Production system

A production system and productivity technology, applied in the field of production systems, can solve problems such as reduced repair work efficiency, inappropriate repair work difficulty, etc., to achieve the effect of suppressing the decrease in productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

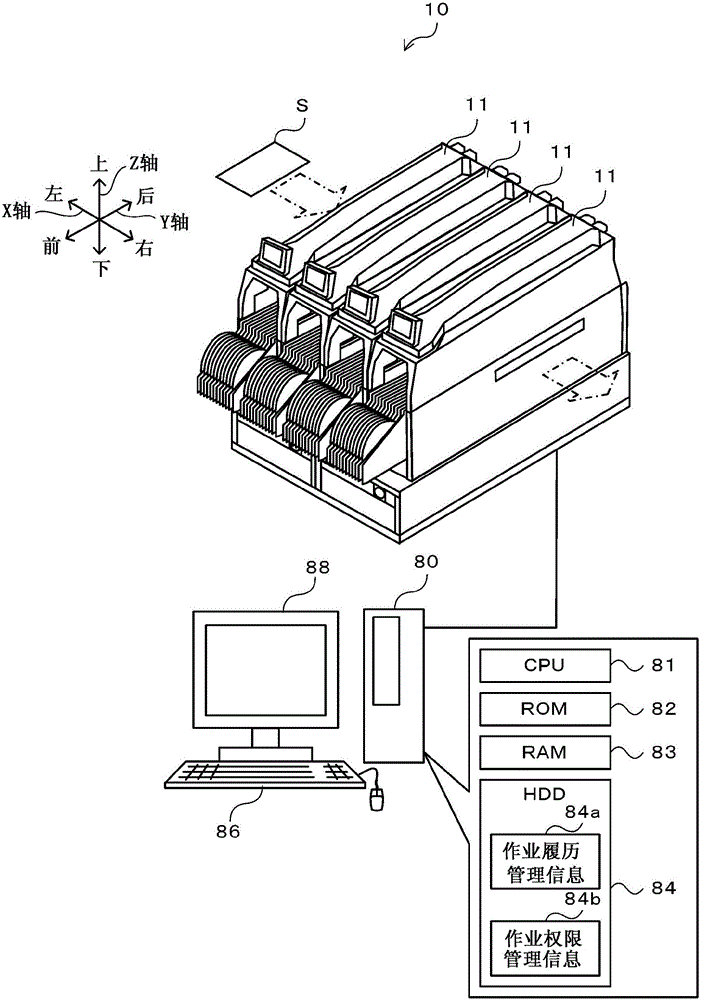

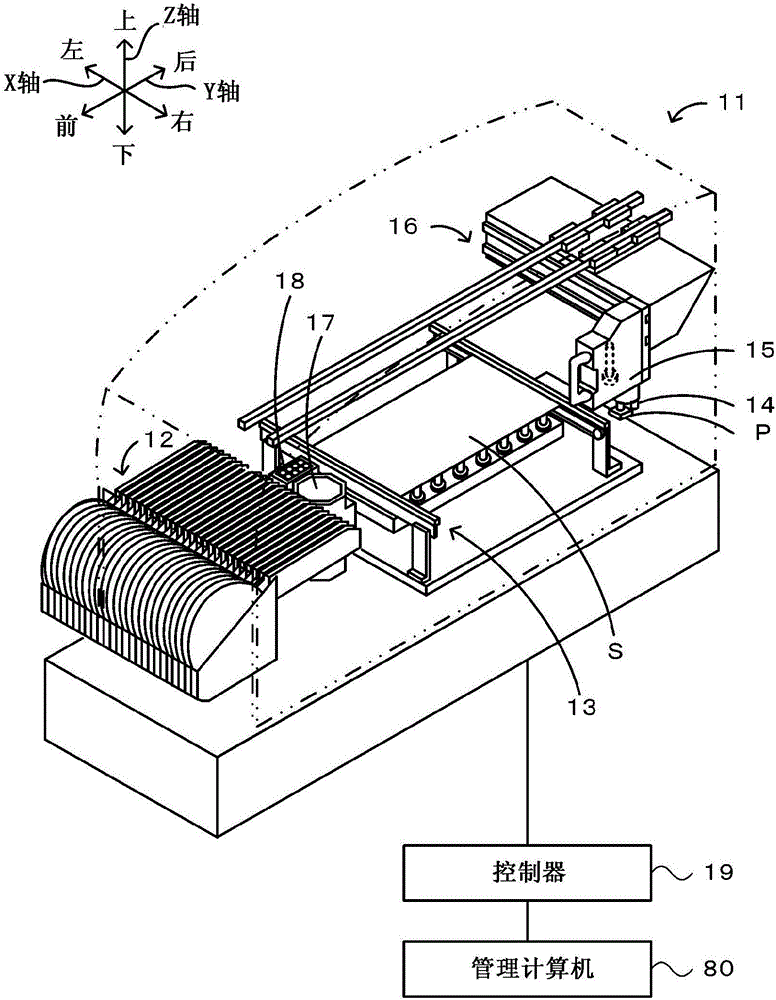

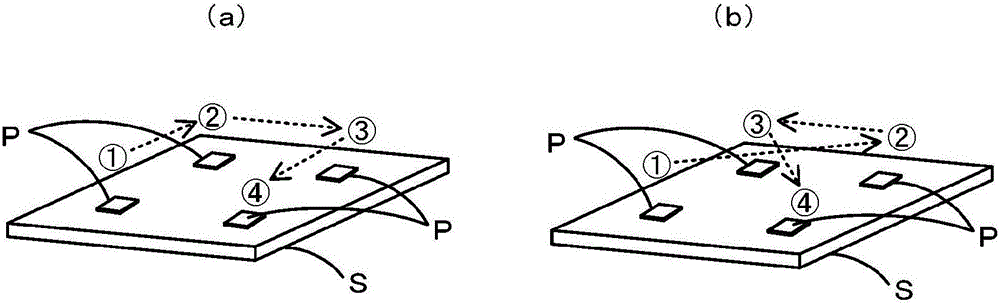

[0022] figure 1 It is a structural diagram showing the outline of the structure of the installation system 10, figure 2 It is a configuration diagram showing a schematic configuration of the mounting device 11 . Furthermore, in this embodiment, figure 1 and figure 2 The left and right direction is the X axis direction, the front and rear direction is the Y axis direction, and the up and down direction is the Z axis direction.

[0023] Mounting system 10 is equipped with electronic components (hereinafter referred to as "components P" (refer to figure 2 )) A plurality of mounting devices 11 for mounting on the substrate S and a management computer 80 for managing production of the entire system such as management of each mounting device 11 . In addition, the mounting process includes processes of arranging the component P on the substrate S, assembling, inserting, joining, bonding, and the like. In addition, the plurality of mounting devices 11 are viewed from the upstr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com