Coating processing apparatus and coating liquid collecting member

A technology for processing devices and coating liquids, which is applied in the direction of surface coating liquid devices, spraying devices, coatings, etc., which can solve problems such as poor productivity, lower exhaust pressure, and easy scattering of coating liquids, and achieve suppression Effect of accumulation, suppression of decrease in productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

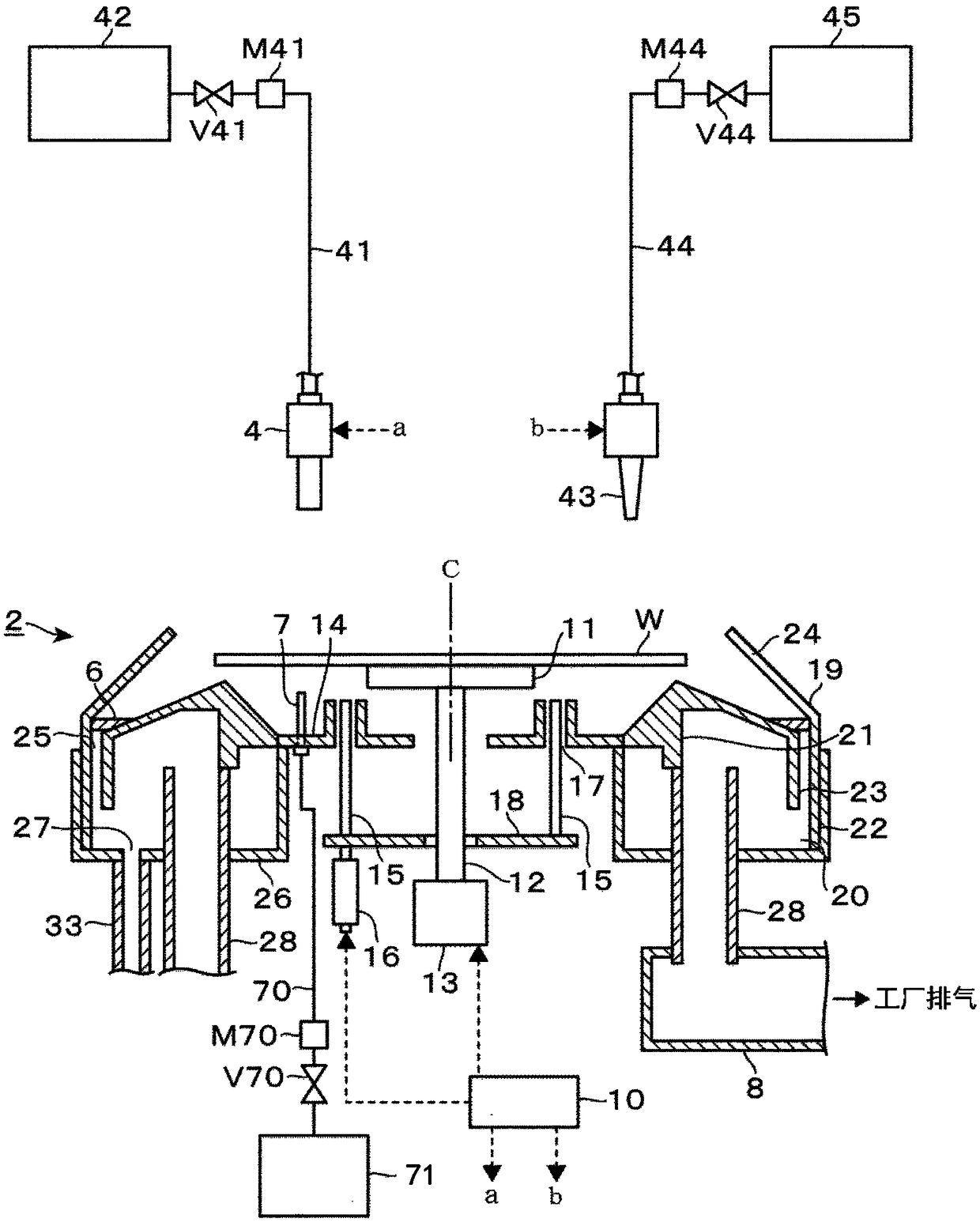

[0077] In order to verify the suppression of fluctuations in exhaust pressure due to the installation of coating liquid trapping members, use figure 1 In the resist coating apparatus shown, the set exhaust pressure of the cup body 2 set by the opening degree of the regulating valve provided to the exhaust duct 8 is set to 50 Pa, and the exhaust pressure shown in the embodiment is followed. In the method, 100 wafers W are coated with a resist solution, and the inside of the cup body 2 (closer to the coating liquid collection member 6) when 0, 25, 50, 75, and 100 wafers W are processed The exhaust pressure at the position on the downstream side) was measured. In addition, as a comparative example, processing was performed in the same manner as in the examples except that the coating liquid collecting member 6 was not provided.

[0078] Figure 13 This result is shown in a characteristic diagram in which the number of processed wafers W is shown on the horizontal axis and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com