Biomass rotary fire grate combustor

A technology of rotary grate and biomass, applied in the combustion method, combustion equipment, combustion of solid fuel, etc., can solve the problems of inability to work at the same time, incomplete combustion, rising exhaust gas temperature, etc., to expand compatibility and stability , The fuel combustion process is sufficient, and the effect of improving the combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

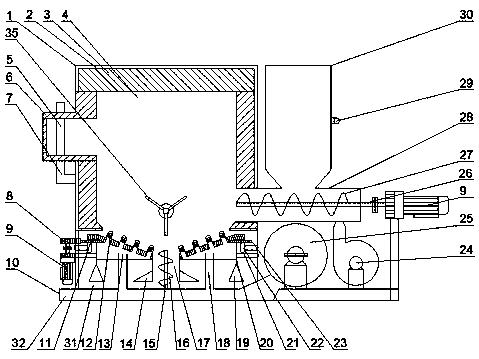

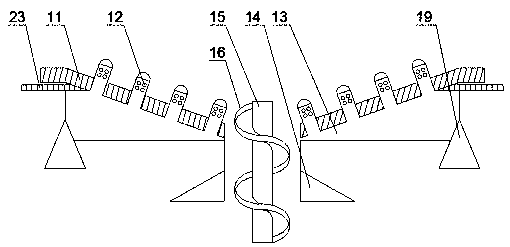

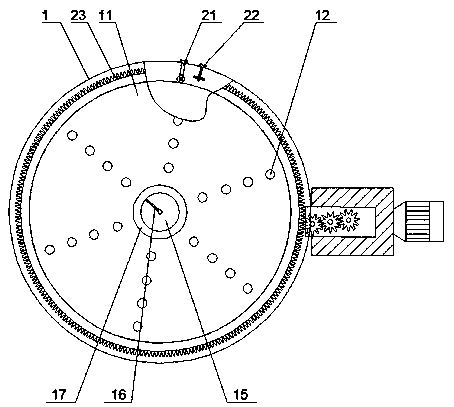

[0026] The invention provides a biomass rotary grate burner, which consists of a furnace body 1, a water interlayer 2, a refractory pouring layer 3, a furnace 4, an air distribution port 5, a flame nozzle 6, an air distribution pipe 7, a driving gear 8, and a driving motor 9. Furnace body base 10, rotating grate 11, wind cap 12, water-sealed air cavity 13, inner ash removal piece 14, installation shaft 15, screw auger 16, ash drop port 17, air inlet sleeve 18, outer ash removal piece 19. Positioning ring 20, positioning support 21, bottom support 22, gear ring 23, secondary blower 24, primary blower 25, auger drive shaft 26, spiral reamer 27, rotating auger 28, vibration rod 29, feed bin 30, slag collection tank 31, built-in air distributor 32, secondary spiral air duct 33, drive rod 34, stirring rod 35, conveyor belt 36, slag discharge plate 37, drive wheel 38, and is set in the furnace body 1 to rotate The grate device and the three-dimensional slag removal mechanism are loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com