Fire grate for motor grate combustion appts. and grate body for forming grate

A technology of motorized grate and combustion device, applied in the direction of combustion method, combustion type, combustion equipment, etc., can solve the problems of assembly and disassembly of components that are difficult to easily constitute

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

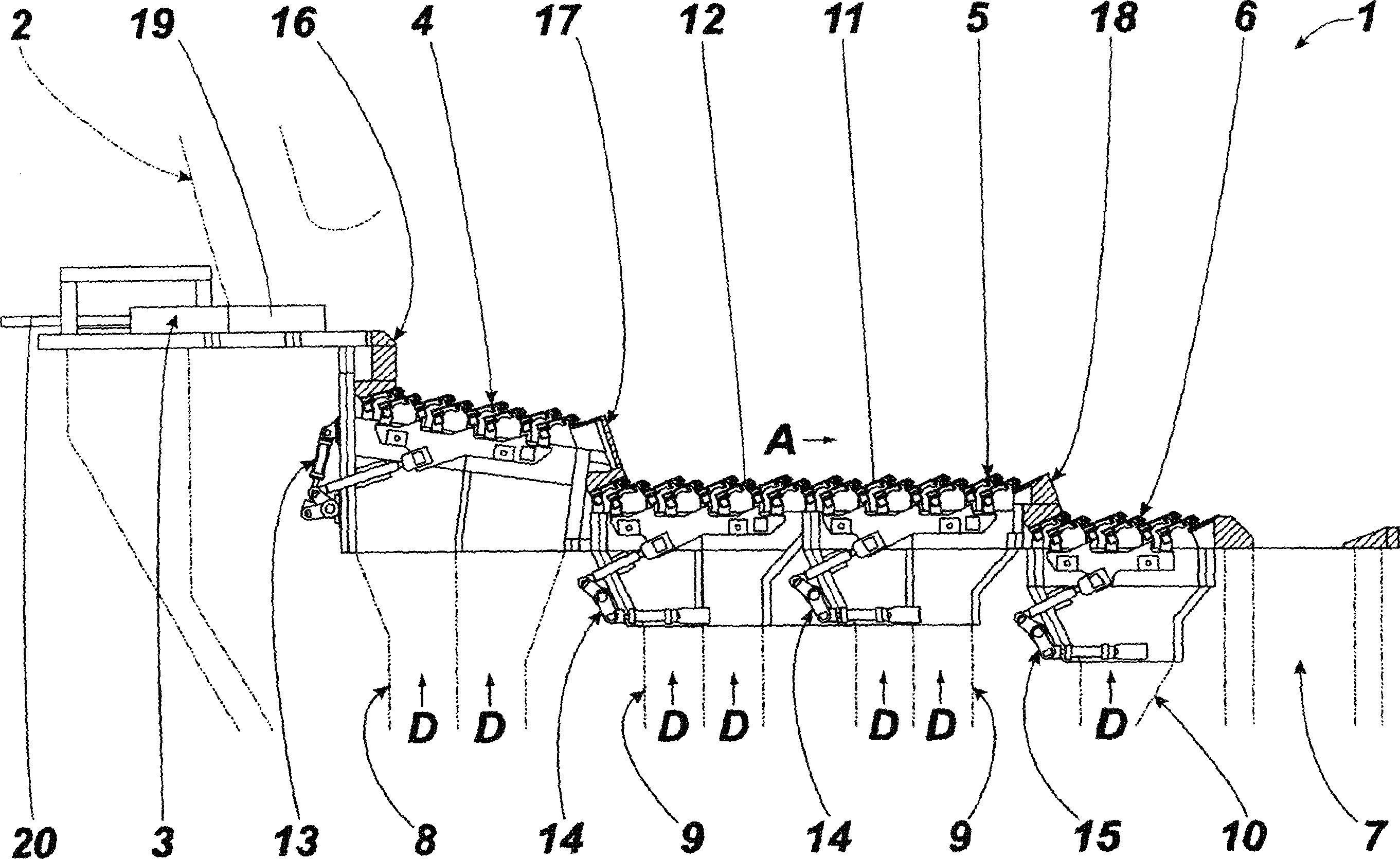

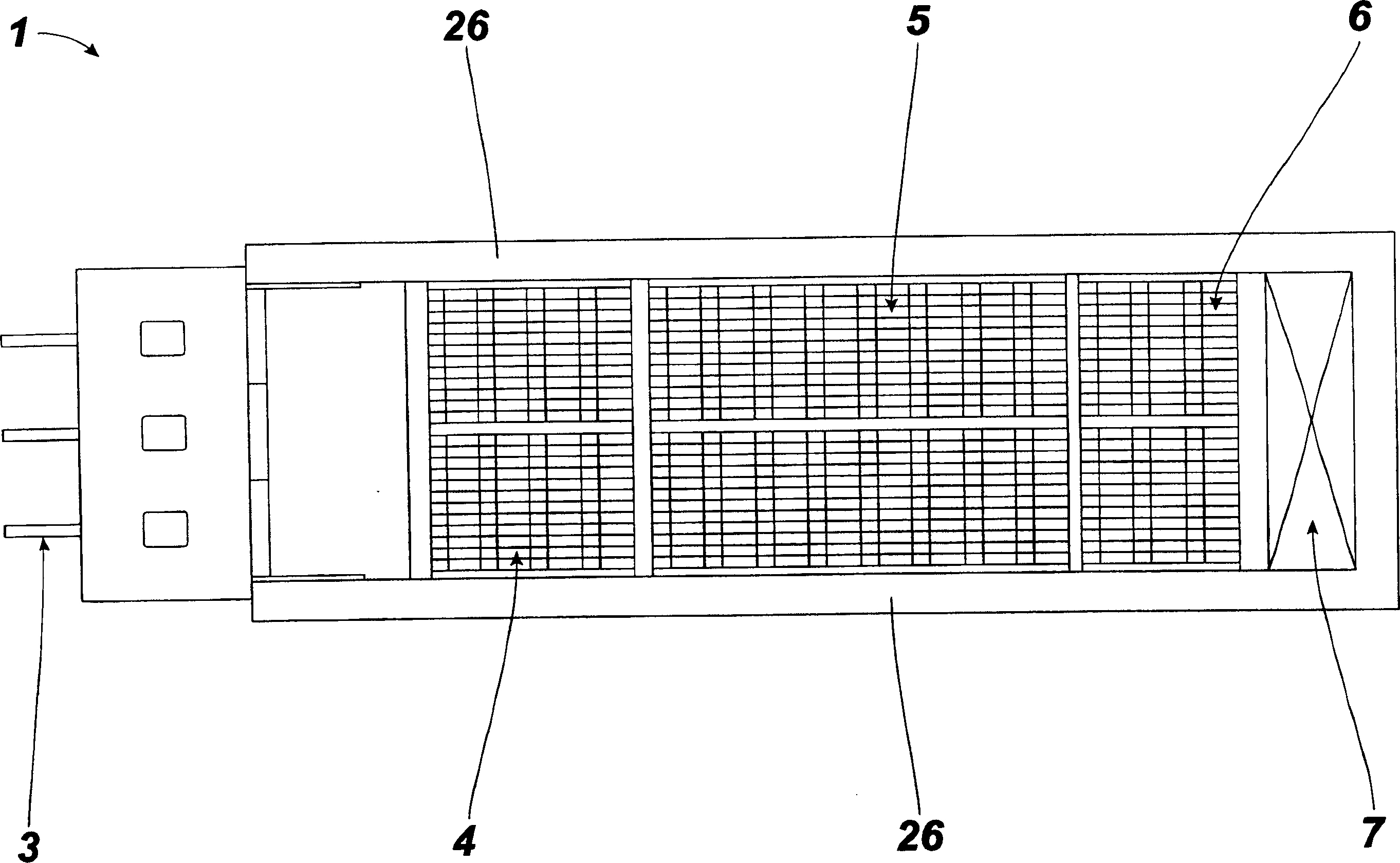

Method used

Image

Examples

Embodiment 2

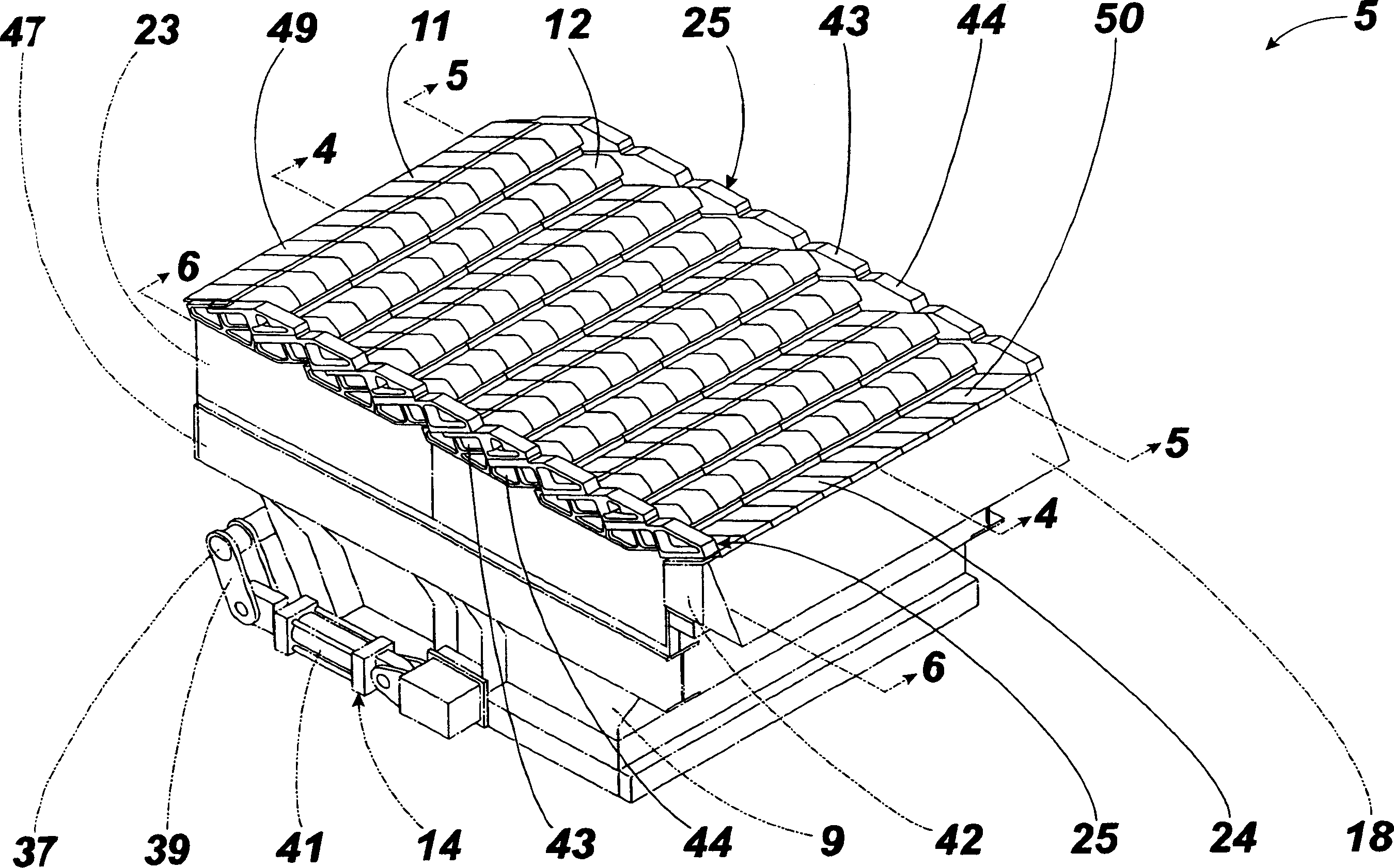

[0097] Embodiment 2 is different from Embodiment 1 except that an air channel 69 is formed on the side plate 25 for air cooling, and the others are the same as Embodiment 1.

[0098] The air passage 69 is formed on the side plate 25 and circulates the cooling air H in the direction opposite to the refuse conveying direction A, while being formed only on the upper portion of the side plate 25 .

[0099] That is, the side plate on the most upstream side ( Figure 14 The fixed grate on the left side is hollow except for the side plate 43), and is provided with a partition wall 70 that separates the hollow part up and down.

[0100] The side plate on the most upstream side ( Figure 14 The fixed fire grate on the leftmost side (side plate 43) in the center is hollow, and an inlet 71 is formed on the front side, and an outlet 72 is formed on the lower side.

[0101] Adjacent front and rear side plates 43 and 44 communicate with adjacent outlets 72 and inlets 71 respectively to fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com