Large-sized grate firing pressurized phase inversion heat-exchanging hot water boiler

A phase change heat and hot water boiler technology, which is applied to heat storage heaters, fluid heaters, lighting and heating equipment, etc. Competitive advantages and other issues, to achieve the effect of reducing the ash on the heated area, reducing the thermal resistance and flow resistance, and reducing the steel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

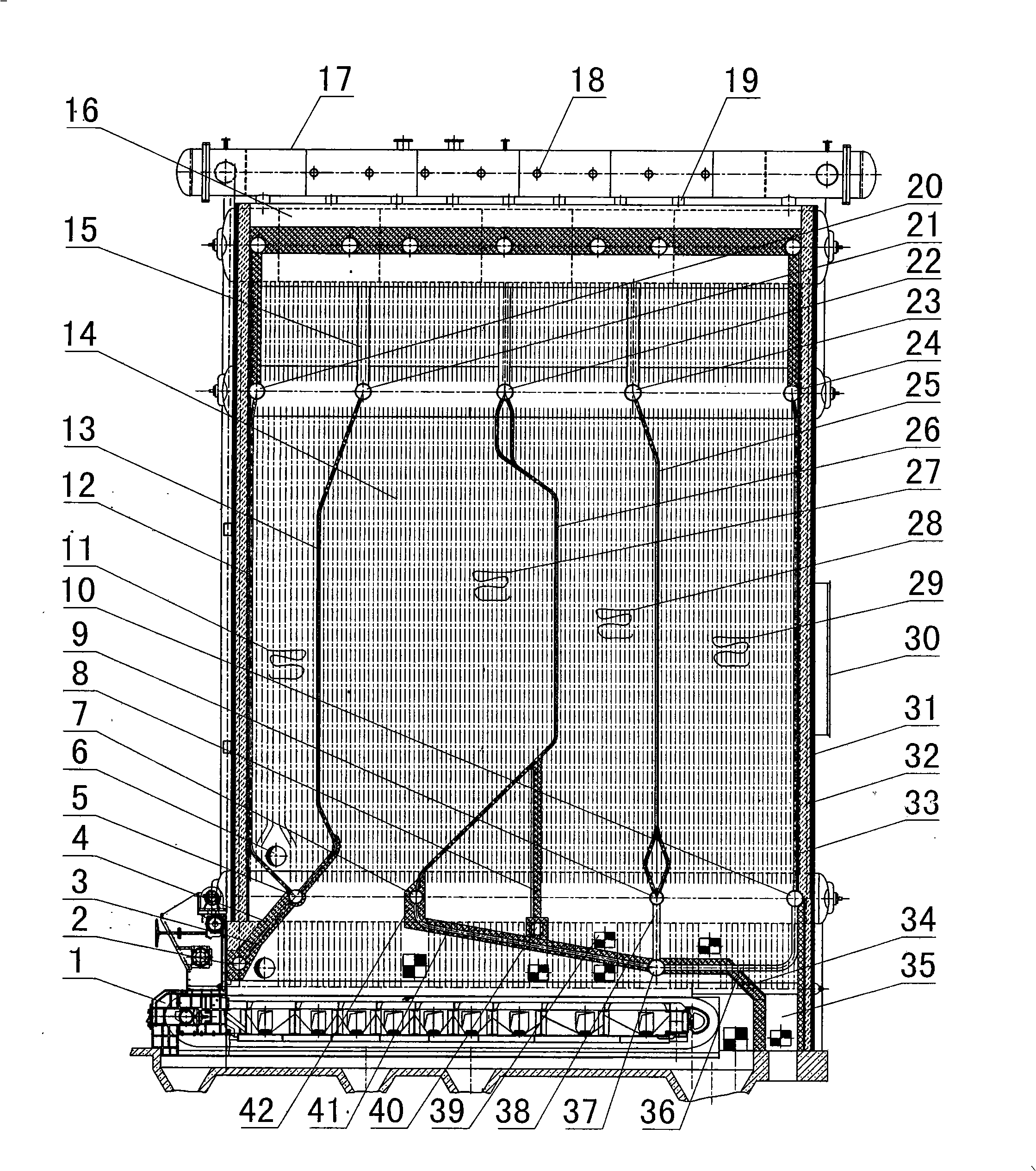

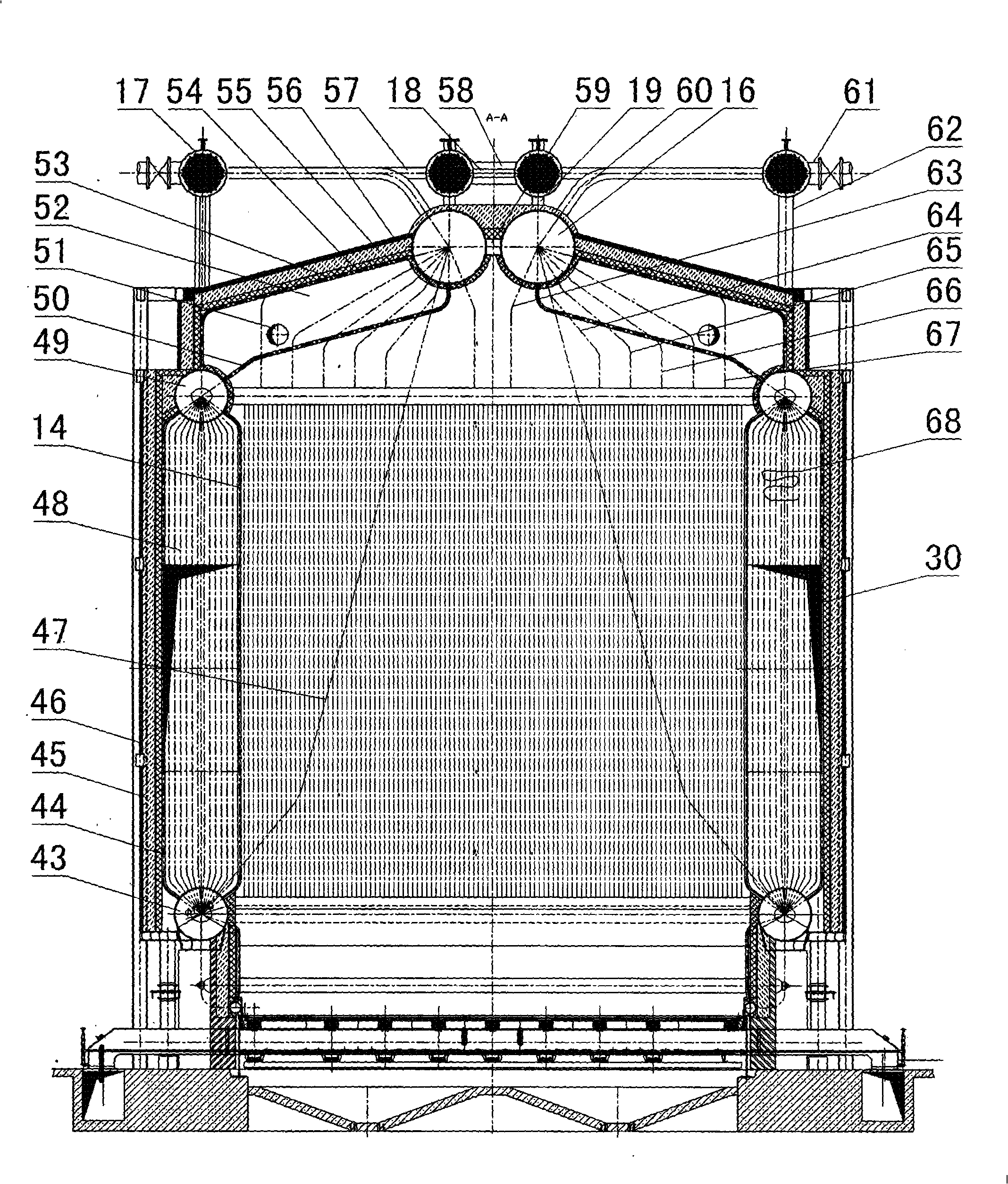

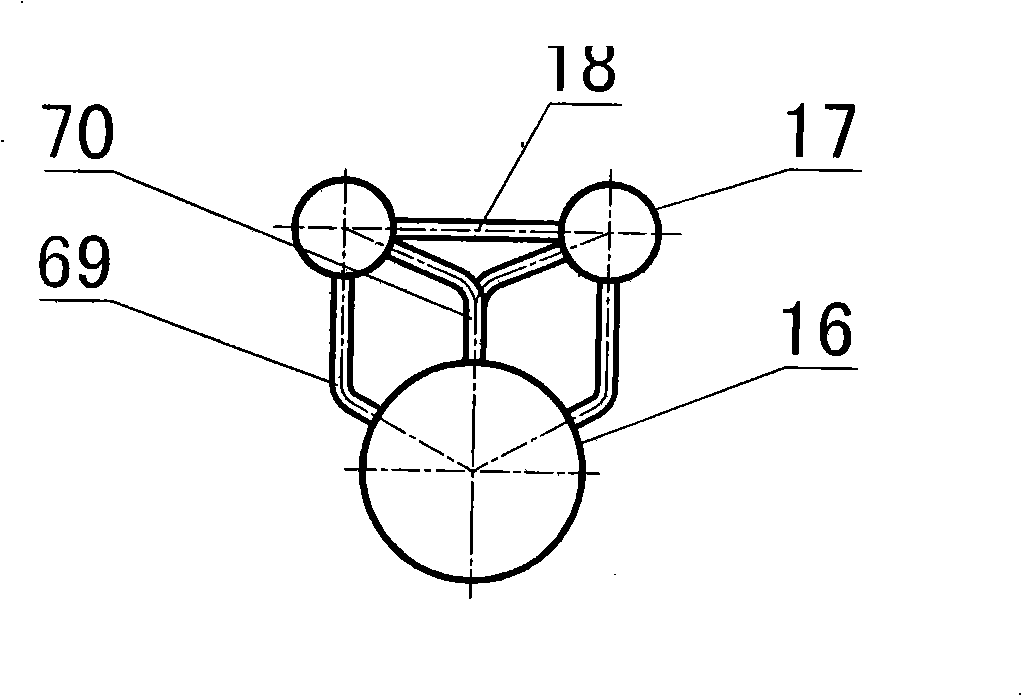

[0020] Below in conjunction with accompanying drawing, the present invention is described in detail, a kind of large-scale layer fire has pressure phase change hot water boiler, by drum (16), side upper and lower header (49) (43), heat exchanger (17) )constitute. It is characterized in that the upper end of the communication pipe (62) communicates with the lower center of the heat exchanger (17), and its lower end communicates with the upper center of the side upper header (49); the inner lower end of the communication pipe (60) communicates with the drum (16 ) is radially connected to the outer side of the upper part, and its outer side is connected to the inner center of the heat exchanger (17); the two ends of the connecting pipes (57) and (18) are respectively connected to the side centers of the two heat exchangers; the connecting pipe (59 ) are respectively communicated with the drum (16) side center, and the two ends of the upper horizontal header (20) (21) (22) (23) (2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com