Manufacturing apparatus and manufacturing method for hat-shaped section component with curved projection portion

A manufacturing device and bending technology, which is applied to the manufacturing device and manufacturing field of hat-shaped cross-section parts with curved convex parts, can solve the problems of deviation in the length direction of the predetermined part of the top plate, cracks in the top plate, etc., and achieve the purpose of suppressing the reduction of productivity and the occurrence of cracks , to ensure the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

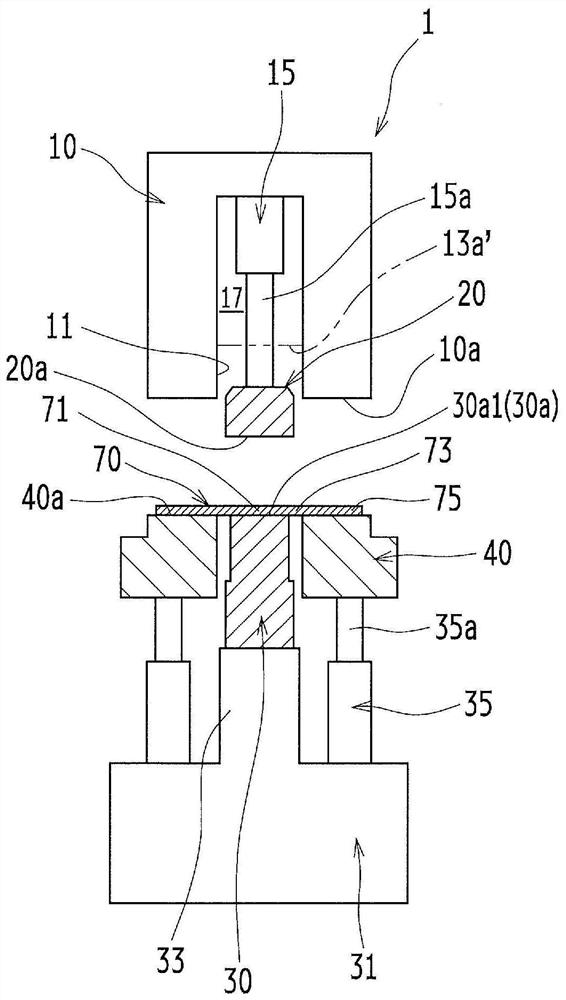

[0044] Hereinafter, the form for implementing this invention is demonstrated based on drawing.

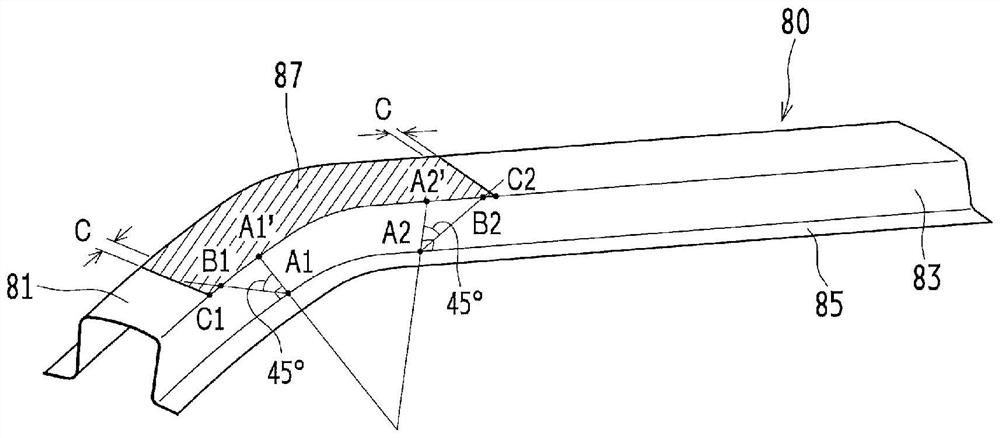

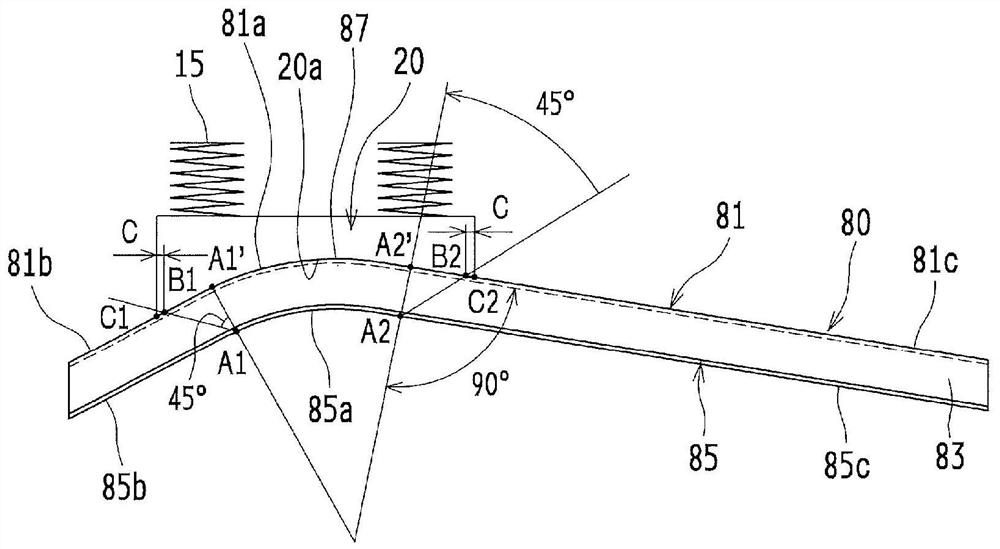

[0045] figure 1 is a perspective view schematically showing a hat-shaped cross-sectional member 80 manufactured by the manufacturing apparatus 1 and the manufacturing method according to the present embodiment, figure 2 It is a side view schematically showing the relationship between the hat-shaped cross-sectional member 80 and the pad 20 . The hat-shaped cross-section member 80 is prepared by using the manufacturing device 1 described later to form a flat workpiece 70 (refer to figure 2 ) is manufactured by performing press processing (drawing processing).

[0046] Such as figure 1 As shown, the hat-shaped cross-sectional member 80 has: a top plate 81 having a curved convex portion 87 protruding upward in a longitudinal direction; 83; and a pair of flanges 85 respectively extending outward in the width direction from the lower ends of the pair of vertical walls 83; Inverted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com