Manufacturing device and manufacturing method

A technology for manufacturing devices and manufacturing methods, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as increased operating costs, and achieve the goal of suppressing the reduction in productivity, reducing processing load, and suppressing manufacturing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

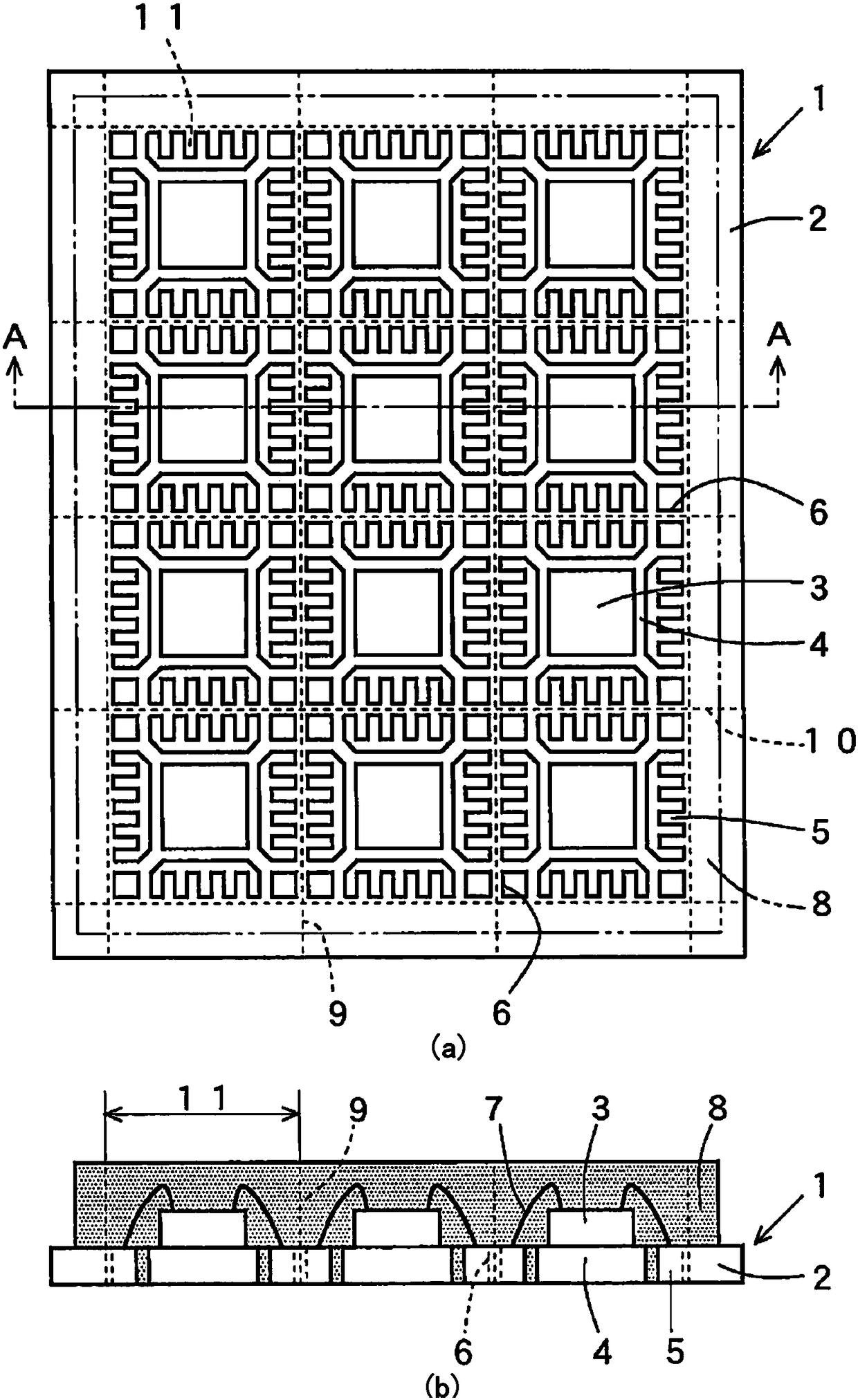

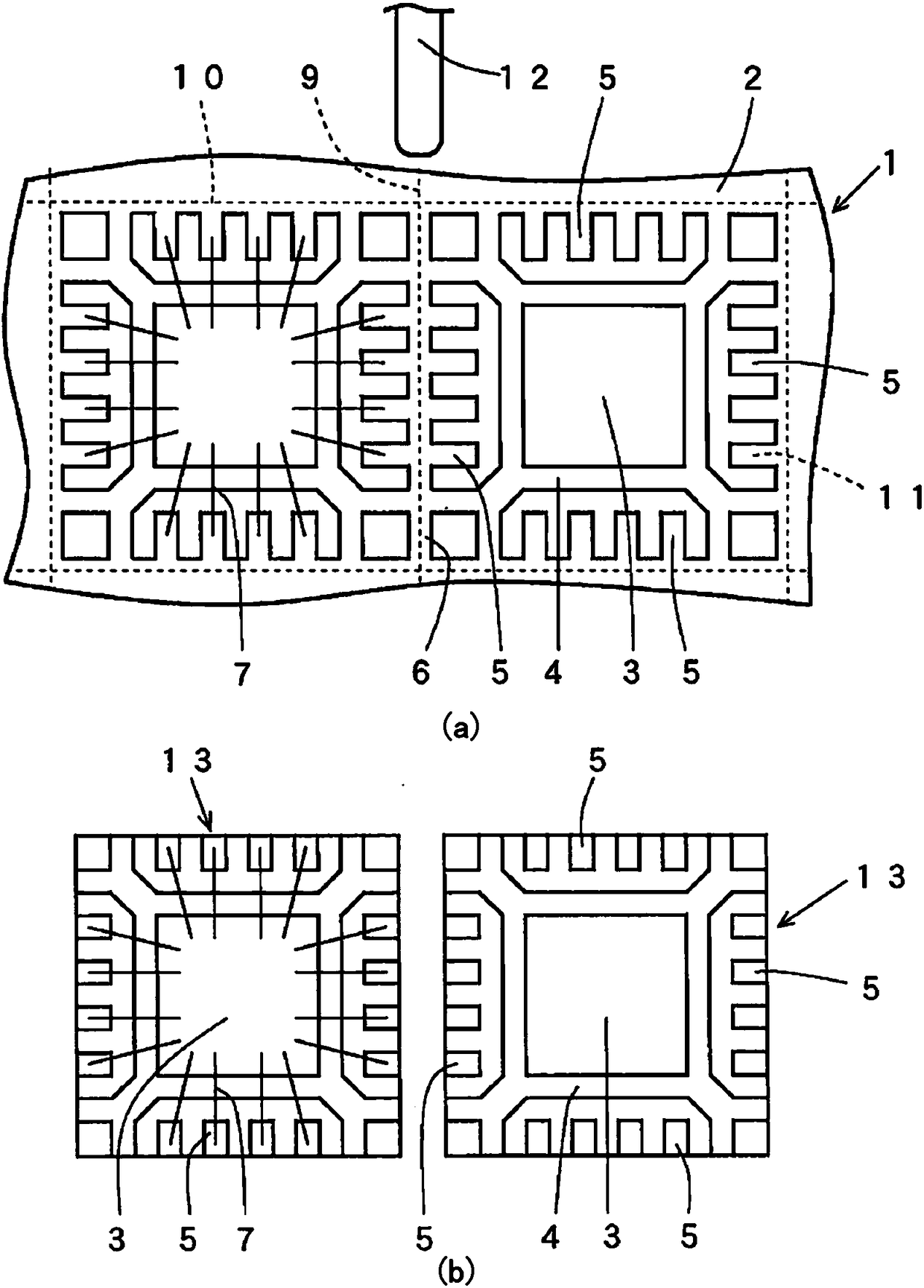

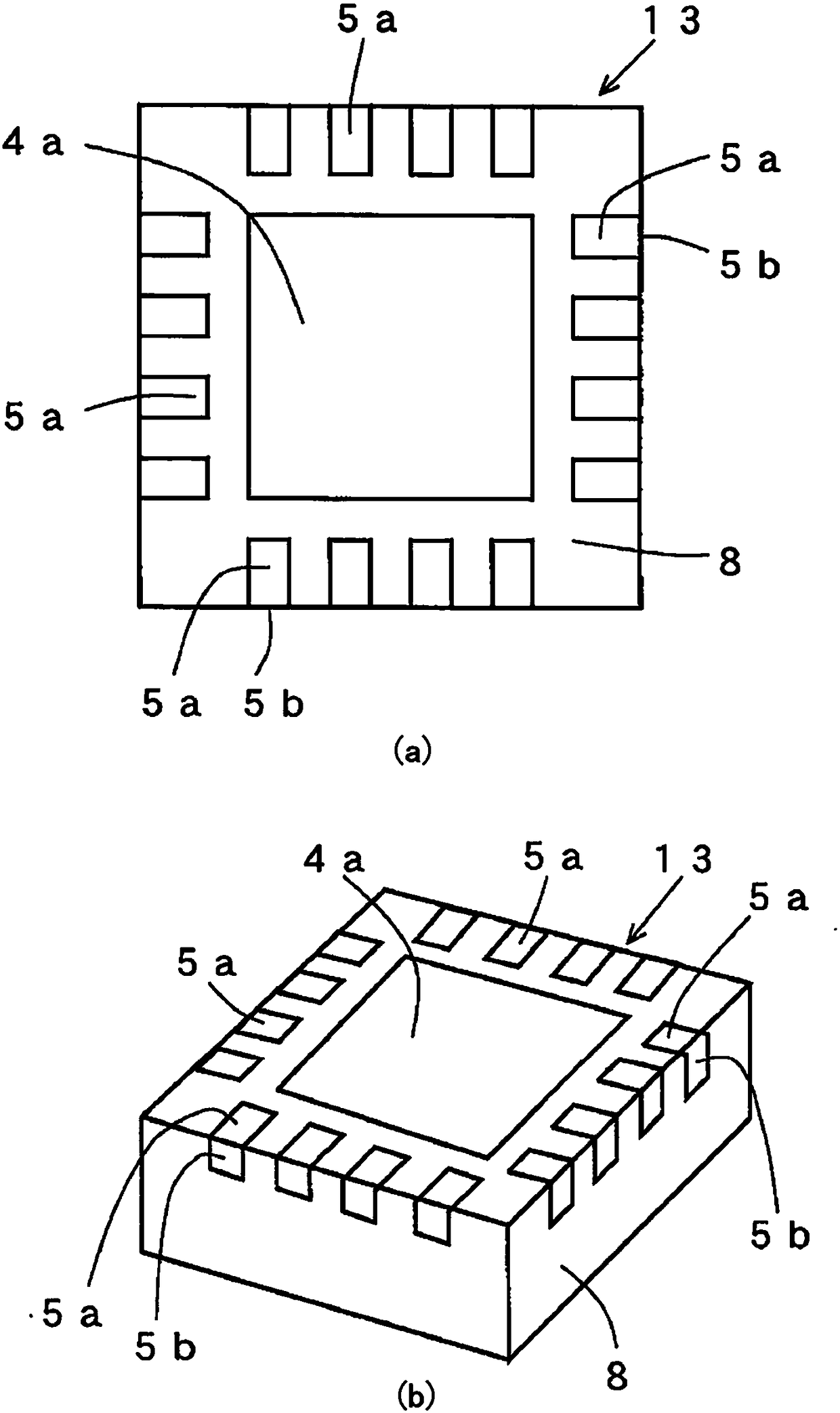

[0042] refer to figure 1 (a)~ Figure 7 (b) Example 1 of the production apparatus of the present invention will be described. For easy understanding, any of the drawings in this application document is appropriately omitted or exaggerated and schematically shown. The same reference numerals are assigned to the same constituent elements, and explanations thereof are appropriately omitted.

[0043] Such as figure 1 of (a), figure 1 As shown in (b), the QFN substrate 1 has a lead frame 2 . Semiconductor chip mounting portions (die pads: Japanese: dipad) 4 for mounting semiconductor chips (functional elements) 3 are arranged in a grid pattern on the lead frame 2 . The lead frame 2 is formed of metal such as copper (Cu) and 42 alloy (Fe—Ni), and its surface is subjected to lead-free tin plating (not shown). Many pins 5 are arranged around each die pad 4 . exist figure 1 of (a), figure 1 In (b), four pins 5 connected to electrodes (not shown) of the semiconductor chip 3 are...

Embodiment 2

[0078] refer to Figure 8 Example 2 of the production apparatus of the present invention will be described. Such as Figure 8 As shown, the manufacturing device 27 is a device for singulating a cut object (multilayer structure) into a plurality of products. The manufacturing apparatus 27 includes a substrate supply module A, a substrate cutting module B, and an inspection module C as respective components. Each component (modules A to C) is detachable and replaceable with respect to other components.

[0079] The substrate supply module A is provided with a substrate supply mechanism 28 . The QFN substrate 1 corresponding to the object to be cut is delivered from the substrate supply mechanism 28 and transferred to the substrate cutting module B by a transfer mechanism (not shown). In the board|substrate supply module A, the control part CTL for setting and controlling the operation|movement of the manufacturing apparatus 27, cutting conditions, etc. is provided.

[0080]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com