Boiling type biomass gasification process

A biomass and boiling technology, applied in the direction of granular/powder fuel gasification, etc., can solve the problems of burn-through, prone to burn-out, high gas tar content, achieve suitable airflow speed, smooth slag discharge, and prevent tar precipitation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

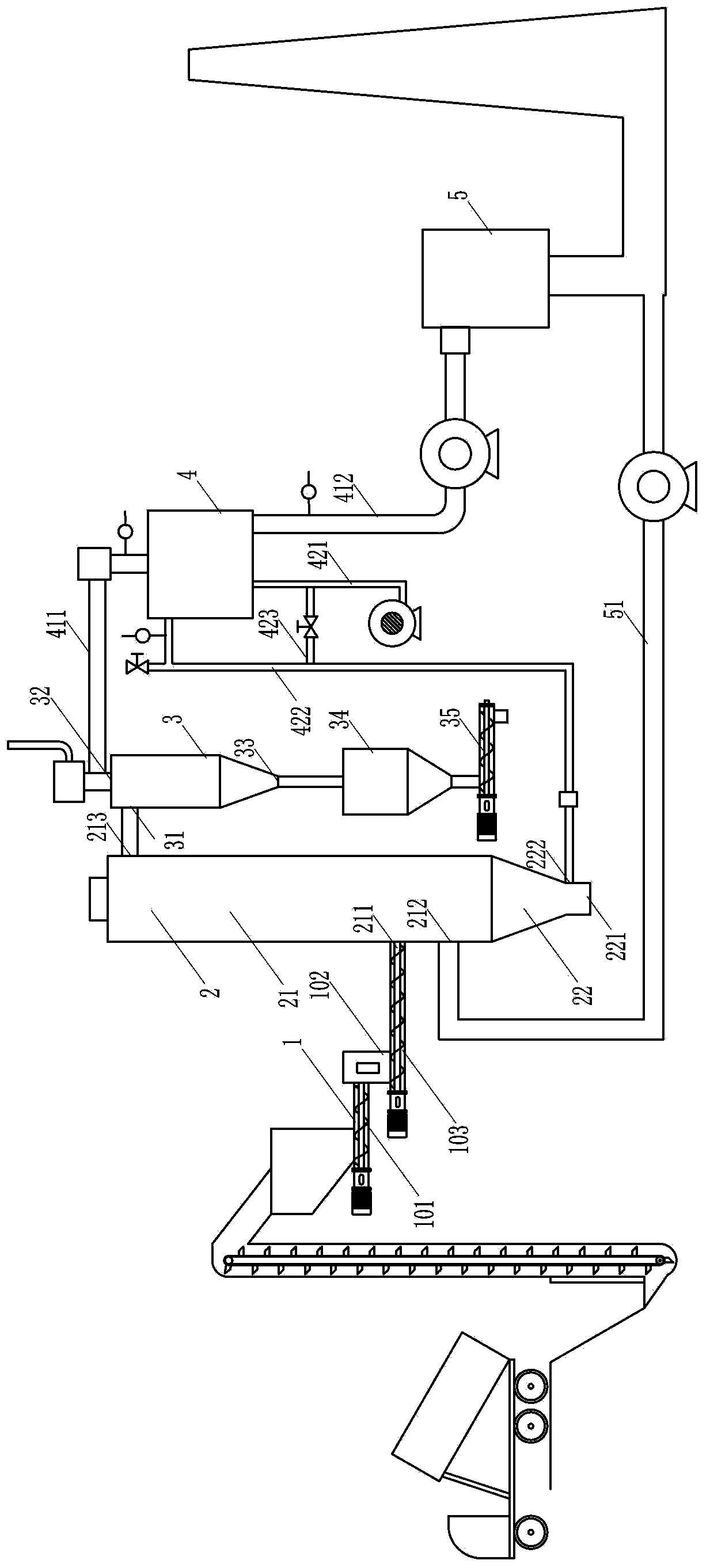

[0049] The boiling type biomass gasification process of the present embodiment comprises the following steps:

[0050] (1) Furnace start-up in the form of a fixed bed: ignite in the gasifier, feed the gasification medium (air) at a small flow rate from the side of the tail ash section of the gasifier, and The feed port on the side is fed into the biomass raw material, and the feed port is located at a position 1 / 4 of the height from the bottom of the reaction section; among them, multi-stage feeding is carried out through a multi-stage feeding device;

[0051] (2) First, the biomass raw material in the gasifier is combusted on the grate; after the biomass raw material generates gas in the state of layer combustion, the gasification medium is increased to make the biomass raw material in the gasifier The gasification reaction is carried out in a boiling state to generate gas; the height of the material accumulated in the reaction section is controlled to be less than 25% of the...

Embodiment 2

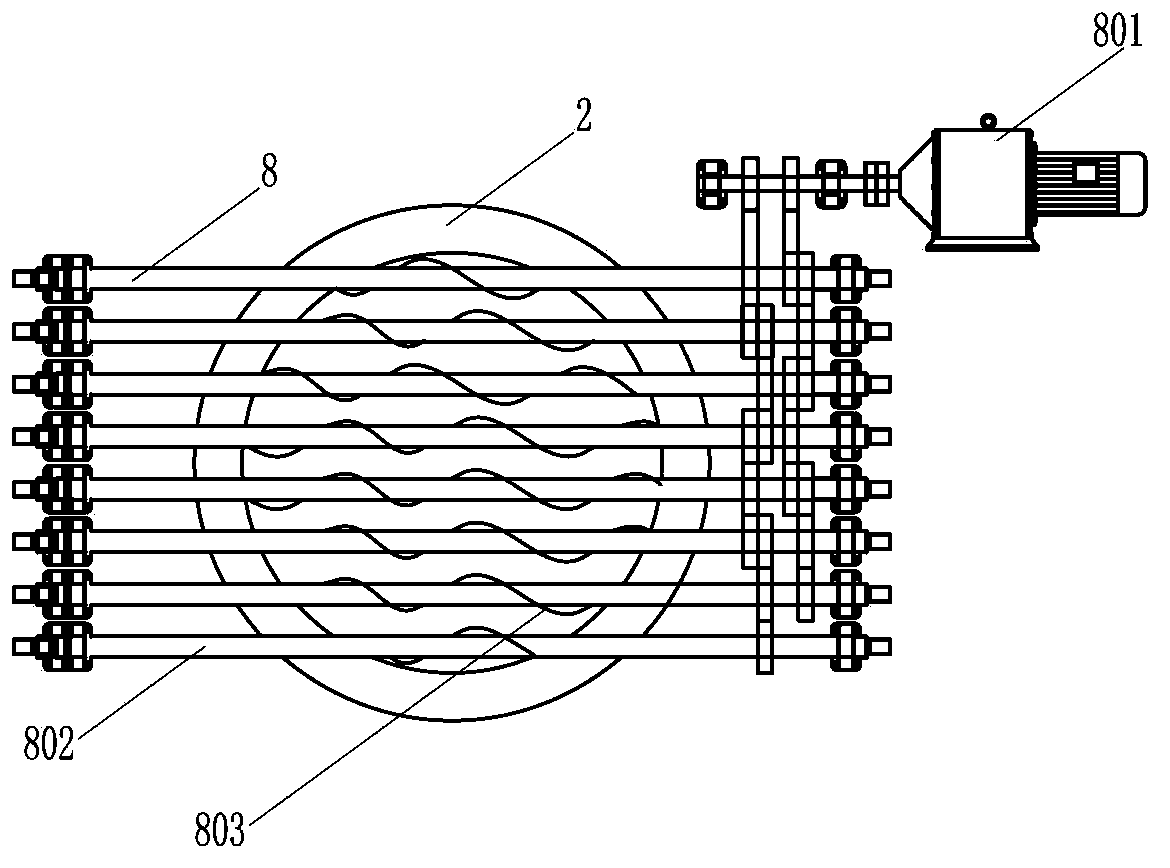

[0063] The difference between this embodiment and Embodiment 1 is that the ash is discharged through the rotating blade type water-cooled grate. Each grate rod can be rotated under the drive of the motor, and each grate rod of the water-cooled grate is equipped with a blade that can be rotated by the grate rod as the rotation axis, so as to discharge slag through the rotation of the blade.

[0064] Such as figure 2As shown, the grate for realizing the process of this embodiment is a water-cooled grate 8, which includes an adjustable-speed driving motor 801 and a plurality of grate bars 802 arranged in parallel. The driving motor 801 is used to drive each grate bar 802 to rotate. Each grate rod 802 is a metal tube with a cavity, and the two ends of each grate rod 802 are located outside the furnace body 2 of the gasifier, and the two ends of each grate rod 802 are equipped with water cooling Rotary joint. Each grate rod 802 is equipped with a helical blade 803, which can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com