Incinerator of multi-element multi-dimension chemical hazardous waste

A hazardous waste and incinerator technology, applied in the direction of incinerator, combustion method, combustion type, etc., can solve the problems of furnace lining and heat exchange surface corrosion, single use of incinerator, blockage, etc., and achieve stable combustion effect and easy incineration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with drawings and embodiments.

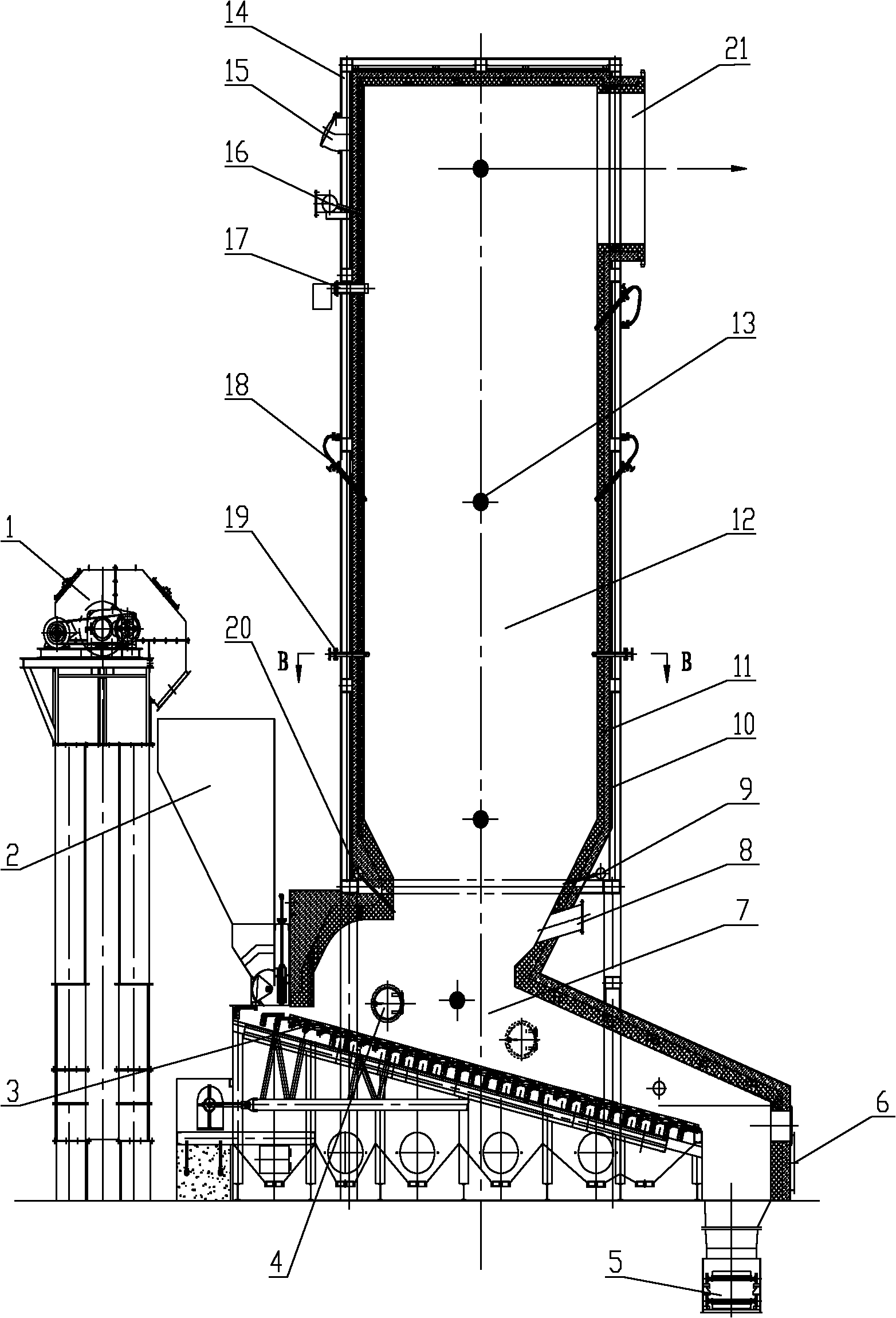

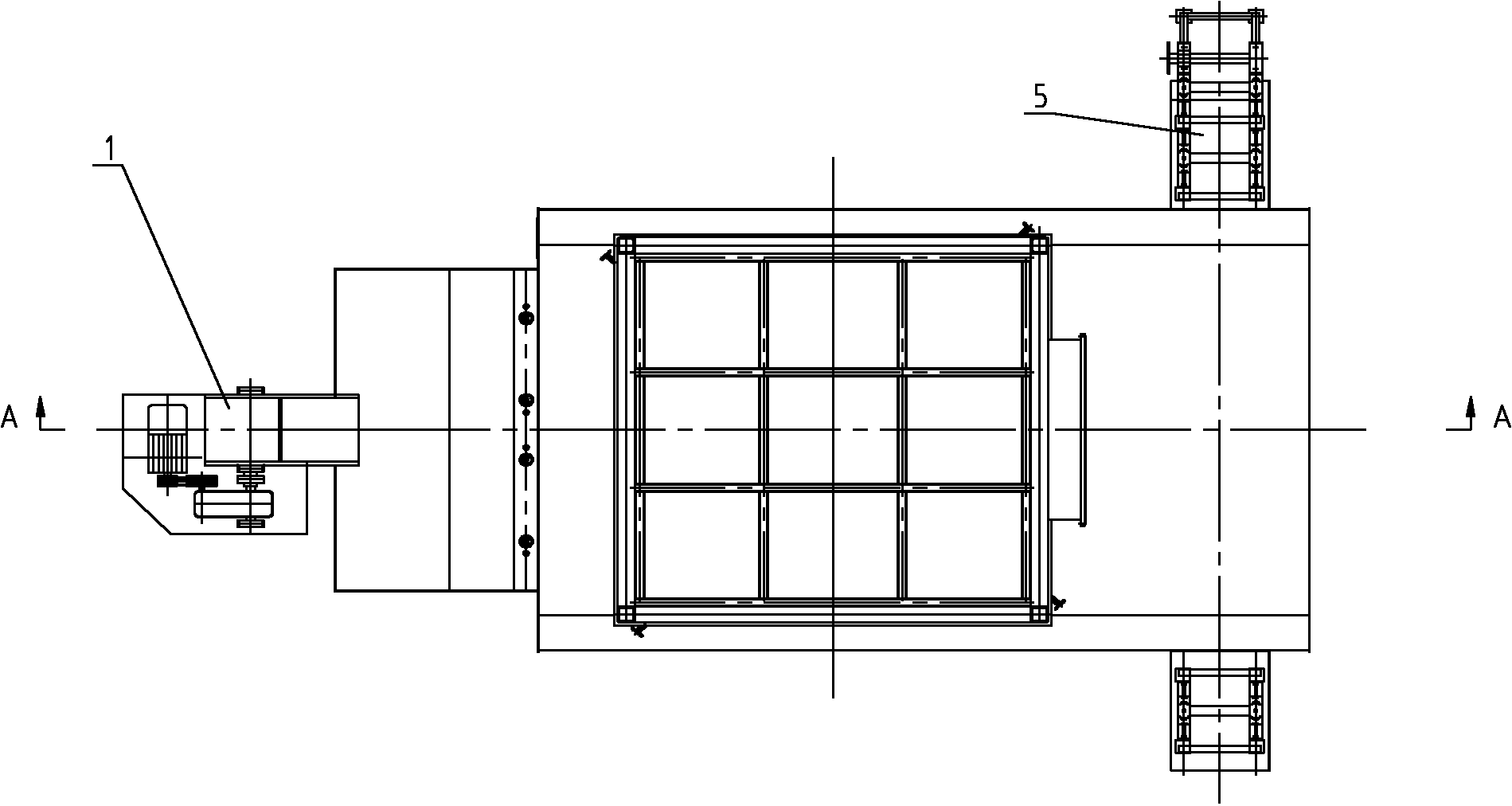

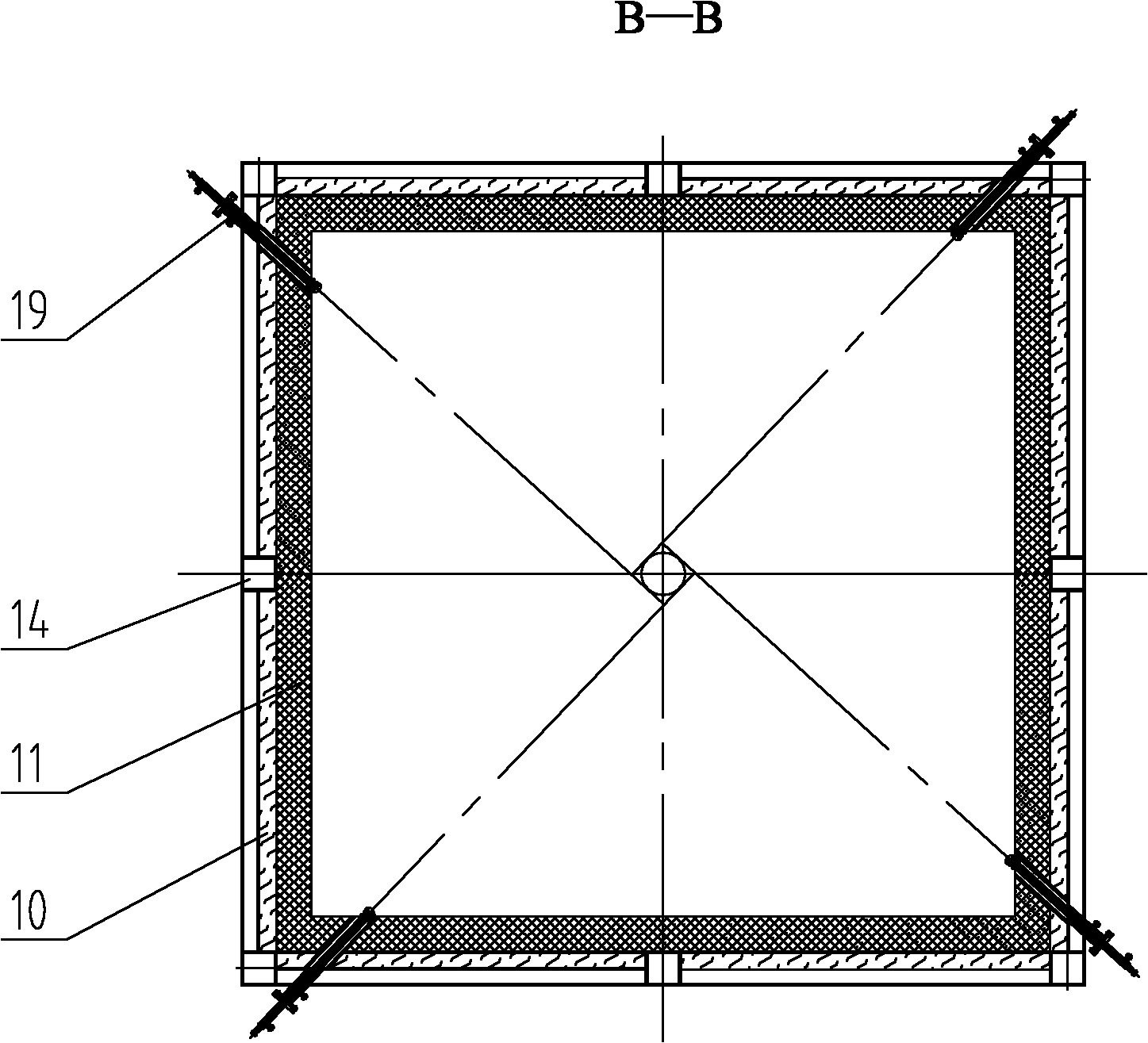

[0020] The accompanying drawing shows a multi-dimensional multi-dimensional chemical hazardous waste incinerator with a square hearth cross section, including an auxiliary fuel device and an incinerator. The auxiliary fuel supply device supplies auxiliary fuel to the incinerator. The incinerator includes a furnace body, a furnace chamber, an inclined The reciprocating fire grate 3, the slag removal device 5 and the air supply system, the inclined reciprocating fire grate 3 is arranged at the bottom of the furnace body, and the inclined reciprocating fire grate 3 is inclined from front to back by 11-30°. The slag removal device 5 is below the end of the inclined reciprocating fire grate 3. The auxiliary fuel supply device includes a primary auxiliary fuel supply device and a secondary auxiliary fuel supply device. The primary auxiliary fuel supply device includes an auxil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com