Carburized-steel-component production method, and carburized steel component

一种制造方法、渗碳钢的技术,应用在渗碳钢部件的制造,渗碳钢部件领域,能够解决工序数量降低生产率、提高制造成本等问题,达到抑制生产率的降低、提高气体渗碳性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

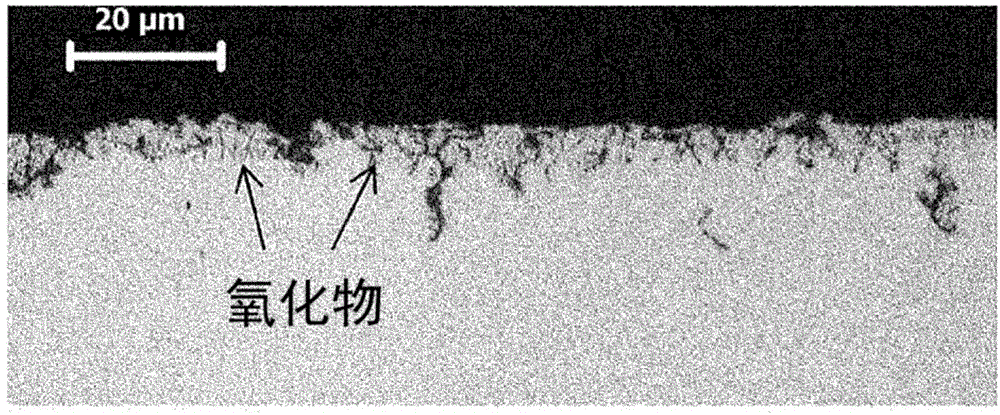

[0174] [Measurement of effective hardened layer depth and internal oxide ratio of carburized steel parts]

[0175] Steel materials of steel numbers 1 to 34 having the chemical compositions shown in Table 1 were prepared. Each steel material is subjected to hot forging and heat treatment to produce an intermediate product. Cutting processing (machining) was performed on the intermediate product to manufacture a 20 mm×20 mm square column-shaped steel part.

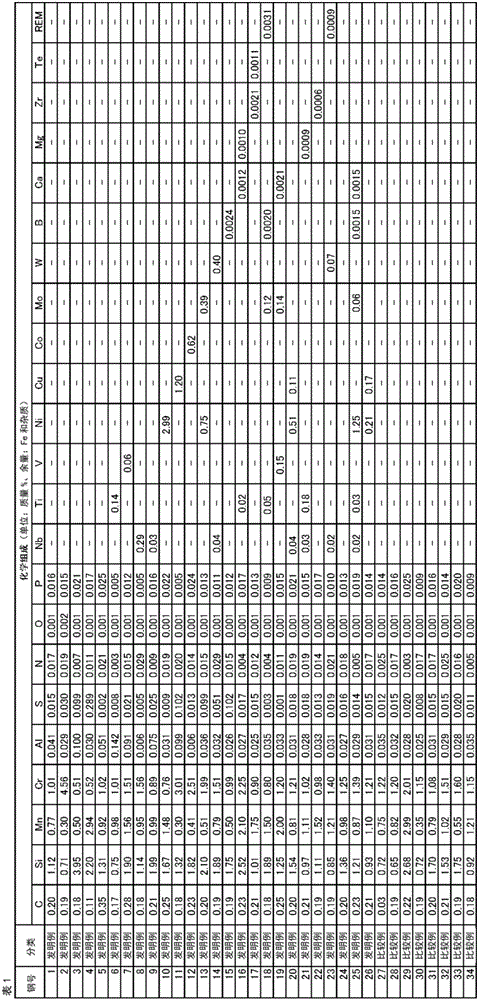

[0176] Table 1

[0177]

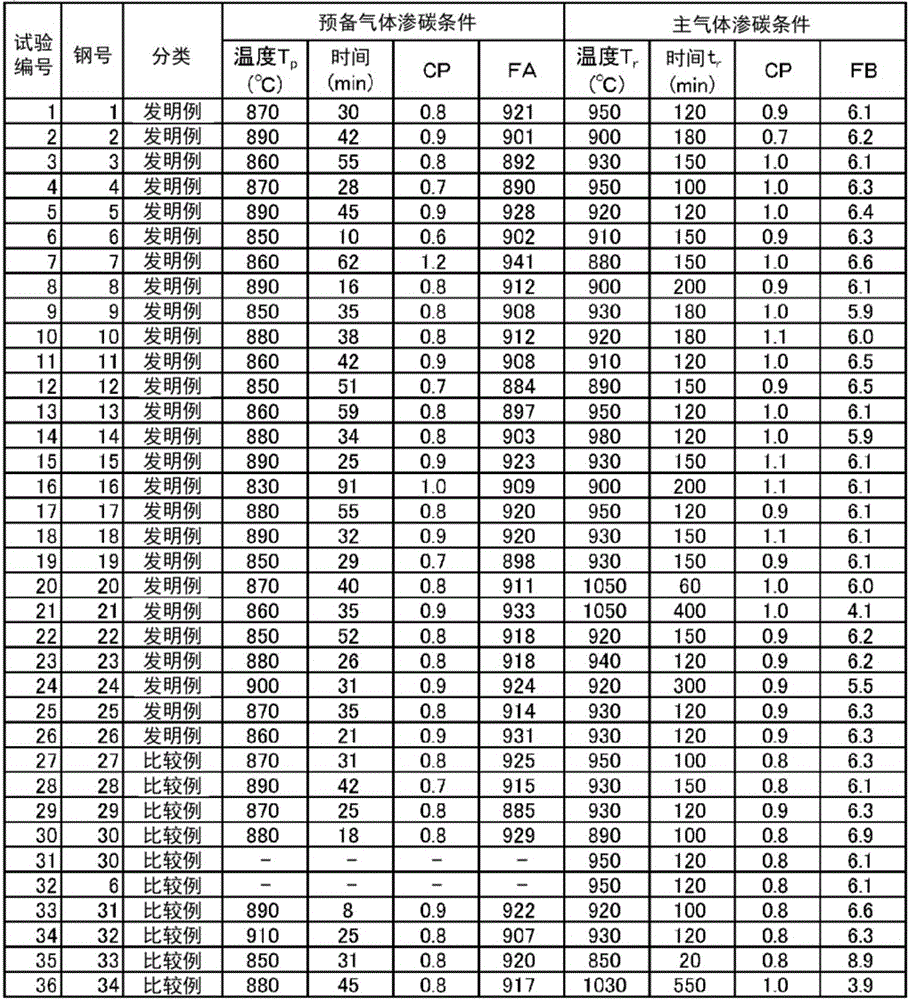

[0178] As shown in Table 2, the preliminary gas carburization and the main gas carburization were performed on the steel parts of each test number under the conditions shown in Table 2.

[0179] [Table 2]

[0180] Table 2

[0181]

[0182] In test numbers 1 to 30 and 33 to 36, the preliminary gas carburizing step was implemented under the conditions (carburizing temperature, carburizing time, carbon potential CP) shown in Table 2. Furthermore, following the preliminary gas carburizing ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com