Substrate processing apparatus and substrate processing method

A technology of a substrate processing device and a substrate processing method, which is applied to the device for coating liquid on the surface, transportation and packaging, electrical components, etc., which can solve the problems of reduced component operation rate, difficulty in transportation control, and reduced productivity, so as to achieve suppressed productivity. the reduced effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

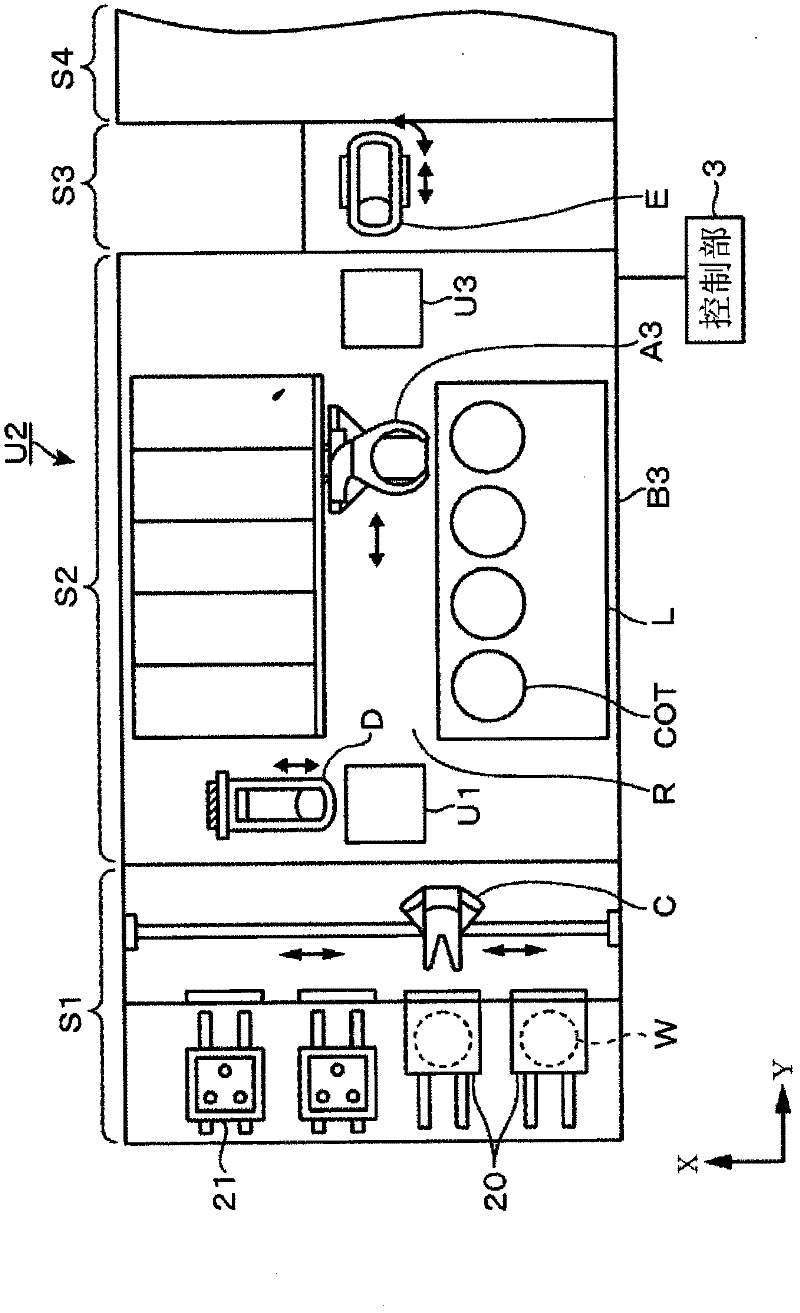

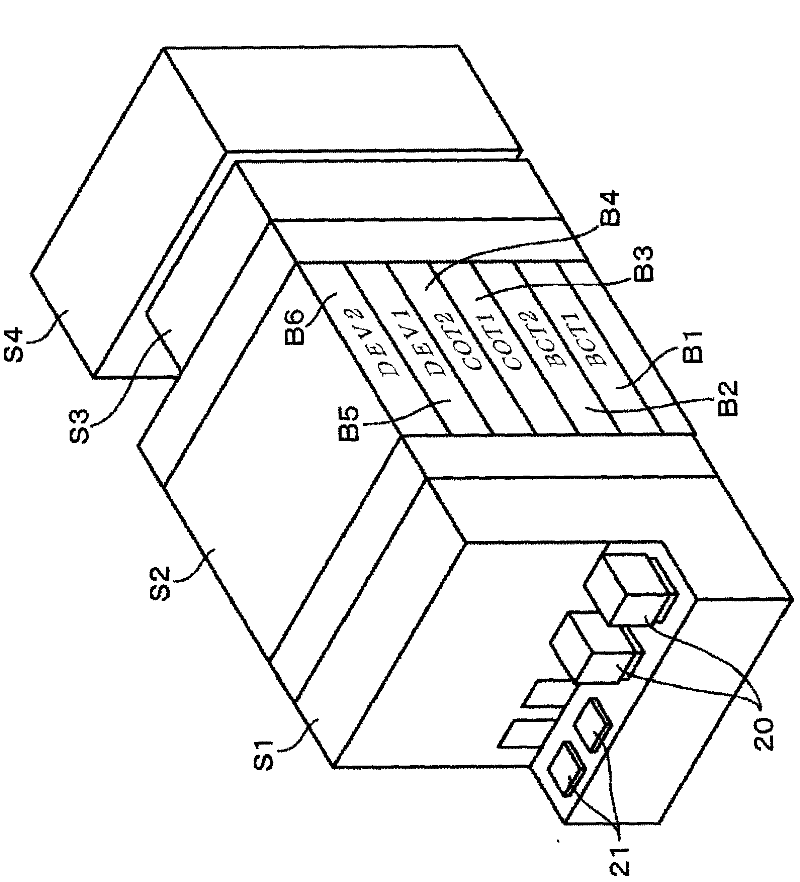

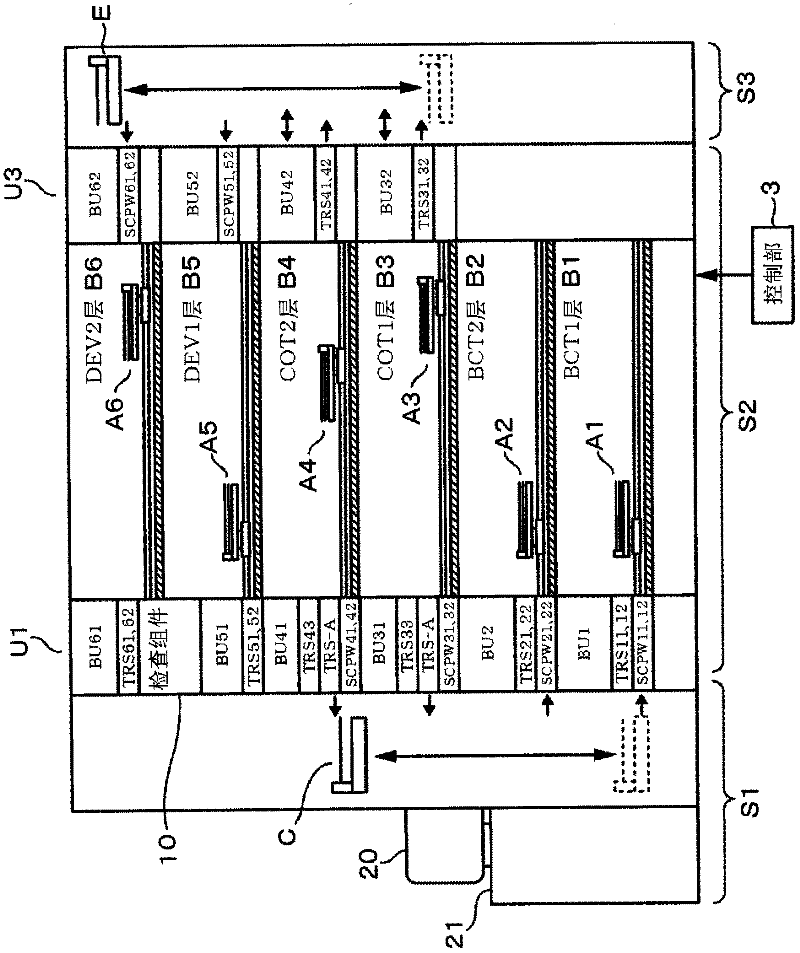

[0068] Next, an example of a resist pattern forming apparatus in which an exposure apparatus is connected to the coating-developing apparatus of the present invention will be briefly described with reference to the drawings. figure 1 It is a plan view showing one embodiment of the above resist pattern forming apparatus, figure 2 It is a schematic perspective view showing one embodiment of the above resist pattern forming apparatus. The device includes a carrying area S1, a processing area S2, a transfer area S3, and an exposure device S4. In the carrying area S1, the transfer arm C takes the wafer W out of the airtight carrier 20 placed on the mounting table 21, and transfers it to the processing area S2 adjacent to the carrying area S1, and the above-mentioned The delivery arm C receives the processed wafer W processed in the processing area S2 and sends it back to the carrier 20 .

[0069] The above-mentioned processing area S2 is constituted by a plurality of, for exampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com