Vibration-damping reinforcing composition, vibration-damping reinforcing material, and vibration-damping reinforcing method for thin plate

A composition and thin plate technology, applied in chemical instruments and methods, thin material processing, non-rotational vibration suppression, etc., can solve the problems of reduced operability, reduced productivity, and complicated manufacturing methods of foamable thermosetting resin sheets. Achieve the effects of less complicated manufacturing method, suppressing the decrease in productivity, and suppressing the increase in weight and thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

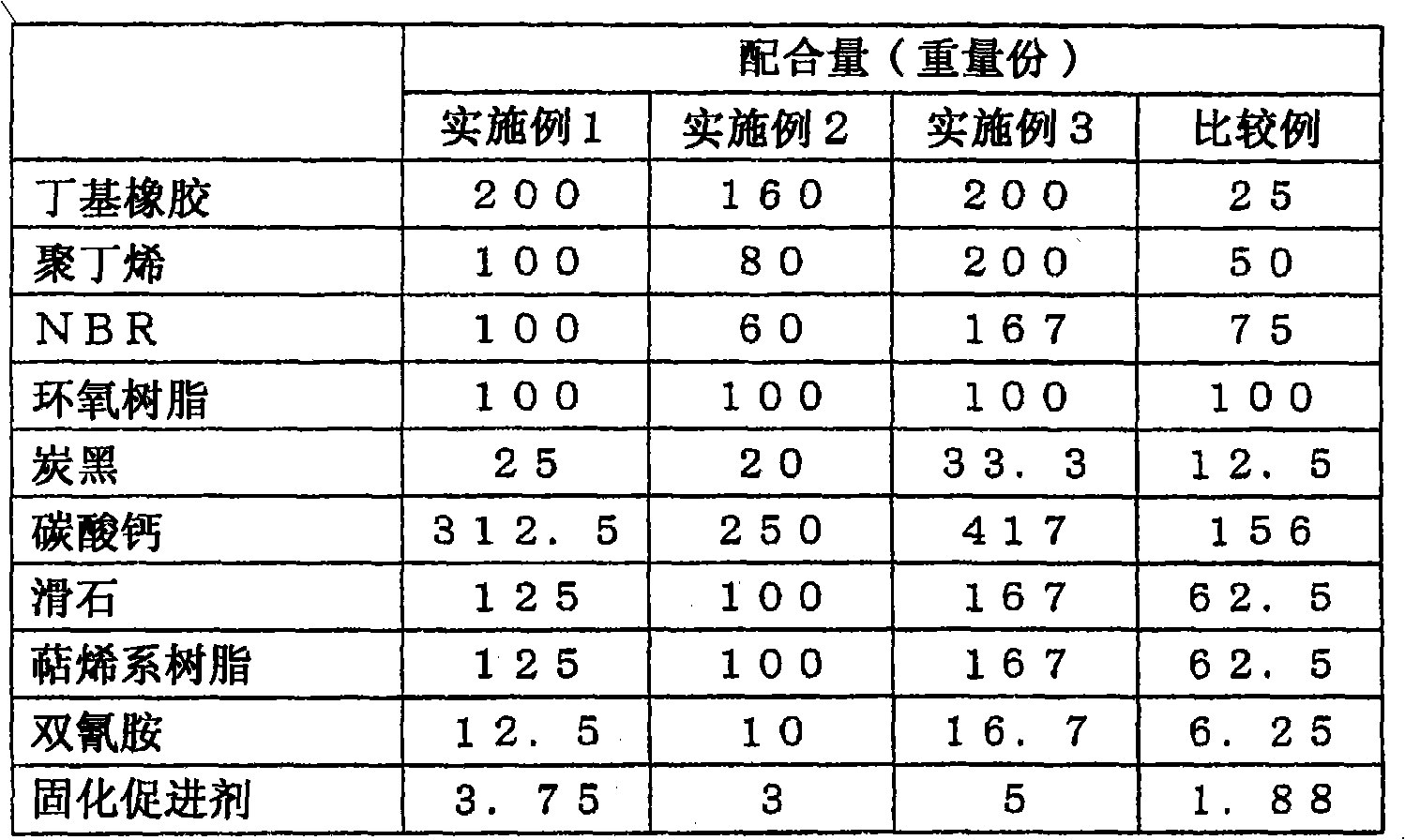

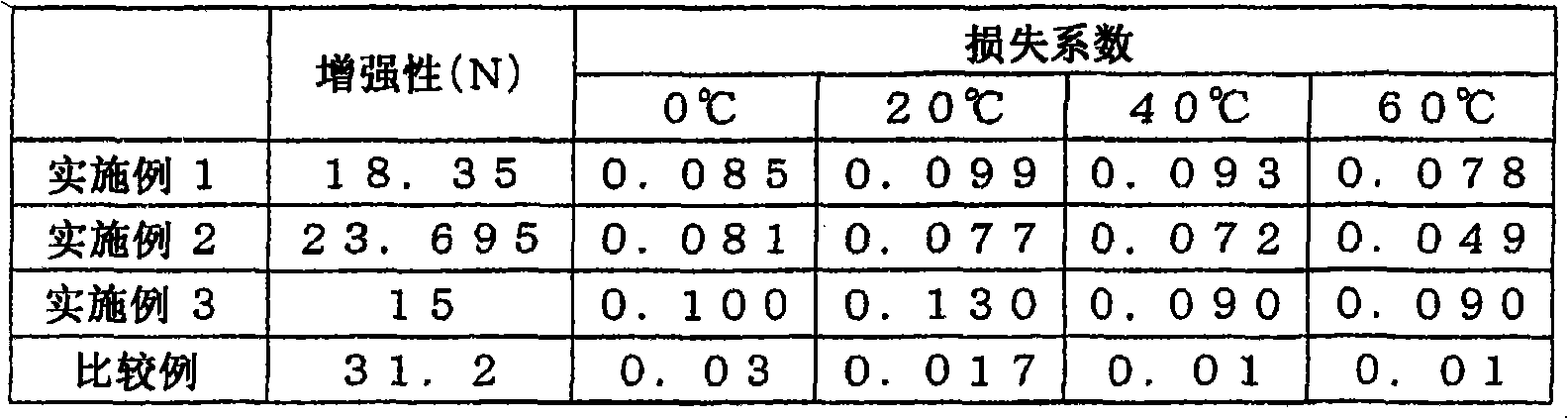

[0080] Examples and comparative examples are given below to describe the present invention in more detail, but the present invention is not limited to the examples and comparative examples.

[0081] Embodiment 1~3 and comparative example

[0082] (Preparation of Vibration Reinforcement Composition)

[0083] In the compounding recipe shown in Table 1, each component was compounded on the basis of parts by weight, and these were kneaded by the grinding roll, and the vibration-damping reinforcement composition was prepared.

[0084] Table 1

[0085]

[0086] In addition, the detail of the component in Table 1 or its abbreviation is shown below.

[0087] Butyl rubber: JSR butyl 268, unsaturation 1.6, Mooney viscosity 51 (ML 1+8 , at125°C), manufactured by JIS Corporation

[0088] Polybutene: Japanese stone polybutene HV300, dynamic viscosity 26000mm 2 / s(at40℃), dynamic viscosity 590mm 2 / s(at100℃), manufactured by Nippon Oil Corporation

[0089] NBR: acrylonitrile-butadie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com