Efficient environment-friendly cheap adhesion agent of pellet and preparation method thereof

A technology for pellets and binders, applied in the field of binders, can solve the problems of destroying the structure of preheated pellets, demanding process requirements, and reducing blast furnace coefficients, and achieves good roasting performance, lower roasting temperature, and low production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

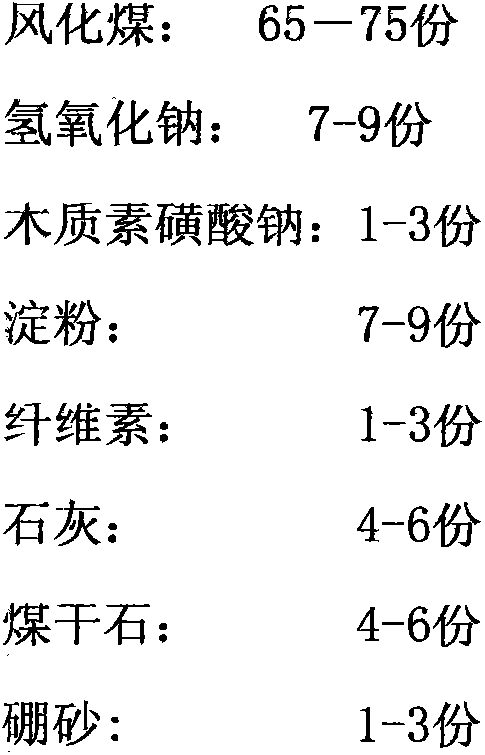

[0025] Embodiment 1: A highly efficient, environmentally friendly and cheap binder for pellets, prepared from the following raw materials in parts by weight:

[0026]

[0027]

[0028] The above-mentioned materials are processed by the following steps, and are prepared into an efficient, environmentally friendly and cheap binder for pellets:

[0029] 1) Take out the weathered coal, lime, and coal dry stone according to the required parts by weight respectively, after mixing, pulverize with a crusher to powder between 40-80 mesh, and set aside;

[0030] 2) Take out the sodium hydroxide of the required parts by weight, add 15% water, heat and stir until it fully melts, and set aside after fully melting;

[0031] 3) Mix the sodium hydroxide solution prepared in step 2) with the mixed powder prepared in step 1), stir until they are evenly mixed, then dry with a dryer, and then pulverize to 40-80 mesh for later use;

[0032] 4) Take out the sodium lignosulfonate, starch, cel...

Embodiment 2

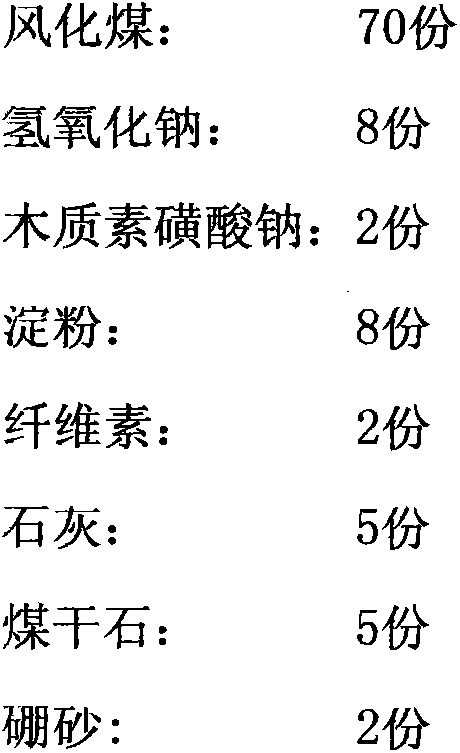

[0034] A high-efficiency, environment-friendly and cheap binder for pellets, which is prepared from the following raw materials in parts by weight:

[0035]

[0036] The preparation method is the same as in Example 1.

Embodiment 3

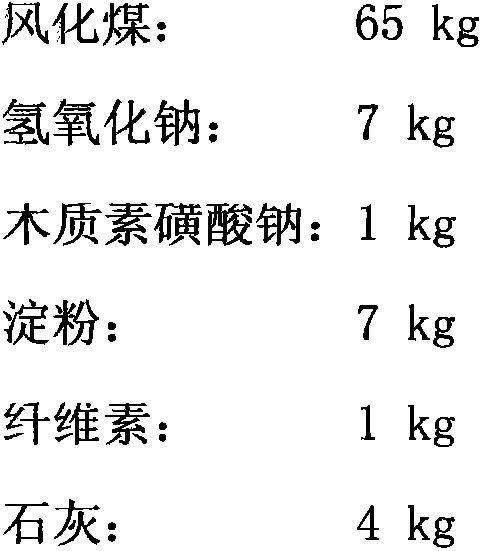

[0037] Embodiment 3: A highly efficient, environmentally friendly and cheap binder for pellets, which is prepared from the following raw materials in preferred parts by weight:

[0038]

[0039]

[0040] The preparation method is the same as in Example 1.

[0041] The above embodiment was tried out in a steel factory, and the effect was very good. The binder used in this embodiment 2 has strong cohesiveness. The compressive strength exceeds the performance index of the pellets produced by the existing binder, and can increase the calorific value of clean coal by 1600 kcal. It is tested by the National Coal Quality Supervision and Testing Center: increase thermal stability by 92.6%, and has great Good heat resistance, heat strength at 1016 degrees. And have sulfur-fixing discharge effect, same coal kind can increase thermal efficiency 20% to 25%, the add-on of the binding agent of the present embodiment is 0.8-1.0% of concentrate powder quality, has reduced the consumpti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com