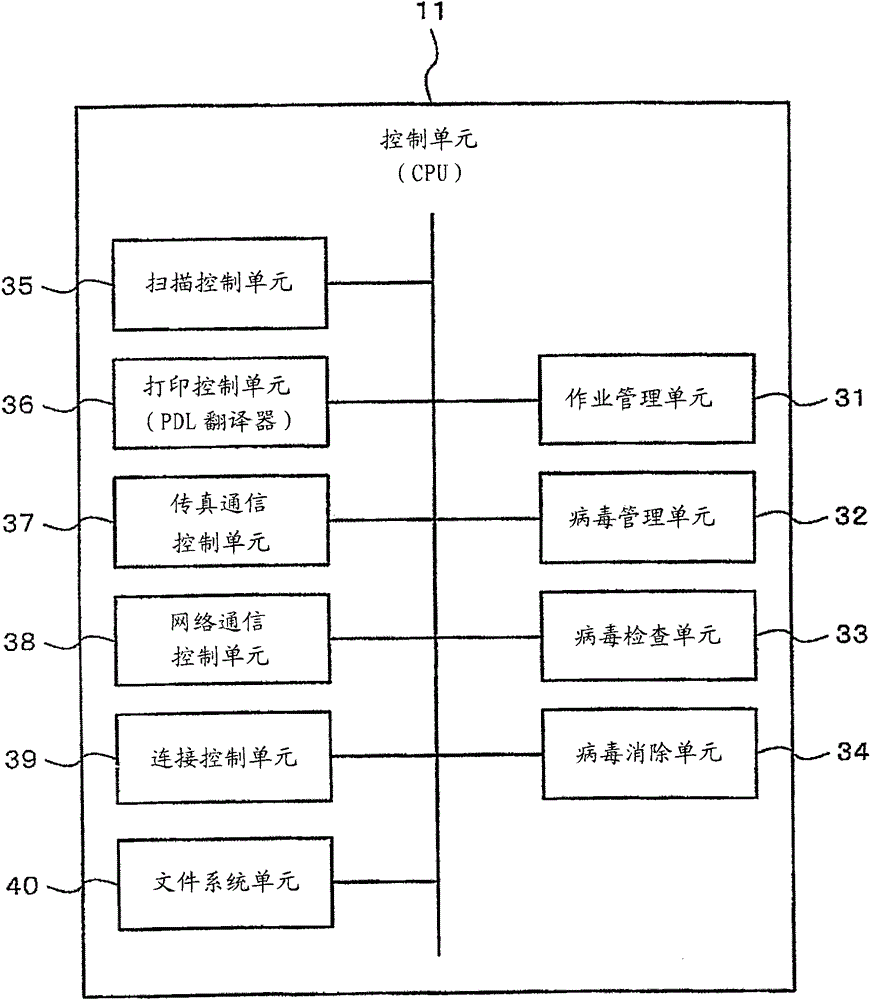

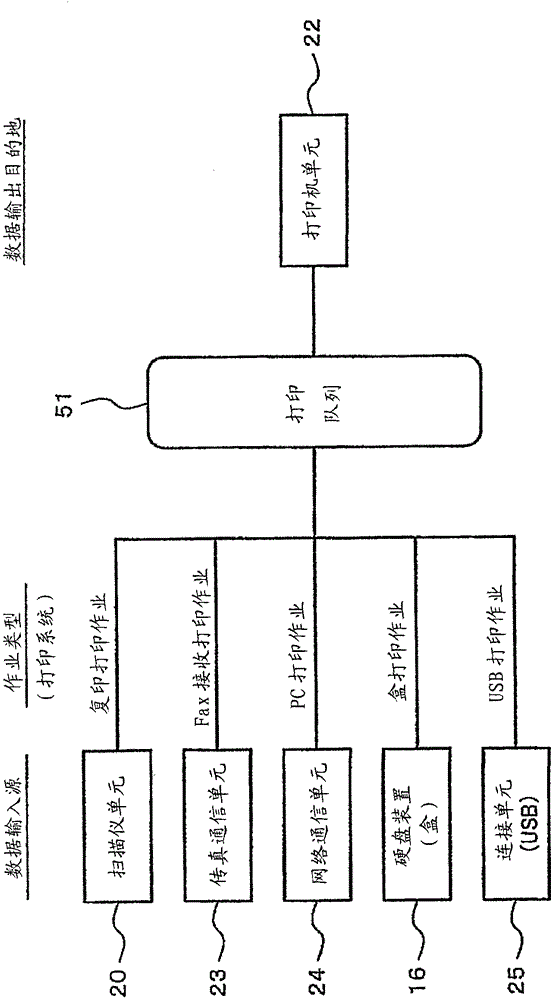

Job processing system and image processing apparatus

ActiveCN102025869AInhibition effectRestraining the drop in productivityElectrographic process apparatusPlatform integrity maintainanceImaging processingFile system

A multi function periphery includes a plurality of the modules (a scan control section 35 to file system section 40) provided corresponding to a plurality of functions, a virus check section 33 to perform the virus check with respect to the plurality of the control modules, a virus control section 32 to make the virus check section 33 to perform the virus check respectively for some control modules among the plurality of the control modules, a job administration section 31 to allow the job using only the control modules which have been confirmed not to be infected by the virus via the virus check.

Owner:KONICA MINOLTA BUSINESS TECH INC

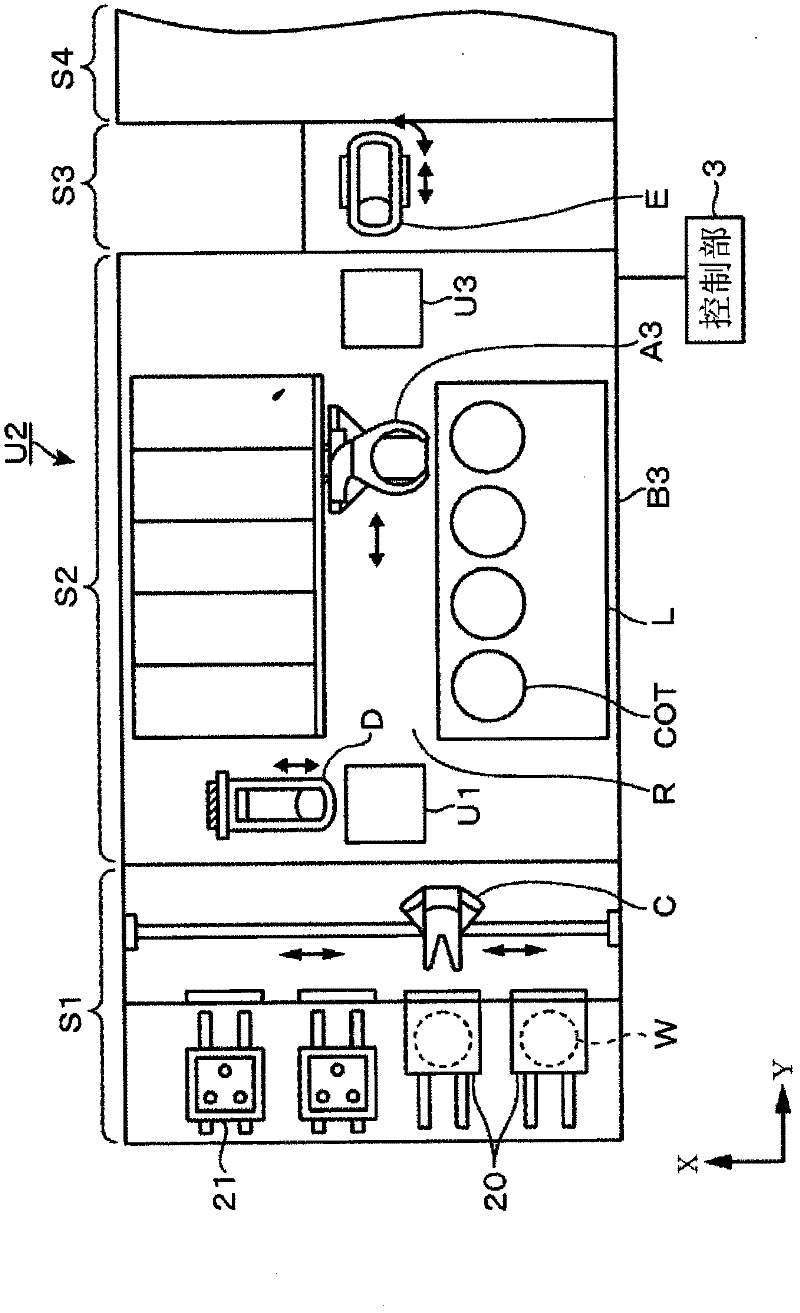

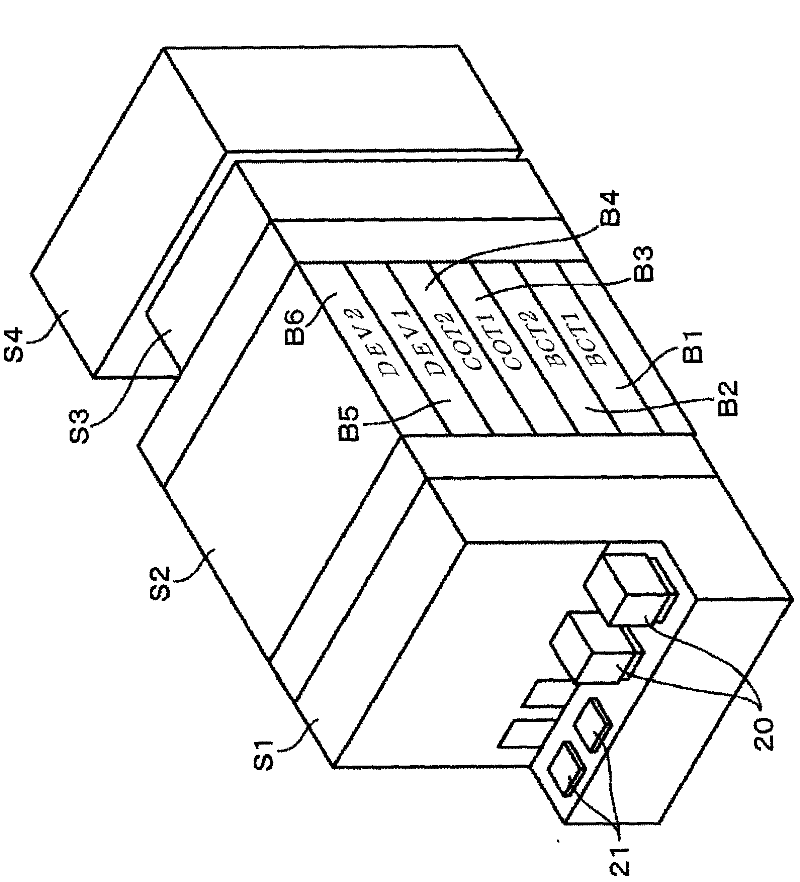

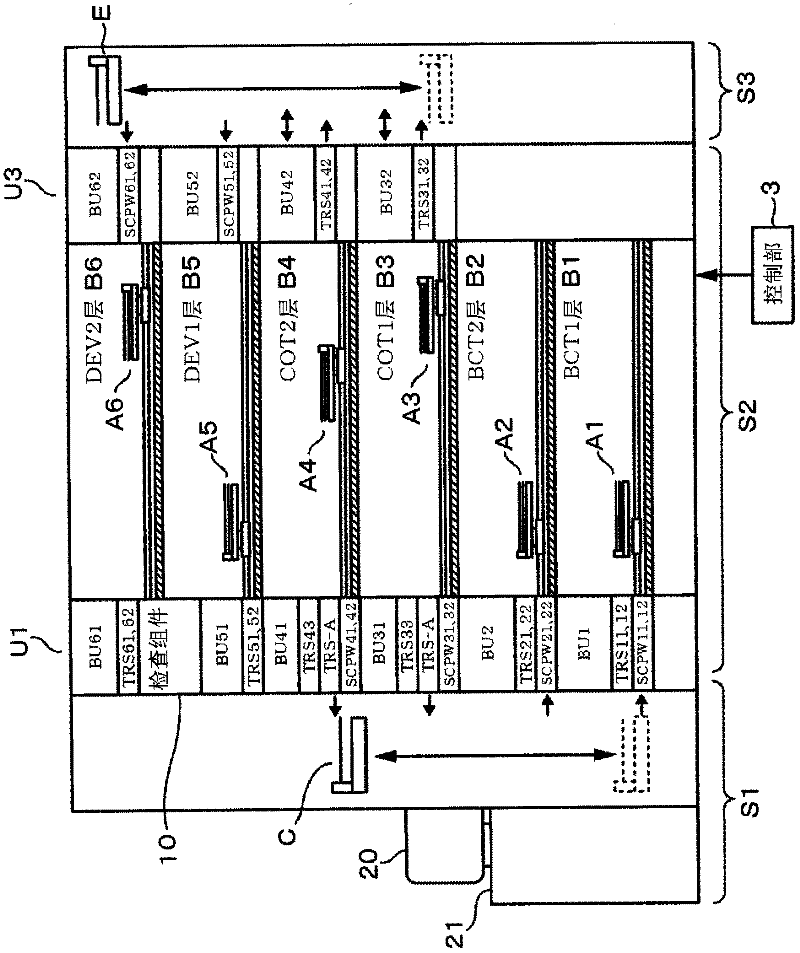

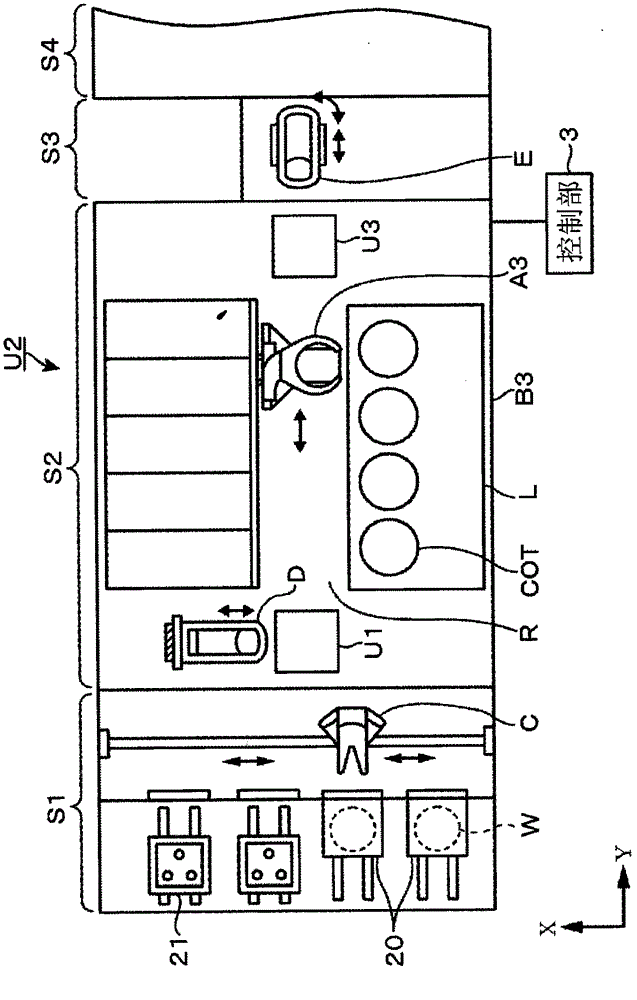

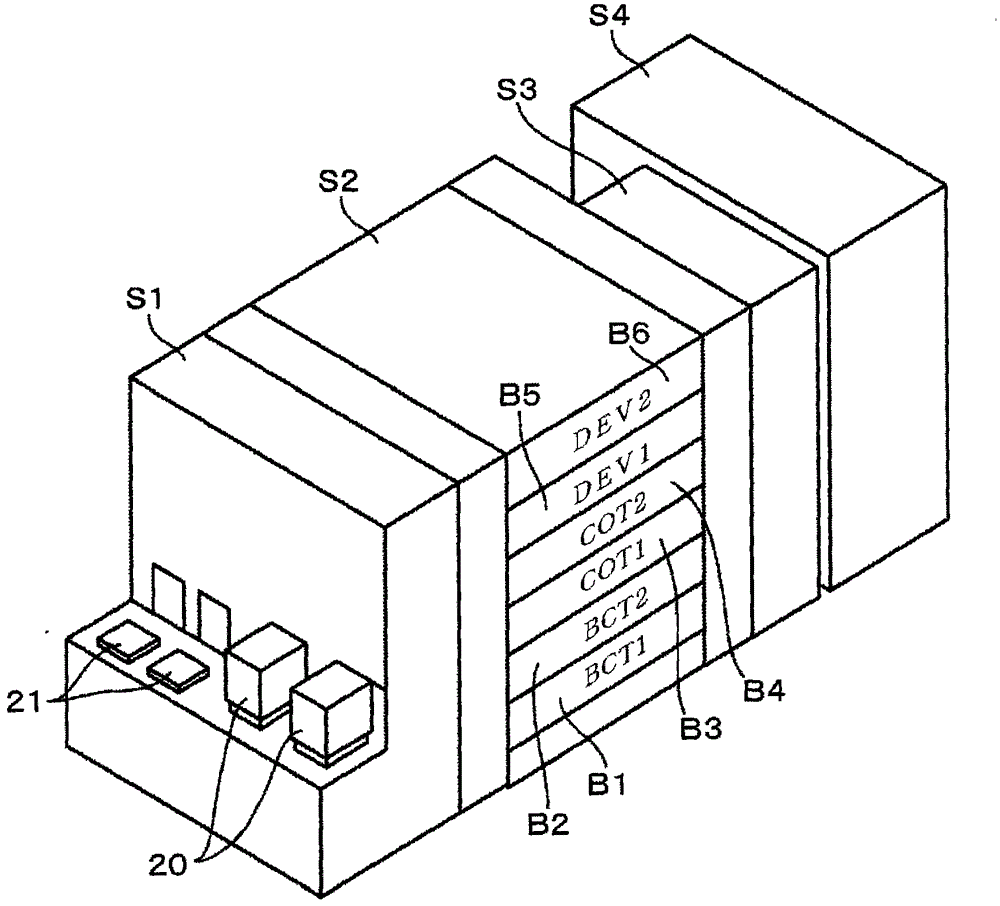

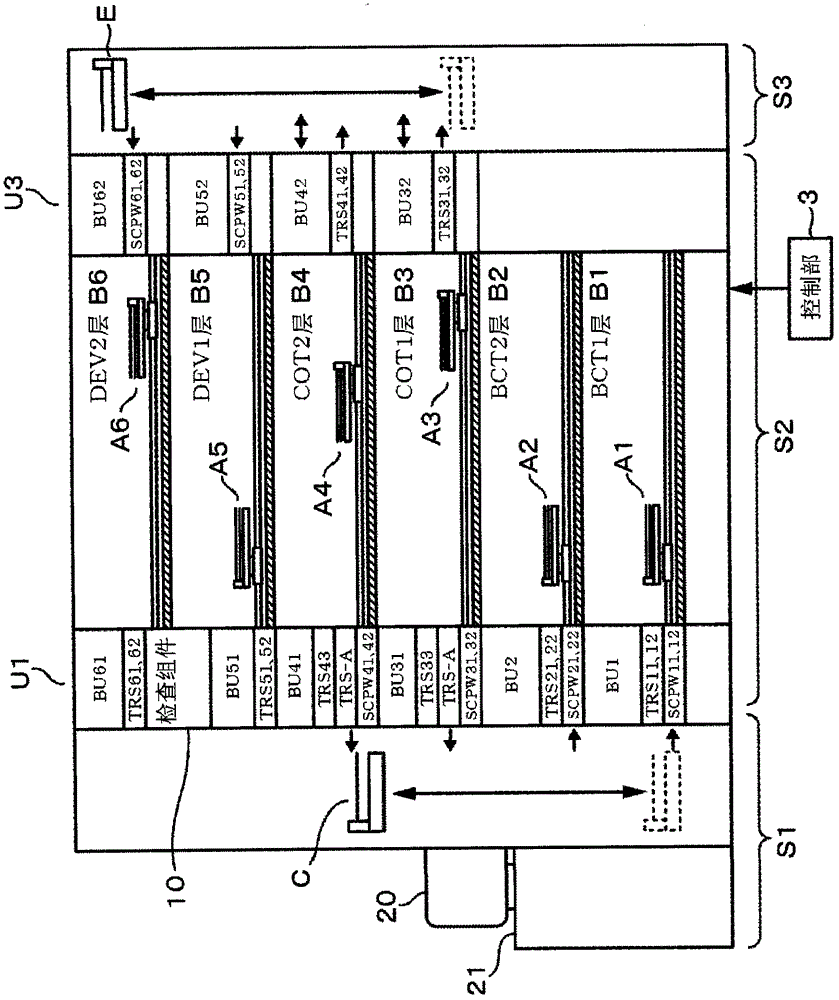

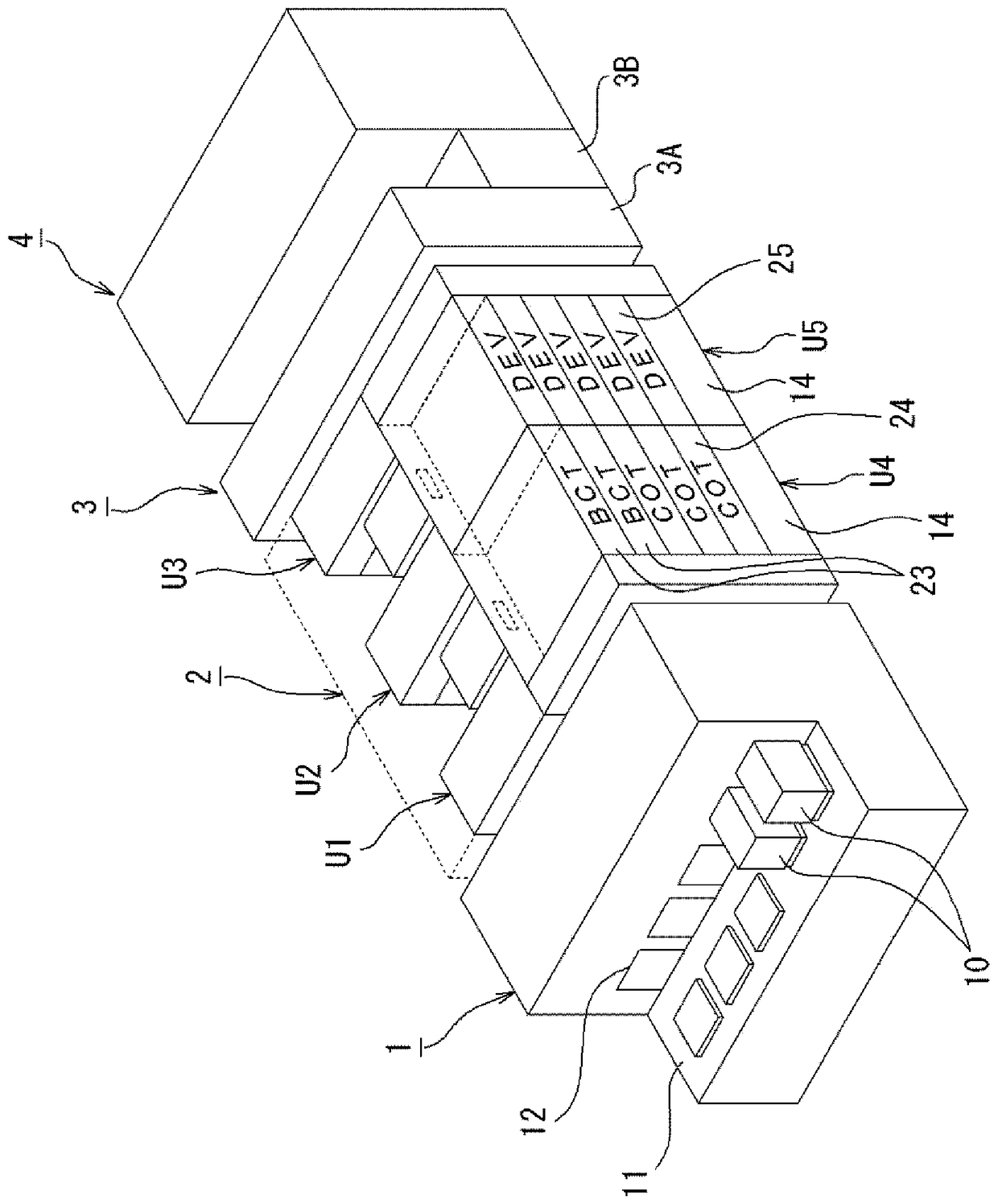

Coating and developing apparatus and developing method

ActiveCN102193342ARestraining the drop in productivitySemiconductor/solid-state device manufacturingPhotosensitive material processingTemperature controlProduction rate

The present disclosure provides a coating and developing apparatus capable of forming a liquid film of a developing solution on an entire surface of a substrate with high uniformity and achieving high throughput, and the present disclosure also provides a developing method. The coating and developing apparatus comprises: a developing module; a cleaning module; and a transfer mechanism configured to transfer a substrate developed by the developing module to the cleaning module, wherein the developing module includes: an airtightly sealed processing vessel configured to form a processing atmosphere therein; a temperature control plate that is provided in the processing vessel and mounts thereon the substrate and cools the substrate; an atmosphere gas supply unit configured to supply an atmosphere gas including mist of a developing solution to a surface of the substrate within the processing vessel, and a temperature control unit for adjusting the temperature of the temperature control plate to the temperature for making the atmosphere gas dew on the substrate. The developing module and the cleaning module can concurrently perform to obtain high throughput.

Owner:TOKYO ELECTRON LTD

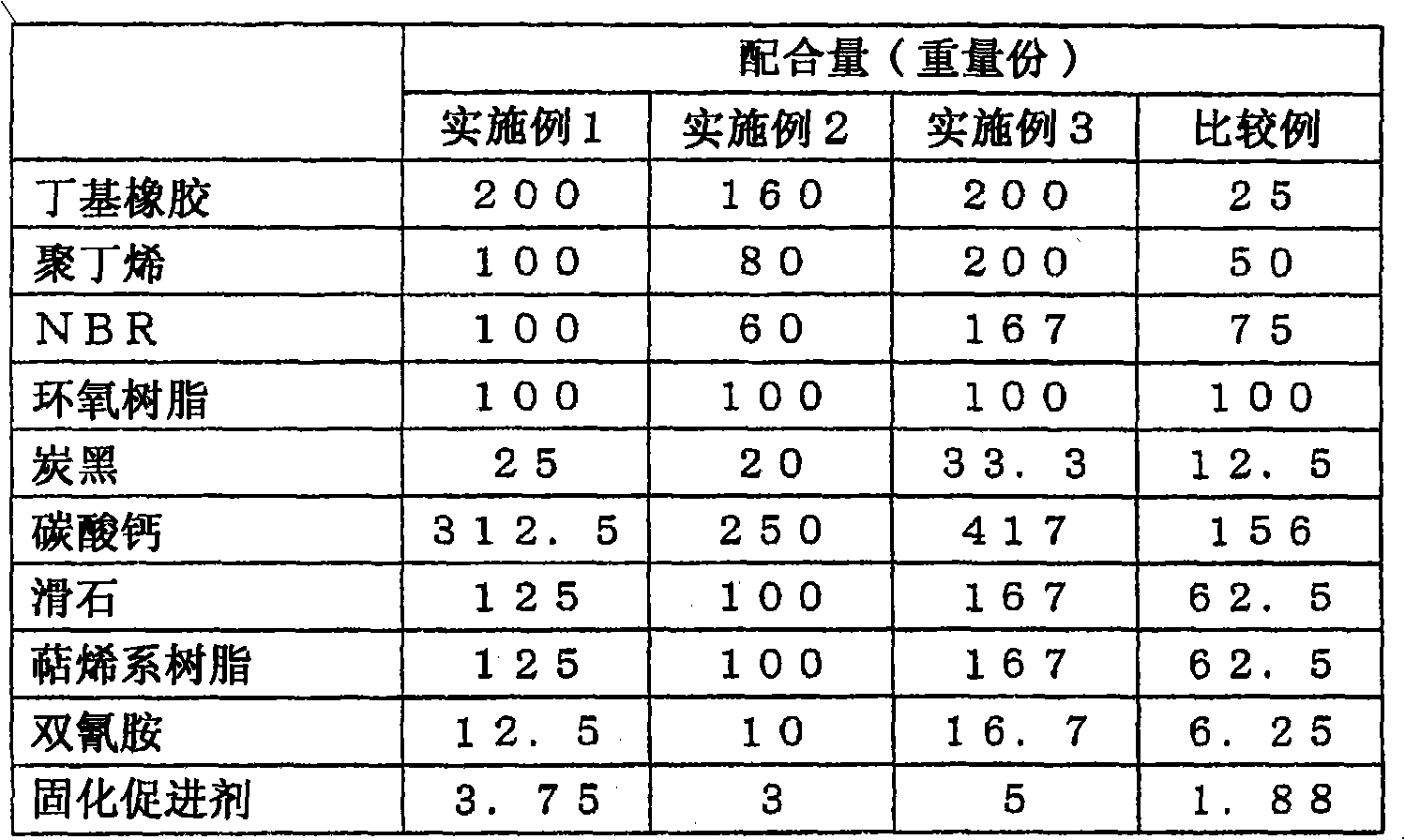

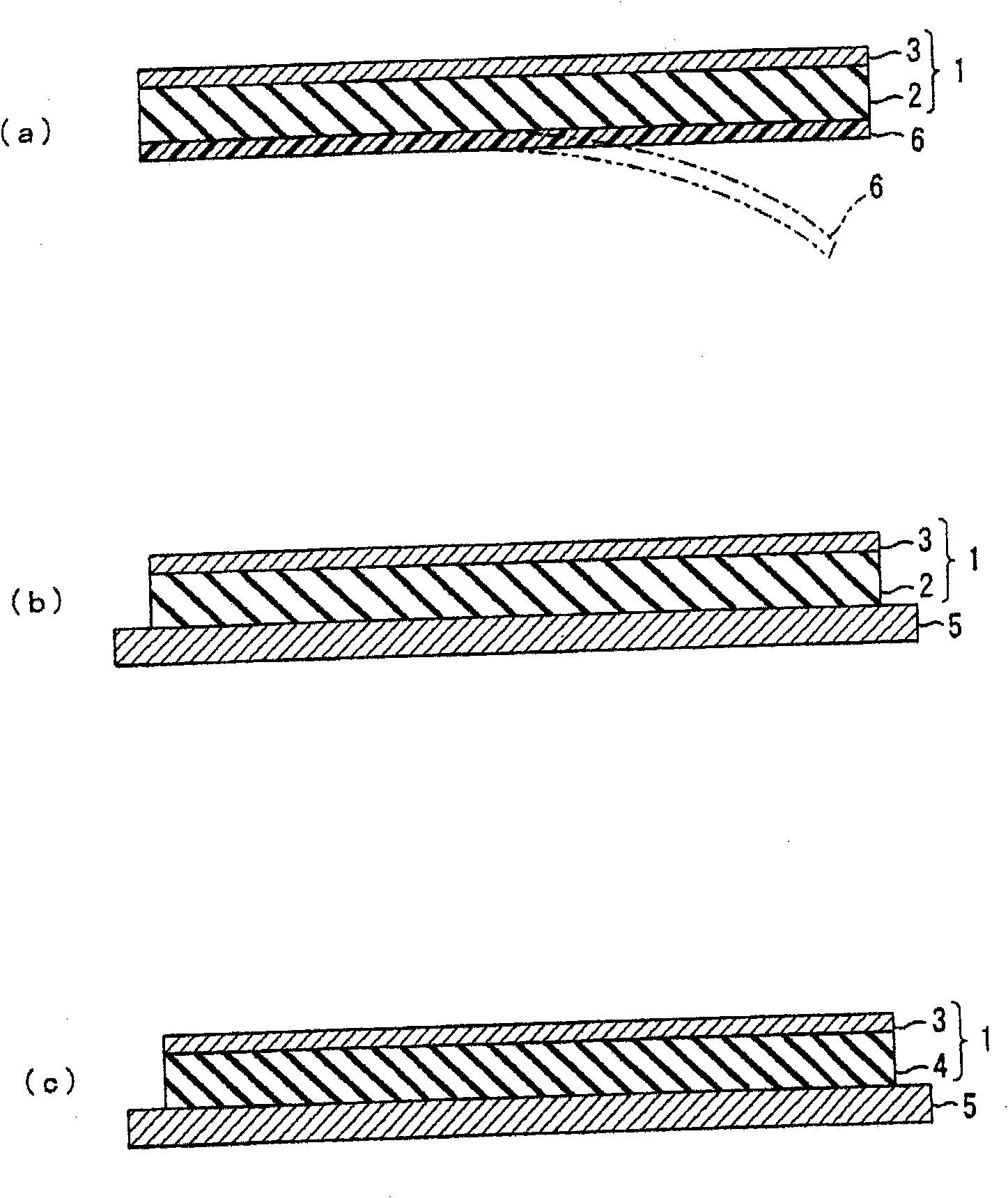

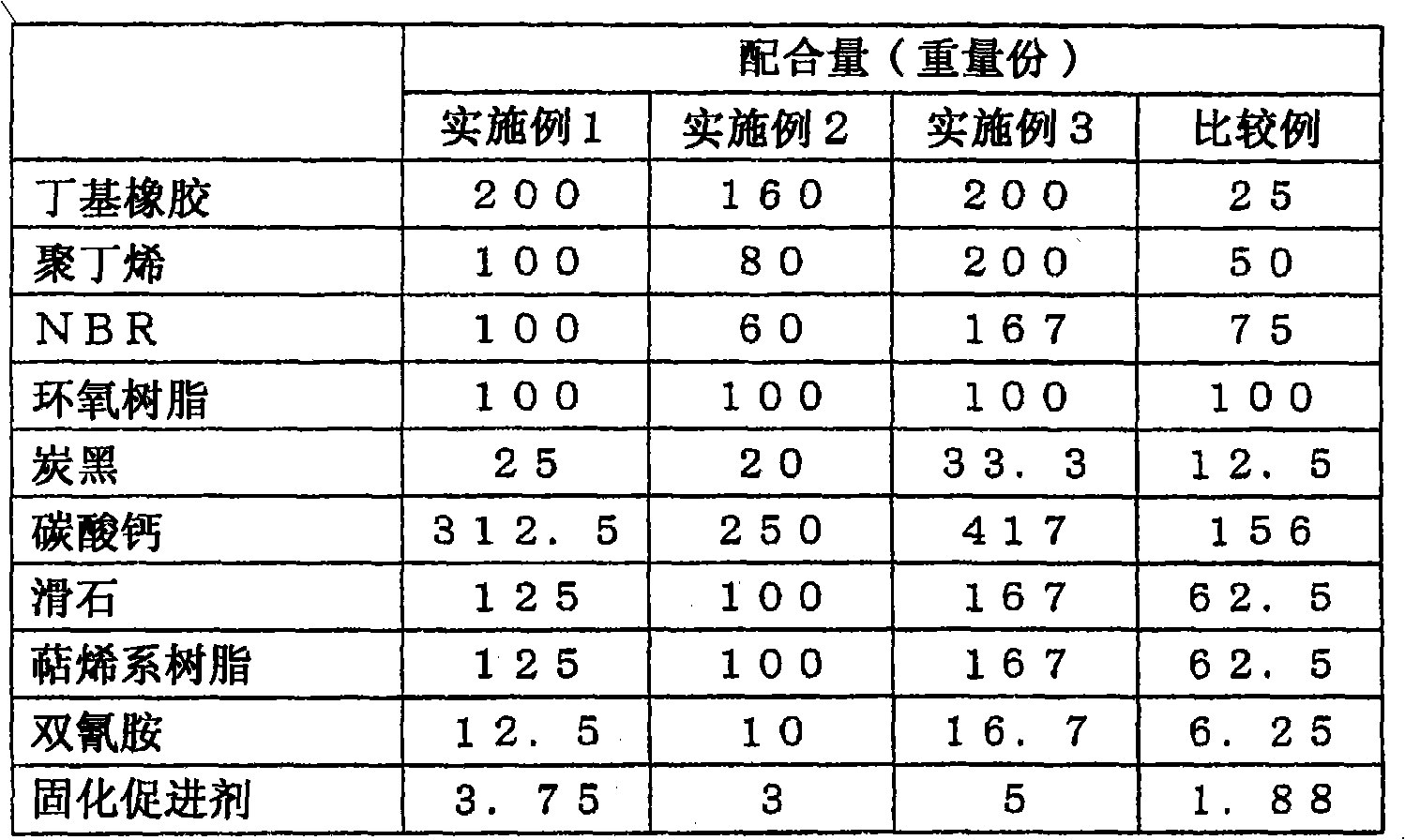

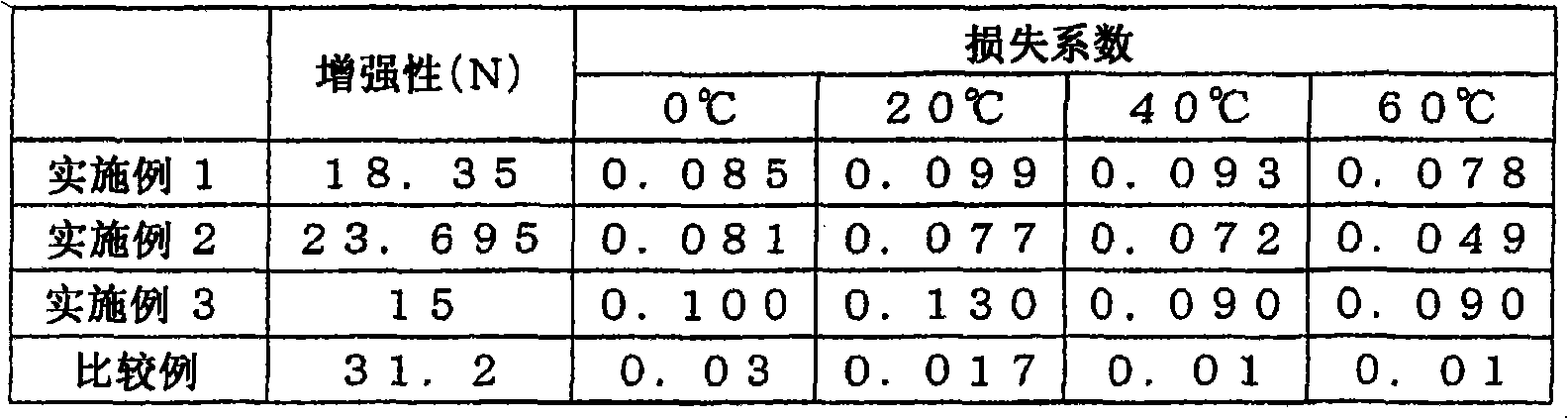

Vibration-damping reinforcing composition, vibration-damping reinforcing member, and vibration-damping reinforcing method for thin plate

InactiveCN101889051AImprove acceleration performanceImprove vibration damping effectNon-rotating vibration suppressionAdhesivesChemistryButyl rubber

Disclosed is a vibration-damping reinforcing composition containing 30-300 parts by weight of a butyl rubber, 30-300 parts by weight of an acrylonitrile-butadiene rubber, 100 parts by weight of an epoxy resin, and 0.5-30 parts by weight of an epoxy resin curing agent.

Owner:NITTO DENKO CORP

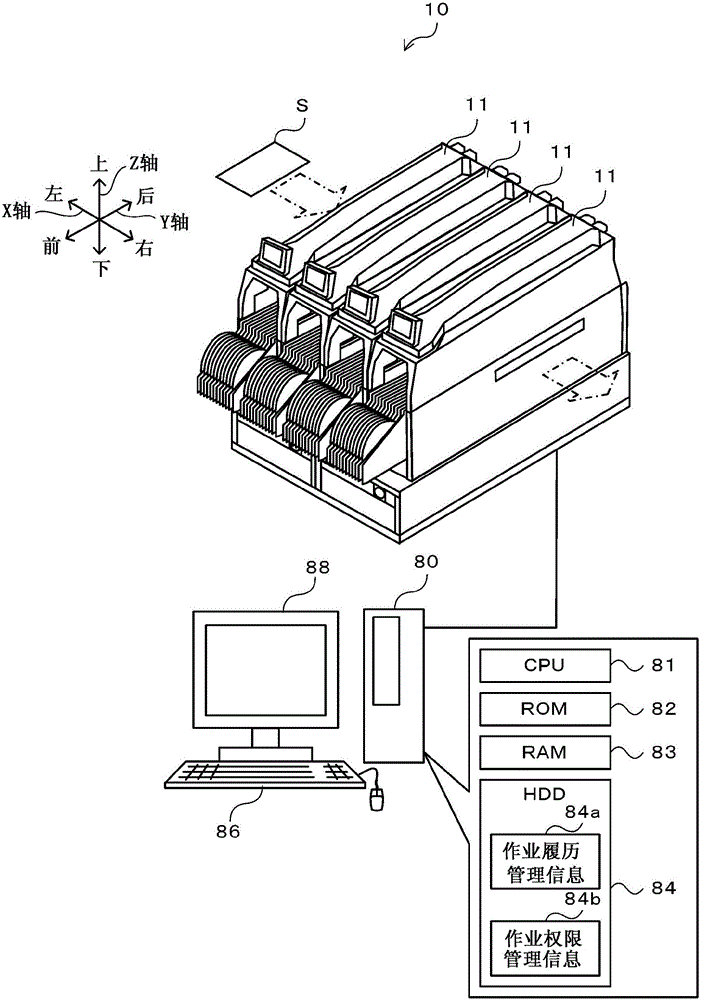

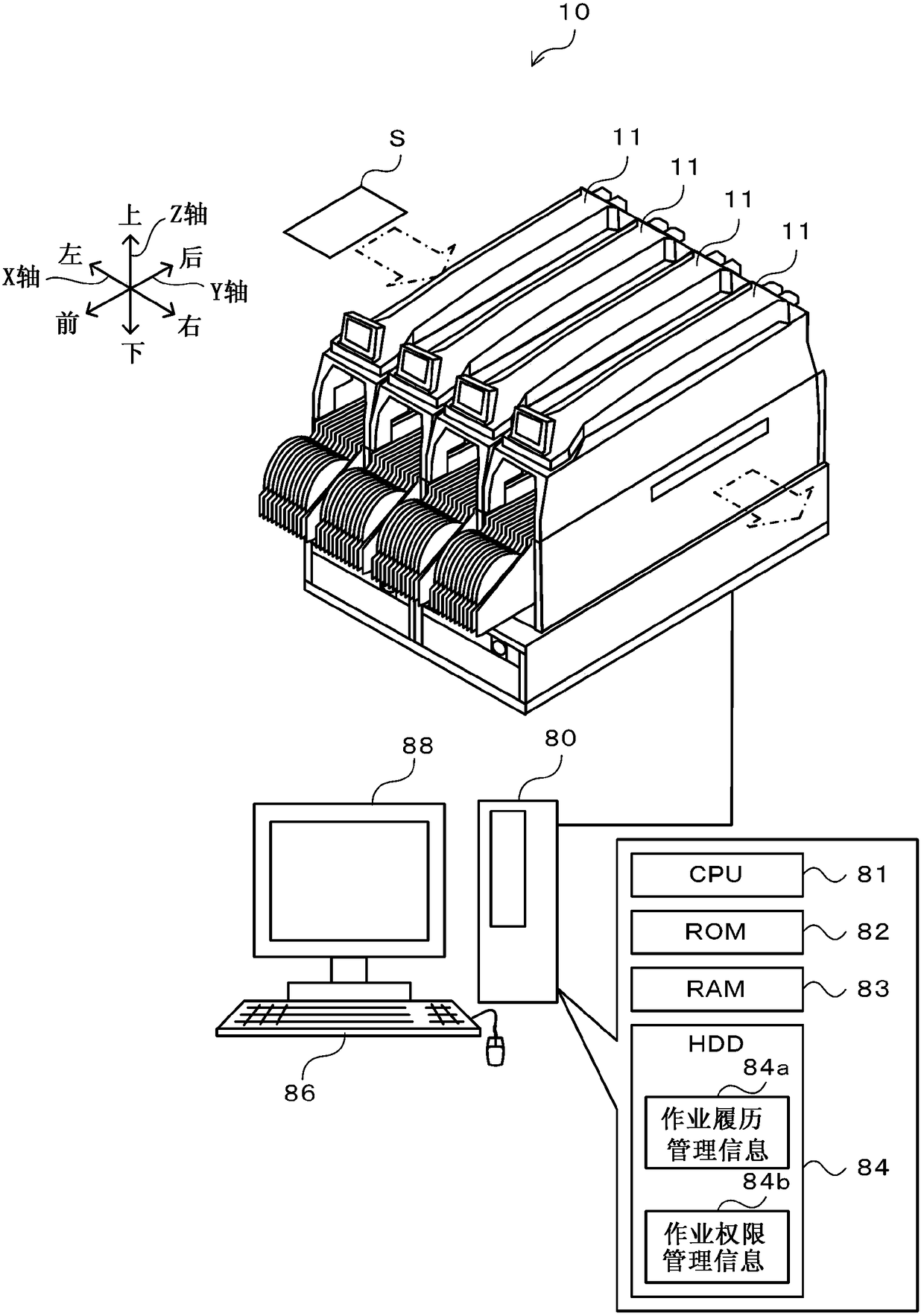

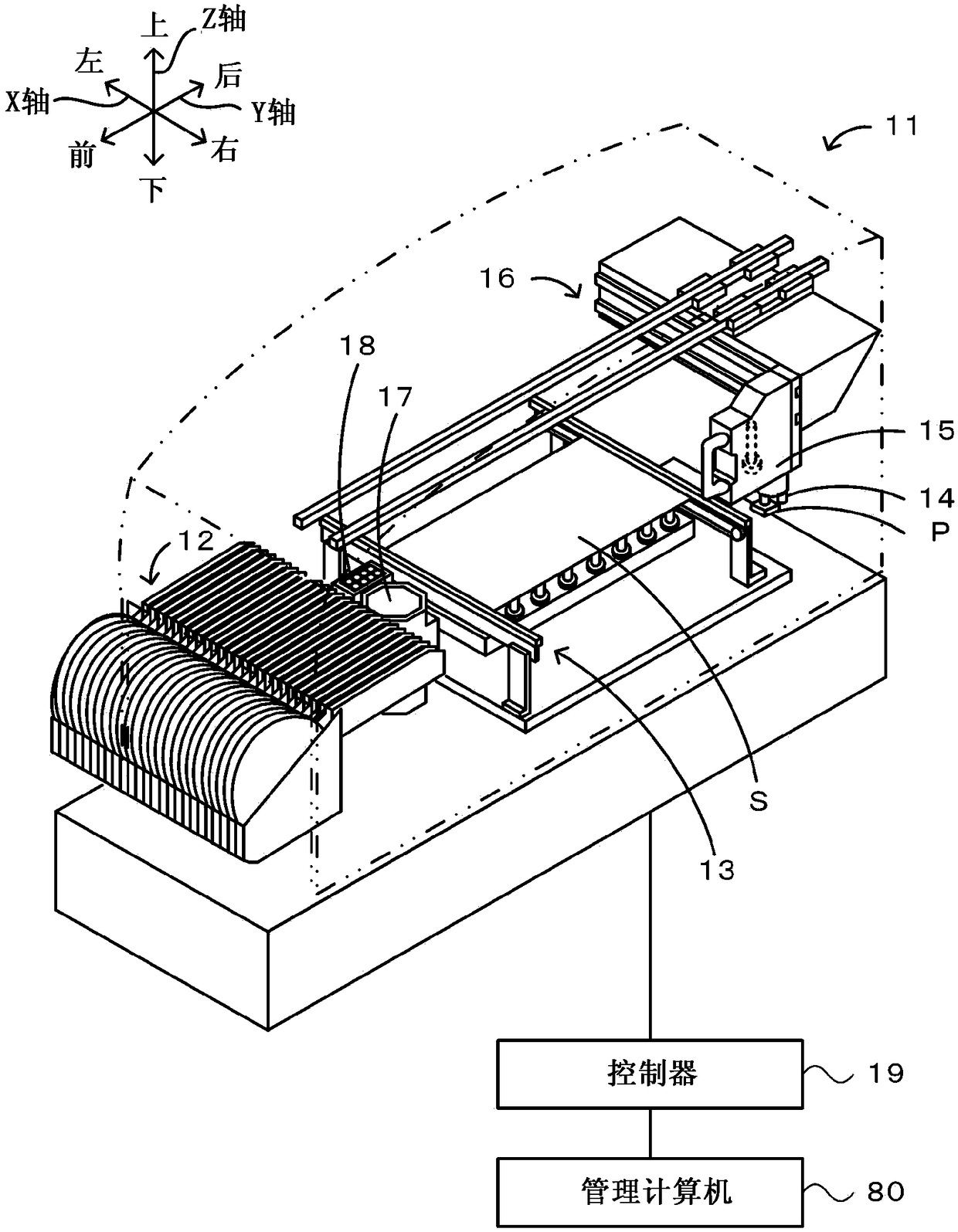

Production system

ActiveCN106415418AAvoid repeated executionRestraining the drop in productivityComputer controlRegistering/indicating working of machinesProduction rateIndustrial engineering

When a drop in productivity has occurred (S230), a management computer of a mounting system identifies a worker and a work type from work history (S240), reads a management value (P) of the identified worker in performing the identified work type (S250), and increments the management value (P) by one (S260). Then, upon determining that the management value (P) is equal to or greater than a second threshold value (P2) (S310), the management computer of the mounting system imposes a restriction on the identified worker in performing the identified work type (S340). Consequently, a drop in productivity due to repetition of work by the same worker can be suppressed.

Owner:FUJI KK

Substrate processing apparatus and substrate processing method

ActiveCN102386119ASuppression of productivity dropShorten the timeSemiconductor/solid-state device manufacturingSpecial surfacesProduction rateEngineering

The present disclosure relates to a substrate processing apparatus and a substrate processing method suppressing deterioration of a throughput when a module forming a multi-component is disabled. When a module is disabled, a substrate is provided to a carry-in module capable of placing the wafers most rapidly in the plurality of unit blocks and the substrates are sequentially transported to the module group by the transportation means to be delivered to the carry-out module according to a providing sequence of the substrate to the carry-in module in each of the plurality of unit blocks. In particular, the substrates are extracted from the carry-out module according to a providing sequence of the substrate to the carry-in module and transported to a rear module or a substrate placing part. Thereafter, the substrates are transported to the rear module from the carry-out module or the substrate placing part according to a predetermined sequence in which the substrate is provided to the carry-in module in a normal state.

Owner:TOKYO ELECTRON LTD

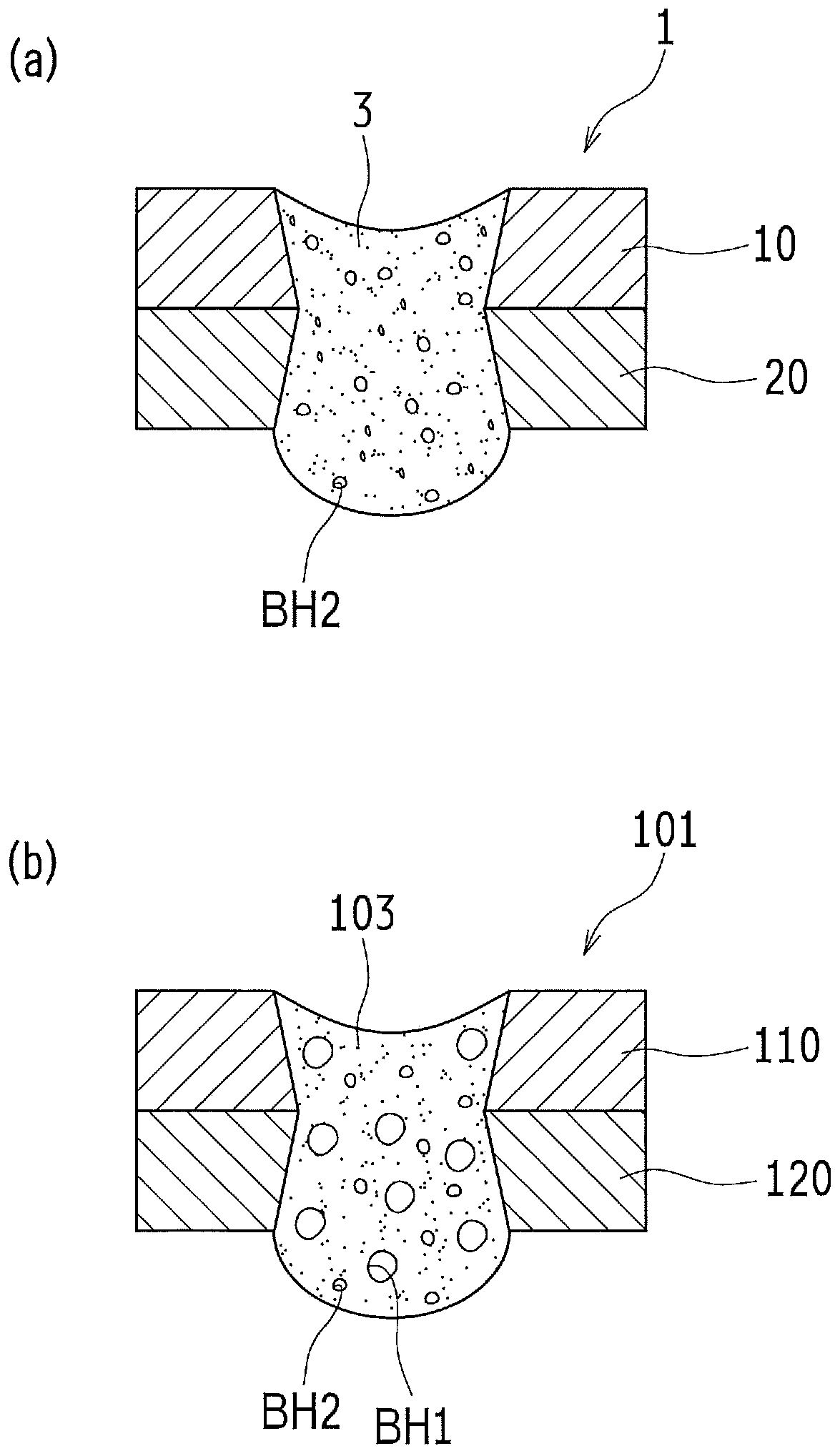

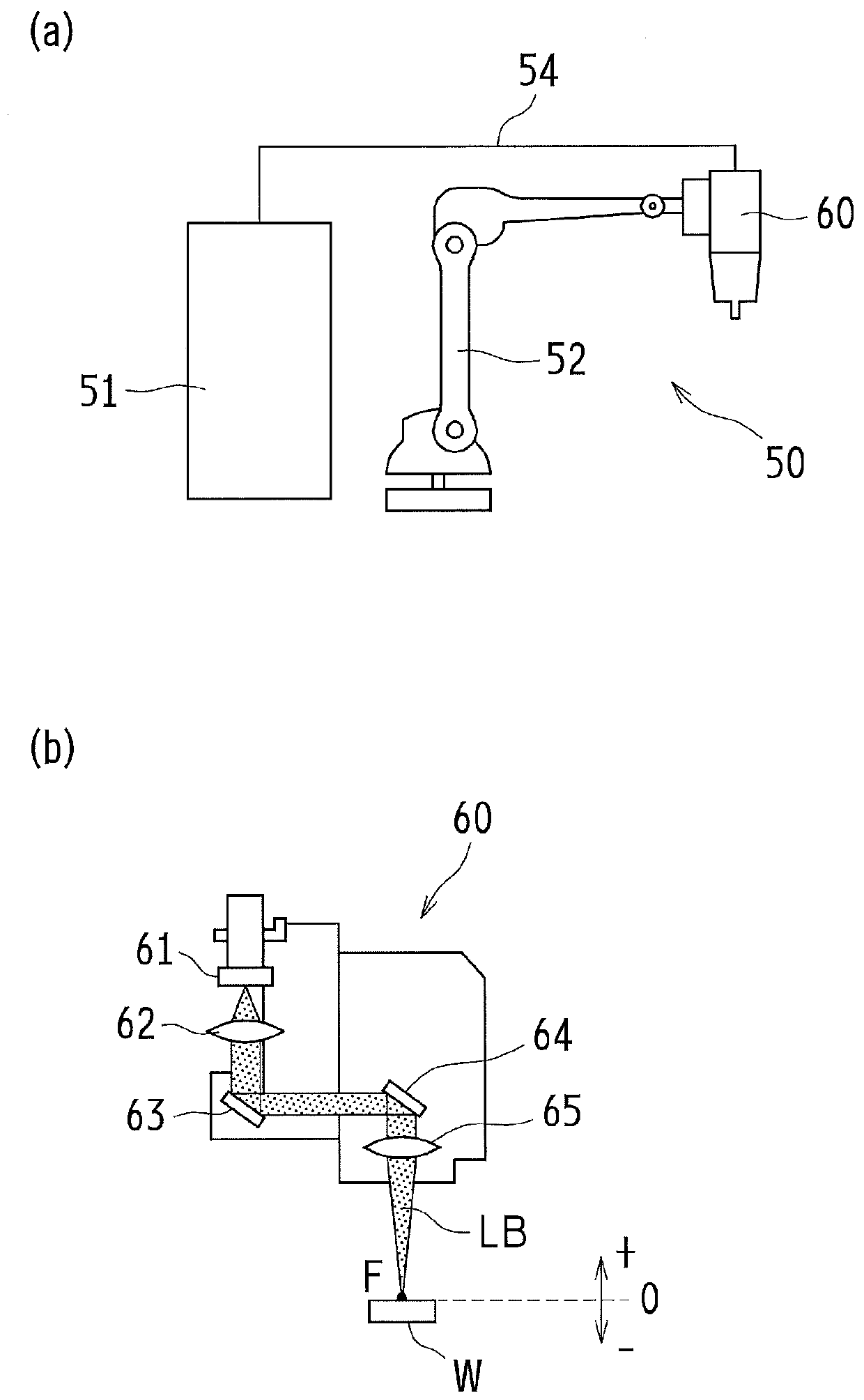

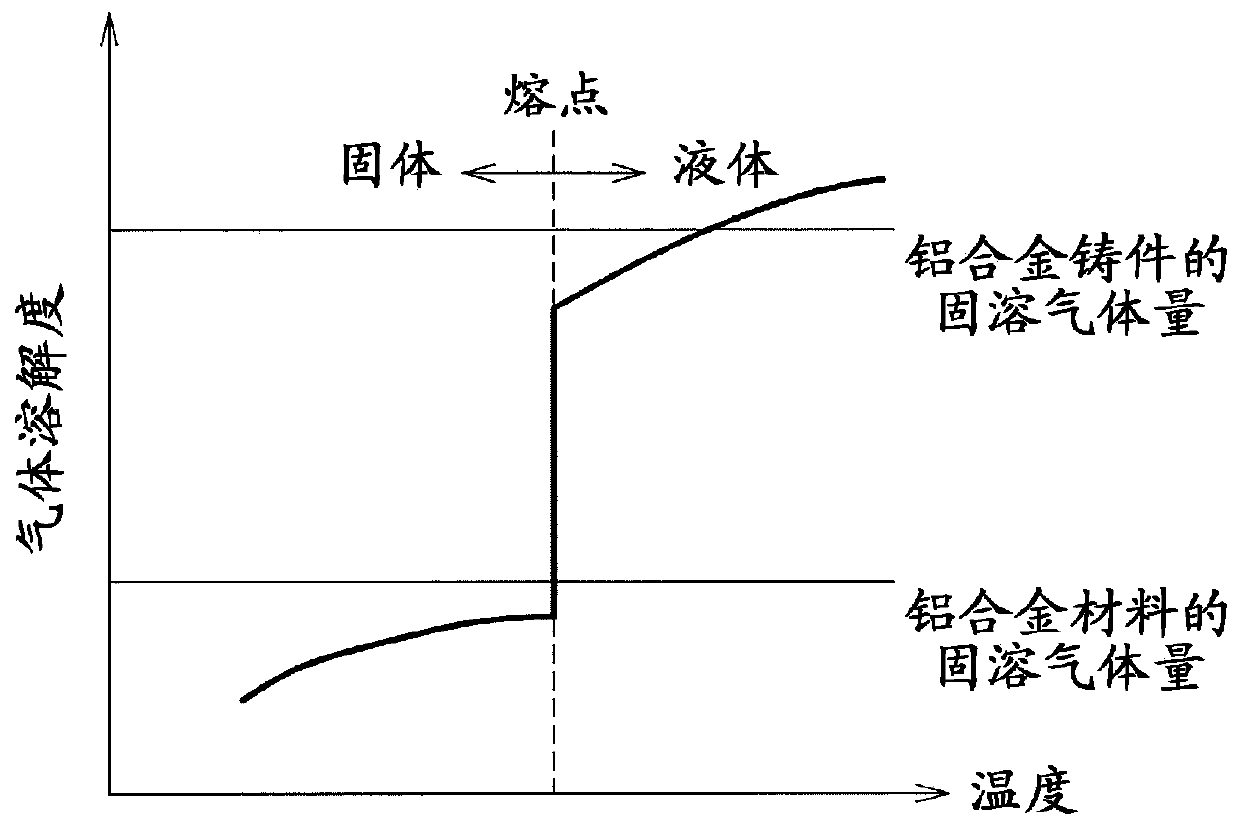

Laser welding method

ActiveCN110560895ARestraining the drop in productivityWelding/soldering/cutting articlesLaser beam welding apparatusProduction rateLaser soldering

An object of the present invention is to provide a laser welding method for lap welding of a plurality of metal plates including an aluminum alloy casting, in which generation of relatively large blowholes in a welding part is reduced while decrease in productivity is reduced. As a means for solving the problem, a laser welding method for lap welding, using a laser beam (LB), of a plurality of metal plates (10, 20) including an aluminum alloy cast plate (20) is provided, which includes: a melting path of scanning and irradiating circularly a superimposed part (5) of the aluminum alloy plate (20) and the aluminum alloy cast plate (20) with a first laser beam (LB1) to form a molten pool (7) of the molten aluminum alloy plate (10) and the molten aluminum alloy cast plate (20); and a stirringpath of scanning and irradiating circularly the molten pool (7) with a second laser beam (LB2) having a scanning speed (V2) faster than a scanning speed V1 of the first laser beam (LB1) to stir the molten pool (7).

Owner:TOYOTA JIDOSHA KK

Coating processing apparatus and coating liquid collecting member

ActiveCN109420590AAvoid accumulationReduce productivityLiquid surface applicatorsSpraying apparatusWaferPhysical chemistry

Some embodiments of the present disclosure provide a technique capable of collecting and removing a coating liquid scattering from a substrate when performing a coating process on the substrate onto which a coating liquid of high viscosity is supplied while rotating the substrate, and capable of suppressing degradation in throughput. In a resist coating apparatus that applies a resist liquid whilerotating a wafer, a coating liquid collecting member that traps a linear coating liquid generated by rotation of the wafer is provided in an exhaust path provided along a circumferential direction ofa cup body, and the coating liquid collecting member is provided with a solvent reservoir. When the wafer is subjected to the back side solvent supply treatment, the solvent that has been cleaved from the wafer falls to the coating liquid collecting member, and is stored in the solvent reservoir. In addition, when the solvent is deposited in the solvent reservoir, it is possible to dissolve and remove the linear coating liquid collected by the coating liquid collecting member during the resist coating process when the subsequent wafer is subjected to the resist coating treatment, thereby suppressing a decrease in productivity.

Owner:TOKYO ELECTRON LTD

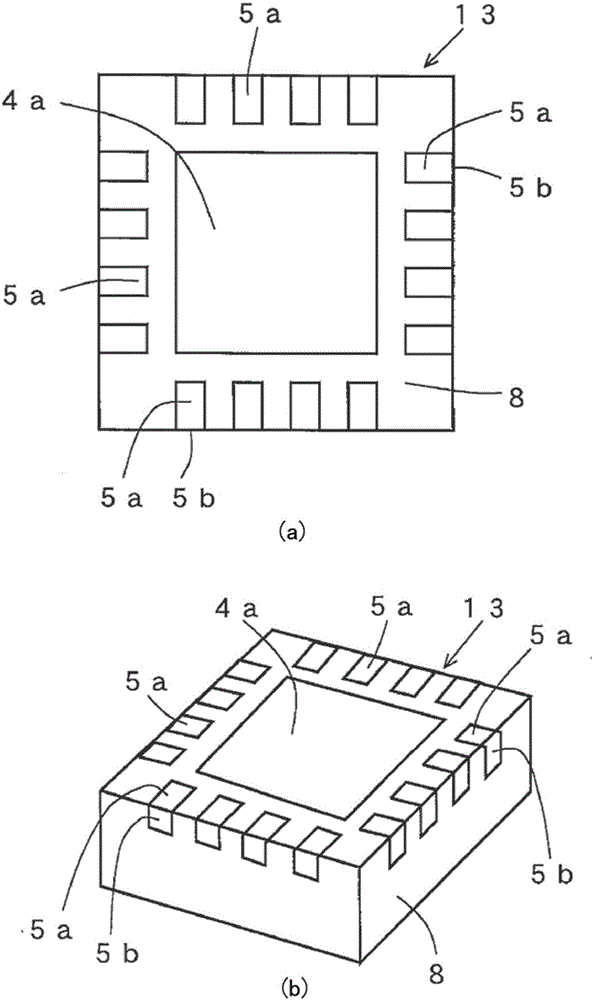

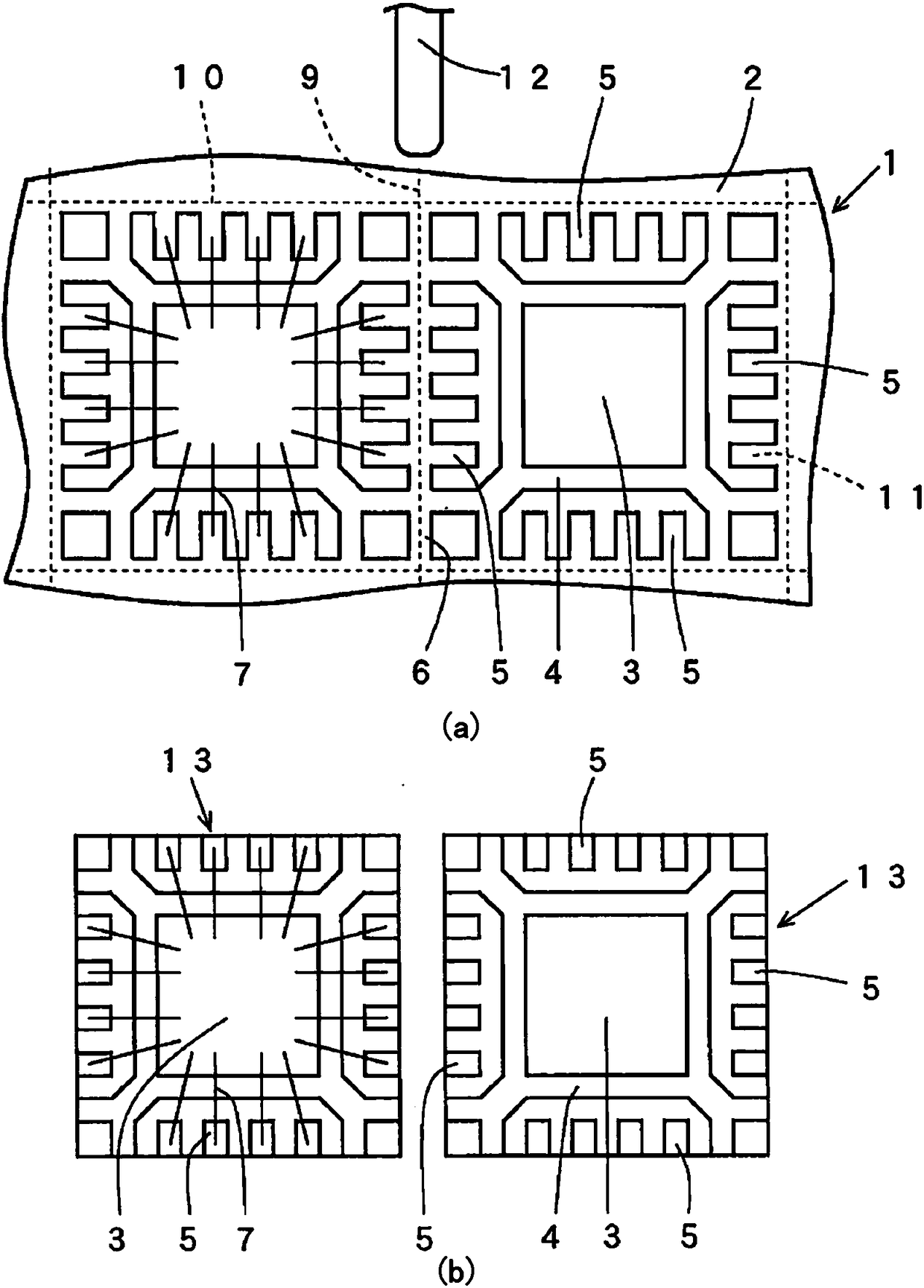

Manufacturing apparatus and manufacturing method

ActiveCN105938808AIncrease manufacturing costReduce productivitySolid-state devicesSemiconductor/solid-state device manufacturingManufactured apparatusEngineering

The invention provides a manufacturing apparatus and a manufacturing method. The method cuts off a QFN substrate in three segments along a plurality of cutting lines set in a latticed shape on a QFN substrate, and comprises the steps of: first, along cutting lines in the length direction of the QFN substrate, cutting the portion having similar thickness with the connecting rod of a lead frame to form a cutting groove; second, along cutting lines in the width direction of the QFN substrate, cutting off the lead frame and sealing resin together; and third, in the cutting groove along the length direction of the QFN substrate, cutting the portion having similar thickness with residual sealing resin. Through only cutting off partial sealing resin in the cutting groove, the method can finally reduce the processing load of processing a QFN substrate uniwafer into a QFN substrate product, and thereby prevent the QFN substrate product from deviating or dispersing from a preset position of a cutting clamp tool.

Owner:TOWA

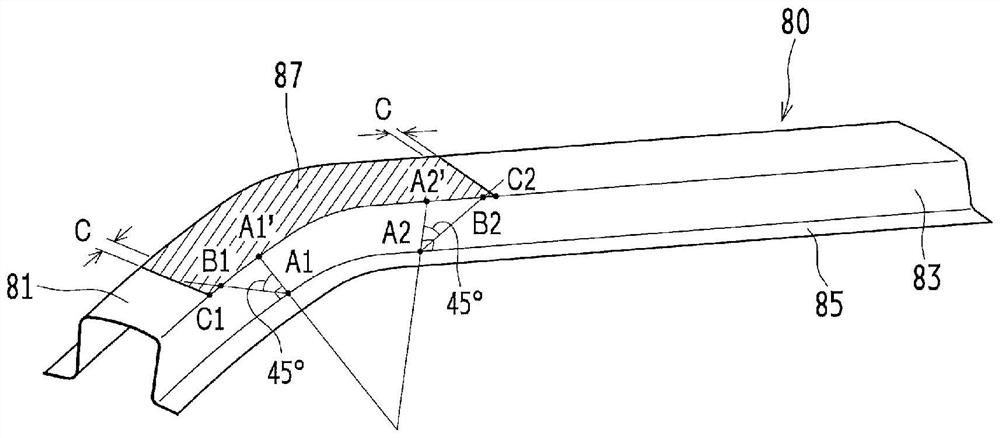

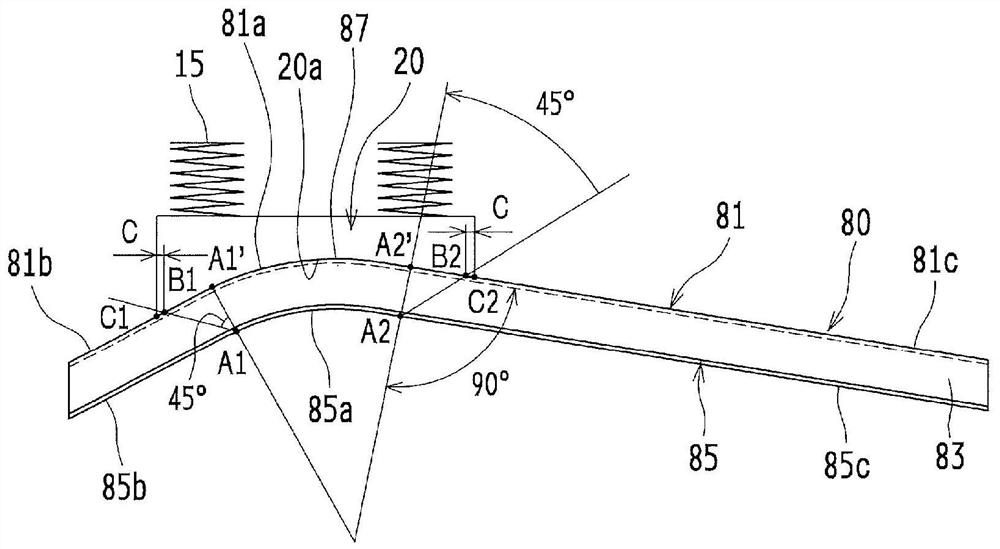

Manufacturing apparatus and manufacturing method for hat-shaped section component with curved projection portion

ActiveCN112496137AAvoid crackingRestraining the drop in productivityStripping-off devicesManufactured apparatusMechanical engineering

Provided is a manufacturing apparatus for manufacturing a hat-shaped section component including a curved projection portion such that a to-become-top-plate portion is pressed by a punch in a state where a to-become-flange portion is sandwiched between a die and a holder. The manufacturing apparatus includes the punch having a first mold surface including a curved projection portion mold surface,the holder, and the die having a fourth mold surface facing the first mold surface. An opening is formed in a part, of the fourth mold surface, that corresponds to the curved projection portion mold surface. The manufacturing apparatus includes a pad provided in the die and having a fifth mold surface facing the curved projection portion mold surface, the pad being configured to be relatively movable upward against downward biasing force so that the fifth mold surface becomes flush with the fourth mold surface.

Owner:TOYOTA JIDOSHA KK

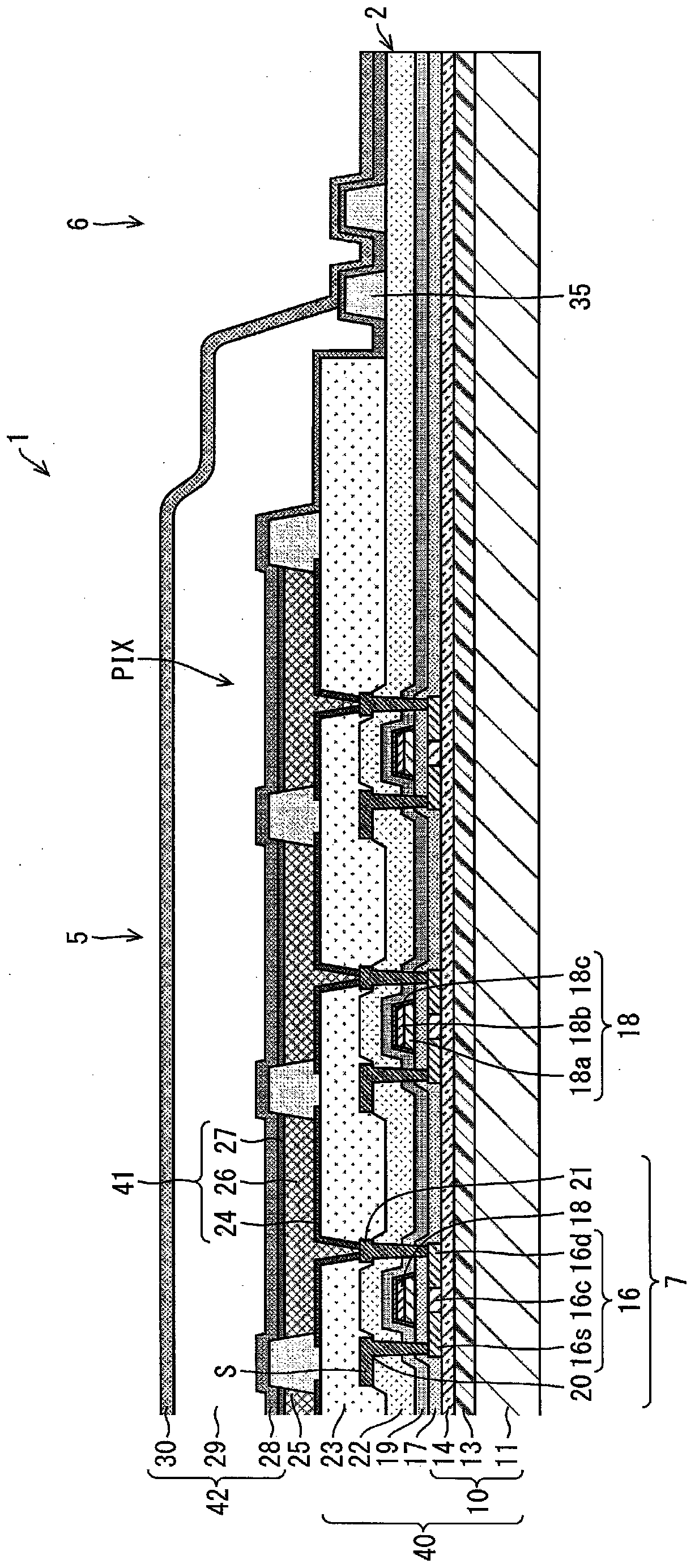

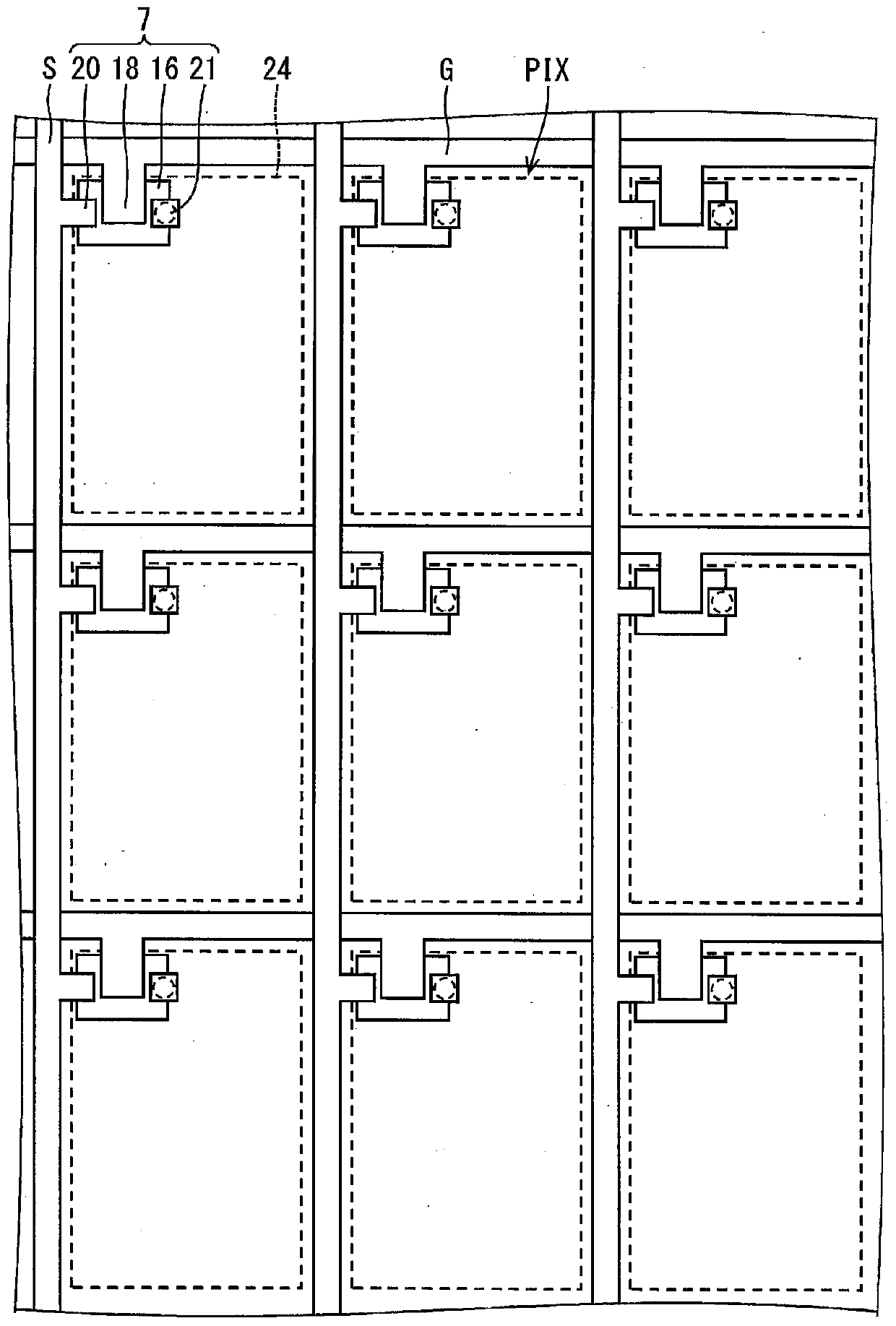

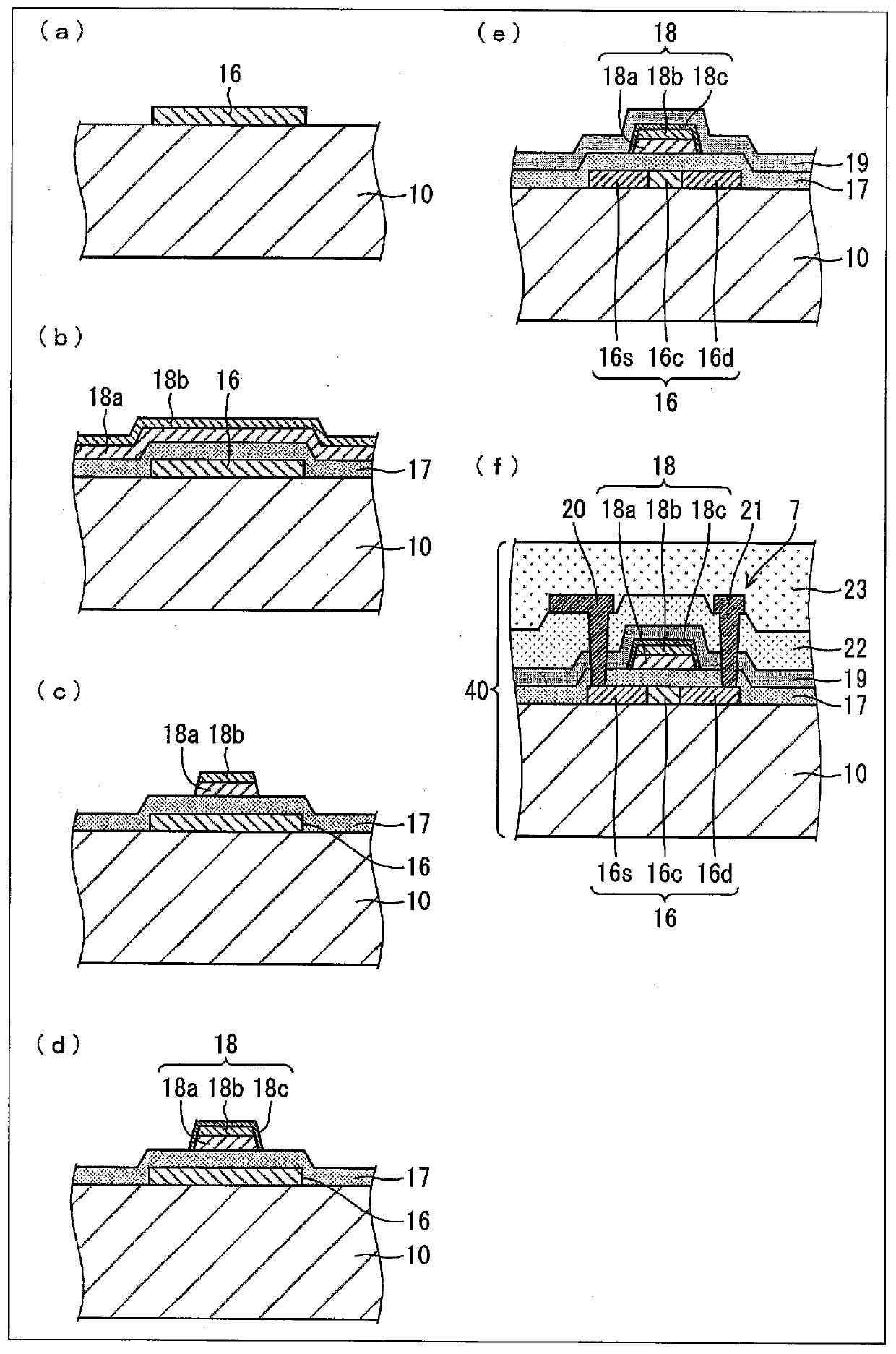

Method for manufacturing active matrix substrate, method for manufacturing organic el display device, and active matrix substrate

ActiveCN110383434ASuppression of productivity dropRestraining the drop in productivityTransistorSolid-state devicesActive matrixDisplay device

In the gate electrode forming step according to the present invention, a second metal film (18b) is formed on a first metal film (18a) by adding oxygen or nitrogen to an inert gas atmosphere, and after patterning the first metal film (18a) and the second metal film (18b), a third metal film (18c) is formed by performing plasma treatment using oxygen or nitrogen, thereby forming a gate electrode (18a). Consequently, a needle crystal or granular crystal is prevented from being formed, while suppressing deterioration of production efficiency.

Owner:SHARP KK

Coating processing device and coating liquid collecting member

ActiveCN109420590BAvoid accumulationRestraining the drop in productivityLiquid surface applicatorsSpraying apparatusWaferViscosity

Owner:TOKYO ELECTRON LTD

Electric energy storage device and its manufacturing method

InactiveCN101743654BSimple compositionImprove insulation reliabilityLarge-sized flat cells/batteriesFinal product manufactureEngineeringMetal

There is provided an electric energy storage device which has a connection structure with a high connection reliability and which can suppress any contact of an outer package body with a connection terminal with a simple structure. The electric energy storage device comprises a battery element 10 retained in an outer package body 20 having a metal layer 21b, a tabular internal lead 31 connected to the battery element 10, a tabular external lead 32, a connection terminal 33 electrically connecting the internal lead 31 with the external lead 32, an internal insulating member 41, and an external insulating member 43. Flanges 33T, 33B at both ends of the connection terminal 33 depress the external insulating member 43, the outer package body 20, and the internal insulating member 41 between the tabular external lead 32 and internal lead 31, and the external insulating member 43 and / or internal insulating member 41 is pressed in between a penetration shaft 33S of the connection terminal 33 and the metal layer 21b.

Owner:ENAX INC

production system

ActiveCN106415418BAvoid repeated executionRestraining the drop in productivityComputer controlRegistering/indicating working of machinesComputer scienceIndustrial engineering

The management computer of the installation system determines the operator and the type of operation (S240) from the operation history when the productivity decreases (S230), reads the management value (P) (S250) in the determined type of operation of the determined operator, and converts the management value (P) Increase value 1 (S260). Then, when the management computer of the installed system determines that the management value (P) is equal to or greater than the second threshold (P2) (S310), the specified operator restricts the execution of jobs of the specified job type (S340). Thereby, it is possible to suppress a reduction in productivity due to duplication of work by the same worker.

Owner:FUJI KK

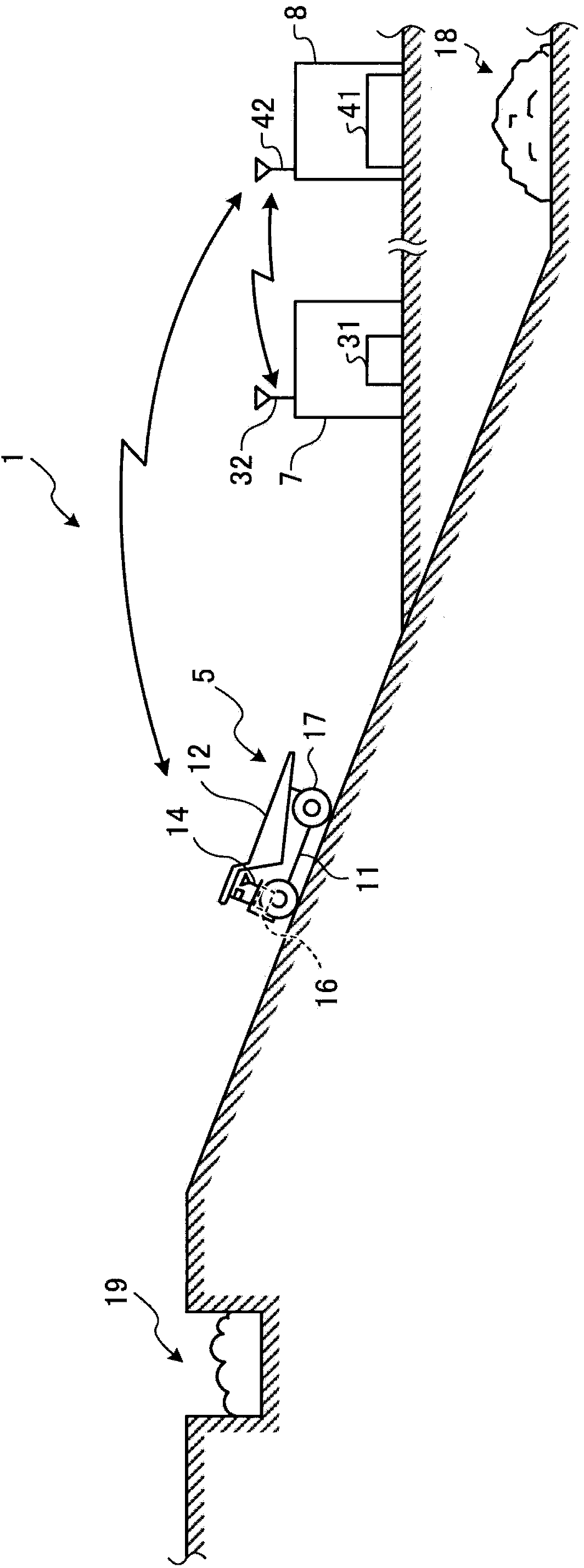

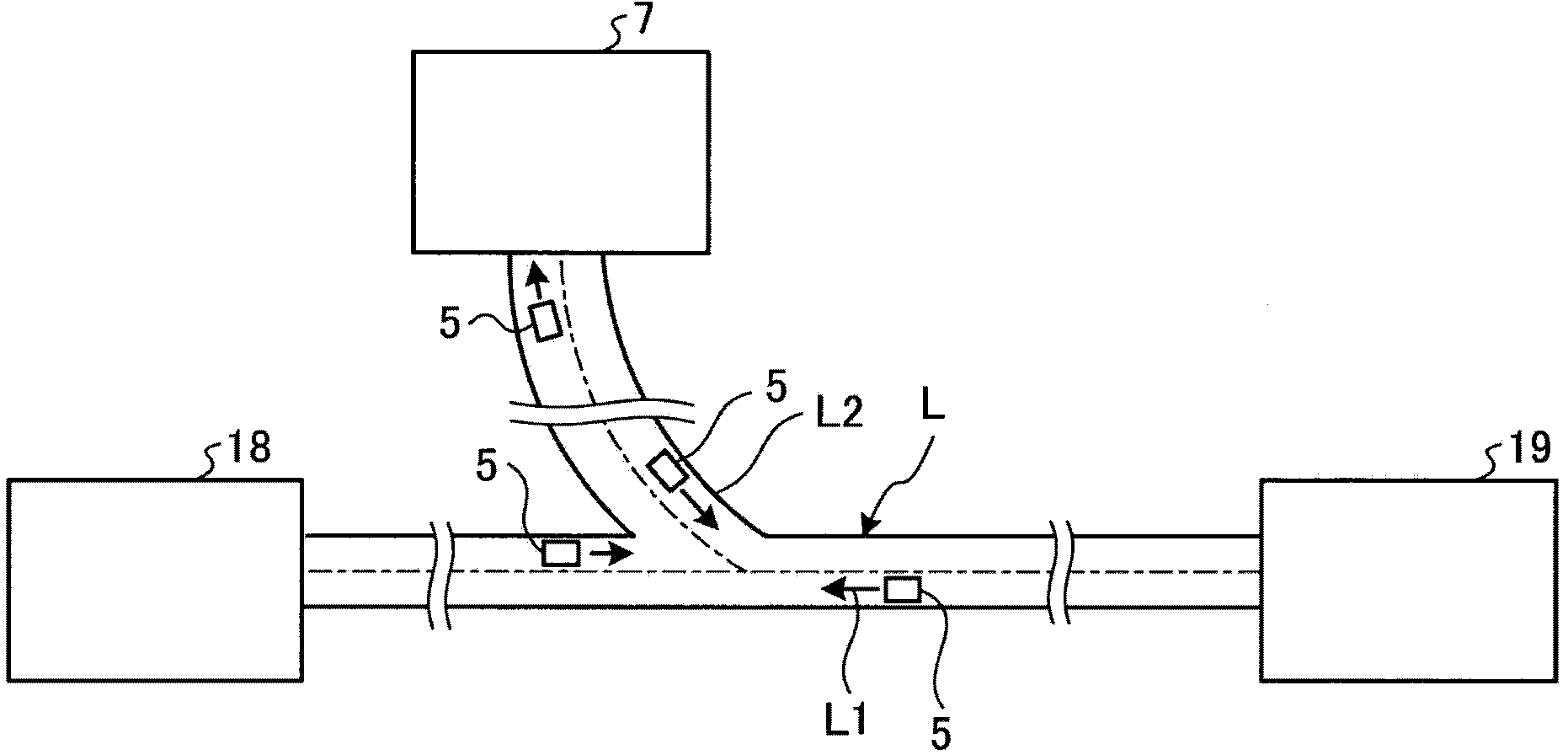

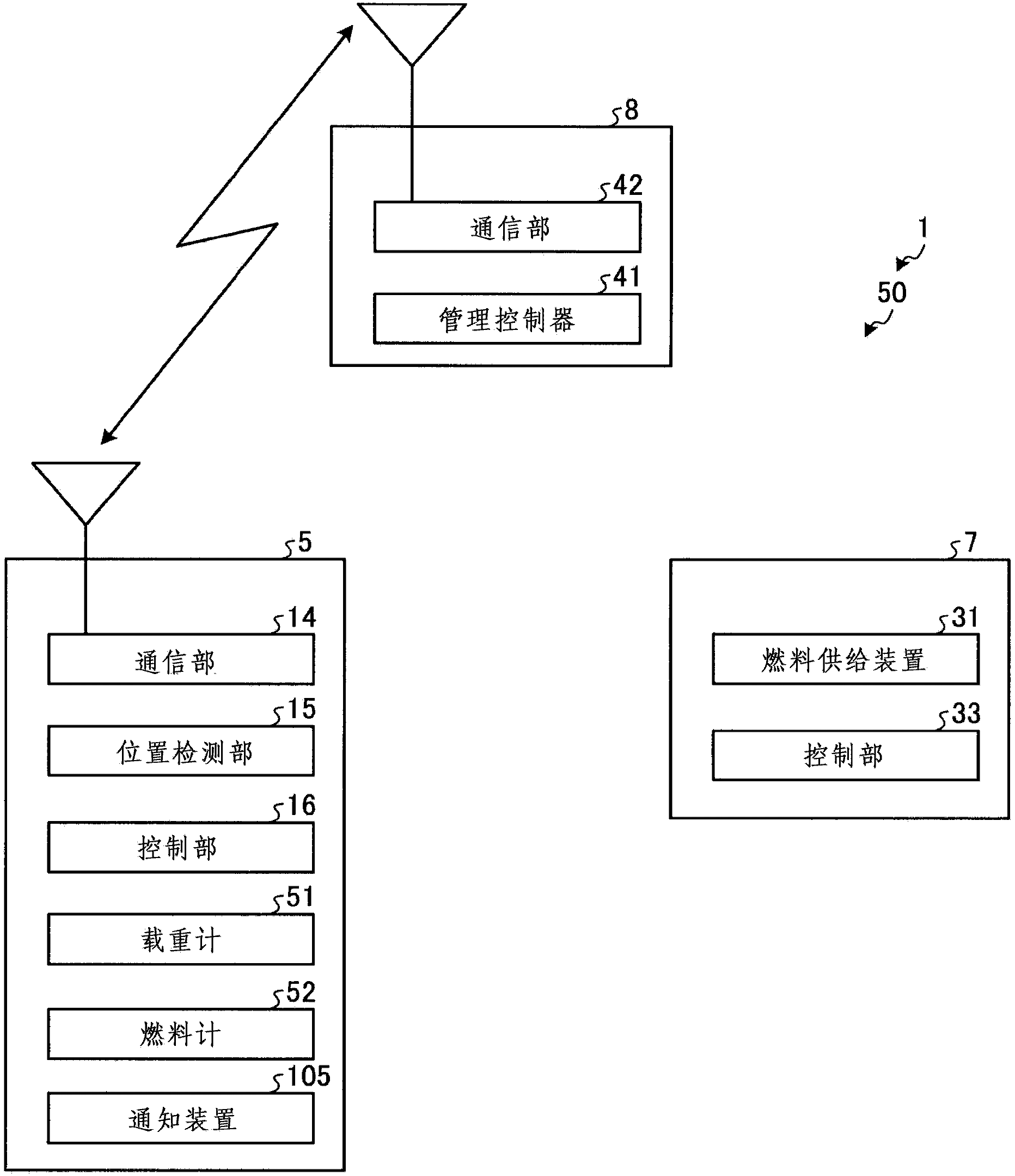

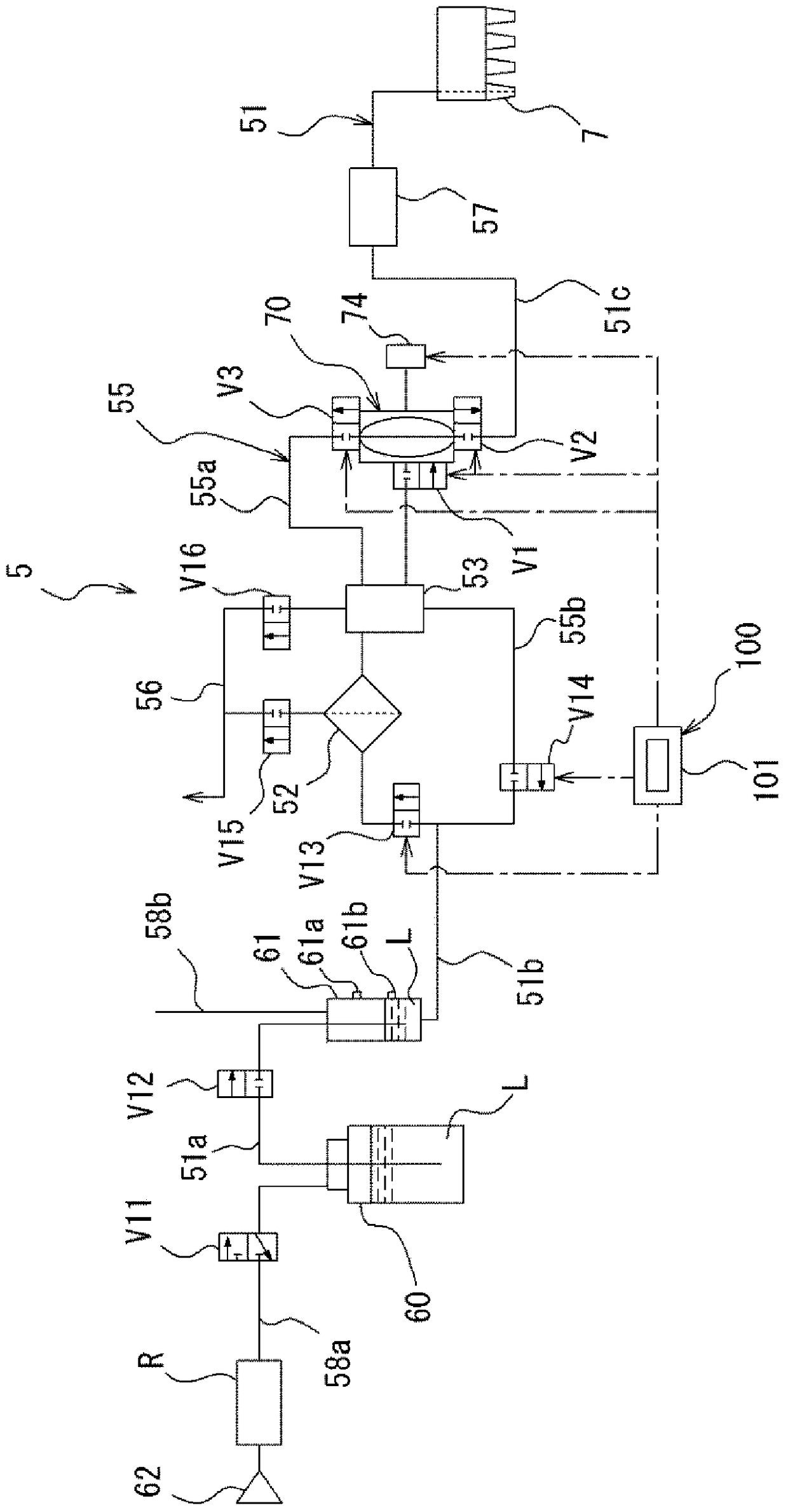

Fuel supply system and construction machine

InactiveCN103548067ARestricted accessSuppression of productivity dropInstruments for road network navigationData processing applicationsFuel supplyCentral management

A fuel supply system comprising: a fuel supply facility capable of supplying fuel; a transport machine capable of traveling toward the fuel supply facility; and a central management control facility for acquiring execution permission information, which is information indicating whether fuel can be supplied to the transport machine, the central management control facility being capable of executing a control based on acquired execution permission information; wherein, when the transport machine is to be supplied with fuel, the central management control facility executes an entry-denying control for denying entry by the transport machine into the fuel supply facility when it is determined that fuel supply to the transport machine is not to be permitted on the basis of the execution permission information.

Owner:KOMATSU LTD

Substrate processing apparatus and substrate processing method

ActiveCN102386119BRestraining the drop in productivityShorten the timeSemiconductor/solid-state device manufacturingCoatingsProduction rateEngineering

Provided is a substrate processing apparatus in which after a module is disabled, a substrate is provided to a carry-in module capable of placing the wafers most rapidly in the plurality of unit blocks and the substrates are sequentially transported to the module group by the transportation means to be delivered to the carry-out module according to a providing sequence of the substrate to the carry-in module in each of the plurality of unit blocks. In particular, the substrates are extracted from the carry-out module according to a providing sequence of the substrate to the carry-in module and transported to a rear module or a substrate placing part. Thereafter, the substrates are transported to the rear module from the carry-out module or the substrate placing part according to a predetermined sequence in which the substrate is provided to the carry-in module in a normal state.

Owner:TOKYO ELECTRON LTD

Substrate processing equipment

ActiveCN103374713BGuaranteed uniformityWhen suppressing a large space that spreads so muchChemical vapor deposition coatingVacuum chamberGas supply

A substrate processing apparatus includes a vacuum chamber; a turntable rotatably provided in the vacuum chamber, on which a circular substrate is to be mounted, and provided with a circular concave portion at a front surface having a larger diameter than that of the substrate, and a circular substrate mounting portion provided in the concave portion having a diameter smaller than that of the concave portion and the substrate at a position higher than a bottom portion of the concave portion, the center of the substrate mounting portion being off center with respect to the center of the concave portion toward an outer peripheral portion side of the turntable; a process gas supplying unit which supplies a process gas to the substrate; and a vacuum evacuation mechanism which evacuates the vacuum chamber.

Owner:TOKYO ELECTRON LTD

Vibration-damping reinforcing composition, vibration-damping reinforcing material, and vibration-damping reinforcing method for thin plate

InactiveCN101889051BImprove acceleration performanceImprove vibration damping effectNon-rotating vibration suppressionAdhesivesEpoxyButyl rubber

A vibration-damping reinforcement composition contains 30 to 300 parts by weight of butyl rubber, 30 to 300 parts by weight of acrylonitrile-butadiene rubber, 100 parts by weight of epoxy resin, and 0.5 to 30 parts by weight of an epoxy resin curing agent.

Owner:NITTO DENKO CORP

Treatment liquid supply device and treatment liquid supply method

ActiveCN104511408BRestraining the drop in productivityLiquid surface applicatorsSemiconductor/solid-state device manufacturingProduction rateResist

Owner:TOKYO ELECTRON LTD

Additional bending device, post-processing device and image forming system

ActiveCN111747198AWon't hurtSuppression of productivity dropMechanical working/deformationFolding thin materialsImage formationStructural engineering

The invention relates to an additional bending device, a post-processing device and an image forming system, which can press or depress a sheet bundle without damaging the end part of the sheet bundleso as to inhibit the reduction of productivity. The additional bending device comprises an additional bending mechanism which clamps a folding seam part of a sheet bundle and presses the sheet bundle. And a moving mechanism for moving the additional bending mechanism in the folding direction of the sheet bundle, wherein the additional bending mechanism includes a pair of pressing members for pressing the folding of the sheet bundle from the thickness direction of the sheet bundle, a pressing mechanism for pressing or releasing the pair of pressing members, and a driving mechanism for drivingthe pressing mechanism. The moving mechanism moves the additional bending mechanism in accordance with the size of the sheet bundle in the folding direction, and the additional bending mechanism presses the sheet bundle from the thickness direction by the pair of pressing members near one end of the sheet bundle, and depresses the pair of pressing members near the other end of the sheet bundle after being moved by the moving mechanism.

Owner:RICOH KK

Job processing system and image processing device

ActiveCN102025869BInhibition effectRestraining the drop in productivityElectrographic process apparatusPlatform integrity maintainanceProcess systemsImaging processing

Provided are a job processing system and an image processing device. The composite machine includes: a plurality of control modules (scanning control unit 35~file system unit 40), which are set corresponding to a plurality of functions; a virus inspection unit (33), which performs virus inspection for the plurality of control modules; a virus management unit ( 32), making the virus checking unit (33) carry out virus checking on each control module of a part of the control modules in the plurality of control modules; The job of the control module.

Owner:KONICA MINOLTA BUSINESS TECH INC

Electronic component installation device and electronic component installation method

ActiveCN106488695AAvoid interferenceSuppression of productivity dropElectrical componentsProduction rateControl signal

The invention provides an electronic component installation device which can avoid mutual interference between electronic components, can convey as many electronic components as possible and can restrain reduction of productivity. The electronic component installation device comprises an installation head unit, a motion system, a component dimension data acquisition part, an installation head dimension data acquisition part, and an installation head control part, wherein the installation head unit comprises multiple installation heads; the motion system makes suction nozzles of the installation heads move; the component dimension data acquisition part acquires component dimension data; the installation head dimension data acquisition part acquires installation head dimension data; and the installation head control part outputs a first control signal based on the component dimension data and the installation head dimension data, so a second electronic component which is supported by a supporting face and has appearance dimensions larger than appearance dimensions of a first electronic component can be separated from the supporting face by a second installation head after the first electronic component supported by the supporting face of an electronic component supply device is separated from the supporting face by a first installation head.

Owner:JUKI CORP

Manufacturing device and manufacturing method

ActiveCN105938808BIncrease manufacturing costRestraining the drop in productivitySolid-state devicesSemiconductor/solid-state device manufacturingThree stageManufactured apparatus

The invention provides a manufacturing device and a manufacturing method. The QFN substrate is cut in three stages along a plurality of cutting lines set in a grid pattern on the QFN substrate. First, at a cutting line along the longitudinal direction of the QFN substrate, a portion approximately equivalent to the thickness of the tie bar of the lead frame is cut to form a cut groove. Next, the lead frame and the sealing resin are cut together at the cutting line along the width direction of the QFN substrate. Next, a portion corresponding to the thickness of the remaining sealing resin was cut in the cut groove along the longitudinal direction of the QFN substrate. By cutting only the part of the sealing resin in the cutting groove, the processing load when singulating the QFN substrate into QFN products can be finally reduced. Therefore, it is possible to prevent the QFN product from being displaced or scattered from the predetermined position of the jig for cutting.

Owner:TOWA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com