Self-service combustion control method of sectional type fire grate garbage incinerator

A waste incinerator and control method technology, which is applied in the direction of combustion method, combustion type, incinerator, etc., can solve the problems of large changes in the calorific value of domestic waste, insufficient waste combustion, and unstable combustion, and achieve real-time adaptation to calorific value changes , The effect of eliminating the formation of dioxins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

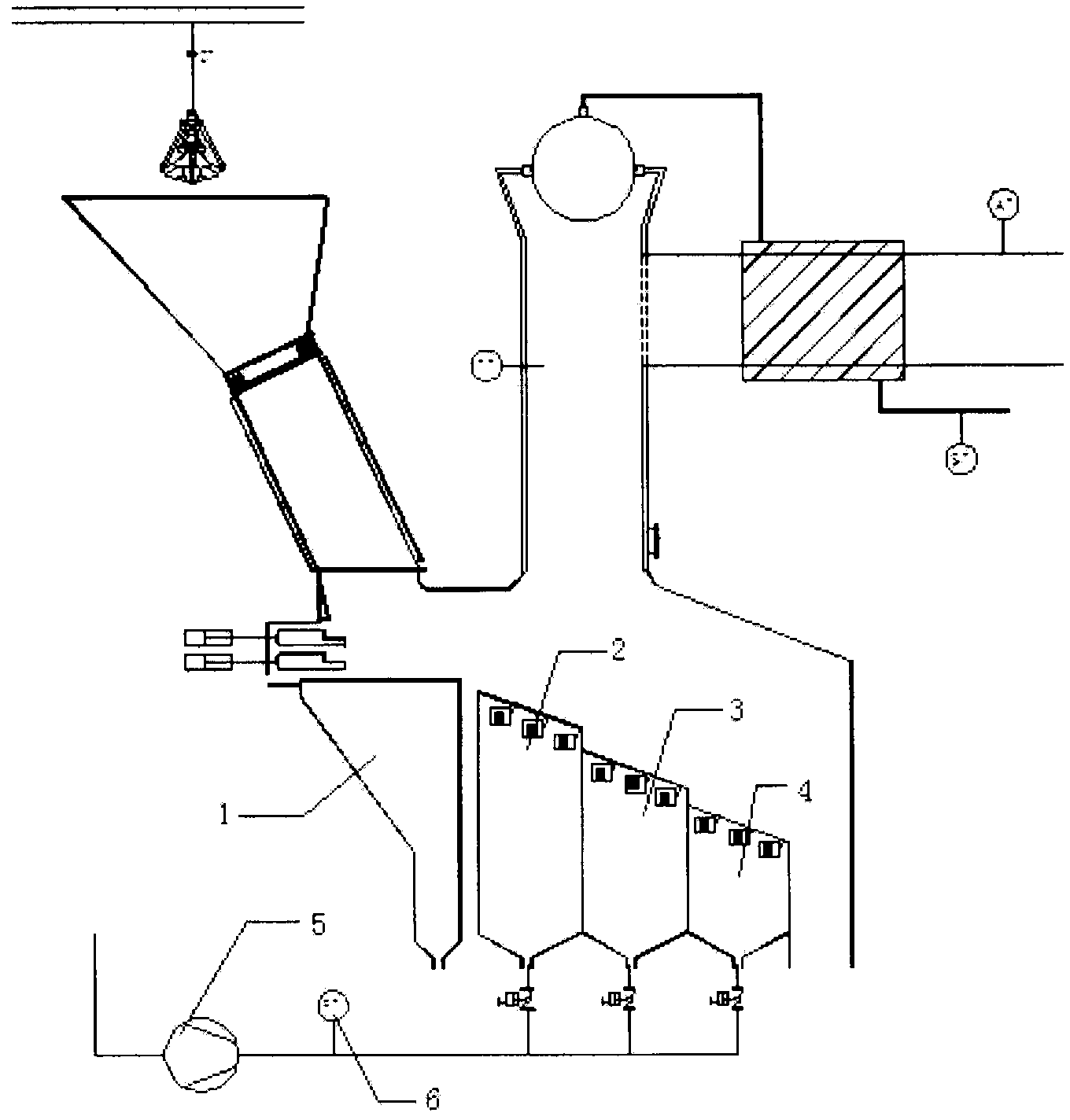

[0055] Below in conjunction with accompanying drawing, the present invention will be further described:

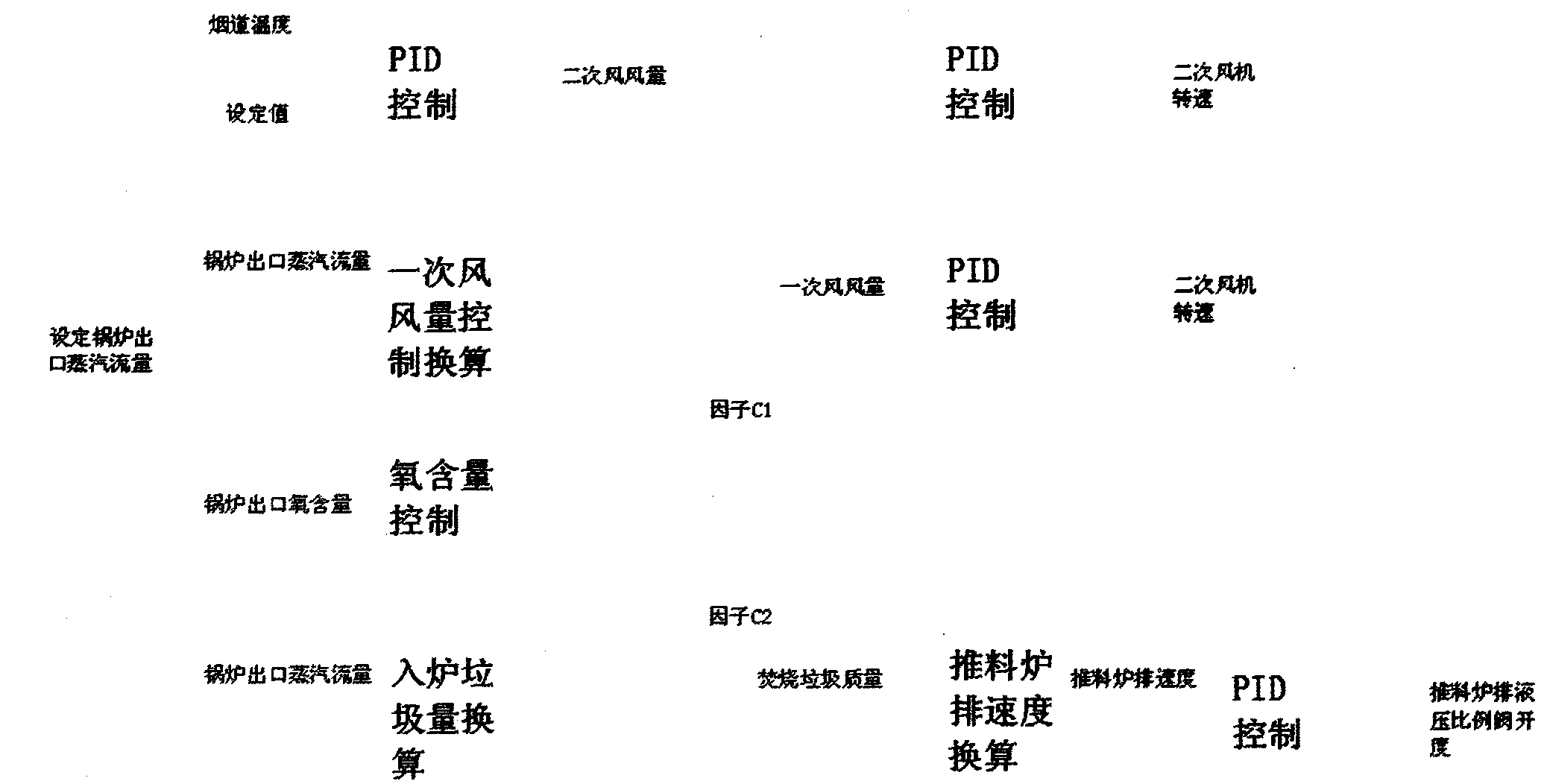

[0056] Such as figure 1 , figure 2 As shown, a segmented grate garbage incinerator self-combustion control method, the control equipment of the control method includes: feeding grate 1, the left end of feeding grate 1 is arranged in parallel with drying section grate 2, combustion end The grate 3, the grate 4 at the burnout end, and the primary fan 5 are connected to the grate 2 at the drying section, the grate 3 at the burner end, and the grate 4 at the burnout end through the primary air flow meter 6; the control method includes the following steps:

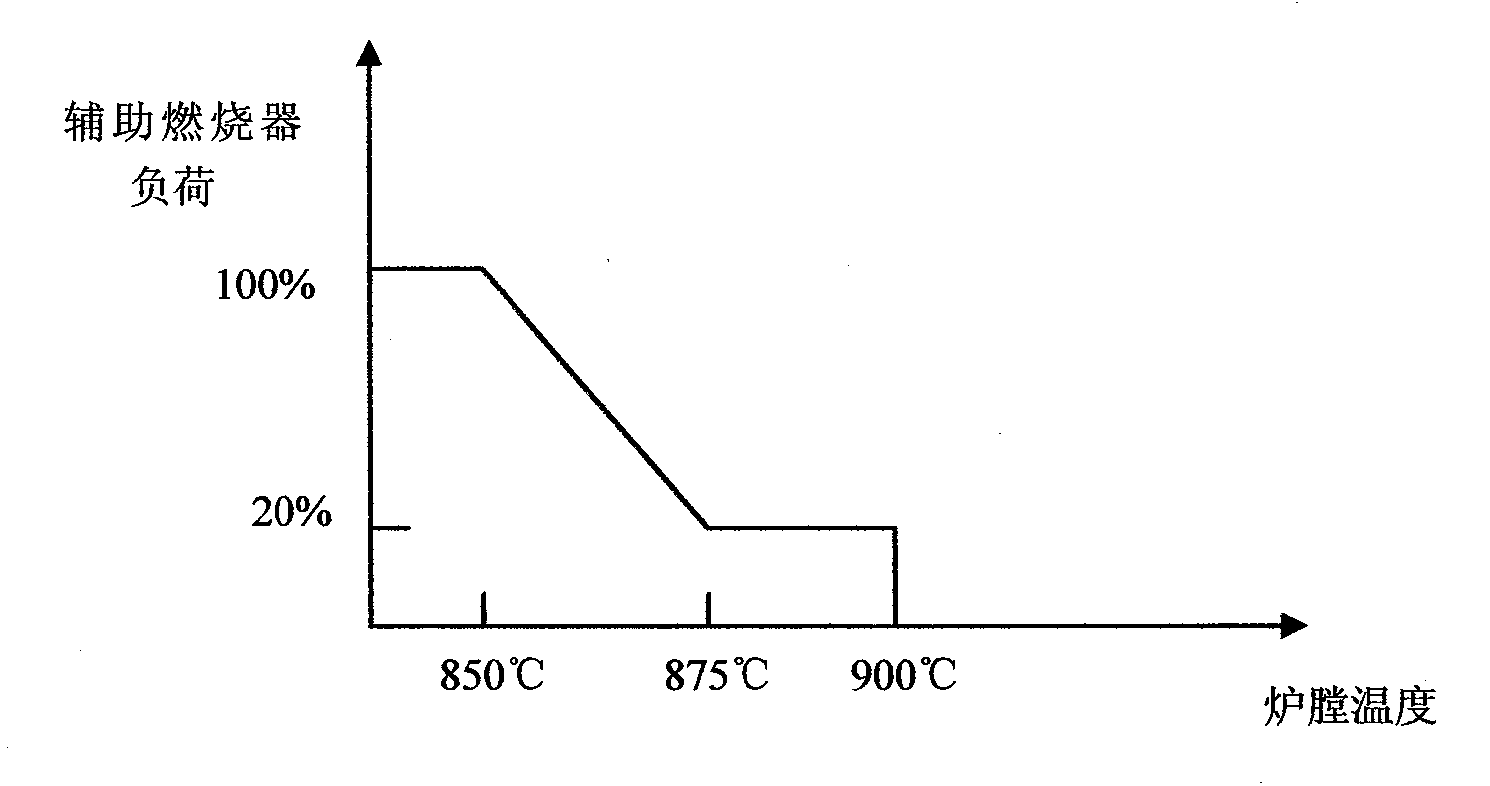

[0057] 1) Judgment of the calorific value of waste incinerated into the furnace According to the ratio of the steam quality generated by the boiler to the amount of waste incinerated in the boiler within a period of time and the establishment of a fuzzy control model to judge the calorific value type of waste in real time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com