Laser welding method

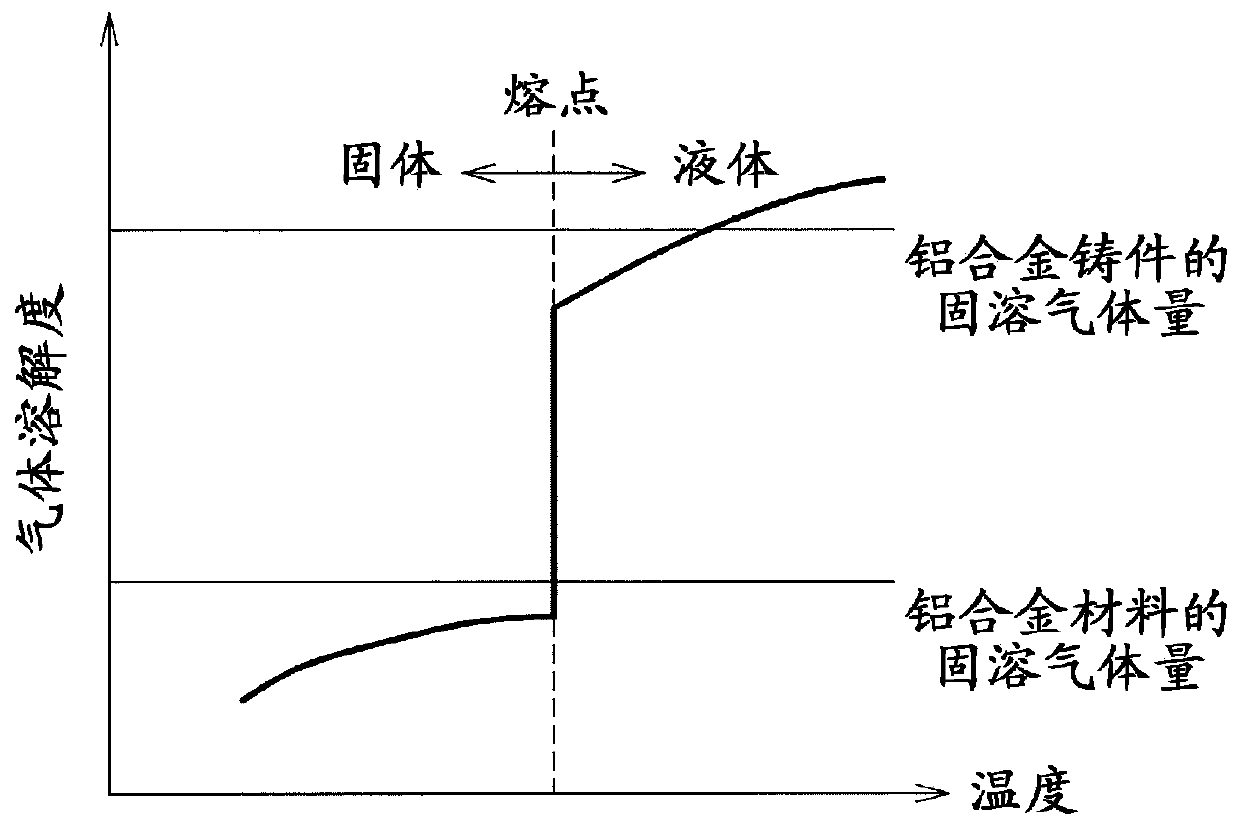

A technology of laser welding and laser beam, which is applied in the direction of laser welding equipment, welding equipment, welding/welding/cutting items, etc., can solve the problems of reduced quality and strength of welded parts, and achieve the effect of suppressing porosity and reducing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

[0092] Next, an experimental example performed to confirm the effect of the laser welding method of this embodiment will be described.

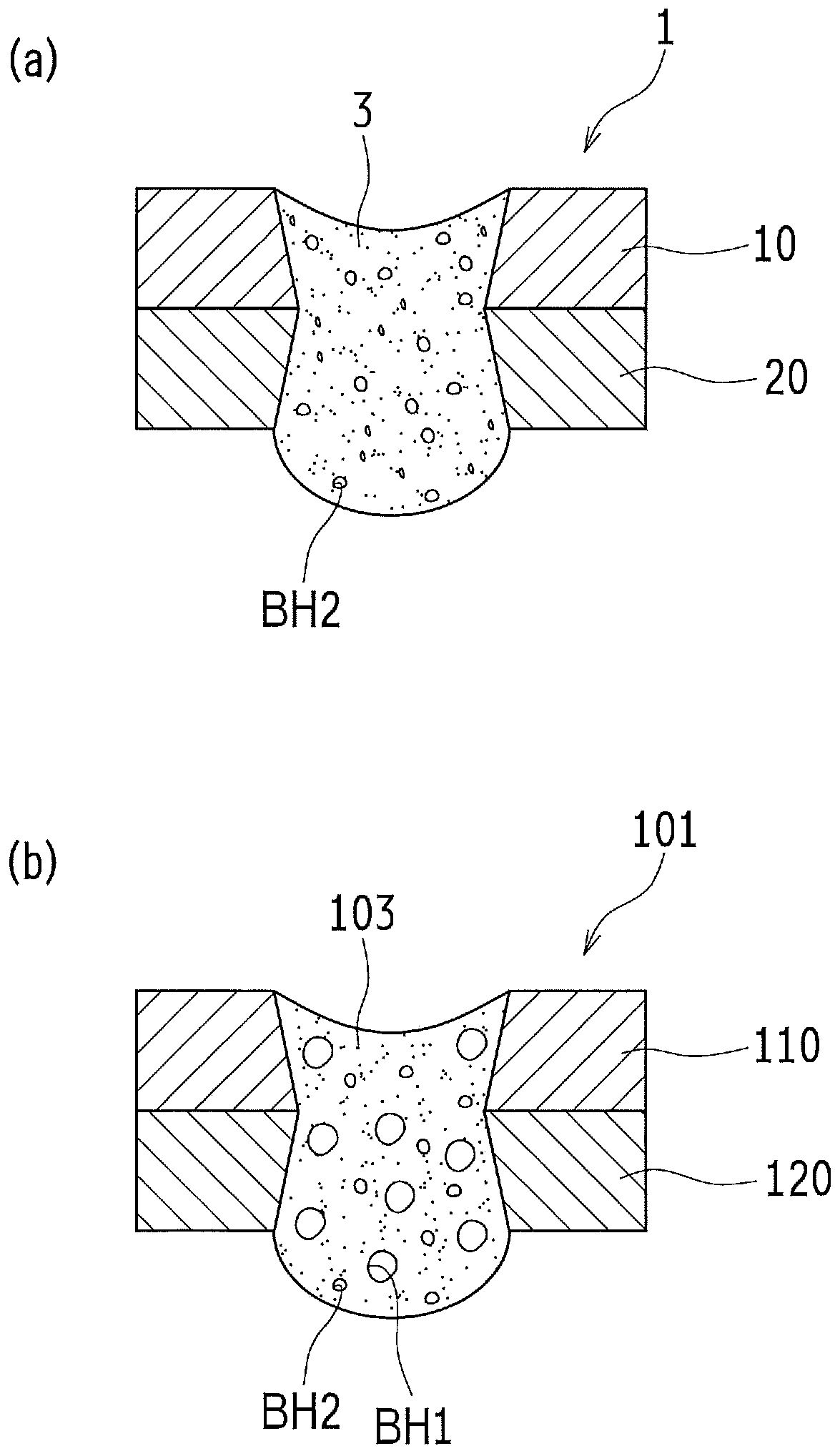

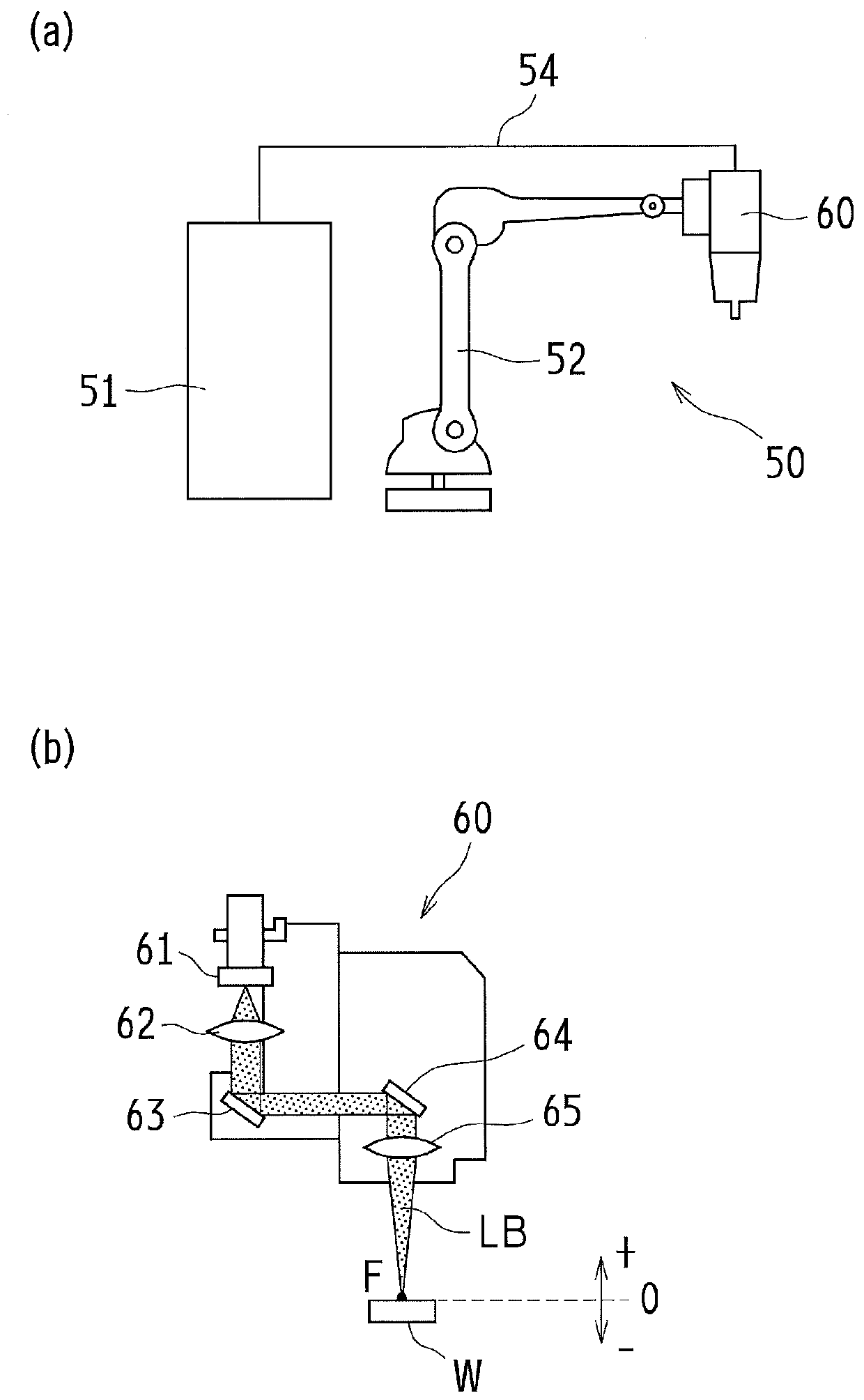

[0093] In the experimental example, such as Figure 8 As shown, an aluminum alloy plate 10 (110) with a width of 30 mm and a length of 100 mm and an aluminum alloy casting plate 20 (120) are placed so that the entire area in the width direction overlaps, and a square area of 30 mm in the length direction from the top Overlapping was carried out, and laser beam LB was irradiated to the center of the overlapping portion 5 (105), thereby manufacturing a test piece in which the aluminum alloy plate 10 (110) and the aluminum alloy casting plate 20 (120) were overlap-welded . In addition, the experimental example in which the said melting path and the said stirring path were implemented at the time of irradiation of the laser beam LB was made into the example of this invention, and the experimental example in which only the said melting path was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com