Electric energy storage device and its manufacturing method

A technology for electrical storage equipment and battery components, which is applied in the manufacture of electrolyte batteries, secondary batteries, and final products, and can solve problems such as short circuit of rivet shafts, increased cost, operability, and insulation damage, so as to improve operability and suppress Productivity reduction, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0153] The specifications of each component used in the verification are as follows.

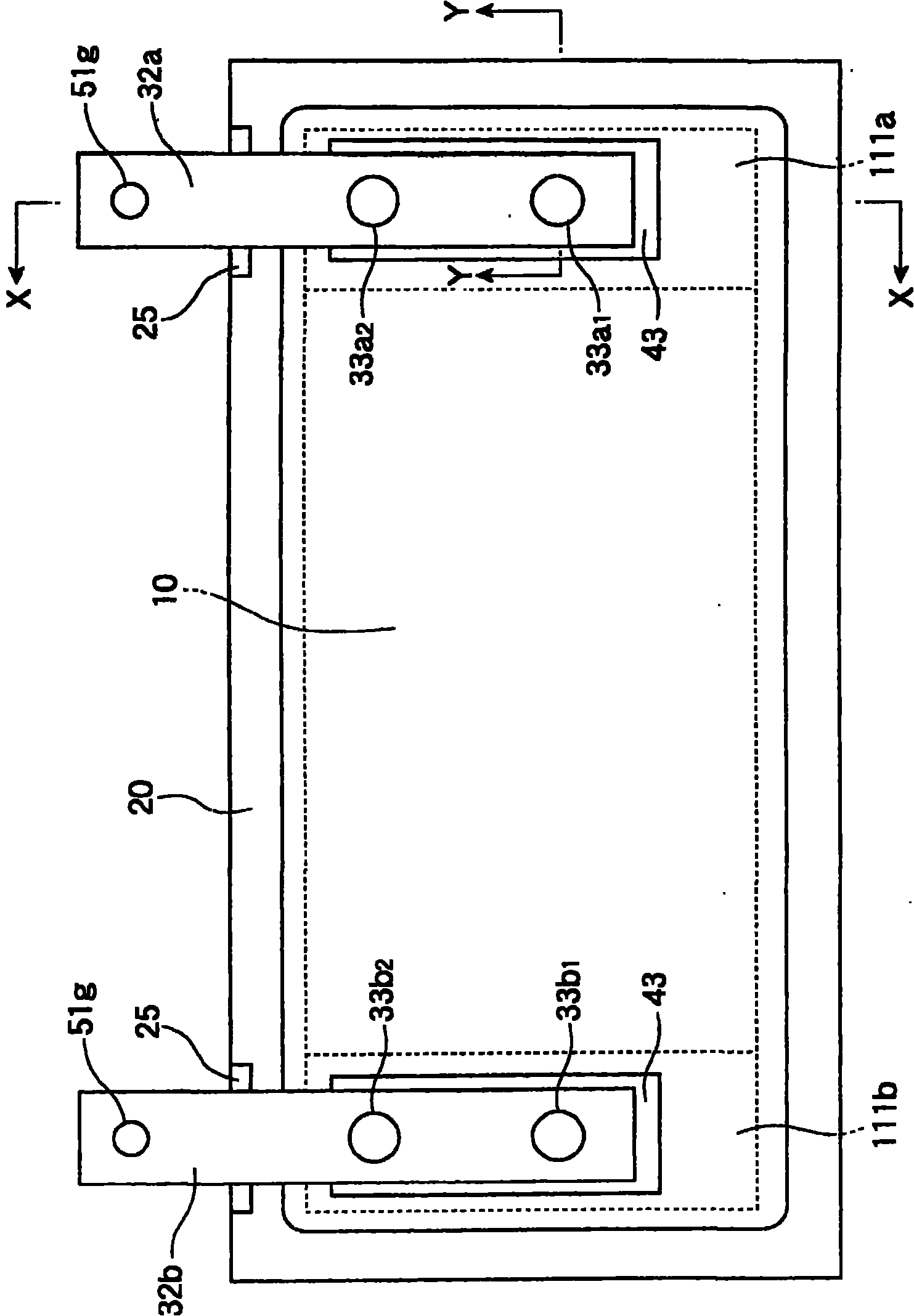

[0154] ・Battery element 10: 300mm (L size) x 120mm (W size) x 5mm (T size)

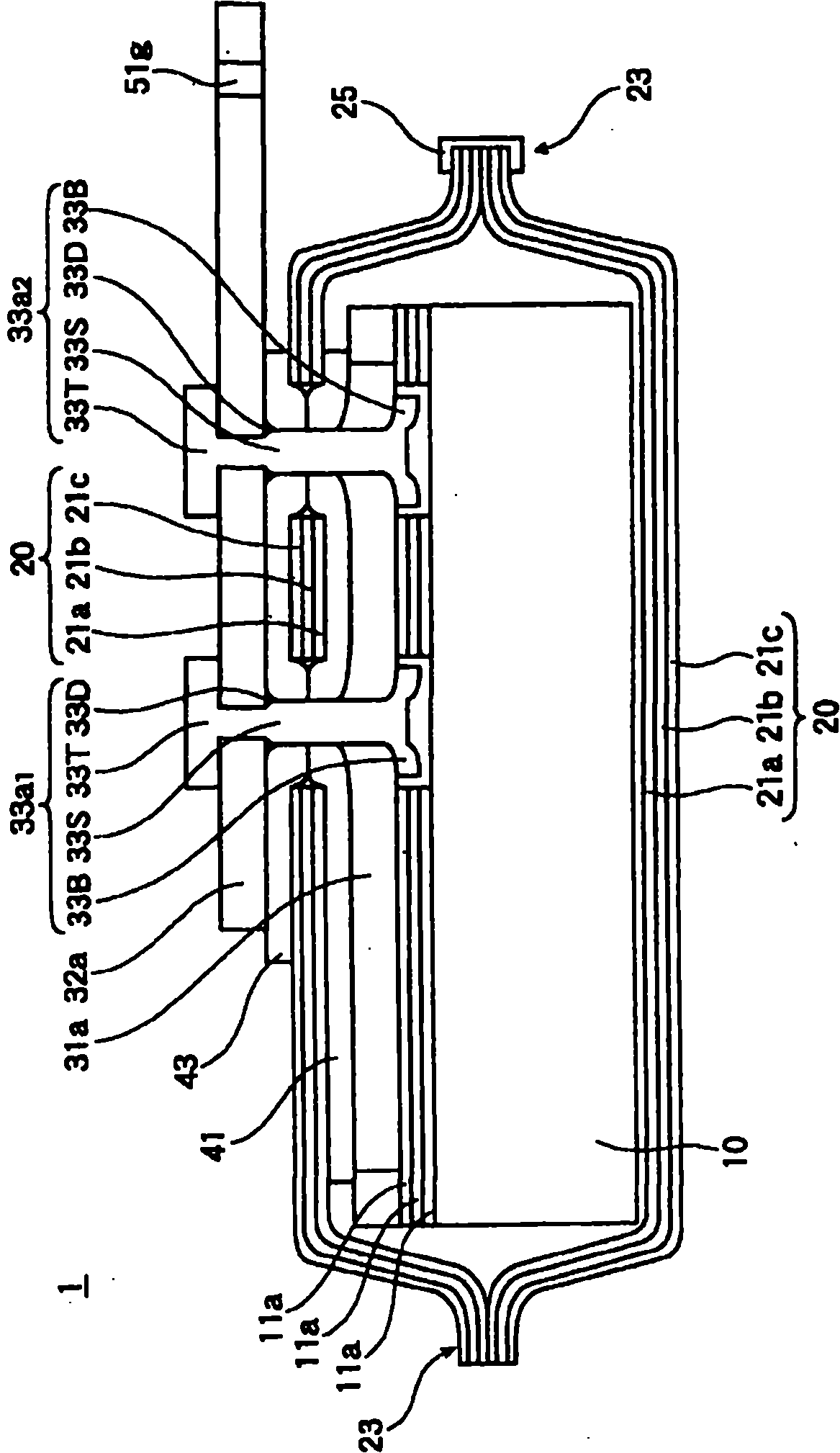

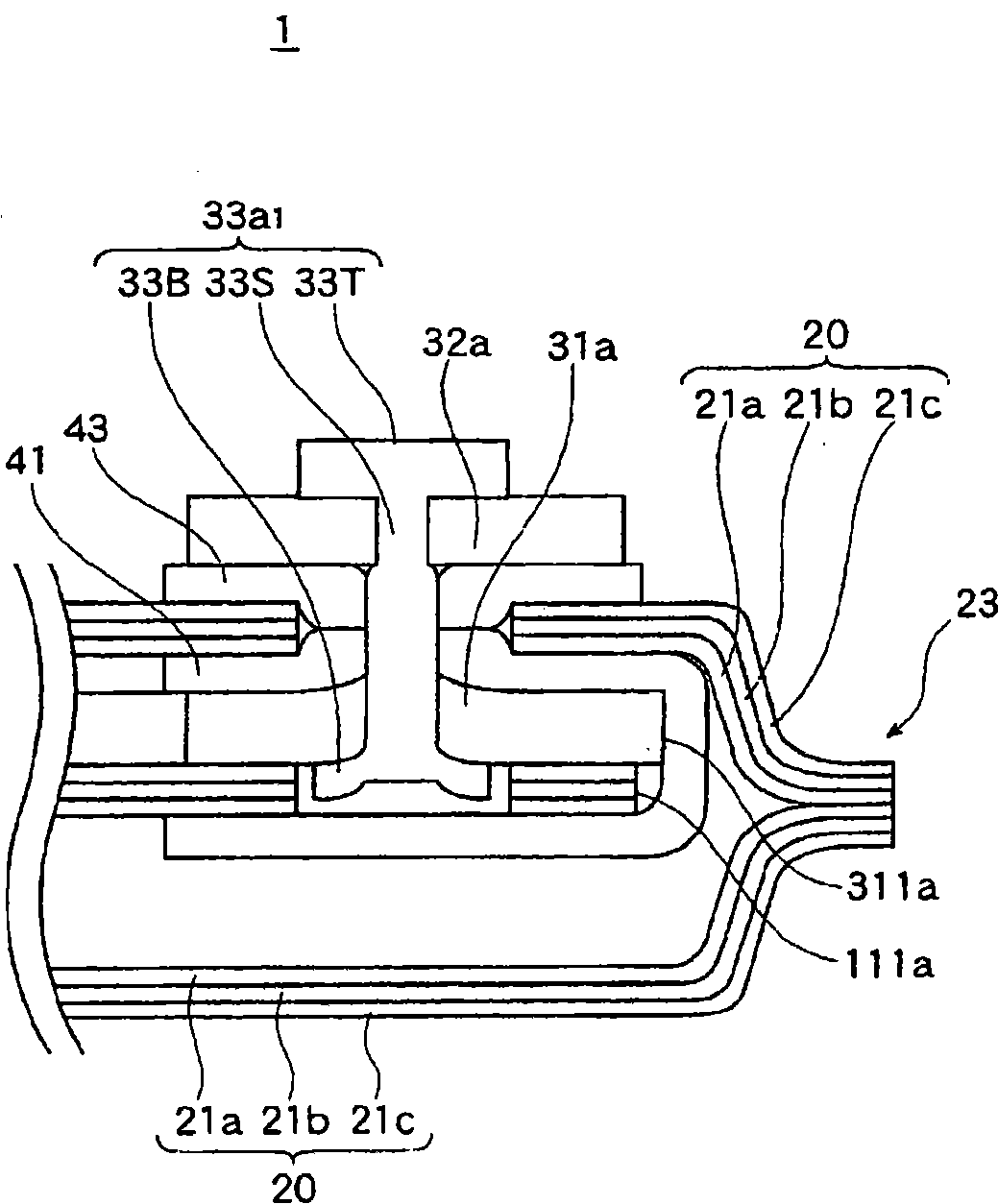

[0155] ・Inner lead wire 31: 100 mm (L size) x 15 mm (W size) x 1.5 mm (T size), made of aluminum, diameter of through hole 51a: 4 mm

[0156] ・External lead wire 32: 100 mm (L size) x 15 mm (W size) x 1.5 mm (T size), made of aluminum or copper, diameter of through hole 51e: 4 mm

[0157] ・Rivet 33: Diameter 4mmΦ×length 6mm of through shaft 33S, rivet made of aluminum or copper, diameter of outer flange portion 33T: 8mm

[0158] ・Inner insulating member 41, outer insulating member 43: made of polypropylene with a thickness of 250 μm, diameter of each through-hole 51b, 51d: 4mm

[0159] ・Outer package 20: 320mm (L size) x 135mm (W size) x 7mm (T size) aluminum laminate (inner surface layer 21a: polypropylene with a thickness of 80 μm, metal layer 21b: aluminum foil with a thickness of 40 μm, outer layer: Nylon wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com