Synthetic fuel production methods and apparatuses

a technology of synthetic fuel and production methods, applied in lighting and heating apparatuses, furnaces, muffler furnaces, etc., can solve the problems of reducing the production of pollutants associated with conventional coal-fired electricity generation operations, and achieve the effects of improving the conversion of carbon, improving the production of carbon monoxide and hydrogen, and enhancing yields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

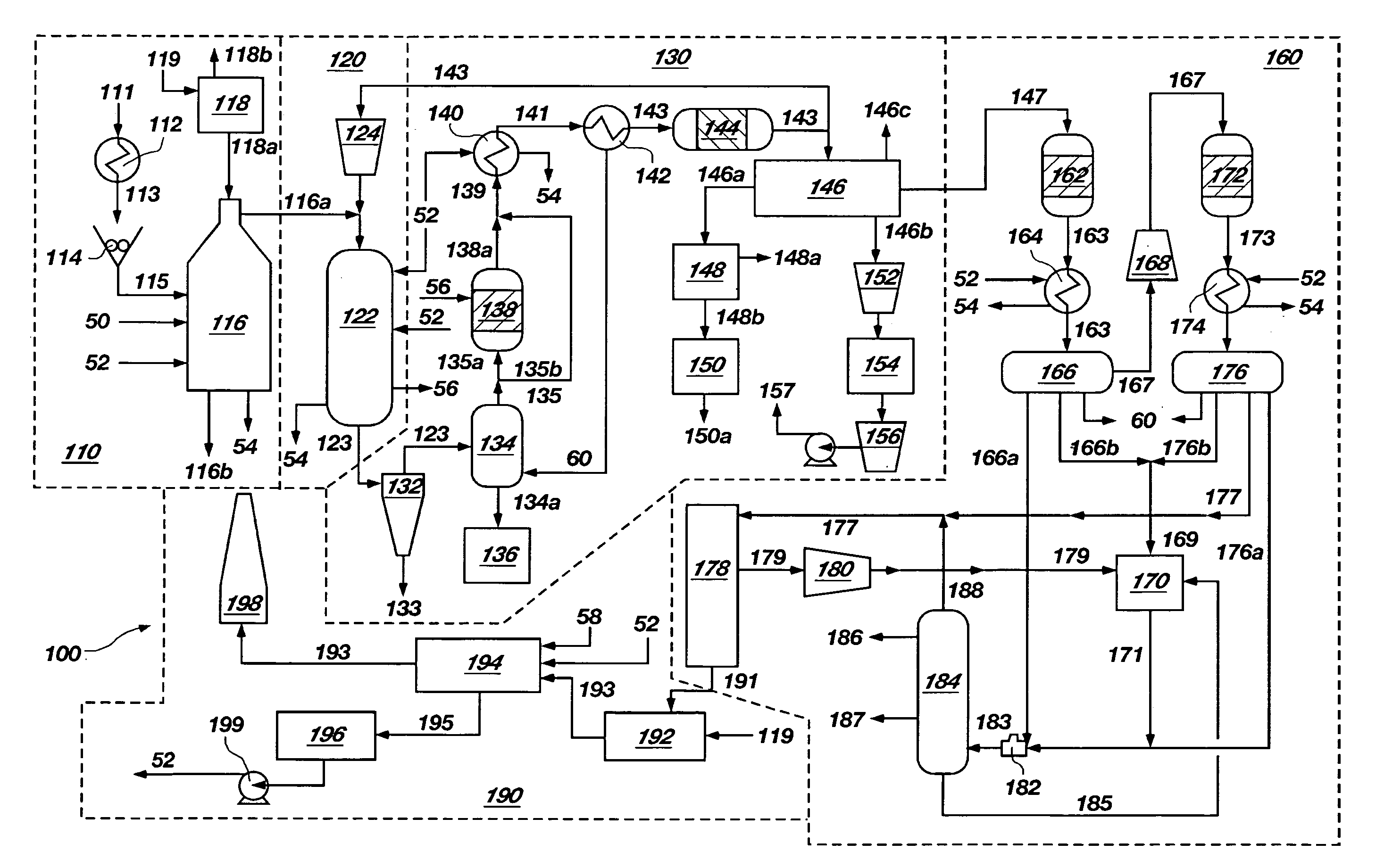

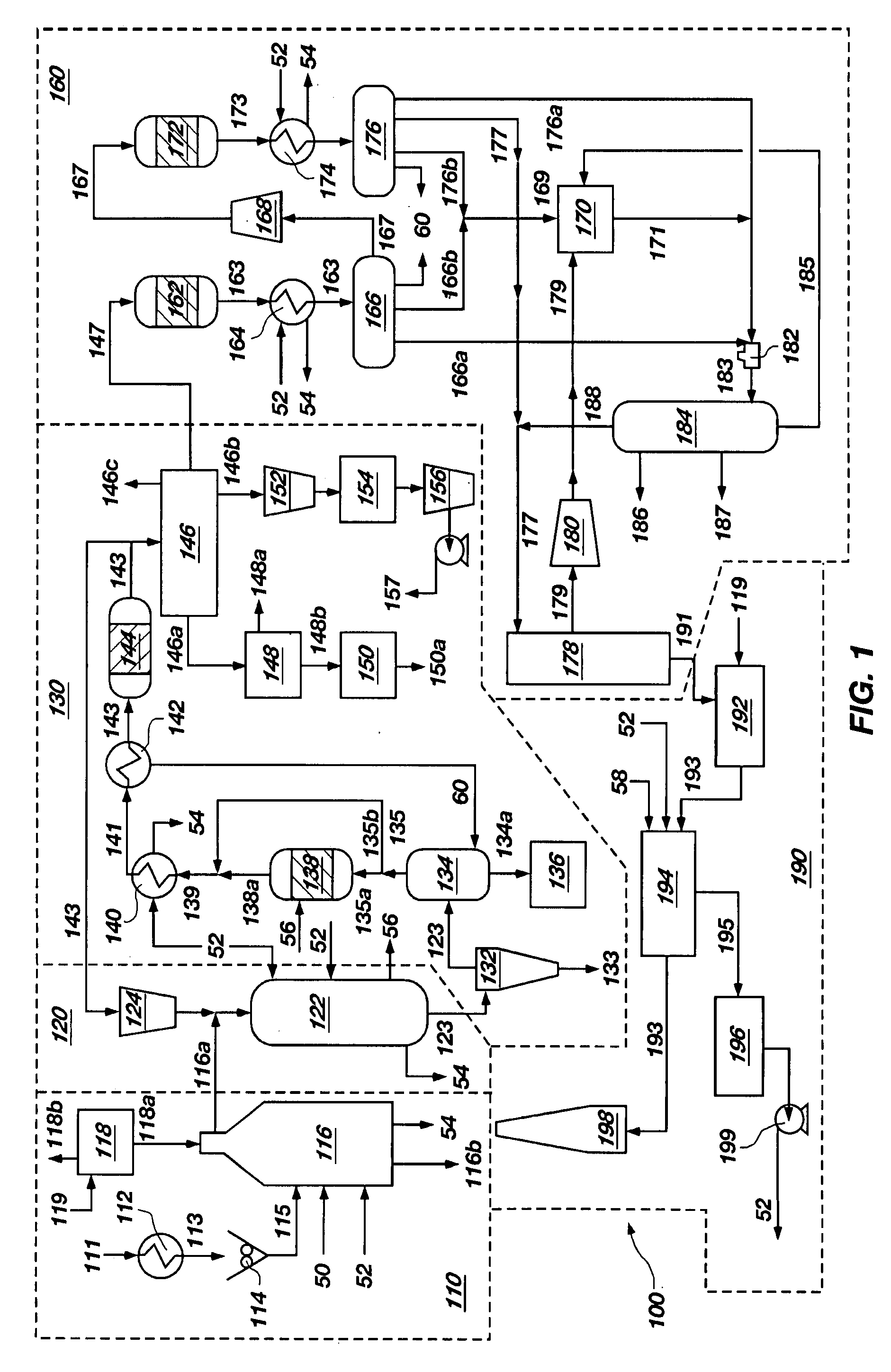

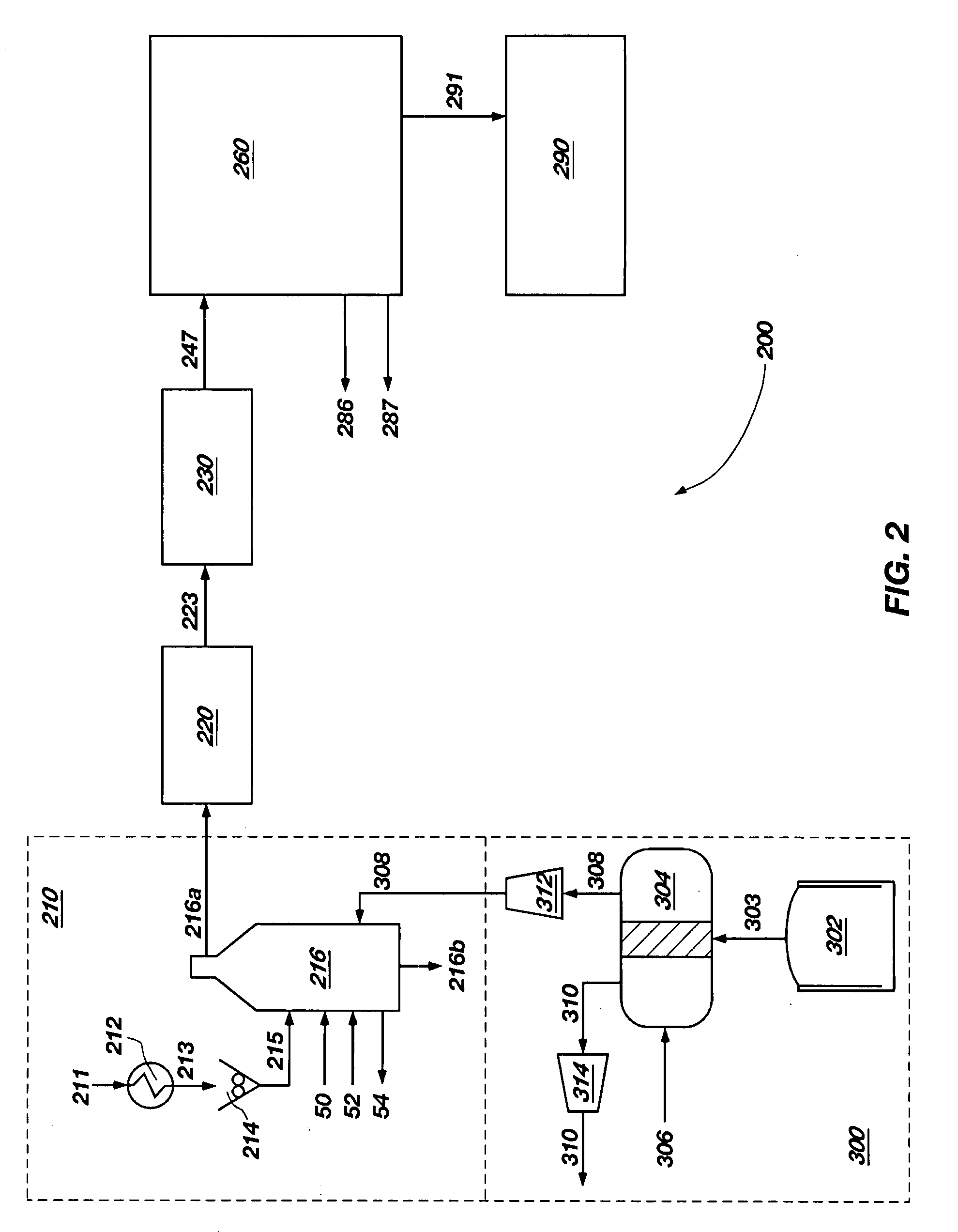

[0053]According to embodiments of the invention, a nuclear power source may be integrated with or incorporated into a liquid fuel production process, such as a coal-to-liquid hydrocarbon production process, to facilitate the production of hydrocarbons and liquid fuel products from coal. Although the additional heat produced by a nuclear power source may not be needed in a conventional coal-to-liquid hydrocarbon production process, the integration of a nuclear power source with a coal-to-liquid hydrocarbon production process, or other liquid fuel production process, facilitates the use of alternative processes to produce oxygen (O2) and hydrogen (H2), allowing expensive equipment to be removed from a liquid fuel production process.

[0054]While various embodiments of the invention may be integrated with liquid fuel production processes, many of the embodiments will be described with respect to a coal-to-liquid hydrocarbon production process. It is understood that other liquid fuel prod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com