Boiler air bin air distributing device with built-in flow stabilization and flow shunting and guide functions

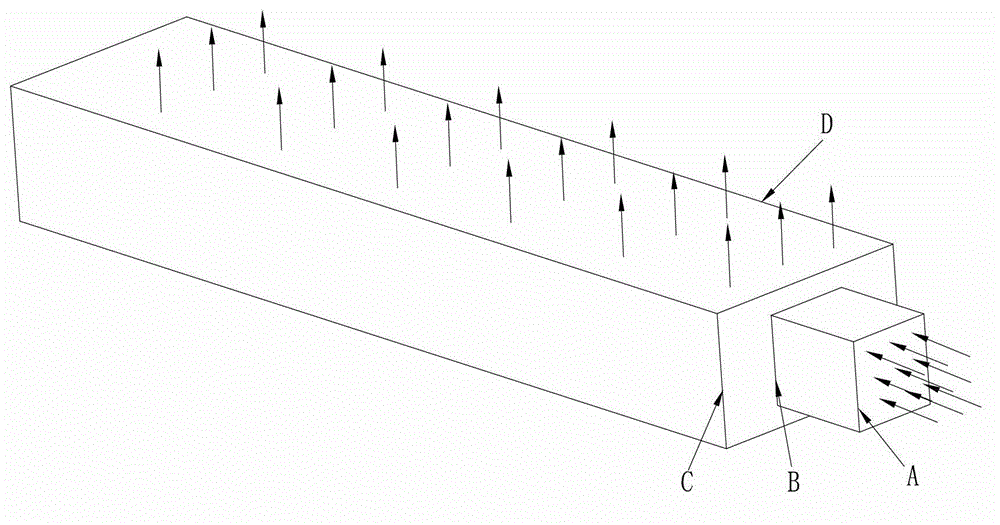

A technology of flow diversion, flow diversion and air distribution device, which is applied in lighting and heating equipment, combustion air/fuel supply, combustion method, etc., and can solve the problems of large loss of air flow resistance, poor operability of air volume distribution, and large consumption of metal materials and other problems, to achieve the effect of uniform horizontal air distribution, simple structure and reduced emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

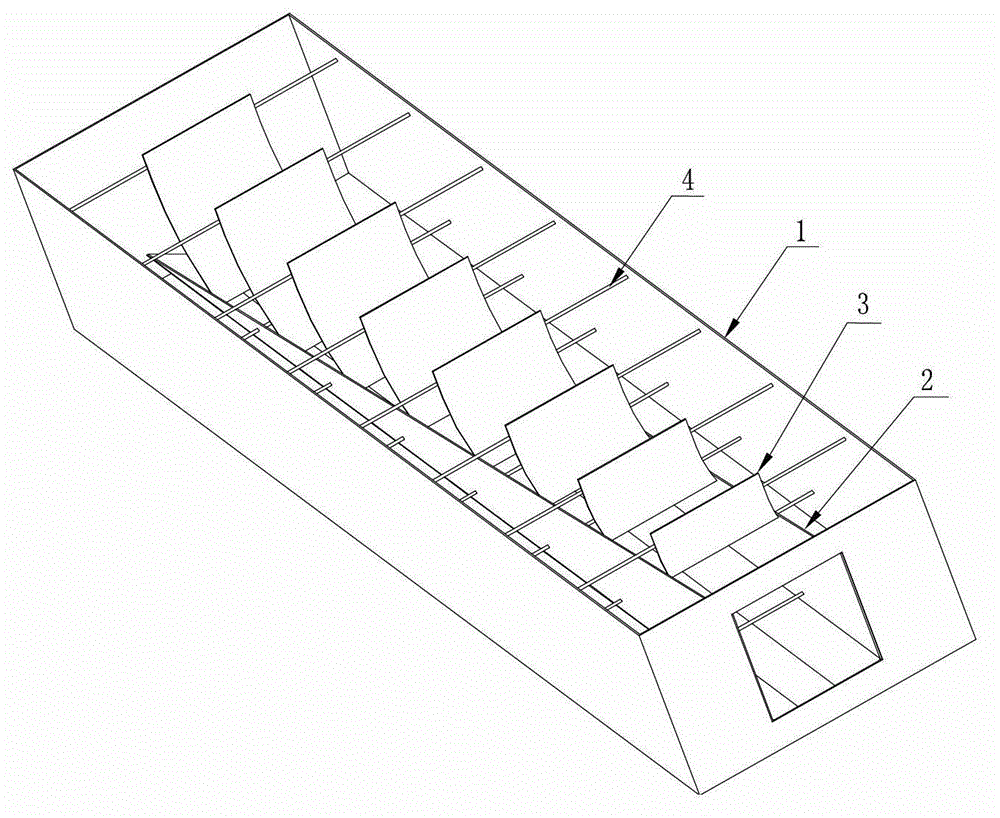

[0021] As shown in FIG. 2 , the built-in air equalization structure of the boiler air chamber of the present invention is composed of an air chamber shell 1 , a built-in stabilizing chamber 2 , a diversion deflector 3 , and a fixed grille 4 .

[0022] The structural dimensions of length, width and height of the silo shell 1 are determined by the tonnage of the boiler and the size of the fire grate, and the size of the air silo inlet is determined by the required air volume, the air flow characteristics of the pipeline and the structural size of the silo.

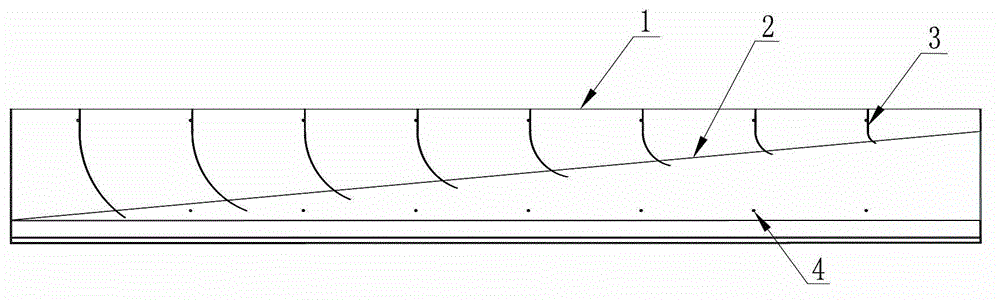

[0023] After the size of the air chamber housing 1 and the size of the inlet are determined, the structural size of the built-in stabilization chamber 2 can be determined. Such as image 3 As shown, the side plate 6 of the built-in stabilizing chamber has a triangular structure, and it can also be rectangular or trapezoidal in consideration of convenient installation and structural fixation. For one-sided air intake, the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com