Insulative film etching device

An etching device and insulating film technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of unstable substrate temperature, non-uniformity, promoting film accumulation, etc., to suppress productivity reduction and cleaning frequency. Less and more efficient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

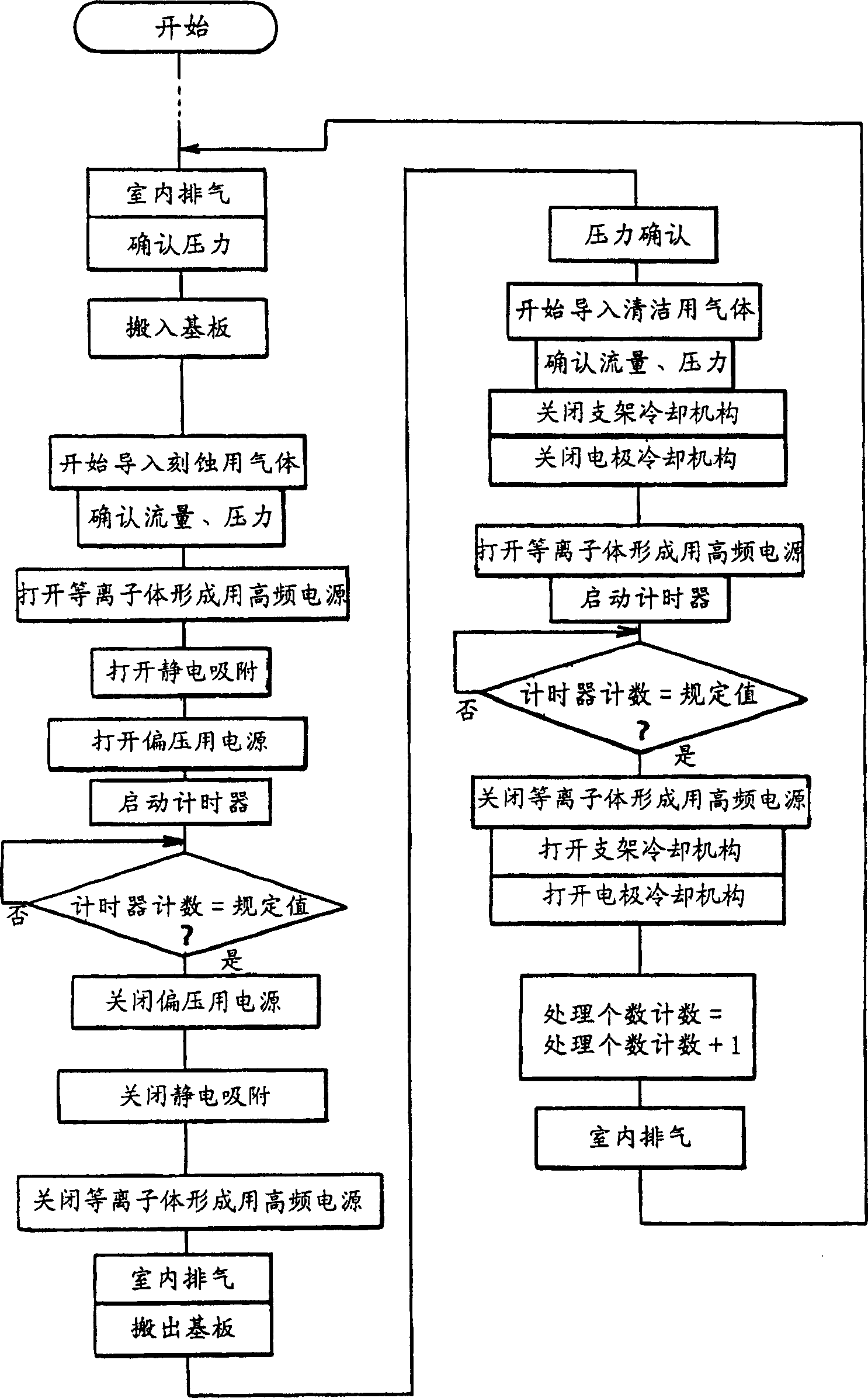

[0033] Next, examples of the present invention will be described.

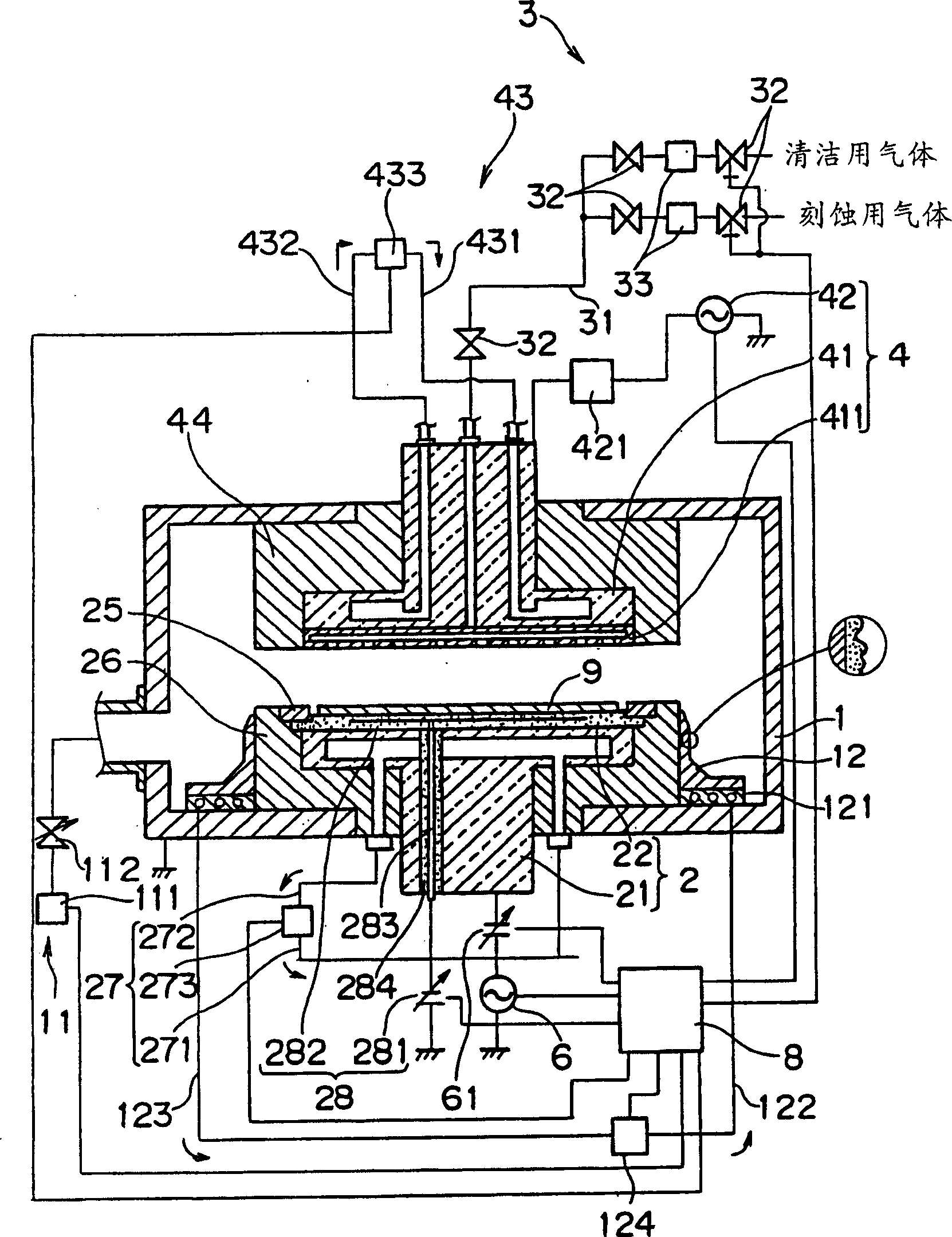

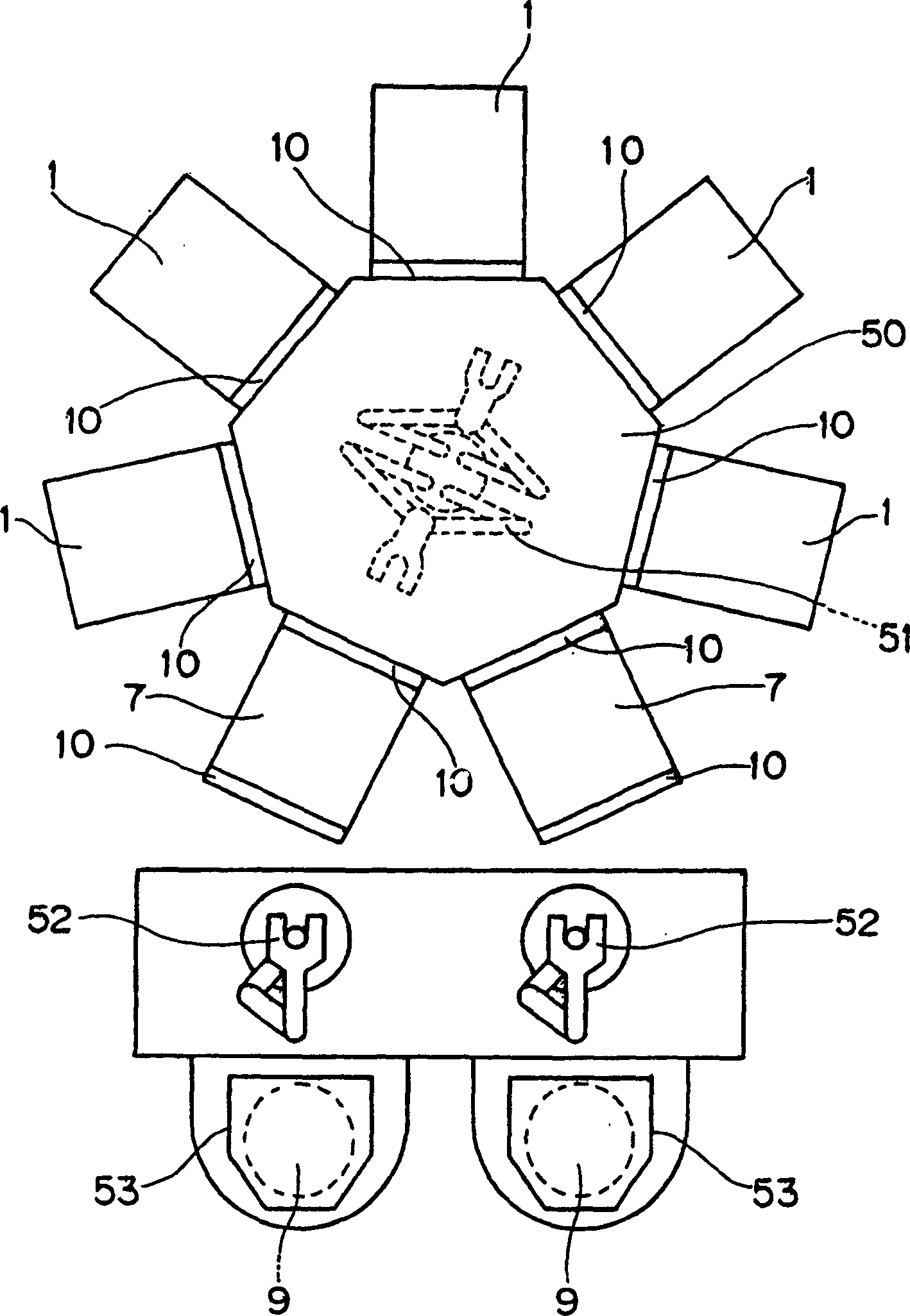

[0034] figure 1 is a schematic front cross-sectional view showing the structure of the main part of the insulating film etching apparatus according to the embodiment of the present invention. figure 1 The shown device has: a processing chamber 1, which has an exhaust system 11, and performs etching processing inside; a substrate holder 2, which keeps the substrate 9 at a predetermined position in the processing chamber 1; a gas introduction system 3, which controls the etching process. The gas is introduced into the processing chamber 1; the plasma forming device 4 forms the plasma of the introduced gas;

[0035] The processing chamber 1 is an airtight vacuum container. The processing chamber 1 is formed of metal such as stainless steel, and is electrically grounded. The exhaust system 11 is equipped with a vacuum pump 111 such as a dry pump and an exhaust speed regulator 112, and can maintain the inside of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com