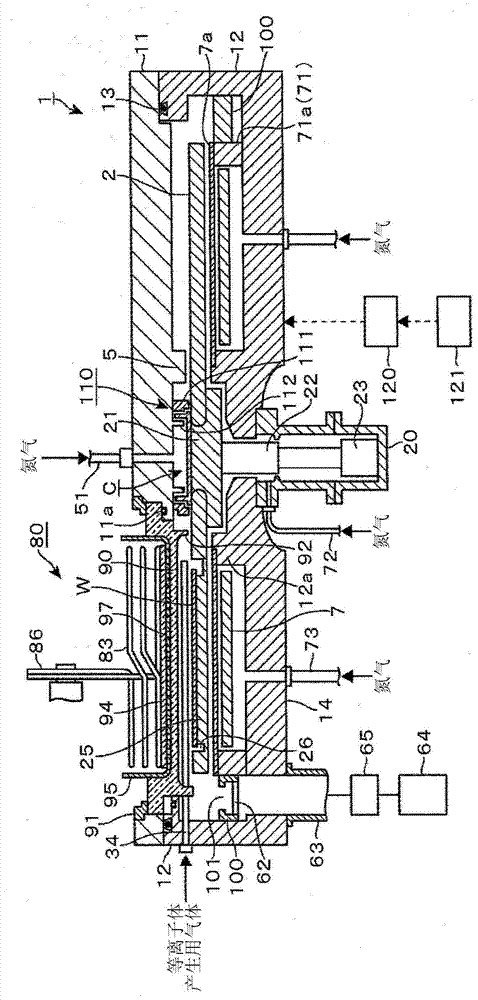

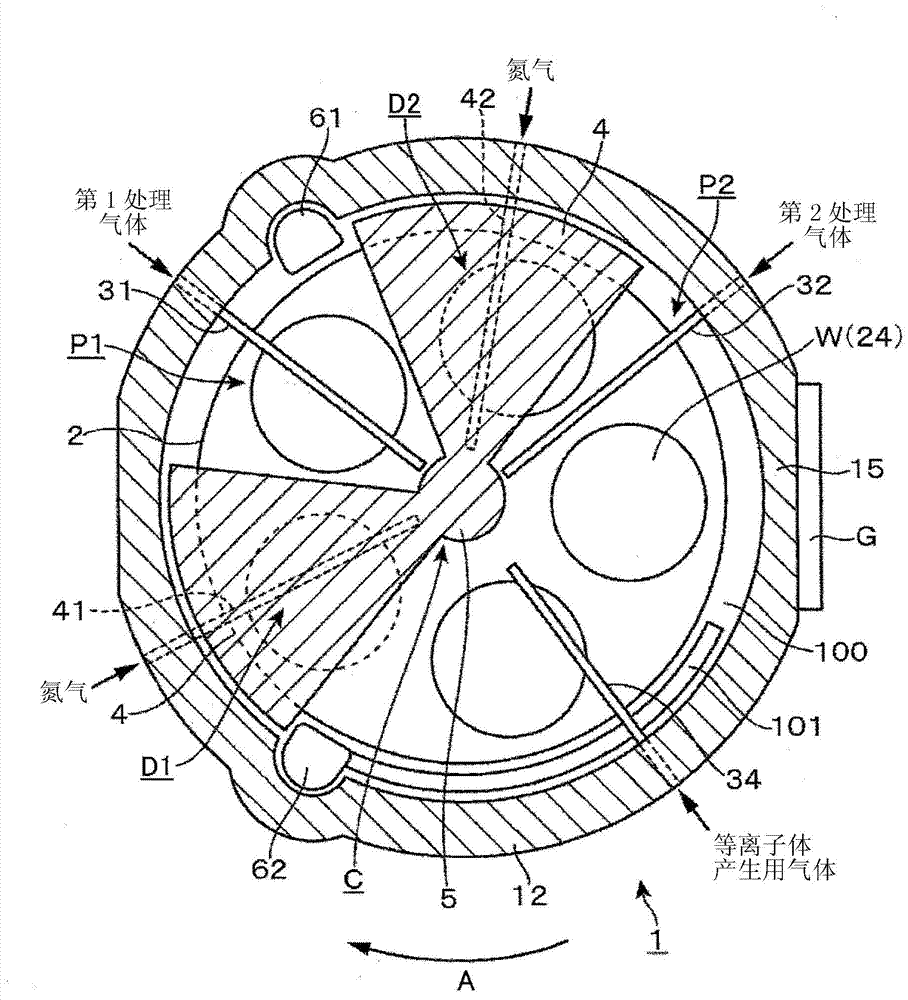

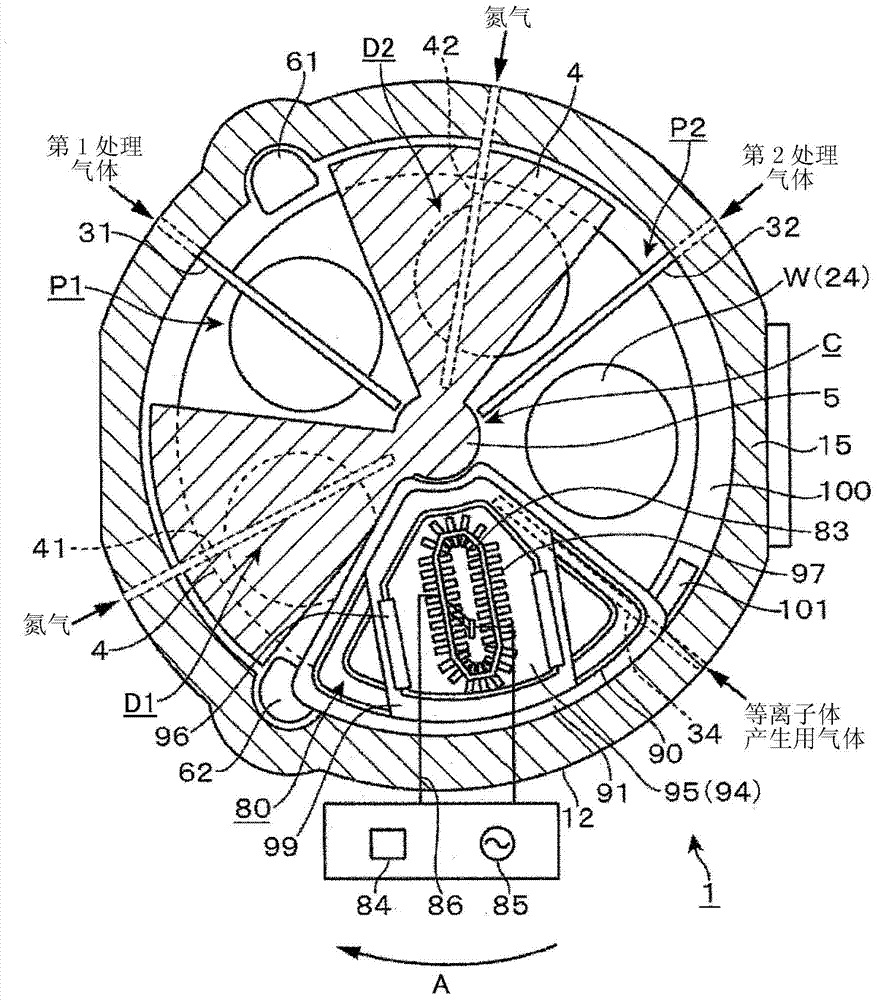

Substrate processing apparatus

A substrate processing device and substrate technology, applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve problems such as productivity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0105] use the above figure 1 The substrate processing device was used to perform film formation on five wafers 1 to 5, and the results are shown in the following Table 2 and Figure 23 As shown in FIG. 2 , there were very few particles adhering to the surfaces of the aforementioned wafers 1 to 5 .

[0106] Table 2: Examples

[0107]

Wafer 1

Wafer 2

Wafer 3

Wafer 4

Wafer 5

0.10μm~0.16μm

13

15

16

15

27

0.16μm~0.30μm

7

21

12

10

9

0.30μm~0.70μm

0

9

3

7

1

0.70μm~3.00μm

0

0

0

0

0

3.00μm~

0

0

0

0

0

total

20

45

31

32

37

average

31

[0108] On the other hand, using the above Figure 7 and Figure 8 The same treatment was carried out on the rotary table 2 described (comparative example 1), and the results are shown in Table 3 and Figure 24 As show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com