Element installation apparatus and method thereof

A technology for installing devices and components, applied in the direction of electrical components, electrical components, etc., can solve problems such as productivity reduction, pasting position restrictions, human errors, etc., to achieve the effect of reducing human errors and suppressing productivity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach )

[0037] (structure)

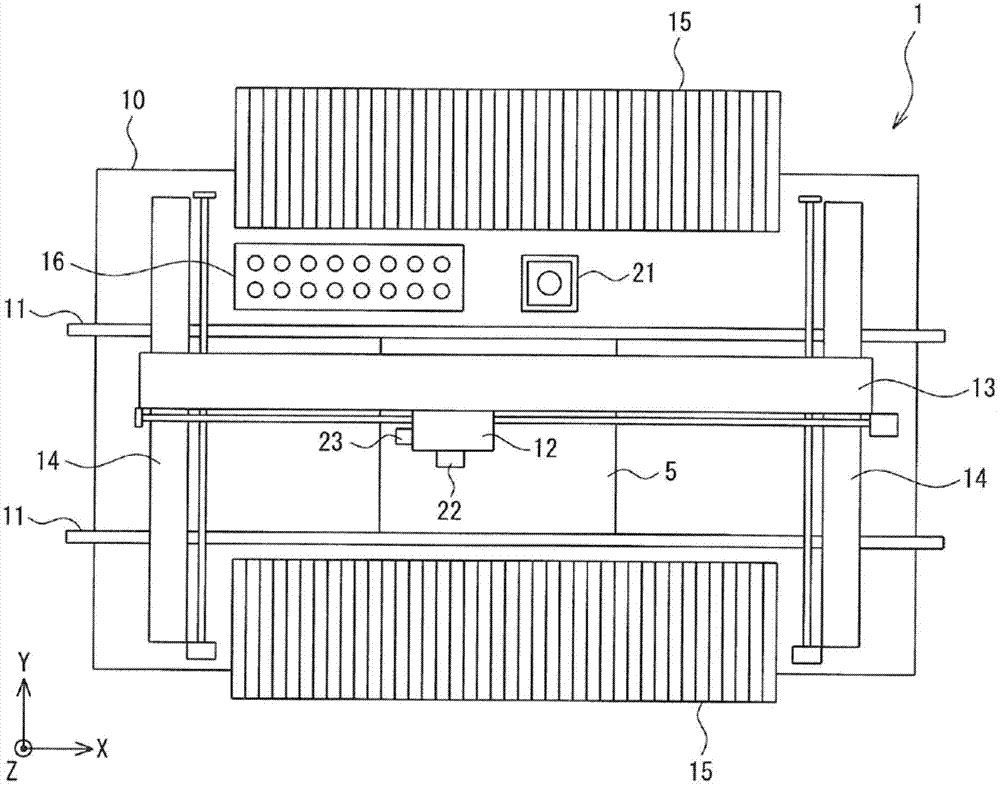

[0038] figure 1 It is a plan view showing the component mounting device according to the first embodiment of the present invention.

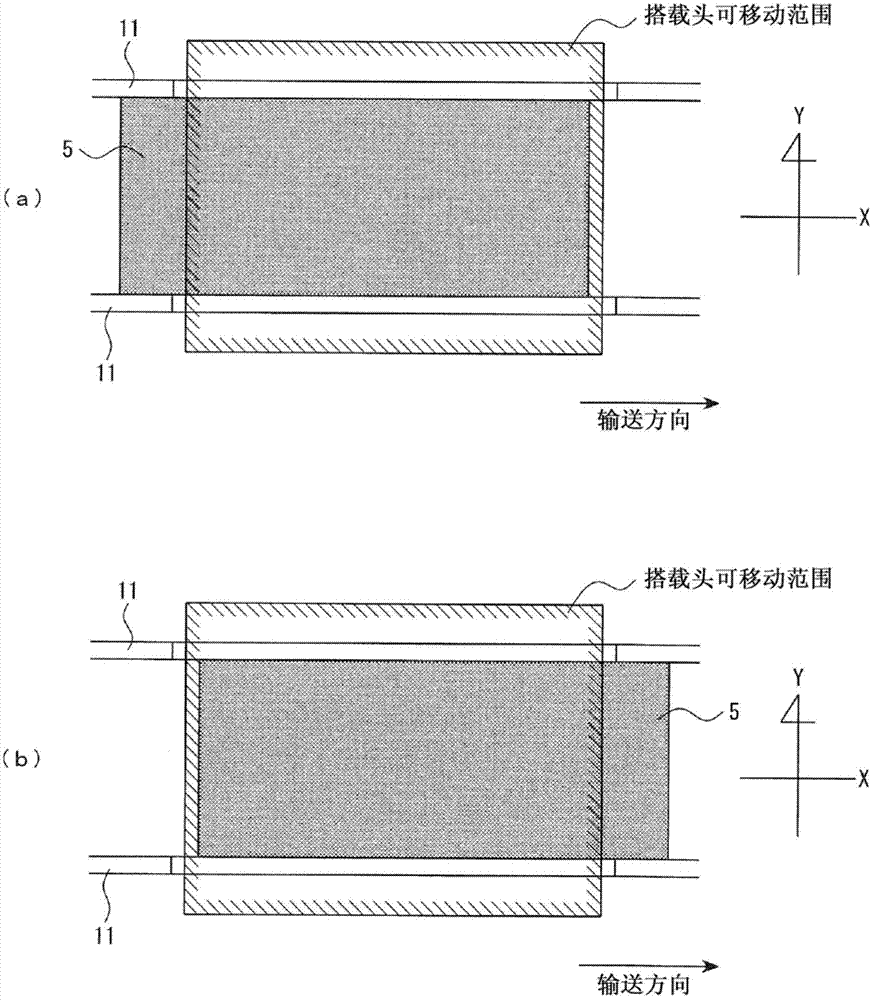

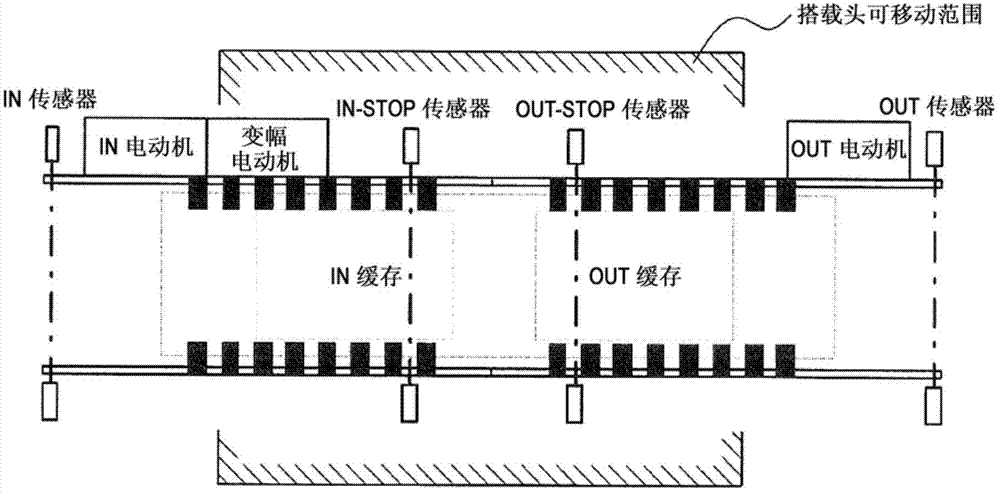

[0039] In the drawings, reference numeral 1 is a component mounting device. The component mounting apparatus 1 has a pair of conveyance rails 11 extending in the X direction on the upper surface of the base 10 . The transport rails 11 support both side edge portions of the circuit board 5 and are driven by a transport motor (not shown) to transport the circuit board 5 in the X direction.

[0040] In addition, the component mounting apparatus 1 has a mounting head 12 . The mounting head 12 has a plurality of suction nozzles for suctioning electronic components on its lower portion, and is configured to be horizontally movable in the XY direction on the base 10 by the X-axis gantry 13 and the Y-axis gantry 14 .

[0041] In this component mounting apparatus 1 , component supply devices 15 for supplying electronic components...

no. 2 Embodiment approach )

[0110] Next, a second embodiment of the present invention will be described.

[0111] In the above-mentioned first embodiment, after the board barcode B is recognized, the components are mounted sequentially from the first stop position, but in this second embodiment, the parts are mounted sequentially from the stop position after the board barcode B is recognized As for mounting components, since the structure of the component mounting device is the same as that of the above-mentioned first embodiment, description thereof will be omitted.

[0112] (structure)

[0113] Figure 9 It is a flowchart showing the flow of component mounting processing executed by the controller 30 in the second embodiment.

[0114] First, in step S41, the controller 30 judges whether or not the circuit board 5 is newly produced according to the production information stored in the memory. In addition, in the case of new production, the process proceeds to step S42, and in the case of continuation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com