Inverted grate-firing boiler

A boiler and furnace body technology, applied in the field of solid fuel boilers, can solve the problems of frequent addition, limited fuel, low thermal efficiency, etc., and achieve the effects of reducing the number of additions, efficient heat conduction, and stable combustion layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

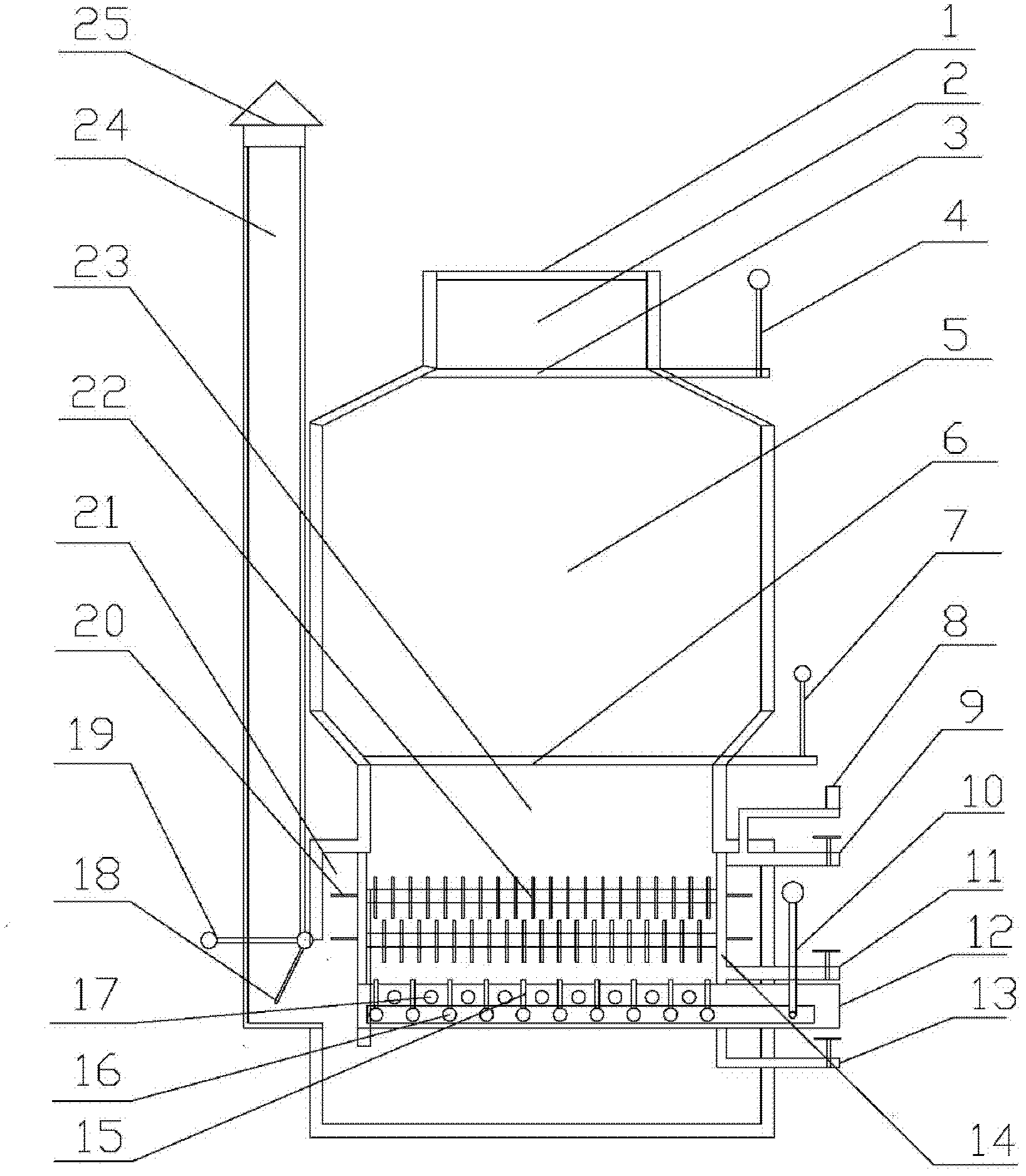

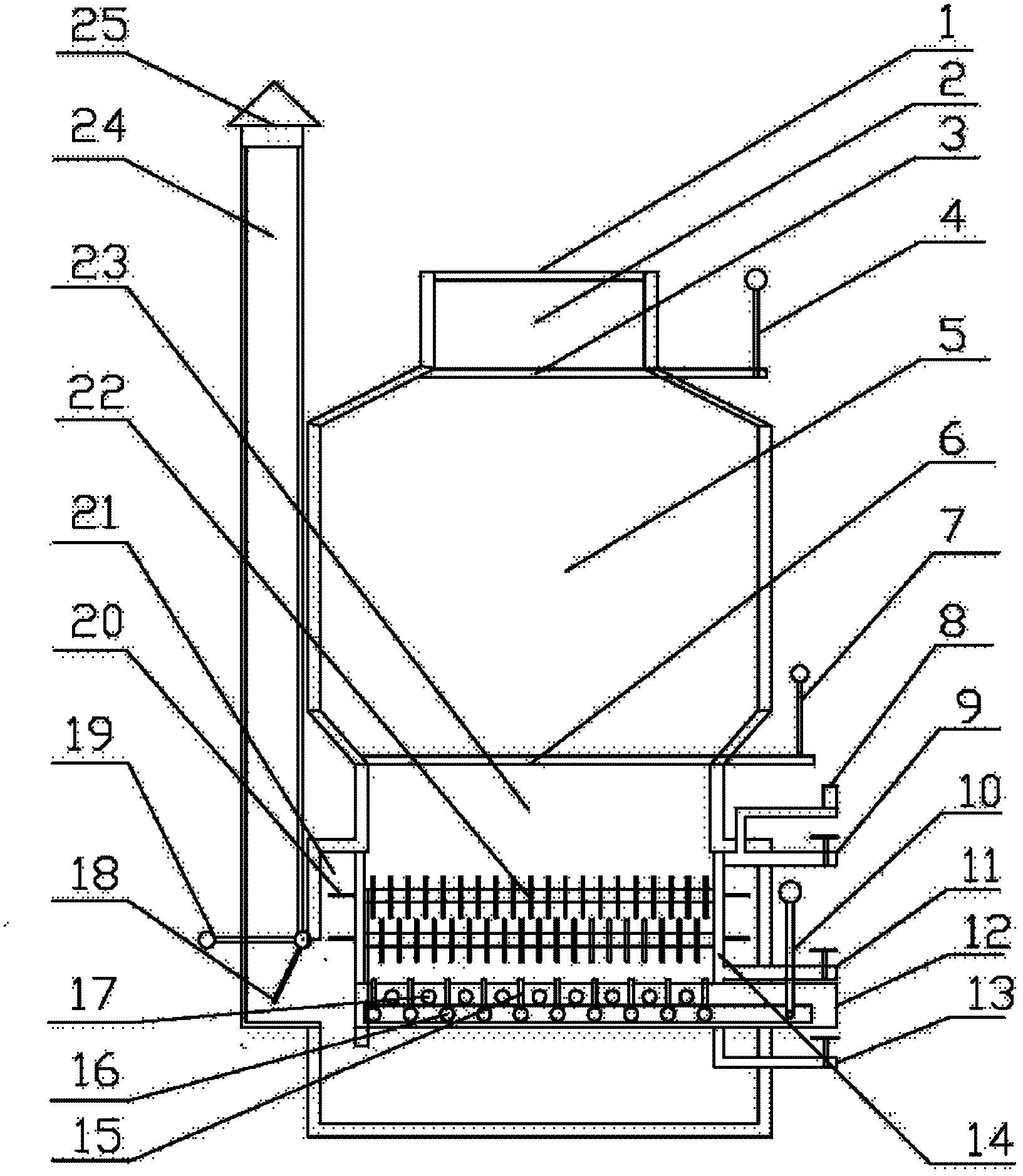

[0016] The inverted layer-fired boiler is an upright cylindrical structure, and the combustion chamber 23 is located at the lower part of the furnace body. There is a silo 5 above the combustion chamber, the upper part of the silo 5 is a feed port 2, and a loam cake 1 is arranged above the feed port 2. There are upper-layer hermetic door 3 and lower hermetic door 6 respectively on the top and bottom of the feed bin 5, hermetic doors 3, 6 are side-by-side doors that turn downwards, and there are control handles 4, 7. There is a counterweight on the airtight door. When there is no fuel on the upper part of the airtight door, the counterweight makes the airtight door return to the closed state. By adjusting the height of the feed bin, the volume of the feed bin of the present invention can be adjusted, thereby affecting the maximum time interval for adding fuel. But when the silo is increased to a certain height, a sealed door must be added in the silo, so that the top of the fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com