Electronic component installation device and electronic component installation method

An electronic component mounting and electronic component technology, applied in the direction of electrical components, electrical components, etc., can solve the problems of reduced productivity and reduced number of electronic component mounting devices, and achieve the effect of suppressing the decrease in productivity and shortening the operation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach >

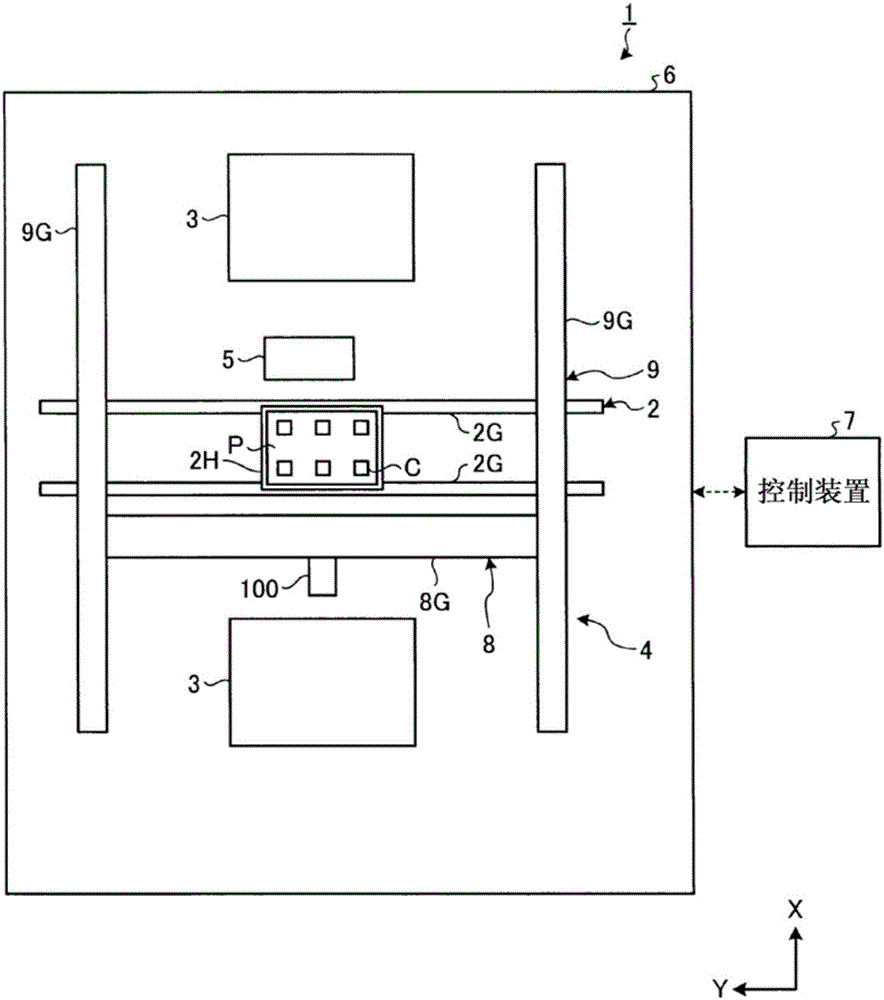

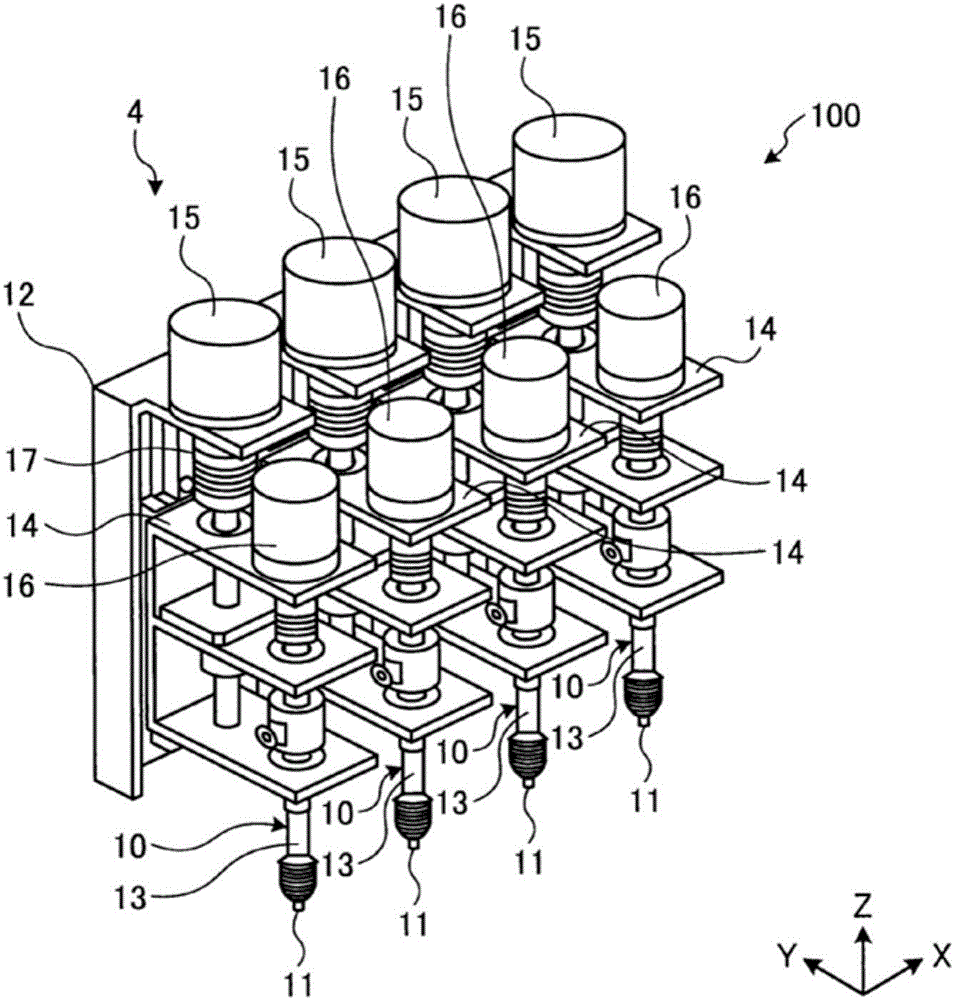

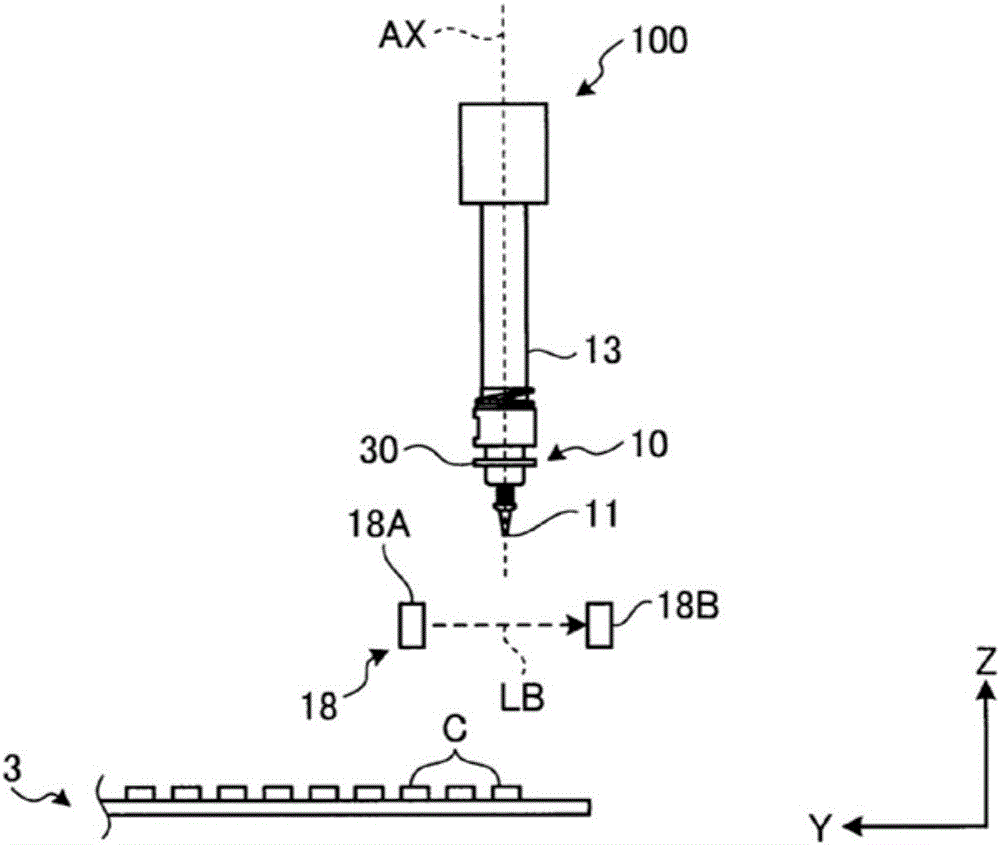

[0085] The first embodiment will be described. figure 1 It is a schematic diagram which shows an example of the electronic component mounting apparatus 1 which concerns on this embodiment. figure 2 It is a perspective view schematically showing an example of the mounting head unit 100 included in the electronic component mounting apparatus 1 according to this embodiment. image 3 It is a side view which shows an example of the mounting head unit 100 which concerns on this embodiment.

[0086] The electronic component mounting apparatus 1 mounts the electronic component C on the board|substrate P. As shown in FIG. The electronic component mounting device 1 is also referred to as a surface mount device 1 or a mounter 1 . The electronic component C may be a lead type electronic component having leads (plug-in type electronic component), or may be a chip type electronic component not having leads (mounted type electronic component). The lead type electronic component is mounte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com